Patents

Literature

199 results about "Hydroxybenzoate Ethers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzoate derivatives that contain one or more alkyl or aryl groups linked to the benzene ring structure by OXYGEN.

Method and composition to reduce cancer incidence

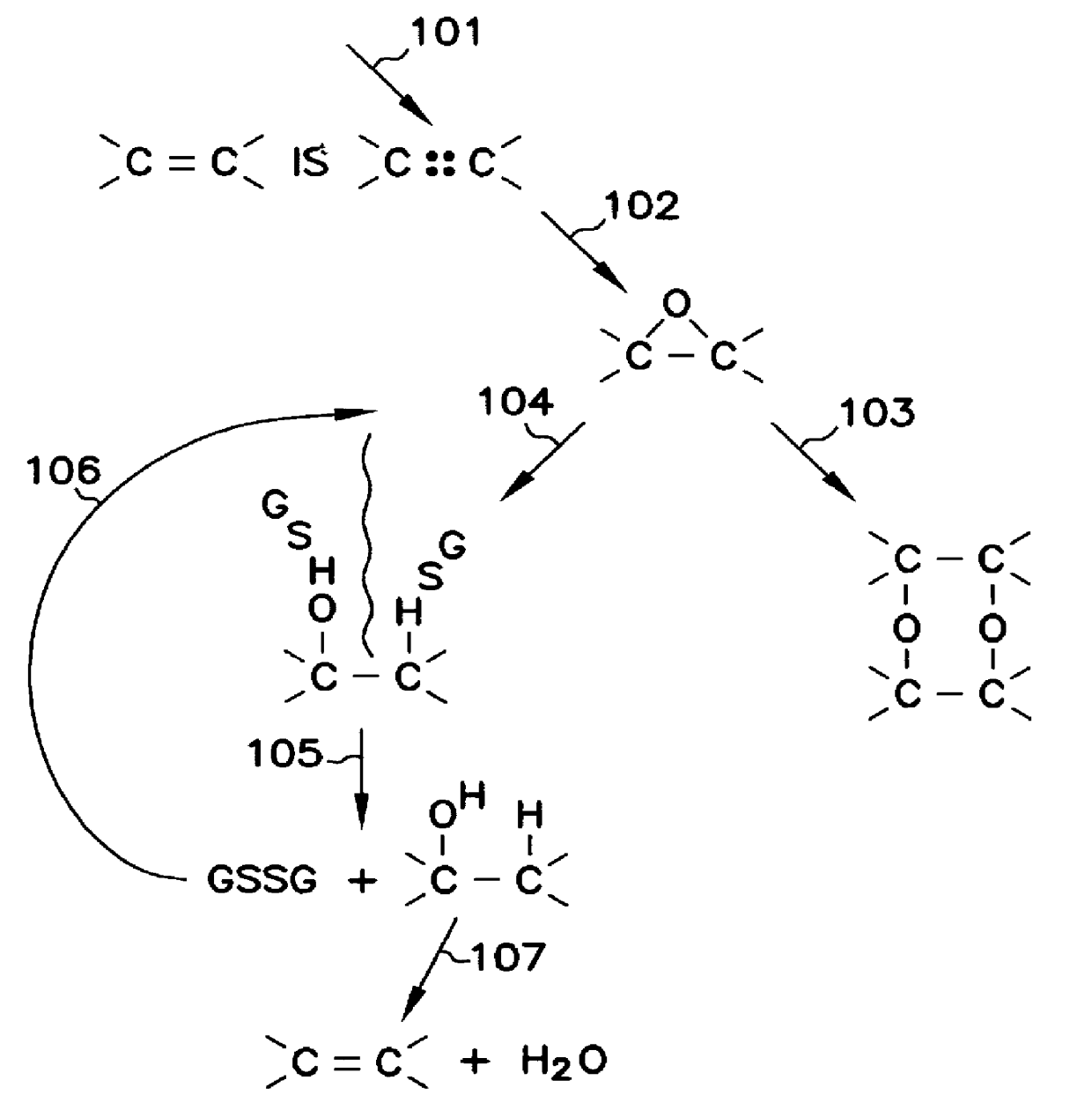

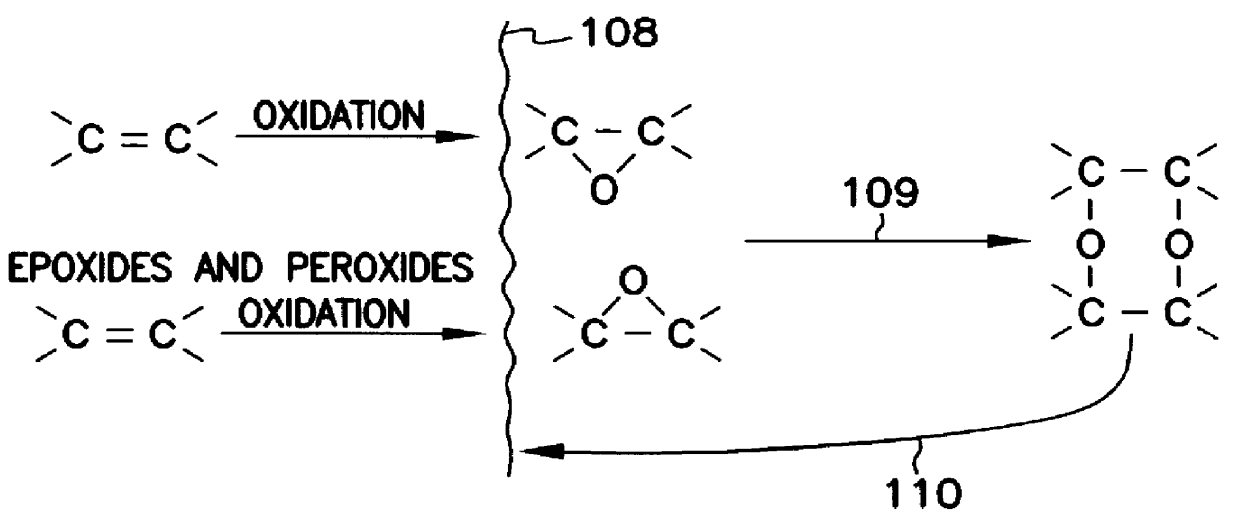

InactiveUS6090414AReduce distractionsInhibition formationBiocideTetrapeptide ingredientsHydroxybenzoate EthersS oxidation

The five component composition consisting essentially of: (1) Water soluble antioxidant vitamin C or ascorbic acid, or any of its forms or derivatives, or mixtures thereof. (2) Oil soluble antioxidant vitamin E or Alpha-tocophorol, or any of its forms or derivatives, or mixtures thereof. (3) The element selenium, or a chemical (or composition) containing it, or mixtures thereof. The most preferred chemical containing selenium is dimethyl selenide and mixtures thereof. The words "dimethyl selenide" here and hereinafter mean dimethyl selenide and / or it's oxidation products, including dimethyl selenoxide. (4) A sulfur amino acid, in any form, or a sulfur peptide, or a sulfur protein, or any of their derivatives, or mixtures thereof. The mixture of methionine and cysteine, which contains as impurities some seleno-methionine and some selenocysteine, is preferred,-the tripeptide glutathione containing cysteine is also preferred. (5) Another antioxidant, other than vitamin C and other than vitamin E, which is synthetic or natural and water soluble or oil soluble, or a mixture of such antioxidants, or a combination of such forms thereof. The mixtures of butylated hydroxyanisole and ethoxyquin is preferred.

Owner:LIFE SCI LAB

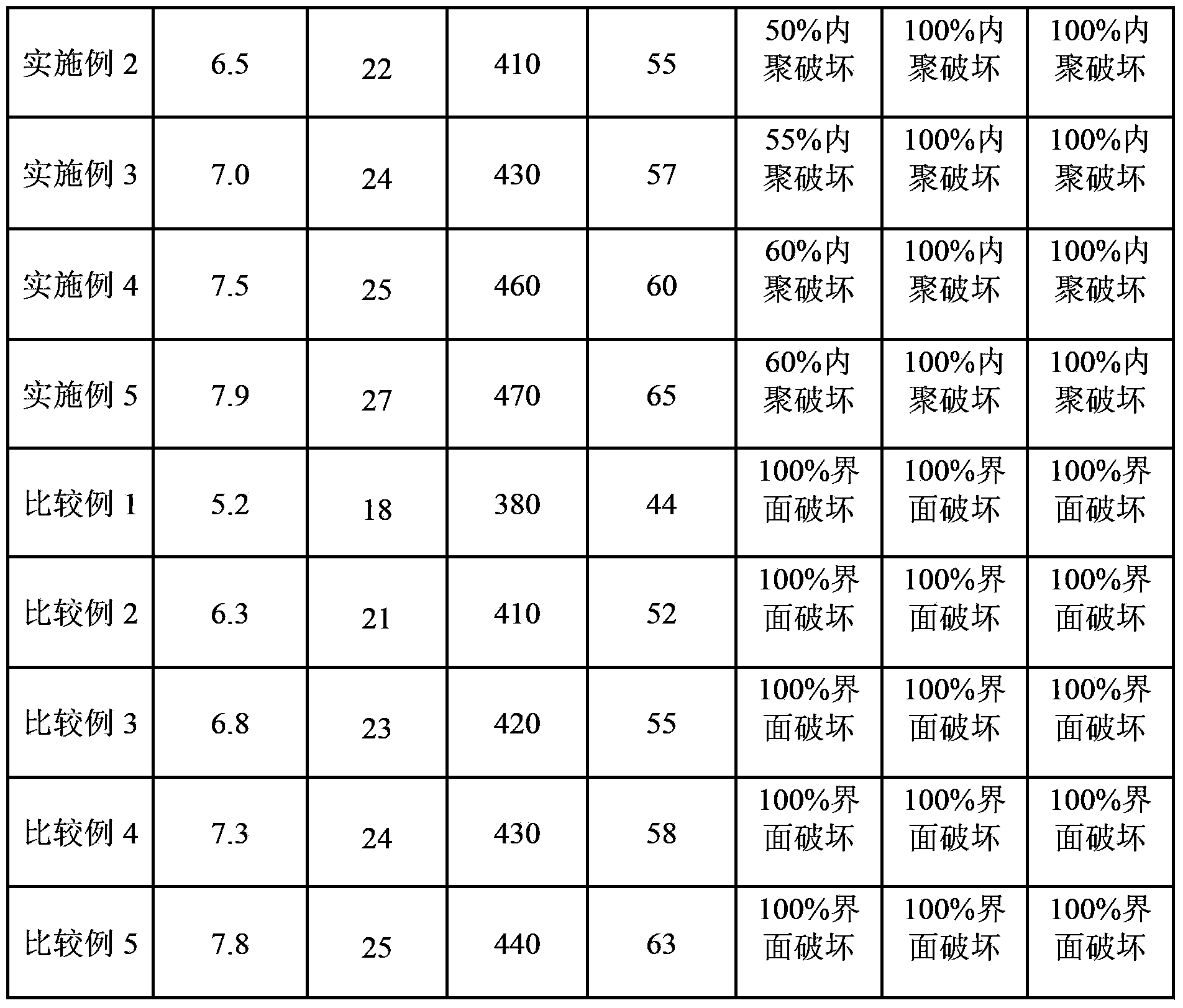

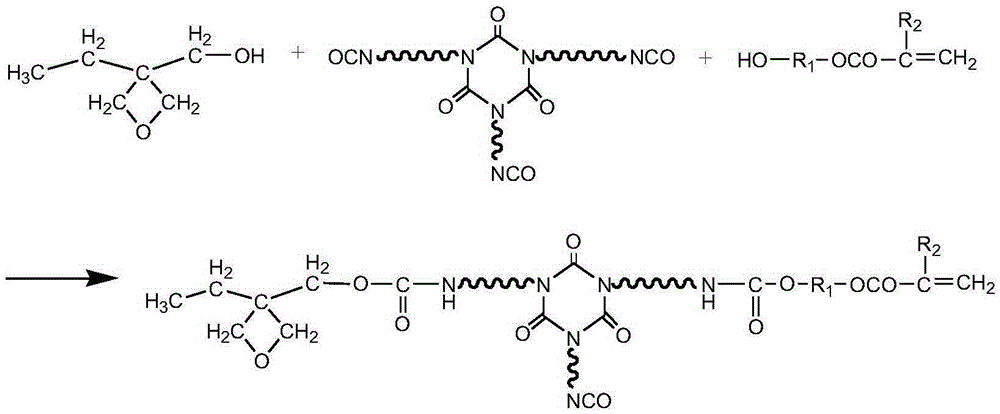

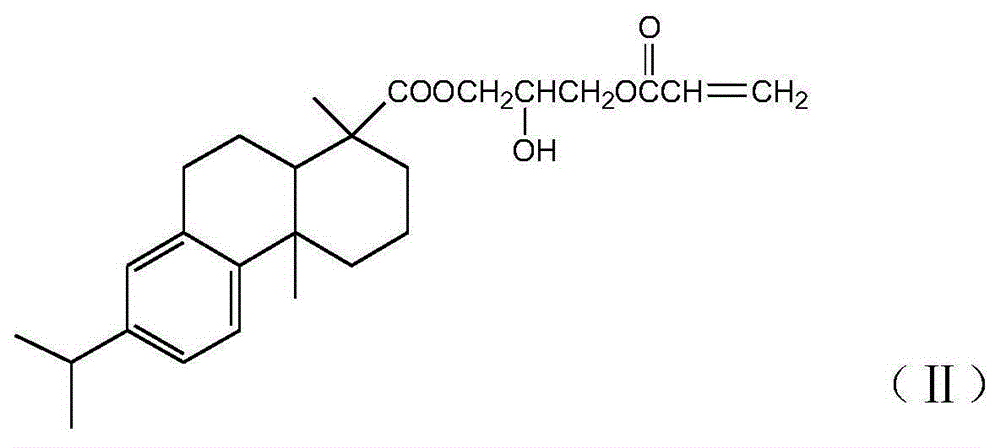

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

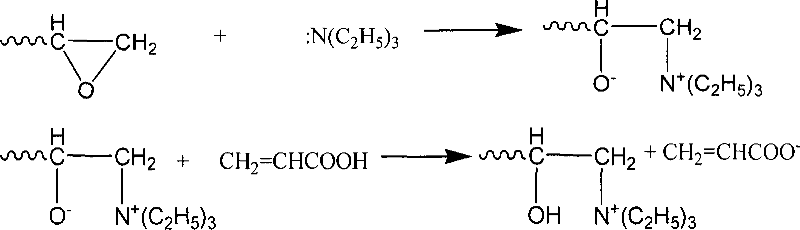

Preparation method of special epoxy resin for aqueous ultraviolet solidifying coating

