High-strength flame-retardant cable material and preparation method thereof

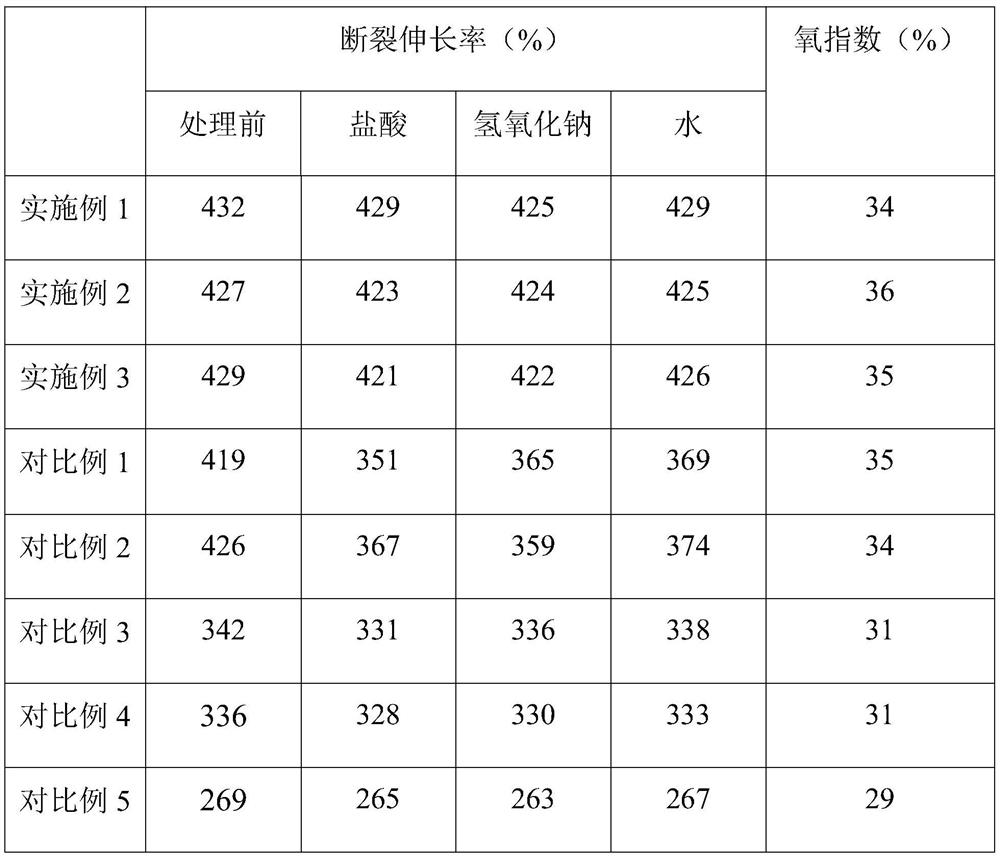

A flame-retardant cable material, high-strength technology, used in the field of cable materials, can solve problems such as corrosion resistance and poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix cyanuric chloride and tetrahydrofuran in a mass ratio of 1:4, and dropwise add 2.2 times the mass of cyanuric chloride with a mass fraction of 52% 3-aminopropyltriethoxysilane at a rate of 3 ml / min. The tetrahydrofuran solution was added dropwise at a rate of 3ml / min with a triethylamine solution with a mass of 1.8 times the mass of cyanuric chloride. The mass ratio of triethylamine and tetrahydrofuran in the triethylamine solution was 2:1. , Rotary steam to constant weight at 35°C to prepare base material; mix base material with absolute ethanol at a mass ratio of 1:2 and stir until dissolved, and dropwise add 2 times the mass of base material at a rate of 3ml / min. The mass fraction is 8 % sodium hydrosulfide in ethanol, heated to 50 °C, reacted for 3 h, and rotary-evaporated at 0.9 MPa and 46 °C to obtain s-triazinedithiolsilane;

[0030] (2) mixing magnesium hydroxide and deionized water in a mass ratio of 1:5, heating to 70° C., stirring to make a slurry, ad...

Embodiment 2

[0036] (1) Mix cyanuric chloride and tetrahydrofuran in a mass ratio of 1:4.1, and dropwise add 2.3 times the mass of cyanuric chloride with a mass fraction of 53% 3-aminopropyltriethoxysilane at a rate of 5ml / min. The tetrahydrofuran solution was added dropwise with a triethylamine solution with a mass of 1.9 times the mass of cyanuric chloride at a rate of 5ml / min. The mass ratio of triethylamine to tetrahydrofuran in the triethylamine solution was 2.2:1. , Rotary steam at 35°C to constant weight to prepare base material; mix base material with absolute ethanol at a mass ratio of 1:2.5 and stir until dissolved, and dropwise add 2 times the mass of base material at a rate of 5ml / min. The mass fraction is 9 % sodium hydrosulfide in ethanol, heated to 55°C, reacted for 3.5h, rotary-evaporated at 0.9MPa and 46°C to obtain s-triazinedithiolsilane;

[0037] (2) mixing magnesium hydroxide and deionized water in a mass ratio of 1:6, heating to 75° C., stirring to make a slurry, addi...

Embodiment 3

[0043] (1) Mix cyanuric chloride and tetrahydrofuran in a mass ratio of 1:4.2, and dropwise add 2.5 times the mass of cyanuric chloride with a mass fraction of 54% of 3-aminopropyltriethoxysilane at a rate of 8 ml / min. The tetrahydrofuran solution was added dropwise to a triethylamine solution with twice the mass of cyanuric chloride at a rate of 8ml / min. The mass ratio of triethylamine to tetrahydrofuran in the triethylamine solution was 2.5:1. After the reaction for 18h, at 0.9MPa Rotary steam to constant weight at 35°C to obtain base material; mix base material with absolute ethanol at a mass ratio of 1:3 and stir until dissolved, and dropwise add 3 times the mass of base material at a rate of 8ml / min. The mass fraction is 10 % sodium hydrosulfide in ethanol, heated to 60°C, reacted for 4h, and rotary-evaporated at 0.9MPa and 46°C to obtain s-triazinedithiolsilane;

[0044] (2) mixing magnesium hydroxide and deionized water in a mass ratio of 1:8, heating to 80° C., stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com