Phenol-formaldehyde resin modified polyurethane/polyurea coating material and preparation method therefor

A technology of phenolic resin and polyurethane, which is applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve the problems of strong acid resistance and high temperature resistance of coatings, and achieve enhanced heat resistance and flame retardancy. Preparation The method is simple and easy, and the effect of dimensional stability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

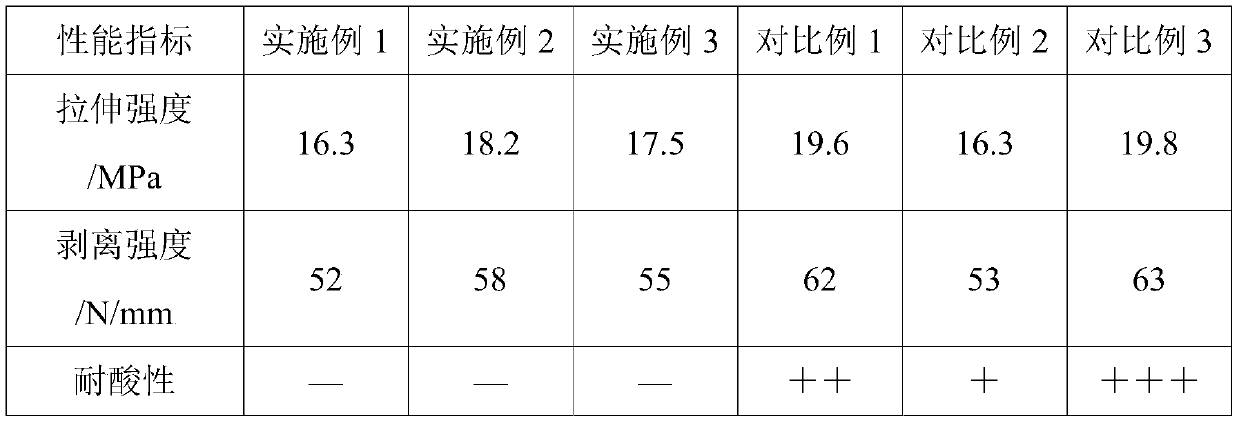

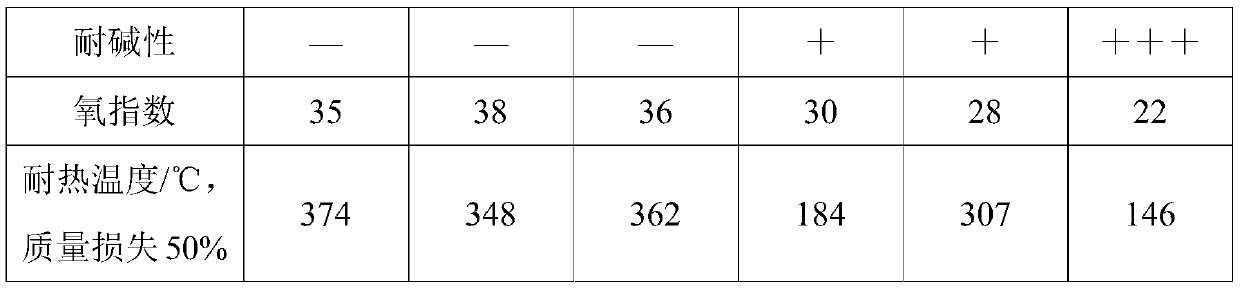

Examples

Embodiment 1

[0027] (1) Heat 30kg of phenolic resin and 10kg of chlorinated polyether polyol to 100°C, stir, vacuumize and dehydrate, then cool down to 50°C, add 63kg of MDI-50, react at 100°C for 4 hours, and cool to 50°C to obtain Semi-prepolymer A component, its -NCO mass content is 12%;

[0028] (2) Mix 50kg of polyether polyol DDL-1000, 10kg of amino-terminated polyether ZD-1200, and 0.2kg of diethanolamine evenly to obtain the R component;

[0029] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

Embodiment 2

[0031] (1) Heat 30kg of phenolic resin and 15kg of brominated polyether polyol to 110°C, stir, vacuumize and dehydrate, then cool down to 40°C, add 73kg of carbodiimide modified MDI-50, and react at 100°C for 3 hours , cooled to 40 ° C, to obtain the semi-prepolymer A component, its -NCO mass content is 14%;

[0032] (2) Mix 50kg of polyether polyol DDL-1000, 27.5kg of amino-terminated polyether ZD-1200, and 0.25kg of triethanolamine evenly to obtain the R component;

[0033] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

Embodiment 3

[0035] (1) Heat 30kg of phenolic resin and 17.5kg of chlorinated polyether polyol to 100°C, stir, vacuumize and dehydrate, then cool down to 50°C, add 59kg of TDI, react at 100°C for 4 hours, cool down to 50°C, and obtain half Prepolymer A component, its -NCO mass content is 12%;

[0036] (2) Mix 50kg of polyether polyol DDL-1000, 10kg of amino-terminated polyether ZD-1200, 0.1kg of ethylenediamine and 0.1kg of methyldiethanolamine to obtain the R component;

[0037] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com