A method of preparing special epoxy resin for water ultraviolet light curing coating includes steps: a) using bisphenol A type epoxy resin and acrylic acid as raw material, adding catalyst of triethylamine and inhibitor of p-hydroxyanisole, reacting at 70-100 DEG C, after mass concentration of acrylic acid lower than 40-50%, raising temperature to 110-120 DEG C until acid value of the system lower than 5mgKOH / 100g and generating epoxy acrylate; b) mixing the maleic anhydride and the epoxy acrylate according mole ratio of 0.8:1.05-0.8:1.05 and reacting water epoxy acrylate, adding catalyst triethylamine and inhibitor of p-hydroxyanisole under temperature of 60-100 DEG C and reacting for 1-3 h, adding dimethlyethanolamine to neutralizing, adding water and obtaining water epoxy acrylate with certain solid content.

Owner:CHINA PETROCHEMICAL CORP

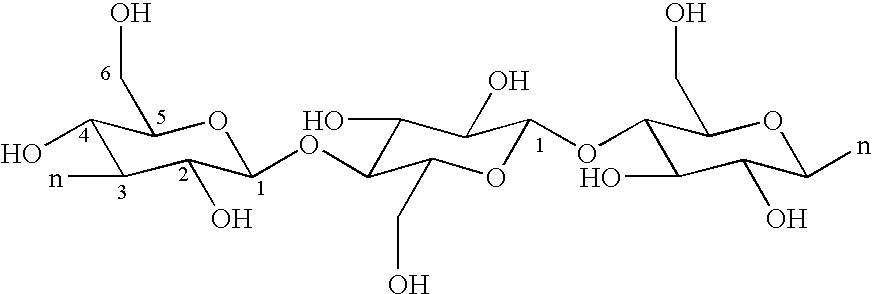

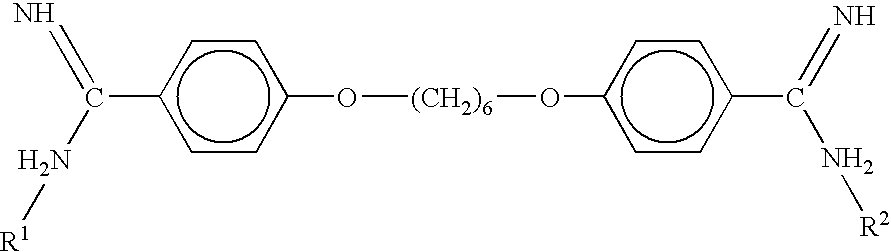

Personal Care Compositions Comprising Alpha-Glucans and/or Beta-Glucans

Personal care compositions containing at an alpha-glucan and / or beta-glucan; at least one additional skin and / or hair care active selected from the group consisting of sugar amine, vitamin B3, retinoids, peptides, phytosterol, dialkanoyl hydroxyproline, hexamidine, salicylic acid, n-acyl amino acid compounds, sunscreen actives, water soluble vitamins, oil soluble vitamins, hesperedin, mustard seed extract, glycyrrhizic acid, glycyrrhetinic acid, carnosine, Butylated Hydroxytoluene (BHT) and Butylated Hydroxyanisole (BHA), menthyl anthranilate, cetyl pyridinium chloride, ergothioneine, vanillin or its derivatives, diethylhexyl syrinylidene malonate, melanostatine, sterol esters, tetrahydrocurcumin, their derivatives, their precursors, and combinations thereof; and a dermatologically acceptable carrier.

Owner:THE PROCTER & GAMBLE COMPANY

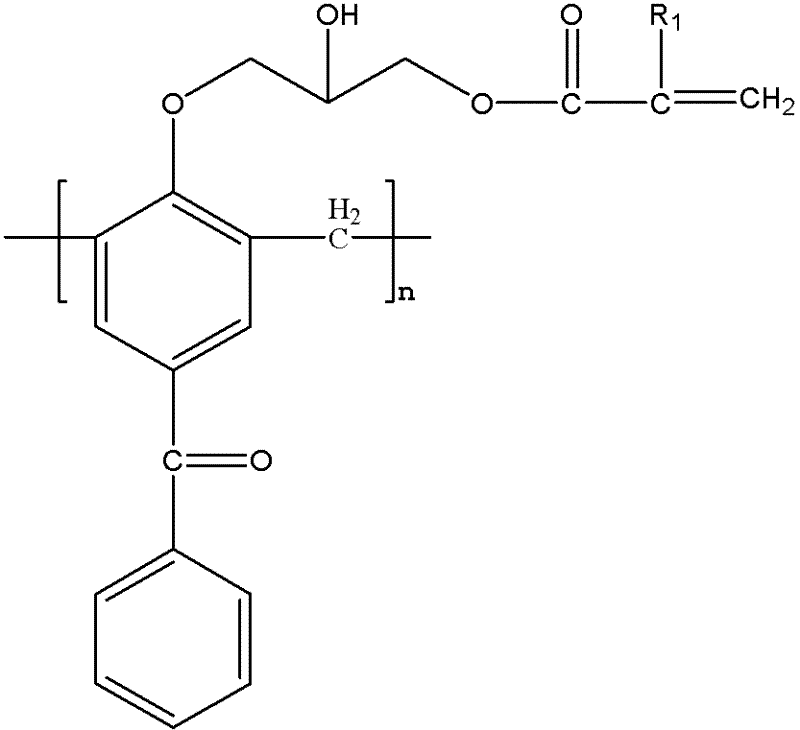

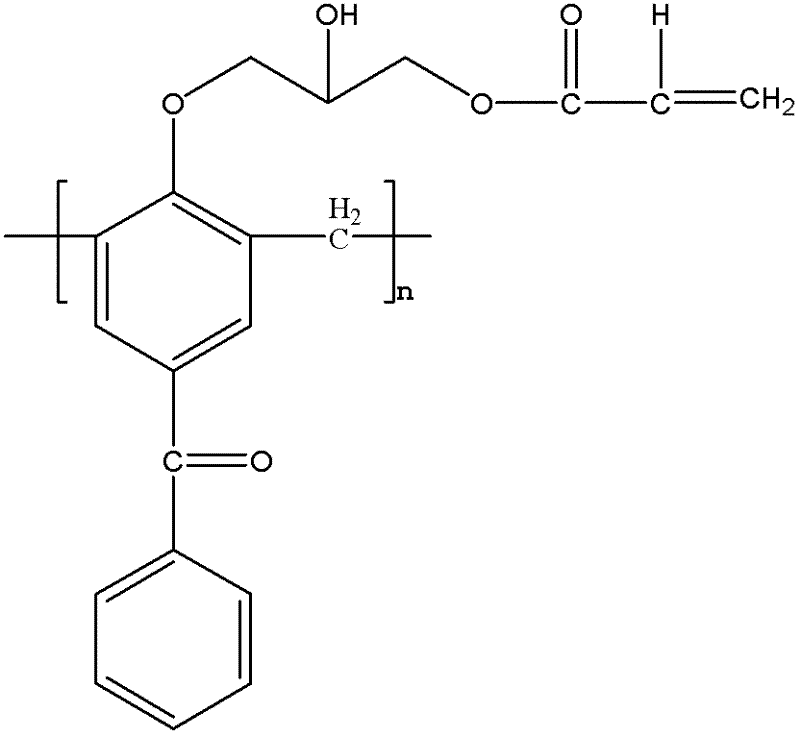

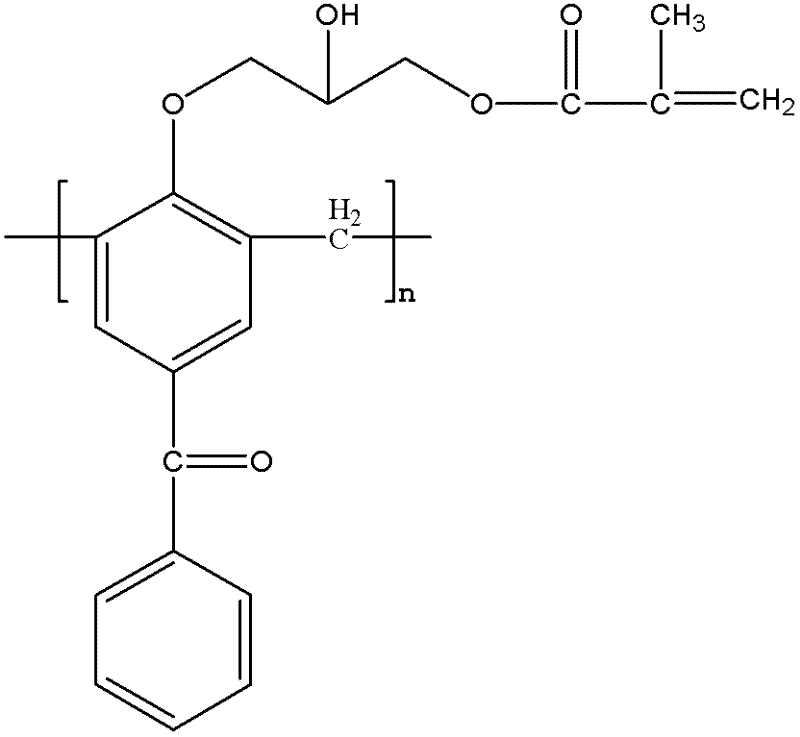

Macromolecular polymerizable photoinitiator and preparation thereof

InactiveCN102585045AAvoid reaction stepSimple operating conditionsHydroxybenzoate EthersOrganic solvent

The invention discloses a macromolecular polymerizable photoinitiator and a preparation thereof. The method comprises the following steps of: adding 4-hydroxybenzophenone and methanal to a three-necked flask, heating to 95 DEG C, reacting for 2 hours, heating to 150DEG C, leaching under at reduced pressure for 20 minutes, cooling to 105 DEG C, collecting products, pouring products into water, leaching to obtain a macromolecular photoinitiator, dissolving the macromolecular photoinitiator in an organic solvent, dissolving epoxy chloropropane in the solvent under catalysis of boron trifluoride,dropwise adding mixed liquid, reacting at a temperature of 0-5 DEG C, then stirring for 3 hours at a temperature of 70 DEG C, removing epoxy chloropropane and solvent, dissolving residues with a solvent, adding alkali and reacting for 0.5 hour at a temperature of 40 DEG C, removing salt and the solvent, re-dissolving residues with a solvent, washing with water and drying, adding crylic acid, p-hydroxyanisole and tetrabutylammonium bromide, heating for reacting for 6 hours, and then removing the solvent so as to obtain macromolecular polymerizable photoinitiator. The macromolecular polymerizable photoinitiator prepared by the method has the advantages of large molecular weight, weak mobility and good polymerizability.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Addition type liquid silicone rubber bonding accelerant and preparation method and application thereof

The invention discloses an addition type liquid silicone rubber bonding accelerant and a preparation method and application thereof. The preparation method comprises the steps as follows: mixing an acrylic ester compound and a platinum catalyst solution, and preheating the mixed solution for 20-60 minutes at the temperature of 30-60 DEG C for later use; adding silicon hydrogen bond, hydrogen-containing silicone oil, methylbenzene and para-hydroxybenzaldehyde into a reactor; stirring while heating; when the temperature in the reactor achieves 30-80 DEG C, dripping the mixture of the acrylic ester compound and the platinum catalyst which are primarily heated to 30-60 DEG C into the reactor, for 0.5-3 hours; after dripping, controlling the reaction temperature within 50-90 DEG C and reacting for 0.5-4 hours; adding activated carbon for adsorption, and then performing suction filtering and rotary evaporation to the solution after reaction so as to obtain the bonding accelerant. The bonding accelerant prepared through the method can remarkably improve the adhesive property of the addition type liquid silicon rubber, the preparation process is simple and convenient, the raw materials are cheap and easy to obtain, and the industrialized production is facilitated.

