Phenolic resin modified polyurethane/polyurea coating and preparation method thereof

A phenolic resin, polyurethane technology, applied in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve the problems of strong acid resistance and high temperature resistance improvement of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

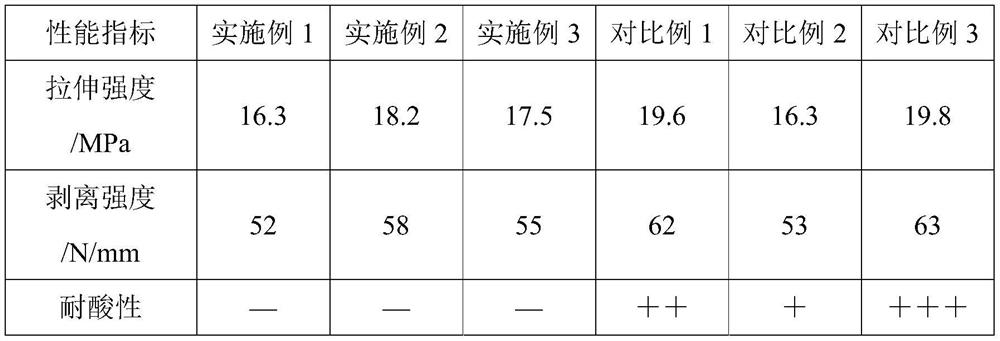

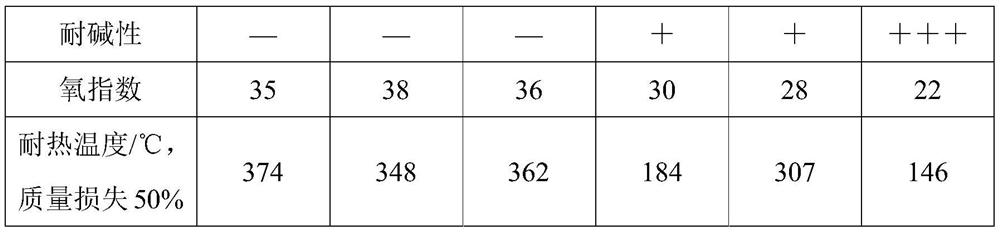

Examples

Embodiment 1

[0027] (1) Heat 30kg of phenolic resin and 10kg of chlorinated polyether polyol to 100°C, stir, vacuumize and dehydrate, then cool down to 50°C, add 63kg of MDI-50, react at 100°C for 4 hours, and cool to 50°C to obtain Semi-prepolymer A component, its -NCO mass content is 12%;

[0028] (2) Mix 50kg of polyether polyol DDL-1000, 10kg of amino-terminated polyether ZD-1200, and 0.2kg of diethanolamine evenly to obtain the R component;

[0029] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

Embodiment 2

[0031] (1) Heat 30kg of phenolic resin and 15kg of brominated polyether polyol to 110°C, stir, vacuumize and dehydrate, then cool down to 40°C, add 73kg of carbodiimide modified MDI-50, and react at 100°C for 3 hours , cooled to 40 ° C, to obtain the semi-prepolymer A component, its -NCO mass content is 14%;

[0032] (2) Mix 50kg of polyether polyol DDL-1000, 27.5kg of amino-terminated polyether ZD-1200, and 0.25kg of triethanolamine evenly to obtain the R component;

[0033] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

Embodiment 3

[0035] (1) Heat 30kg of phenolic resin and 17.5kg of chlorinated polyether polyol to 100°C, stir, vacuumize and dehydrate, then cool down to 50°C, add 59kg of TDI, react at 100°C for 4 hours, cool down to 50°C, and obtain half Prepolymer A component, its -NCO mass content is 12%;

[0036] (2) Mix 50kg of polyether polyol DDL-1000, 10kg of amino-terminated polyether ZD-1200, 0.1kg of ethylenediamine and 0.1kg of methyldiethanolamine to obtain the R component;

[0037] (3) Mix and stir 100kg of component A and 50kg of component R to obtain phenolic resin modified polyurethane / polyurea coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com