A kind of elastomer material modified by amino silicone oil and preparation method thereof

An elastomer material and amino silicone oil technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of inability to improve various properties of polyurea materials, poor compatibility of polyurea materials, and poor water and water resistance performance and other problems, to achieve the effect of mild conditions, improved wear resistance, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

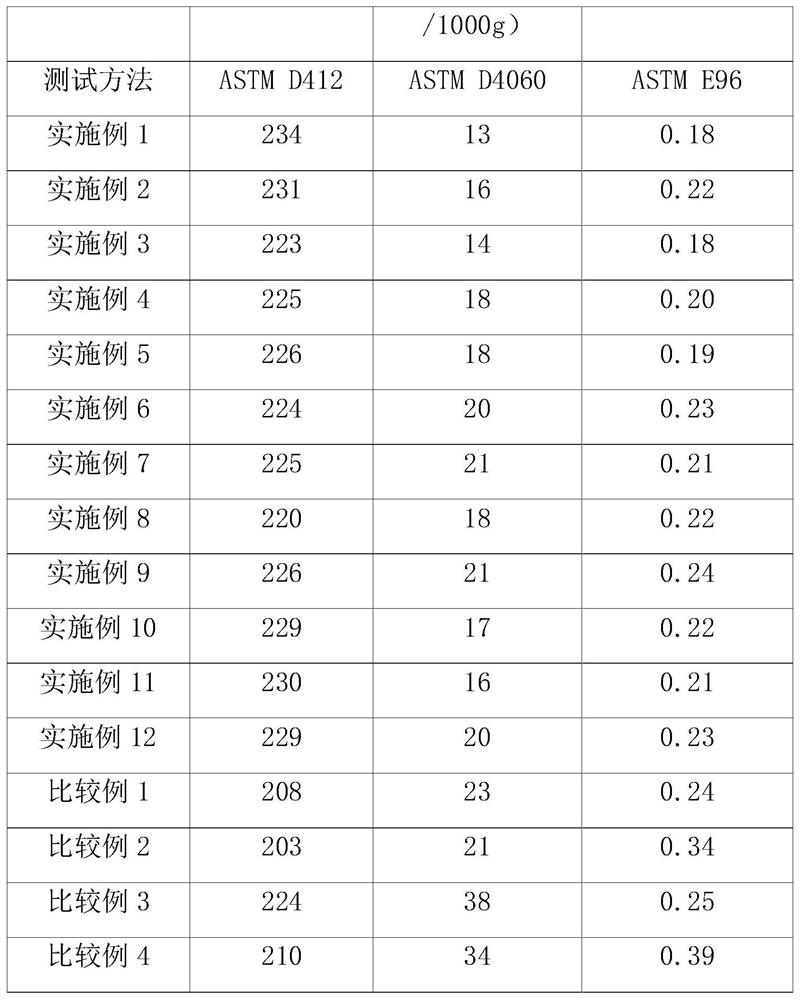

Examples

Embodiment 1

[0053] The elastomer material in this embodiment includes A component and R component.

[0054] Component A includes an isocyanate prepolymer obtained by reacting polyether polyol with methyl isocyanate, p-phenylene diisocyanate, and triphenylmethane isocyanate, and the -NCO content of the isocyanate prepolymer is 25%;

[0055] The R component includes the following components in parts by weight: 12 parts of polyether triamine, 36 parts of polyether diamine, 3 parts of diethylmethylenediamine, 5 parts of polysulfide rubber, surface pretreated nano-dioxide 5 parts of silicon, 5 parts of amino silicone oil.

[0056] The preparation method of elastomeric material comprises the steps:

[0057] (1) Mix 30g of polyether triol and 100g of polyether diol evenly, heat to 100-120°C for dehydration for 2-3 hours, then lower the temperature to 70°C, add 1g of methyl isocyanate, 135g of p-phenylene diisocyanate, three 35g of phenylmethane isocyanate, heat preservation reaction for 2-3h, ...

Embodiment 2

[0062] This embodiment refers to the elastomeric material and its preparation method of Example 1, the only difference being that the -NCO content of the cyanate ester prepolymer of component A is 22%;

[0063] The preparation method of component A includes: mixing 30g of polyether triol and 100g of polyether diol evenly, heating to 100-120°C for dehydration for 2-3 hours, then cooling down to 70°C, adding 0.8g of methyl isocyanate, 110g of phenylene diisocyanate, 30g of triphenylmethane isocyanate, heat preservation reaction for 2-3h, defoaming and cooling down to obtain component A with -NCO content of 22±1%.

Embodiment 3

[0065] This embodiment refers to the elastomer material and its preparation method of Example 1, the only difference being that the -NCO content of the cyanate ester prepolymer of component A is 30%;

[0066] The preparation method of component A includes: mixing 30g of polyether triol and 100g of polyether diol evenly, heating to 100-120°C for dehydration for 2-3 hours, then cooling down to 70°C, adding 1.5g of methyl isocyanate, 200g of phenylene diisocyanate, 55g of triphenylmethane isocyanate, heat preservation reaction for 2-3h, defoaming and cooling down to obtain component A with -NCO content of 30±1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com