Owner:东莞市贝特利新材料有限公司

Compositions containing micronized tanaproget prepared by wet granulation

Compositions, preferably pharmaceutical compositions, containing micronized tanaproget, or pharmaceutically acceptable salt thereof, microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, butylated hydroxyanisole, povidone, and magnesium stearate, are provided. The compositions are useful in contraception and hormone replacement therapy and in the treatment and / or prevention of uterine myometrial fibroids, benign prostatic hypertrophy, benign and malignant neoplastic disease, dysfunctional bleeding, uterine leiomyomata, endometriosis, polycystic ovary syndrome, and carcinomas and adenocarcinomas of the pituitary, endometrium, kidney, ovary, breast, colon, and prostate and other hormone-dependent tumors, and in the preparation of medicaments useful therefor. Additional uses include stimulation of food intake.

Owner:WYETH LLC

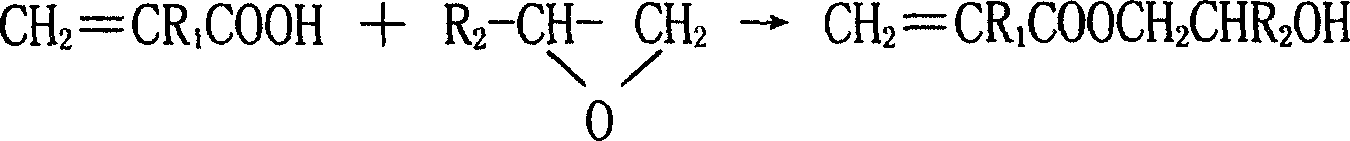

Process for preparing polyalcohol acrylate

ActiveCN1693299AOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate EthersPolyol

A process for preparing polyol acrylate used as the reactive diluent of irradiation solidification includes such steps as providing polyol and acrylic acid, mixing, adding solvent, polymerizing inhibitor, catalyst and decoloring agent, heating, reflux, adding solid alkali for neutralizing, filtering for removing solid, adding P-hydroxyphenyl mether, vacuum removal of solvent and filtering. Its advantage is no generation of sewage.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Modified hydrogen-containing cyclotetrasiloxane bonding accelerant as well as preparation method and application thereof

InactiveCN103360422AGood adhesionCohesive failureSilicon organic compoundsNon-macromolecular adhesive additivesActivated carbonHydroxybenzoate Ethers

The invention discloses a modified hydrogen-containing cyclotetrasiloxane bonding accelerant as well as a preparation method and an application thereof. The preparation method comprises the following steps of: mixing an acrylic ester compound with a platinum catalyst solution, subsequently preheating at 30-60 DEG C, stirring and raising the temperature of 1,3,5,7-tetramethyl cyclotetrasiloxane, methylbenzene and para-hydroxybenzene methyl ether at the same time, when the temperature in a reactor is 30-80 DEG C, dropping a mixture which is preheated to be 30-60 DEG C, of the acrylic ester compound and the platinum catalyst solution, into the reactor, after the dropping, controlling the reaction temperature to be 50-90 DEG C, reacting for 0.5-4 hours, subsequently, adding activated carbon into the reactor to absorb for 0.5-3 hours, and after the absorption, sucking, filtering and evaporating the solution so as to obtain the bonding accelerant. By utilizing the bonding accelerant prepared by using the preparation method, the bonding property of addition-type liquid silica rubber is remarkably improved. The preparation process is simple, raw materials are cheap and easily obtained, and industrial production is easy to realize.

Owner:广州纽楷美新材料科技有限公司

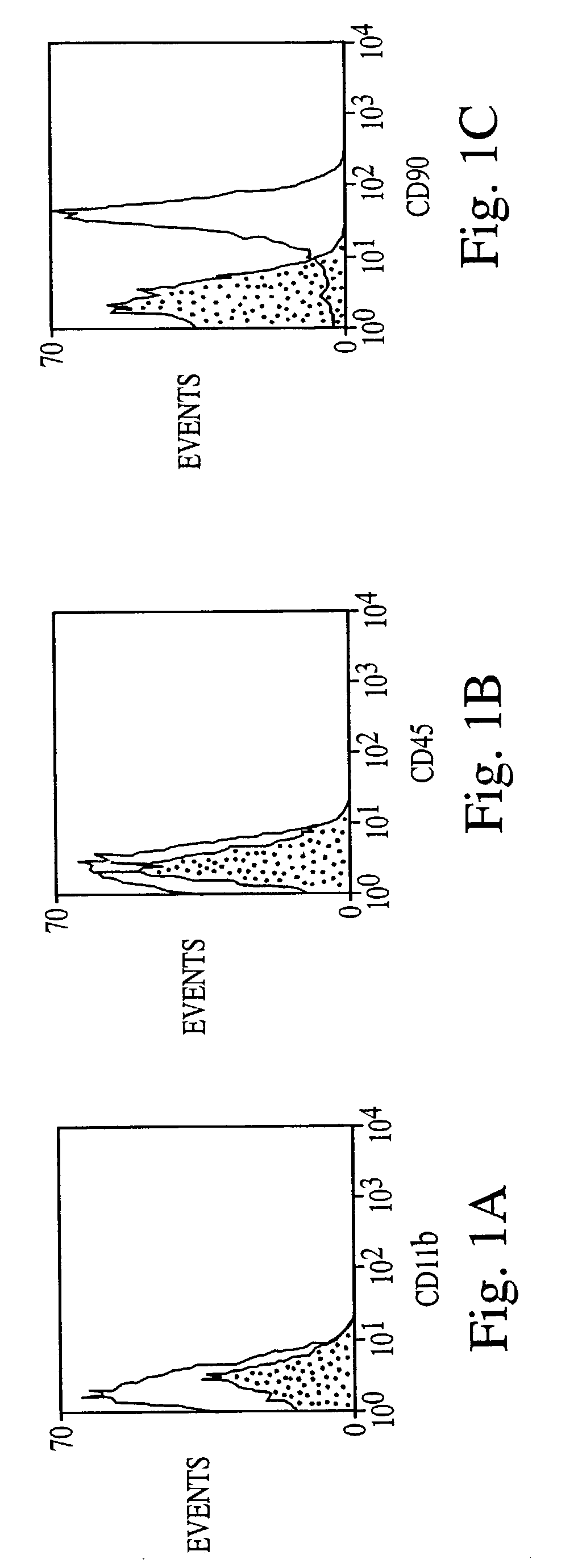

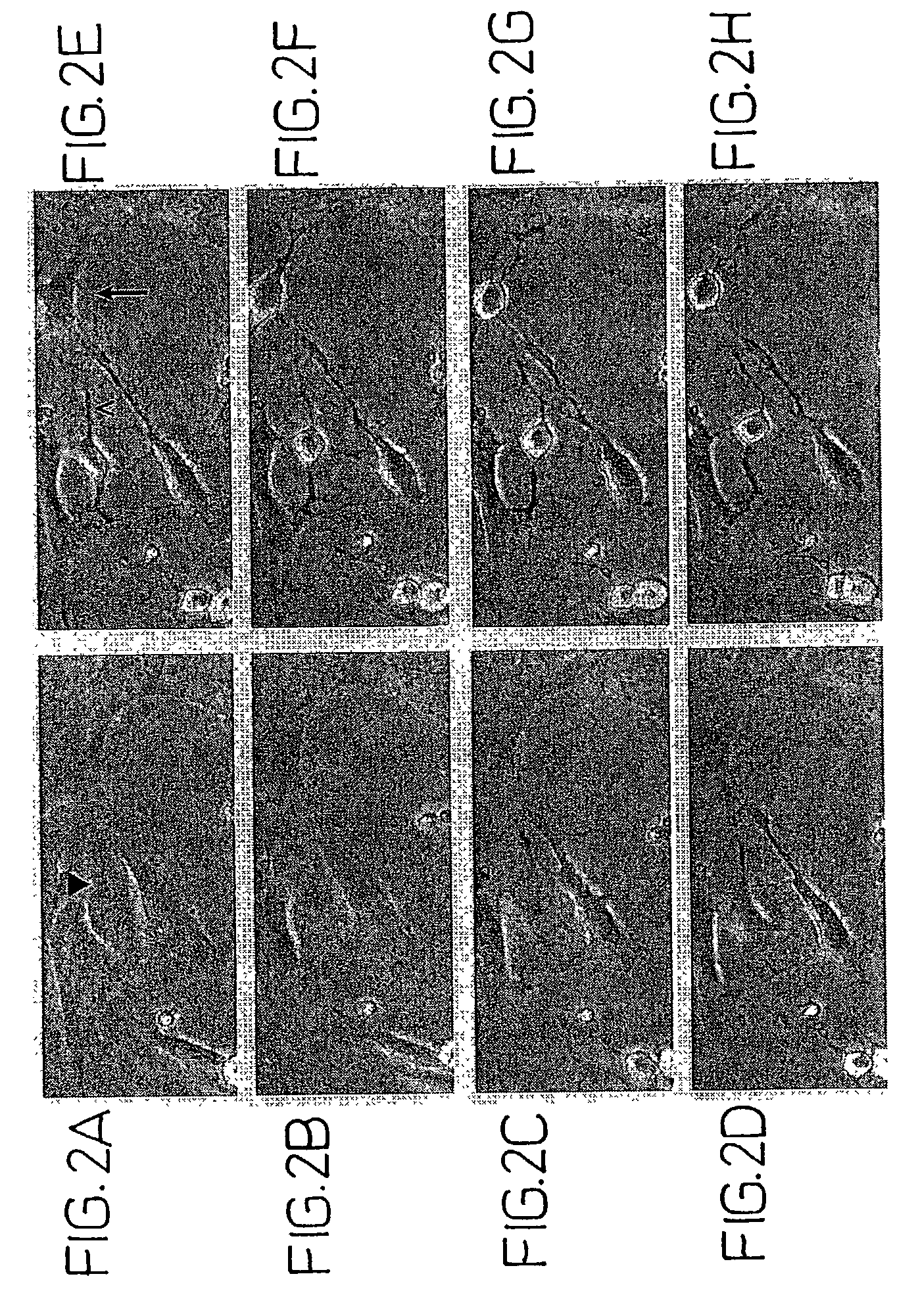

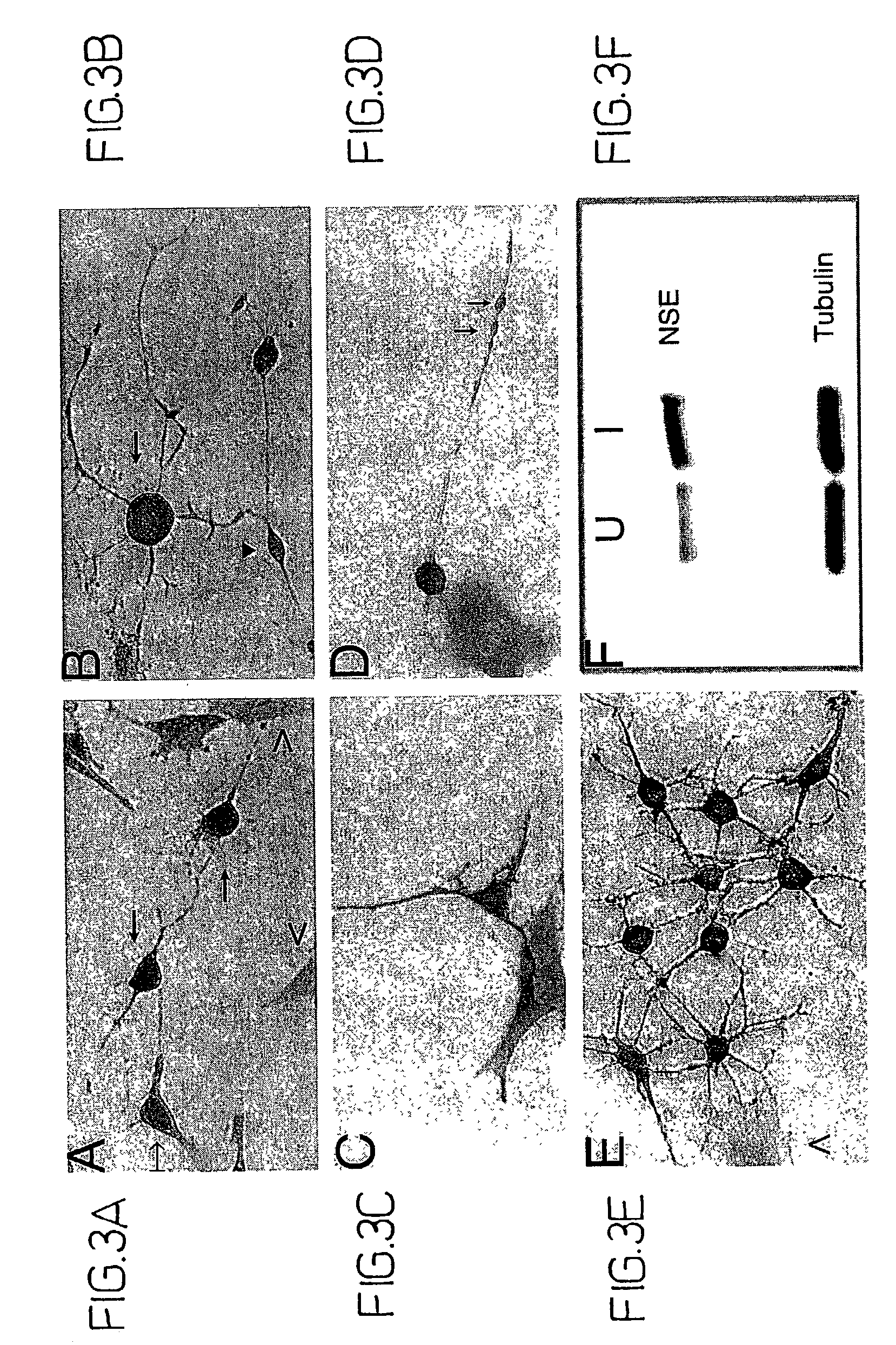

Differentiation of bone marrow cells into neuronal cells and uses therefor

The present invention relates to methods of inducing differentiation of mammalian bone marrow stromal cells into neuronal cells by contacting marrow stromal cells with a neuronal differentiation-inducing compounds. Neuronal differentiation-inducing compounds of the invention include anti-oxidants such as, but not limited to, beta-mercaptoethanol, dimethylsulfoxide, butylated hydroxyanisole, butylated hydroxytoluene, ascorbic acid, dimethylfumarate, and n-acetylcysteine. Once induced to differentiate into neuronal cells, the cells can be used for cell therapy, gene therapy, or both, for treatment of diseases, disorders, or conditions of the central nervous system.

Owner:PHILADELPHIA HEALTH & EDUCATION CORP +1

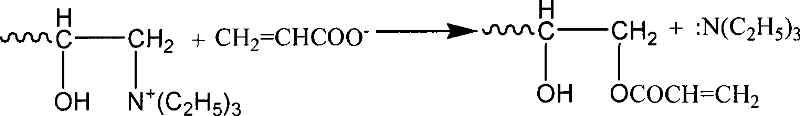

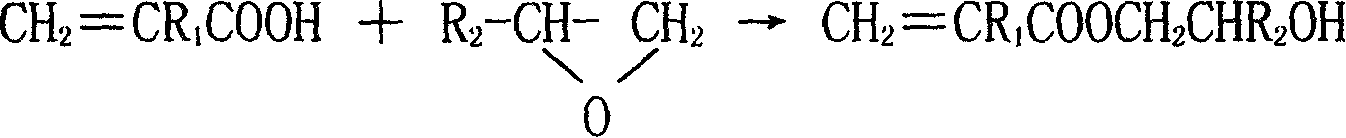

Method for synthesizing acrylic acid and hydroxyalkyl methacrylate

ActiveCN1919826AHigh activityOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate EthersEthylene oxide

The invention discloses a synthesizing method of acroleic acid and methacrylate hydroxyalkyl ester, adopting acroleic acid or methacrylate as raw material; proceeding additional reaction for epoxyethane or epoxypropane with molar rate at 1-1.5: 1 to produce (methyl) acroleic hydroxyethyl (hydroxypropyl) ester; setting the reacting temperature at 60-120 deg.c; using the quantity of catalyst at 0.1-1.0% as reactant.

Owner:NANJING FORESTRY UNIV +1

Preparation technology of tert-butyl acrylate

InactiveCN104987288AHigh yieldIncrease profitOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a preparation technology of tert-butyl acrylate. Acrylic acid, isobutene, an acidic catalyst and a polymerization inhibitor undergo an esterification reaction at 40-120DEG C under 1.0-5.0MPa under an isobutene volume space velocity of 0.5-5.0 / h according to a molar ratio of acrylic acid to isobutene of 1.0:1.0-5.0:1.0, the polymerization inhibitor comprises tert-butylcatechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine according to a weight ratio of 1:3:2:7, and the acidic catalyst is strong-acid cation exchange resin. The method can substantially improve the yield of tert-butyl acrylate.

Owner:QILU UNIV OF TECH

Polyether polyurethane-acrylate and preparation method thereof

InactiveCN101608010AGood chemical resistanceImprove high temperature resistancePolyurea/polyurethane coatingsHydroxybenzoate EthersPolymer science

The invention provides polyether polyurethane-acrylate and a preparation method thereof. The polyether polyurethane-acrylate comprises the following compositions in portion by weight: 40 to 60 portions of polyether glycol, 10 to 30 portions of polyisocyanates, 10 to 30 portions of hydroxypropyl acrylate or hydroxy-ethyl acrylate, 0.1 to 0.5 portion of triethylamine or dibutyltin dilaurate, 5 to 10 portions of absolute ethanol, 0.1 to 0.8 portion of p-hydroxyanisole or 2.6- di-tert-butyl-4-methylphenol, 5 to 20 portions of tripropylene glycol diacrylate, 5 to 20 portions of TMPTA, and 0.01 to 0.02 portion of nitrobenzene. The invention has excellent mechanical abrasion resistance and toughness, high elongation at break, excellent chemical resistance and high temperature resistance when coating a film, has low temperature performance and good adhesive force. The polyether polyurethane-acrylate has better using effect when assembling epoxy acrylate, and is the polyurethane acrylate with lowest cost.

Owner:上海展辰涂料有限公司 +2

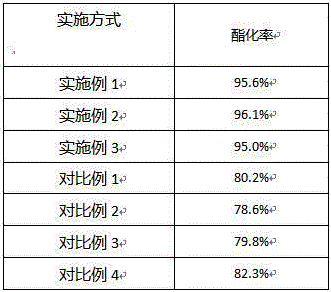

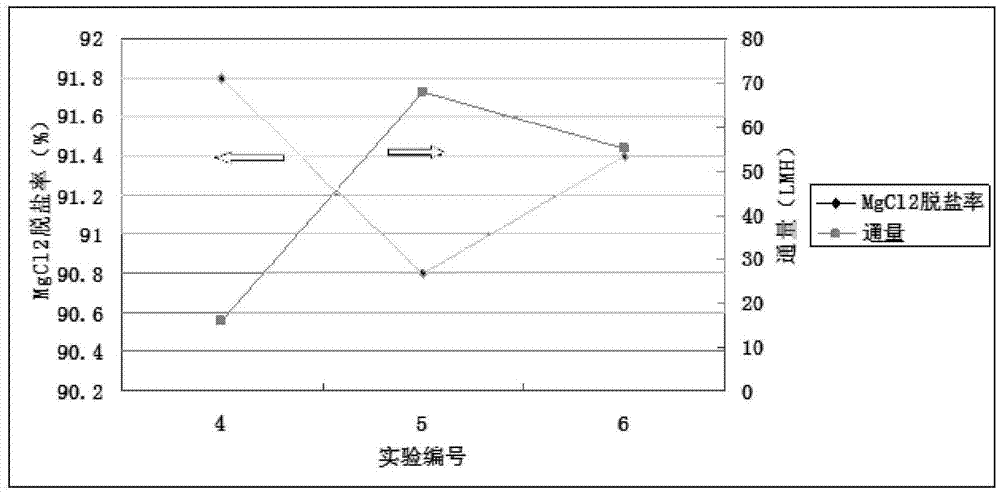

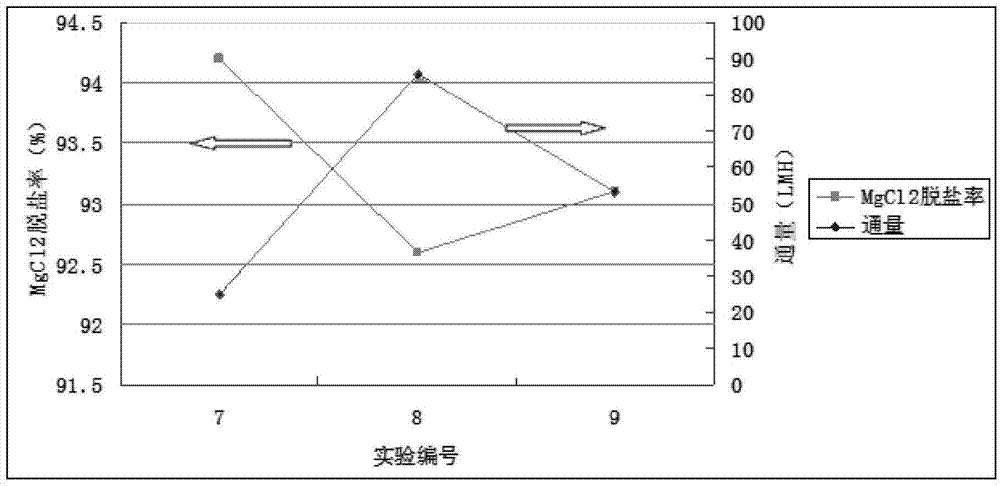

Preparation method for UV-induced photografted charged nanofiltration membrane and product thereof, and application of product

ActiveCN103480286AImprove throughputFlux controlReverse osmosisWater/sewage treatment bu osmosis/dialysisDPPHSodium acetate

The invention relates to a preparation method for a UV-induced photografted charged nanofiltration membrane. The method comprises the following steps: fixing an ultrafiltration membrane with a photo-initiation function in a grafting tank and adding an aqueous solution of a UV grafting monomer, wherein the aqueous solution of the UV grafting monomer further includes a polymerization inhibitor and a chain transferring agent, the polymerization inhibitor is selected from the group consisting of p-hydroxybenzene methyl ether, p-benzoquinone and 1,1-dibenzyl-2-trinitrophenylhydrazine, and the chain transferring agent is selected from the group consisting of sodium formate, sodium acetate and methanol; and allowing the solution to form a liquid film on the ultrafiltration membrane, irradiating the liquid film with an ultraviolet lamp for a reaction and carrying out washing so as to obtain the UV-induced photografted charged nanofiltration membrane. The nanofiltration membrane prepared in the invention has flux of 40 to 120 LMH at an operation pressure of 0.3 Mpa and a salt removing rate of more than 90% on divalent MgCl2.

Owner:北京碧水源净水工程技术股份有限公司

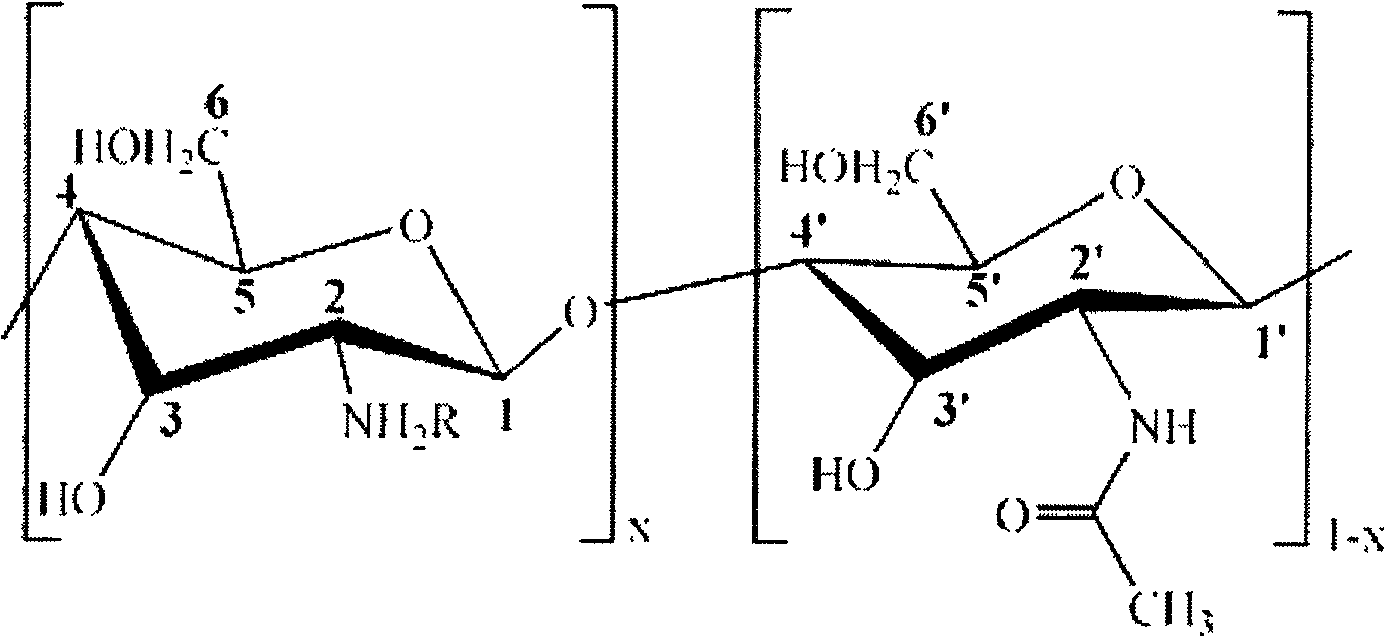

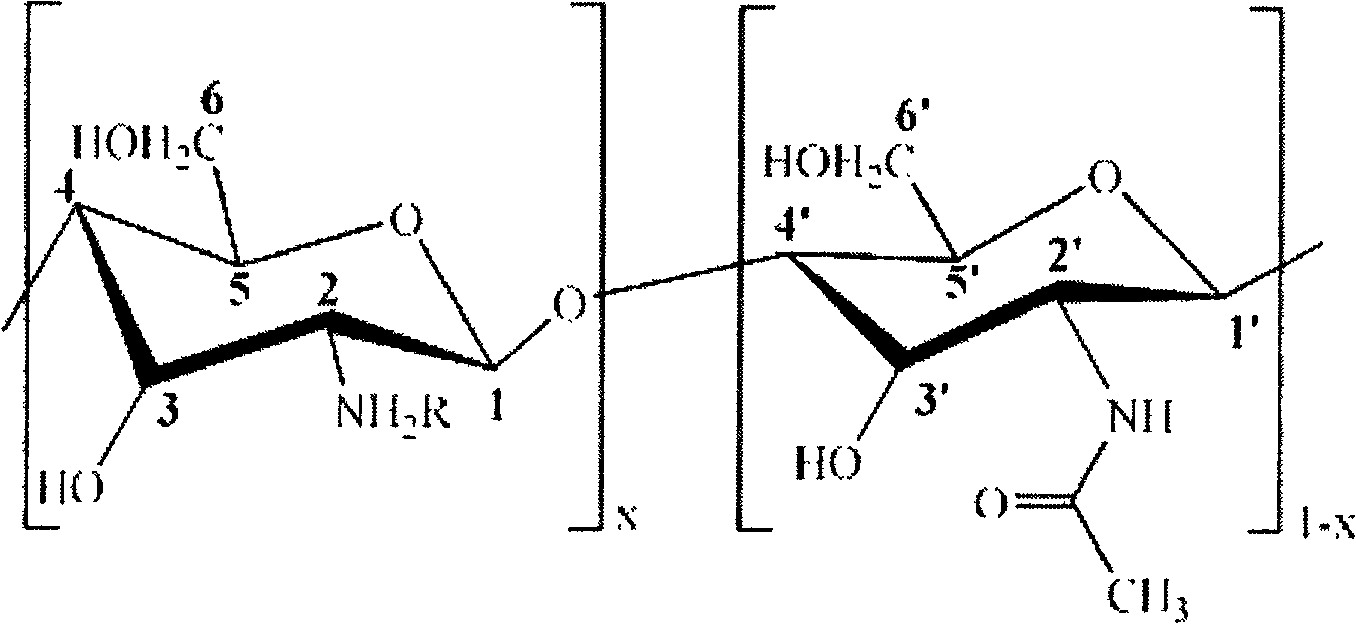

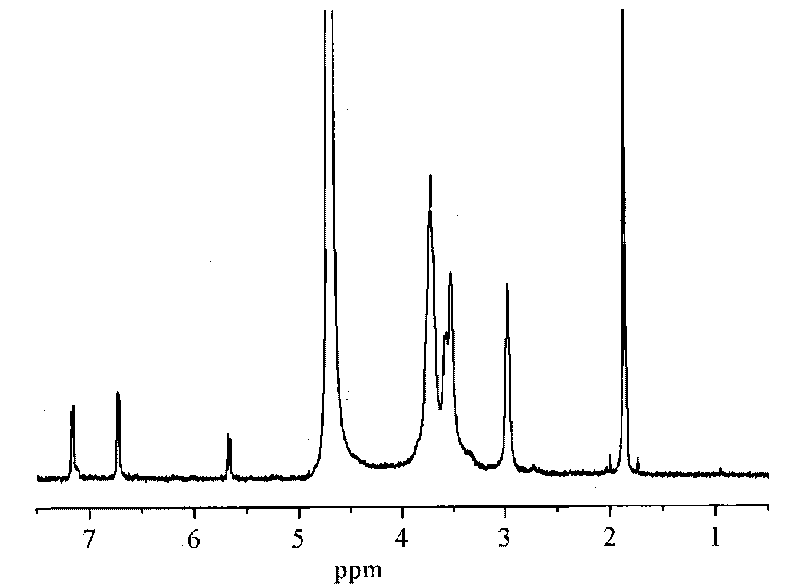

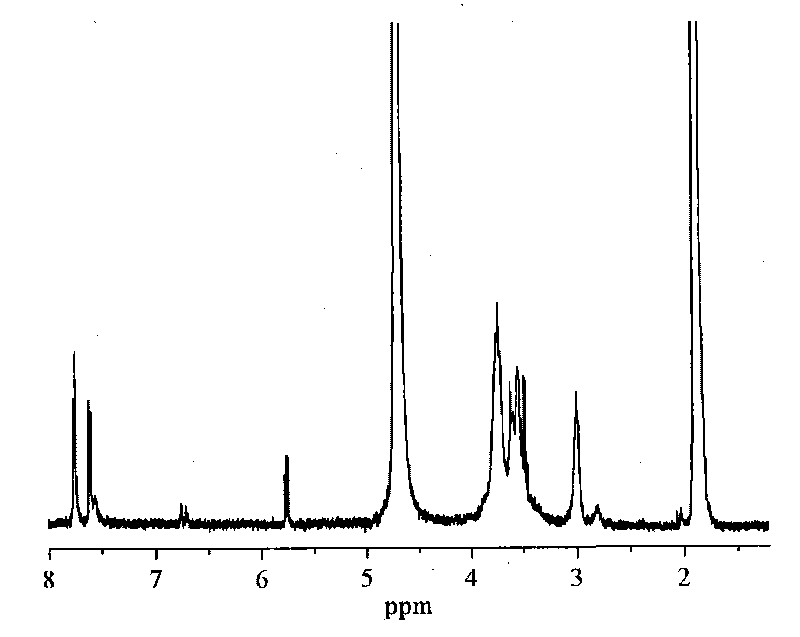

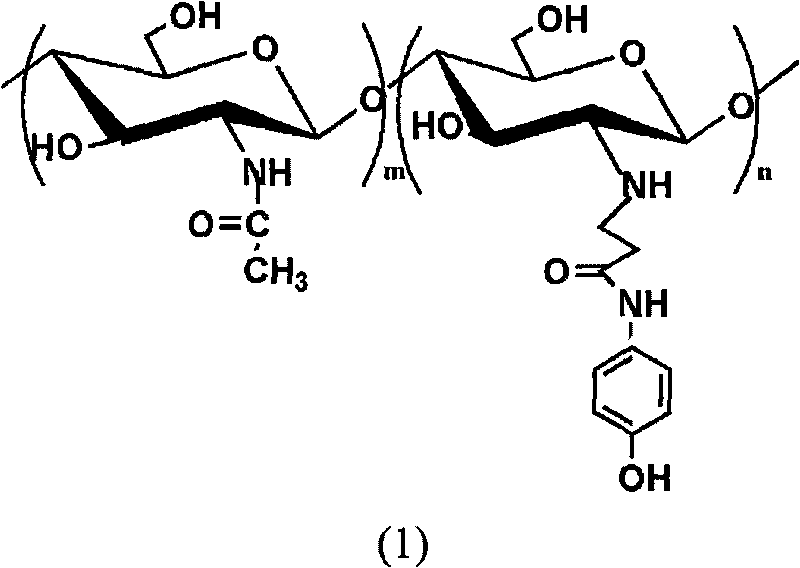

Preparation method of reactive type water-solubility chitosan derivative

InactiveCN101659710ARetain biological activityRetain biocompatibilitySolubilityHydroxybenzoate Ethers

The invention relates to a preparation method of a reactive type water-solubility chitosan derivative, which comprises the steps of adding chitosan into the aqueous solution of 2-acrylamido-2-methylpropanesulfonic acid, stirring for 0.5 hour at room temperature, preparing the chitosan aqueous solution to 2 wt% with the mole number of the 2-acrylamido-2-methylpropanesulfonic acid being 0.5-4 timesof that of amido of the chitosan, adding p-Hydroxyanisole accounting for 1-3 percent of the mole number of the 2-acrylamido-2-methylpropanesulfonic acid in the above solution, keeping stirring for 0.5hour to lead the chitosan to be fully dissolved in the aqueous solution, heating up to 30-60 DEG C fast, and reacting for 2-6 hours, thus obtaining the reactive type water-solubility chitosan derivative. The method has mild reaction condition, easy control, simple procedures, easy control of substitution degree, environment-protecting subsequent treatment and economical reaction process.

Owner:BEIJING UNIV OF CHEM TECH

Thermoplastic fiber-reinforced epoxy composite and applications thereof

ActiveCN102774013AImprove processing and manufacturing speedRealize mass production4-MethoxyphenolEpoxy

The invention discloses a thermoplastic fiber-reinforced epoxy composite and applications thereof. The thermoplastic fiber-reinforced epoxy composite is prepared by taking epoxy resin and crylic acid as raw materials, thermoplastic fiber aramid woven cloths as reinforcing materials, N,N-dimethylaniline as catalyst, 4-methoxyphenol as polymerization inhibitor, trimethylolpropane triacrylate as diluted monomer, isopropylthioxanthone as photoinitiator, silane coupling agent as modifier, and metahanol as solvent, firstly synthesizing epoxy acrylate, diluting with the trimethylolpropane triacrylate, synthesizing photosensitive resin, dipping the thermoplastic fiber aramid woven cloths with the photosensitive resin, and carrying out fast forming of a novel electric car body support frame on photocuring forming equipment. The photocured electric car body support frame prepared by using the method has excellent performances, is environment-friendly, and has no harm influence on human body and ambient environment, and the curing effect meets the national standard.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

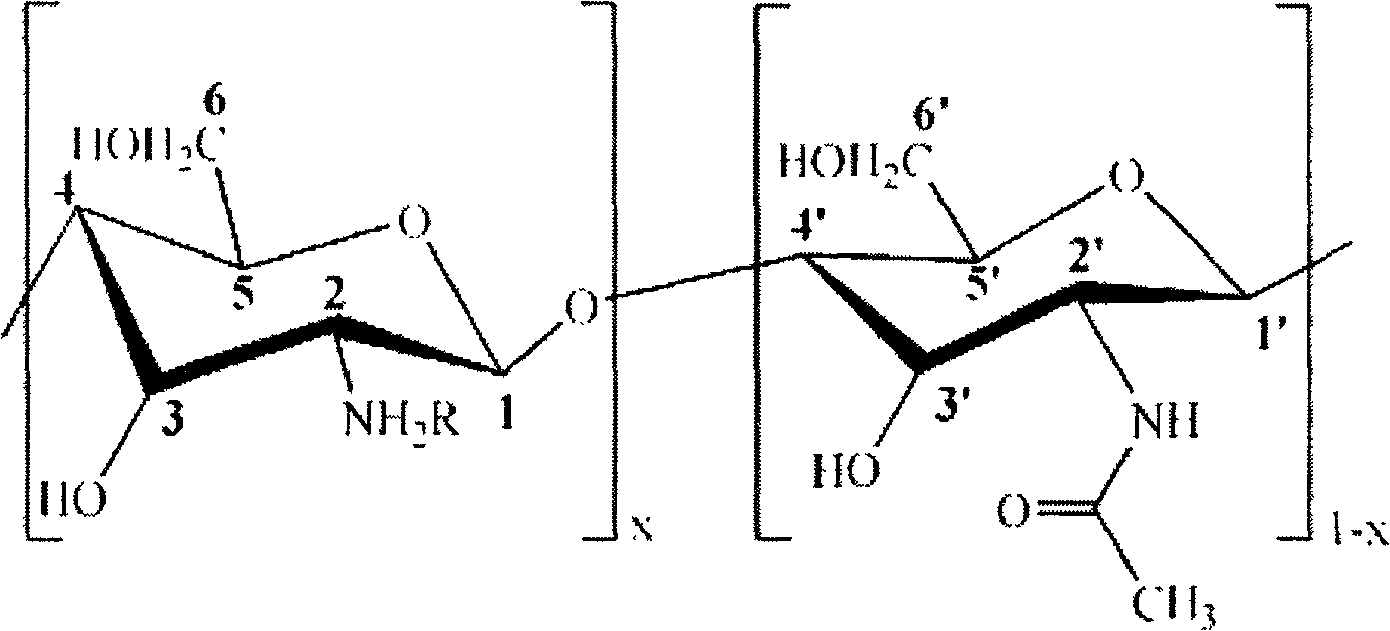

Method for preparing light sensitive type water soluble chitosan derivative

InactiveCN101735338ARetain biological activityRetain biocompatibilityHydroxybenzoate EthersEvaporation

The invention relates to a method for preparing a light sensitive type water soluble chitosan derivative. The method comprises the following steps of: adding chitosan into 2-weight percent dilute solution of acetic acid to prepare 2 weight percent aqueous solution of chitosan; adding a light sensitive acrylamide-type monomer of N-p-hydroxyphenyl acrylamide or N-[4-(sulfonamide)phenyl]acryloyl into ethanol to prepare ethanol solution of the light sensitive acrylamide-type monomer; mixing the2 weight percent aqueous solution of chitosan, and the ethanol solution of the light sensitive acrylamide-type monomer to obtain mixed solution; adding p-hydroxyanisole in to the mixed solution; heating the mixed solution to the temperature of between 50 and 70 DEG C for reaction, neutralizing the mixed solution by using sodium hydroxide and performing rotary evaporation, purifying and vacuum-drying to obtain the light sensitive type water soluble chitosan derivative. The method has the advantages of mild reaction conditions, easy control, simple steps, easily-controllable substitution degree, environmentally-friendly subsequent treatment and economical reaction process.

Owner:BEIJING UNIV OF CHEM TECH

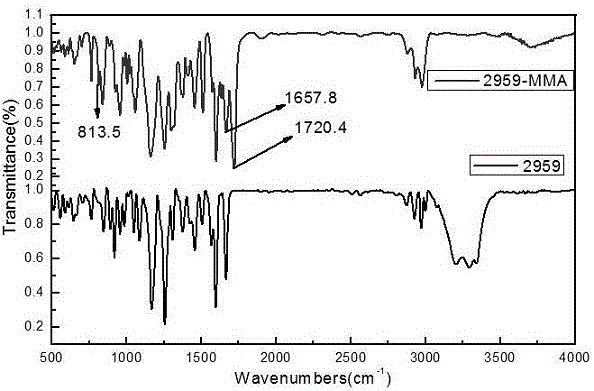

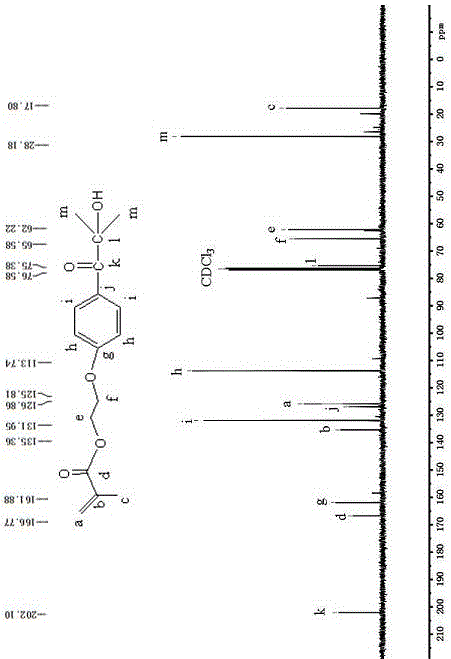

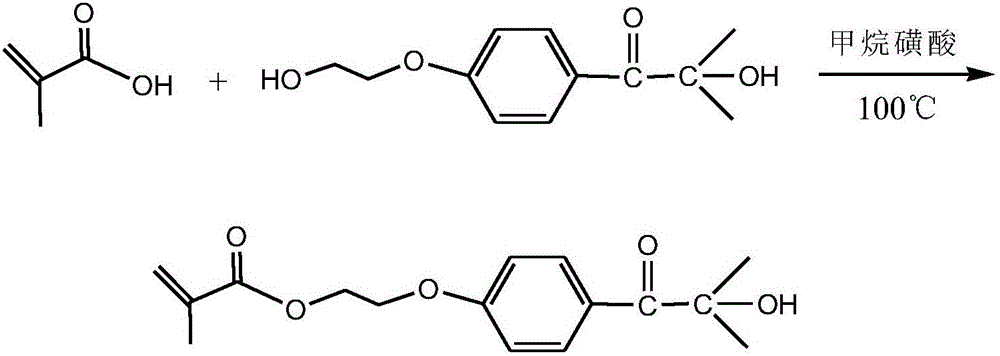

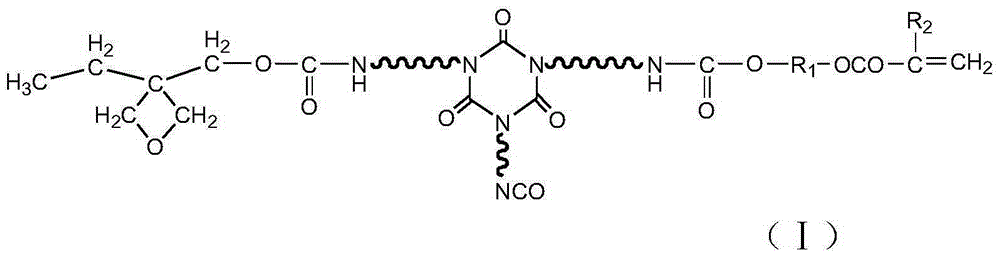

Method for preparing polymerizable photoinitiators

InactiveCN105859551AImprove migration abilityLow mobilityOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate EthersAdhesive

The invention discloses a method for preparing polymerizable photoinitiators. The polymerizable photoinitiators are prepared from methacrylic acid and 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone by the aid of direct esterification processes. The use quantity of polymerization inhibitors in a reaction system accounts for 0.01%-0.5% of the mass of the methacrylic acid, the use quantity of methane sulfonic acid which is a catalyst accounts for 0.1%-2% of the mass of the methacrylic acid, and a molar proportion of the methacrylic acid to the 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone is 1:1-1.2. Each polymerization inhibitor is methoxyphenol or hydroquinone or 2-tertiary butylhydroquinone, and a solvent is toluene or dimethylformamide or tetrahydrofuran. The method has the advantages that the polymerizable photoinitiators are excellent in compatibility with monomers and resin in photo-curing systems fragments obtained after the polymerizable photoinitiators are subjected to illumination pyrolysis are low in migration rate in cured films and are anti-yellowing, excellent initiation effects can be realized, and the method can be applied to the field of photo-cured coating, printing ink, adhesive and the like; the method for synthesizing the polymerizable photoinitiators is low in cost, processes for preparing the polymerizable photoinitiators are simple and convenient, and obvious application effects can be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

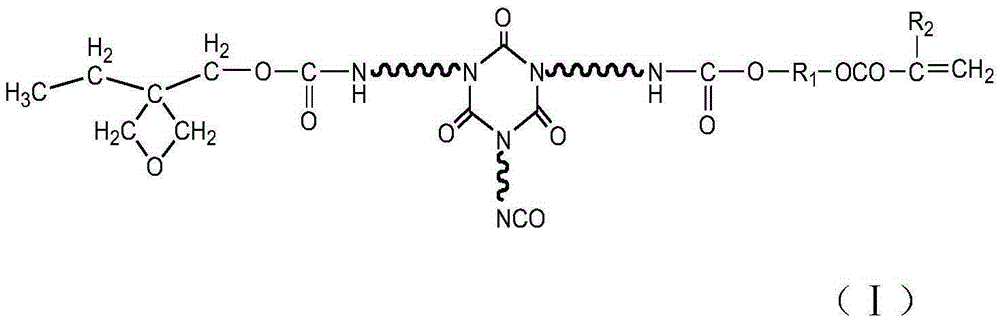

Multi-cured optical resin and synthesizing method thereof

InactiveCN106543154ASpecial chemical structureSolve problems that cannot be curedOrganic chemistryOrganic non-macromolecular adhesive4-MethoxyphenolHydroxybenzoate Ethers

The invention provides a synthesizing method for multi-curing available optical resin. The method comprises the following steps: adding 80-110g of HDI tripolymer, 5-10g of 3-ethyl-3-(hydroxymethyl) oxacyclobutane, 4-10g of hydroxyl acrylate, 0.1g of polymerization inhibitor 4-methoxyphenol and 0.01g of catalyst dibutyltin dilaurate into a three-necked flask with a thermometer, and heating to 65 DEG C; controlling the temperature to be 60-75 DEG C, reacting for 2-3 hours, analyzing NCO group with an infrared infrared spectrometer; and stopping the heat reaction when the NCO peak does not change so as to obtain the multi-cured functional resin capable of free radical+cation+moisture reaction.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

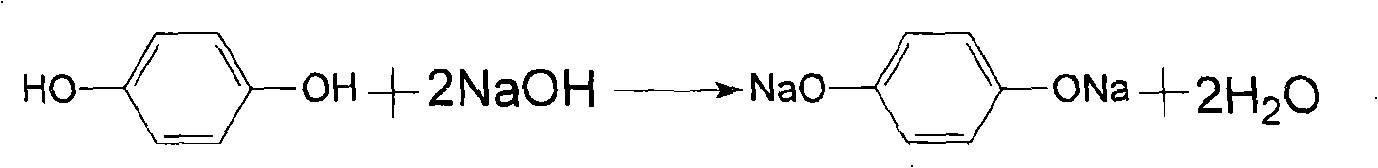

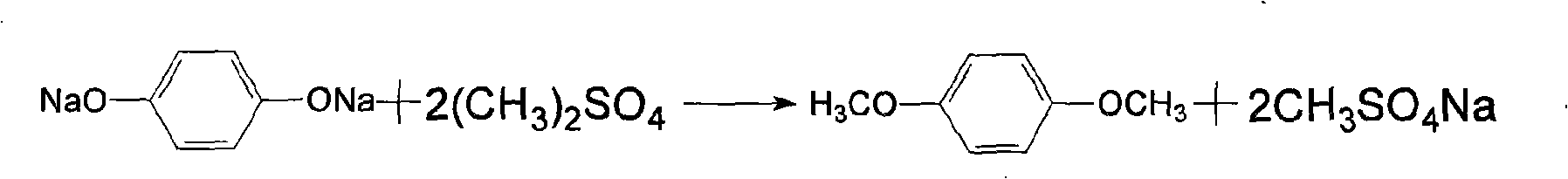

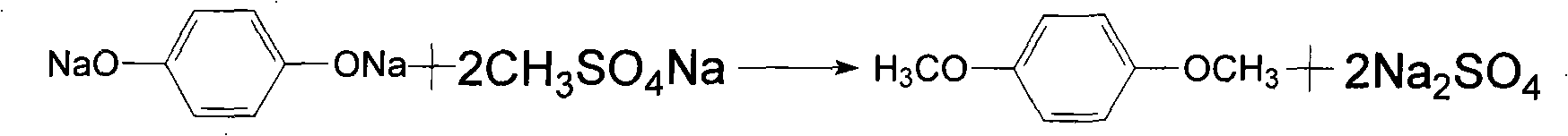

Novel synthetic process of p-phenylene dimethyl ether

InactiveCN101348422AReduce dosageHigh reaction yieldEther preparation by ester reactionsHydroxybenzoate EthersWater vapor

The invention relates to a novel process for synthesizing p-xylene glycol dimethyl ether. The synthesis method takes hydrochinone and dimethyl sulfate as raw materials, and obtains the product through substitution inside an alkaline medium. Moreover, the synthesis method has the technological characteristics that by means of the principle of equilibrium shifting, the product is moved out of a reaction system during reaction, thereby accelerating reaction and ensuring complete reaction; in the prior synthesis process, the auxiliary raw material dimethyl sulfate no longer participates in reaction when reacted to generate monomethyl sodium sulfate, and the theoretical utilization rate of dimethyl sulfate is only 50 percent; therefore, the method greatly increases the utilization rate of dimethyl sulfate, and reduces the consumption of dimethyl sulfate by 40 percent; meanwhile, reaction yield is also increased to a certain extent; moreover, because the process makes use of the special characteristics of azeotropic distillation of the product and water, the product obtained during reaction can be moved out in time, while the reaction raw materials and intermediate product para hydroxyanisole are stored in a reactor in the form of sodium salts in the alkaline medium and do not enter the product when distilled out along with water vapor; therefore, the product has extremely high purity and can be obtained without adopting the prior alcohol refining; and the novel process ensures greatly simplified production process, higher production safety, lower production cost and labor intensity and better operating environment for workers, thereby having significant social benefit and economic benefit.

Owner:舒景林

Antibacterial and durable tooth filling composite material and preparation method thereof

InactiveCN105232339AGood tissue compatibilityGood blood compatibilityImpression capsDentistry preparationsPolymethyl methacrylateMethacrylate methyl

The invention discloses an antibacterial and durable tooth filling composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 30-40 parts of polymethyl methacrylate, 20-25 parts of hydroxyl calcium phosphate, 13-15 parts of acetoacetoxyethyl methacrylate, 3-8 parts of fimbrin, 1-3 parts of 2-thiol benzimidazole, 5-12 parts of a phase transfer agent, 12-30 parts of glycosaminoglycan, 5-10 parts of steamed bone meal, 4-8 parts of silver cyclohexylbutyrate, 3-5 parts of casein, 4-8 parts of hydroxy anisole, 3-8 parts of an antioxidant, 12-24 parts of sorbitol, 8-23 parts of benzyl alcohol and 25-45 parts of double distilled water. The composite material disclosed by the invention is capable of improving tissue compatibility and blood compatibility, and the composite material is antibacterial, capable of improving mechanical and physical properties, wear-resistant and durable to use; and the preparation method has the advantages of being simple in process, easy to operate, high in yield, low in pollution to environment and the like.

Owner:SUZHOU COSMETIC MATERIALS

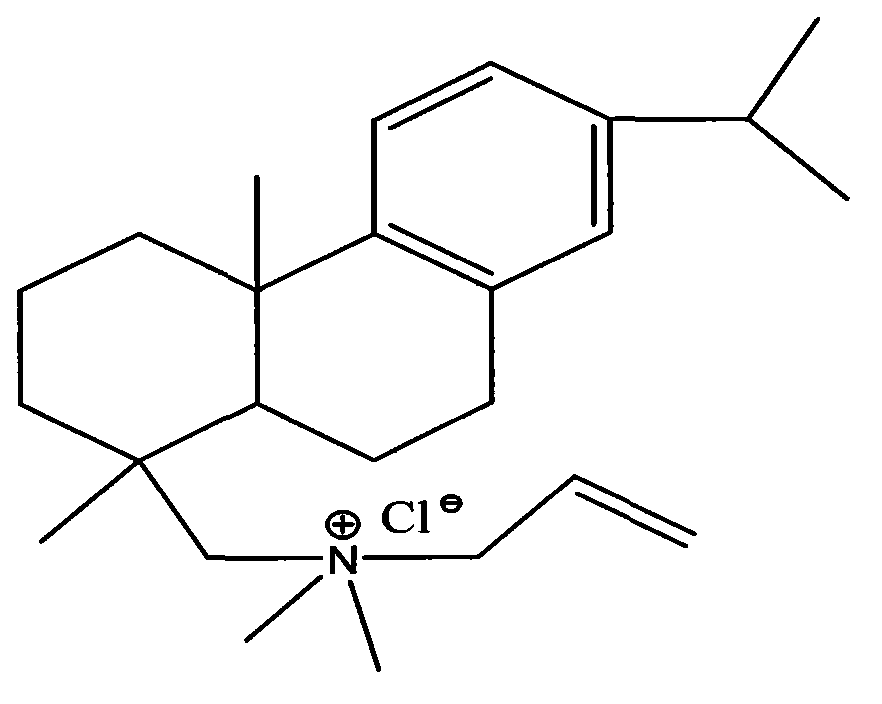

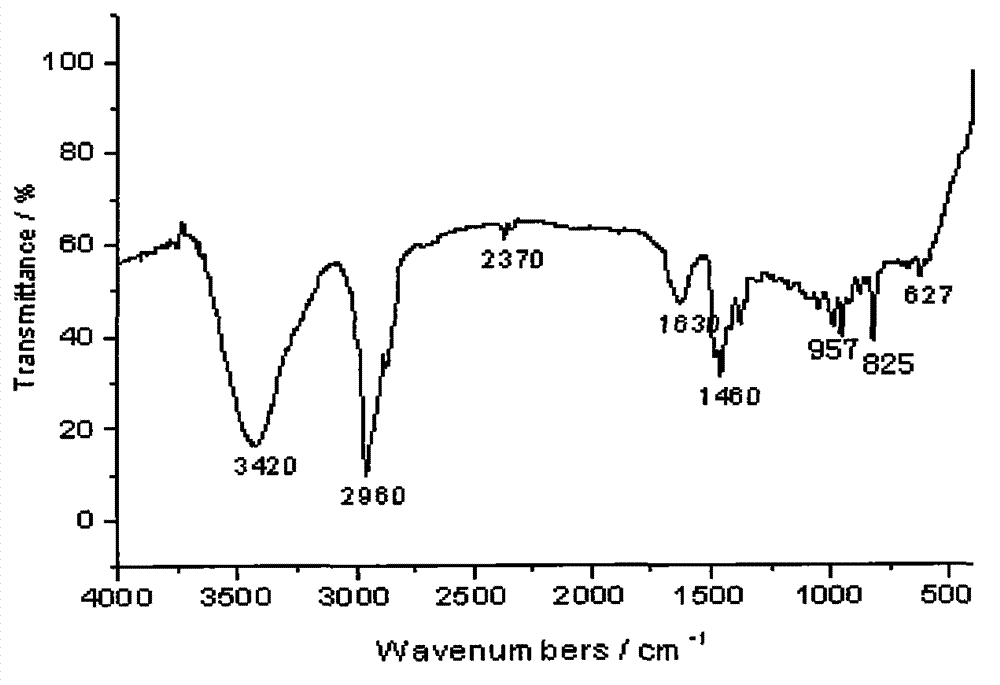

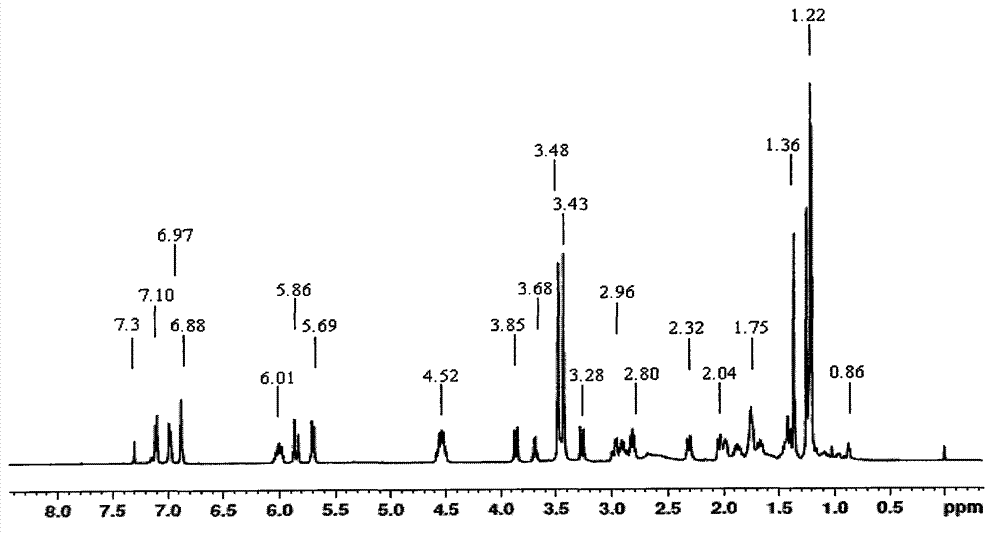

Method for preparing allyldimethyl dehydroabietyl ammonium chloride

InactiveCN102775317AIncrease contentGood water solubilityAmino preparation by functional substitutionHydroxybenzoate EthersDouble bond

The invention relates to a method for preparing allyldimethyl dehydroabietyl ammonium chloride. The allyldimethyl dehydroabietyl ammonium chloride is a cationic surfactant containing unsaturated active C=C double bond and dehydroabietylamine structure. The method comprises the following steps: dissolving dehydroabietylamine in an ethanol-acetonitrile composite solvent, and reacting with formic acid and formaldehyde to obtain N,N-dimethyldehydroabietylamine; in the presence of a composite polymerization inhibitor composed of 2,2,6,6-tetramethylpiperidin-1-yl)oxyl (TEMP), p-hydroxyanisole and hydroquinone in a mass ratio of (0.01-10):(0.01-100):(0.01-10), reacting allyl chloride and the N,N-dimethyldehydroabietylamine at 10-90 DEG C for 5-120 hours to obtain crude allyldimethyl dehydroabietyl ammonium chloride; and finally, recrystallizing by using a composite solvent composed of chloroform, ethyl acetate, aether, dioxane and tetrahydrofuran in a mass ratio of (0.01-10):(0.001-12):(0.1-10):(0.001-16):(0.001-18), and carrying out vacuum drying to obtain the allyldimethyl dehydroabietyl ammonium chloride product of which the mass percentage is greater than 90%.

Owner:YANCHENG INST OF TECH

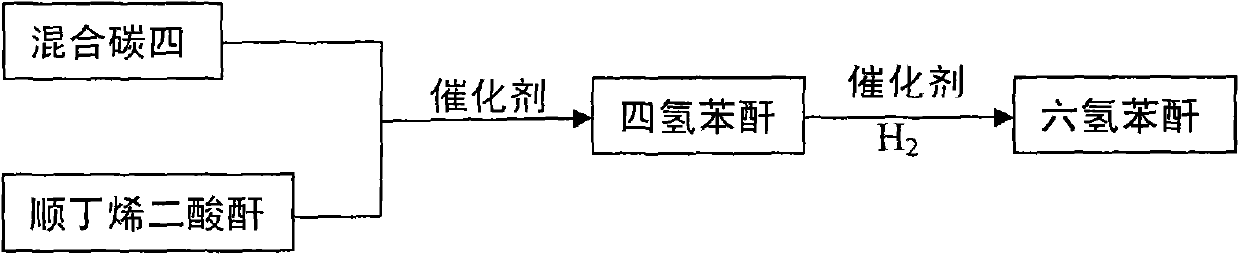

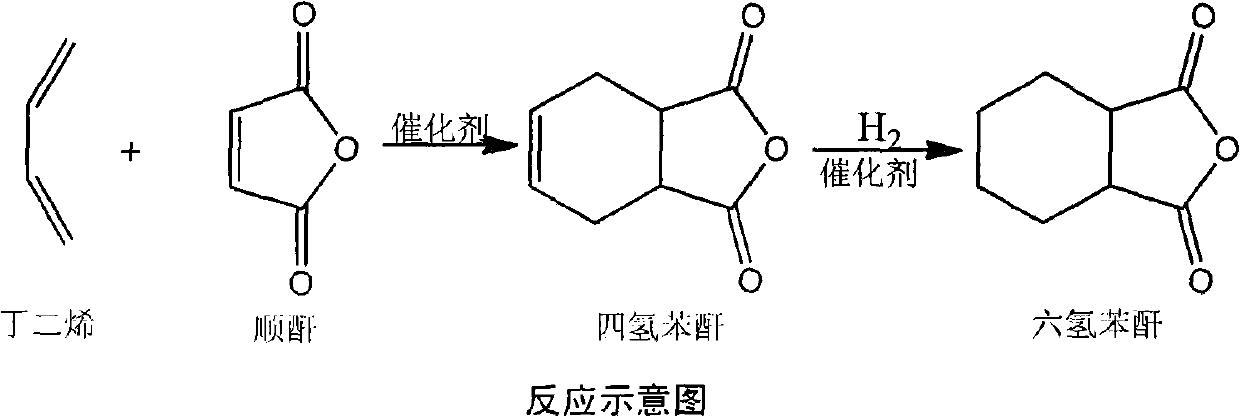

Method for producing hexahydrophthalic anhydride by using C4 mixture

ActiveCN101768143ALow reaction temperatureReduce pollutionOrganic chemistryHydroxybenzoate EthersHexahydrophthalic anhydride

The invention discloses a method for producing hexahydrophthalic anhydride by using C4 mixture and belongs to the field of organic synthesis. The method comprises the following steps: using maleic anhydride and C4 mixture, which mainly containing butadiene, as the raw materials; under the actions of the HC-200102P compound catalyst [p-hydroxyanisole and Cu2(PPh3)6(mu-OOCH)(ClO4), directly using maleic anhydride to absorb the C4 mixture to obtain tetrahydrophthalic anhydride; and carrying out catalytic hydrogenation on the tetrahydrophthalic anhydride by using the CC-1 compound catalyst (Pd / BaSO4 or Pd / BaCO3, and Cu4(C7H4NO4)2(dppm)4(NO3)2, thereby obtaining the hexahydrophthalic anhydride. The method enhances the reaction selectivity, reduces the production cost, reduces the environmental pollution and has industrialized popularization value.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL

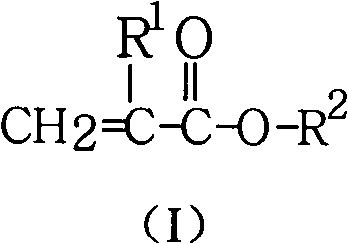

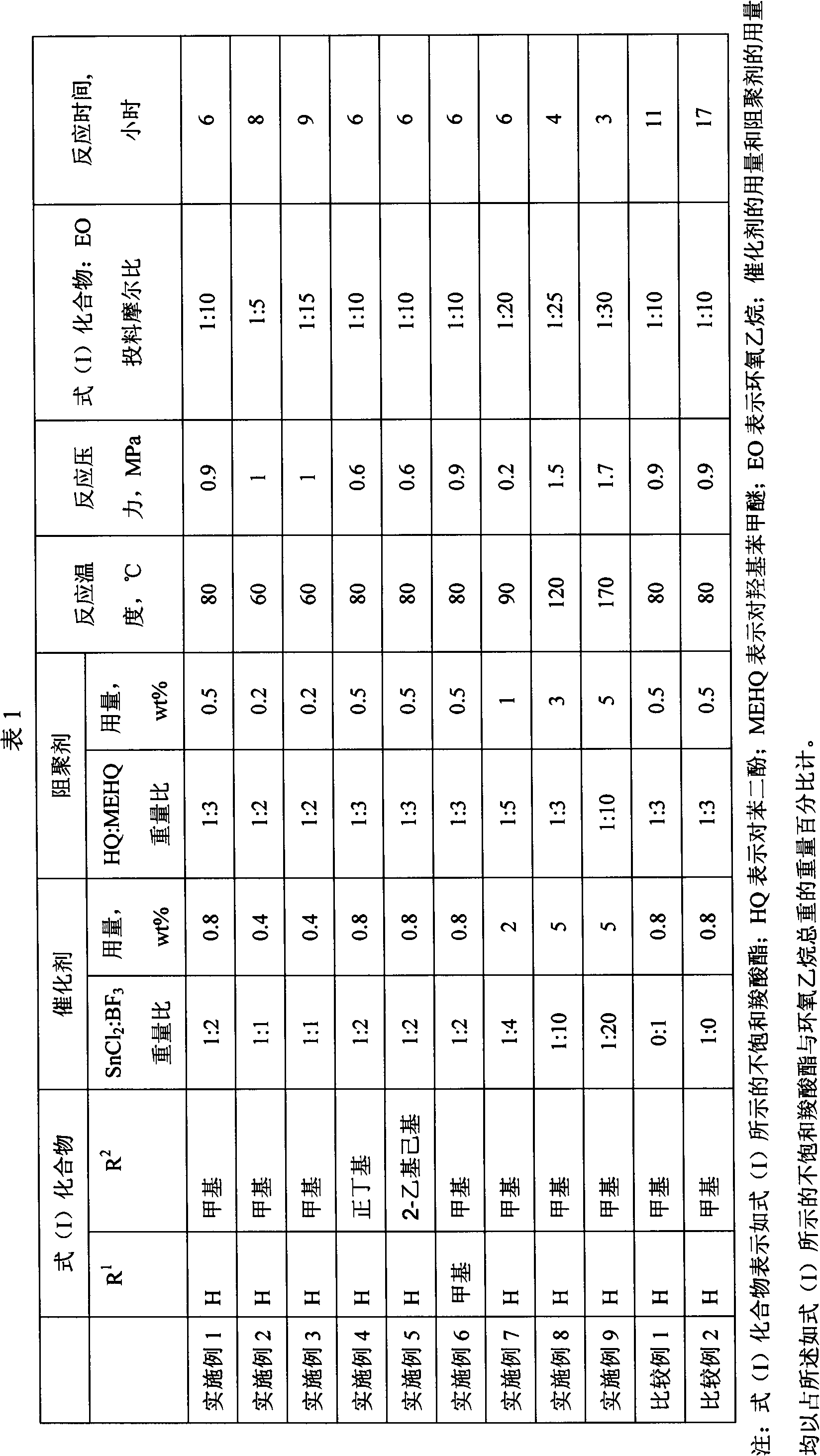

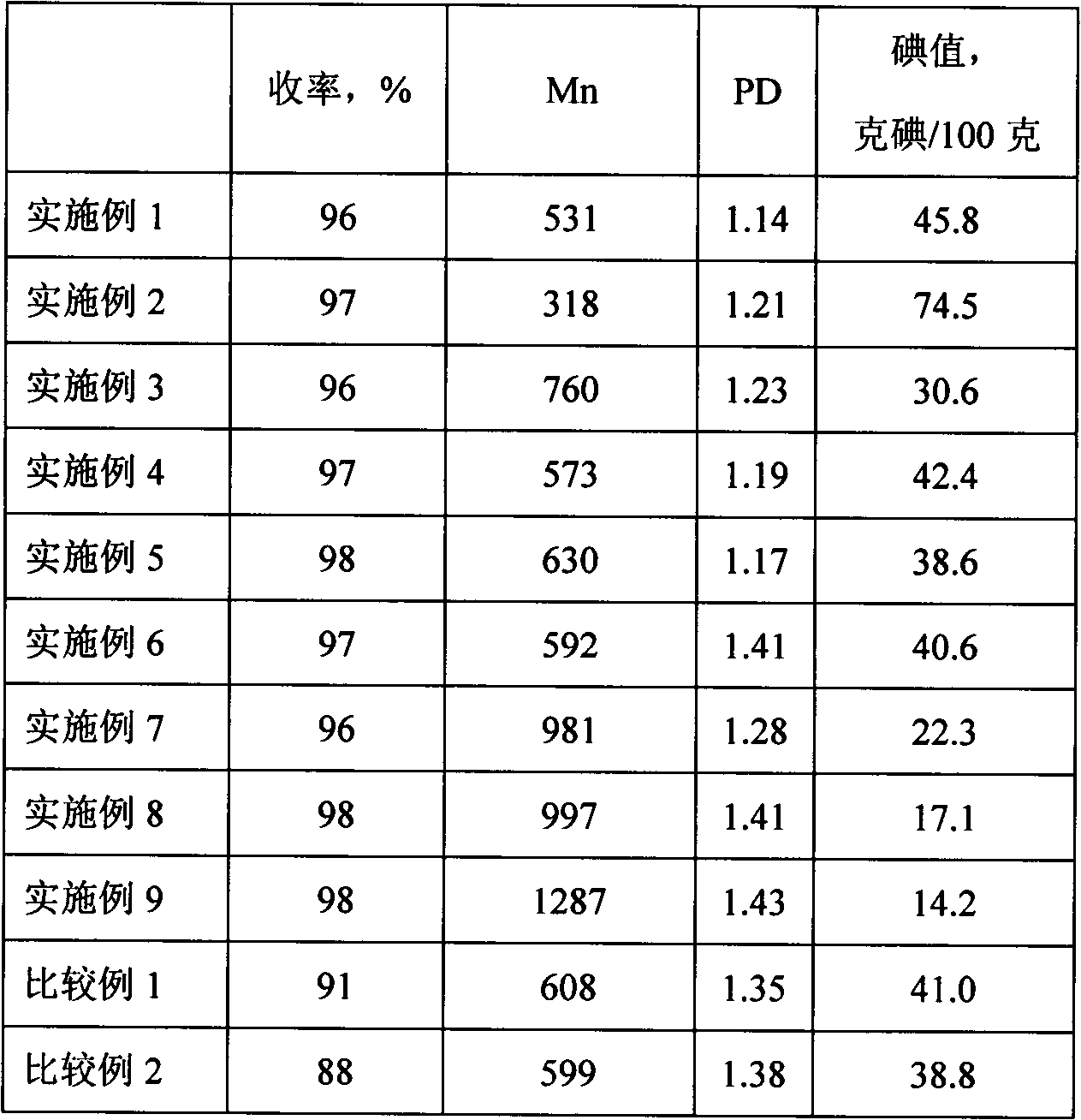

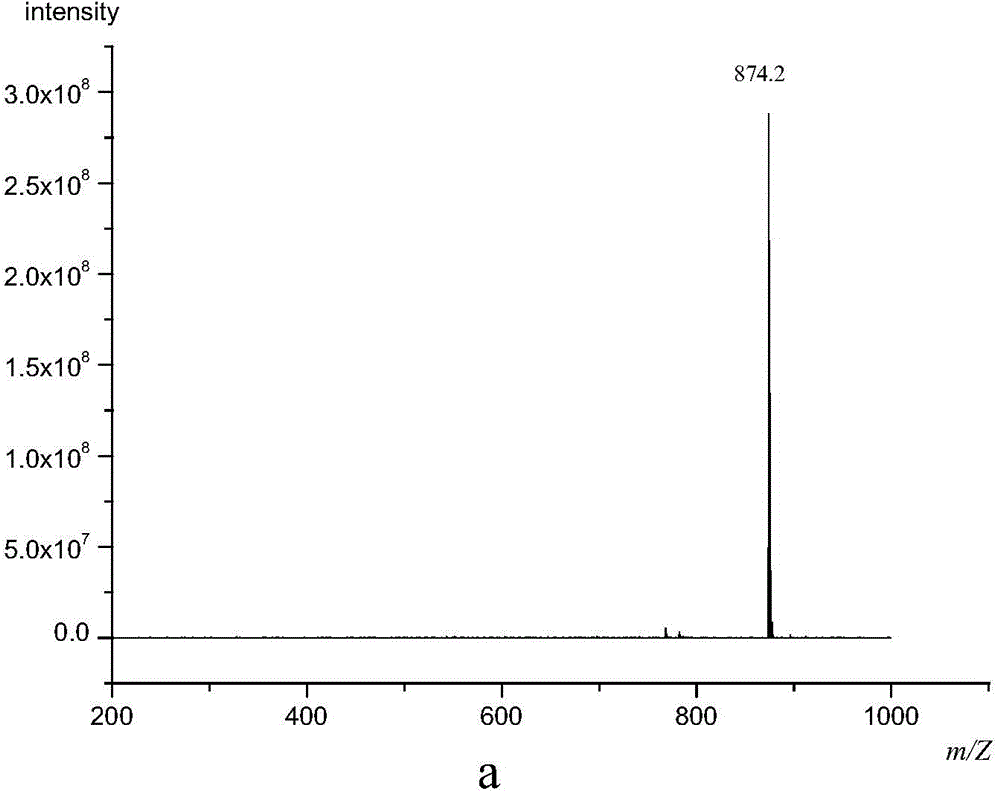

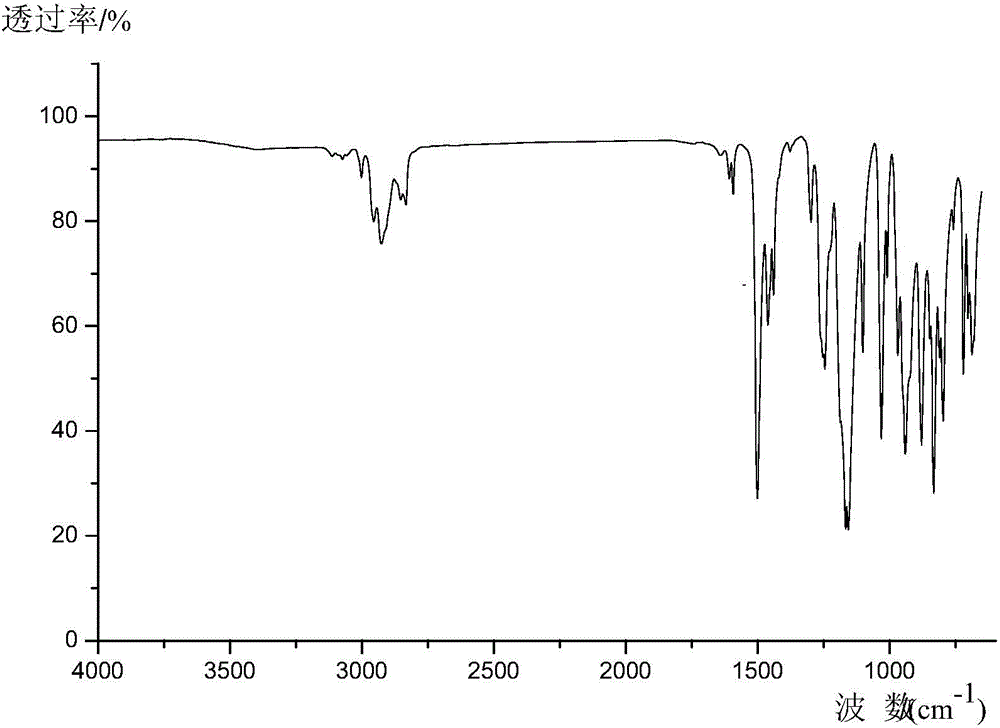

Preparation method for polyethylene glycol mono alkyl ether unsaturated carboxylic ester

ActiveCN102924706ASimple processShort process routeOrganic compound preparationCarboxylic acid esters preparation4-MethoxyphenolHydroxybenzoate Ethers

The present invention relates to a preparation method for polyethylene glycol mono alkyl ether unsaturated carboxylic ester, wherein a purpose of the present invention is to mainly solve the technical problem of long process route of the existing two-step method in the prior art. A technical scheme of the preparation method is that: in the presence of a catalyst, a polymerization inhibitor and an unsaturated carboxylic ester represented by a formula (I), ethylene oxide is added, and a reaction is performed at a reaction temperature of 30-185 DEG C under reaction pressure of -0.01 to 1.9 MPa to obtain the polyethylene glycol mono alkyl ether unsaturated carboxylic ester, wherein the catalyst is SnCl2 and BF3, a weight ratio of SnCl2 to BF3 is 1:0.5-20, the polymerization inhibitor is hydroquinone and / or 4-methoxyphenol, R1 is hydrogen atom or methyl, and R2 is C1-C8 alkyl. With the technical scheme, the technical problem is solved well. The preparation method can be applicable for polyethylene glycol mono alkyl ether unsaturated carboxylic ester production.

Owner:SHANGHAI DUOLUN CHEM

Preparation method of hexa(4-methoxyphenoxyl)cyclotriphosphazene

InactiveCN104311599AMild reaction conditionsEasy to controlGroup 5/15 element organic compounds4-MethoxyphenolHydroxybenzoate Ethers

The invention belongs to the technical field of organic synthesis. An ultrasonic vibration technology is adopted to accelerate the movement of chemical balance to a product direction. The invention relates to a preparation method of hexa(4-methoxyphenoxyl)cyclotriphosphazene. The method comprises a salt forming process, a nucleophilic substitution process and a post-treatment process, and concretely comprises the following steps: adding a 4-methoxyphenol solution into an acid binding agent solution in a dropwise manner under 800-1000W ultrasonic conditions, and reacting at room temperature for 10-30min to obtain a 4-methoxyphenol salt solution; adding a hexachlorocyclotriphosphazene solution into the 4-methoxyphenol salt solution in a dropwise manner under 800-1000W ultrasonic conditions, and reacting at 35-60DEG C for 1-4h; carrying out a refluxing reaction for 8-12h to obtain a hexa(4-methoxyphenoxyl)cyclotriphosphazene solution; and carrying out reduced pressure distillation to evaporate a solvent in the obtained system, dissolving the obtained concentrated in dichloromethane, washing by deionized water, drying, and carrying out reduced pressure distillation to obtain the target product hexa(4-methoxyphenoxyl)cyclotriphosphazene. The preparation method has the advantages of mildness and easy control of reaction conditions, and high yield, and is suitable for preparing hexa(4-methoxyphenoxyl)cyclotriphosphazene.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Method of rectifying and synthesizing N,N-dimethacrylamide by DMDMAA reaction

InactiveCN101033196ANot easy to polymerizeShort reaction timeOrganic compound preparationCarboxylic acid amides preparationHydroxybenzoate EthersGas phase

This invention relates to a method for synthesizing N, N-dimethylacrylamide by the rectifying 3-dimethylamino-N, N-dimethyl propanamide including: adding DMDMAA into a kettle tower to rise the temperature to 210-215deg.C and adding material liquid and oil of vitriol or acetic acid catalyst and inhibitor,and the kettle tower keeps the teperatue at 210-215 for 2-3h then the rectifying tower operates hydroxyl anisole or hydroquinone in vacuum, which first of all carries out total refluence operation at 80-85deg.C under 0.8-1.0KPa, then evaporates a front fraction including methyl acrylate under operation pressure of 0.5-0.8KPa, 92-97deg.C kettle temperature, 51-52deg.C top gas phase temperature, refluence ratio of 3-5 and the collected product at the top of the tower is DMAA, and the collected un-reacted material DMDMAA returns back to the tank of raw materials.

Owner:TIANJIN UNIV

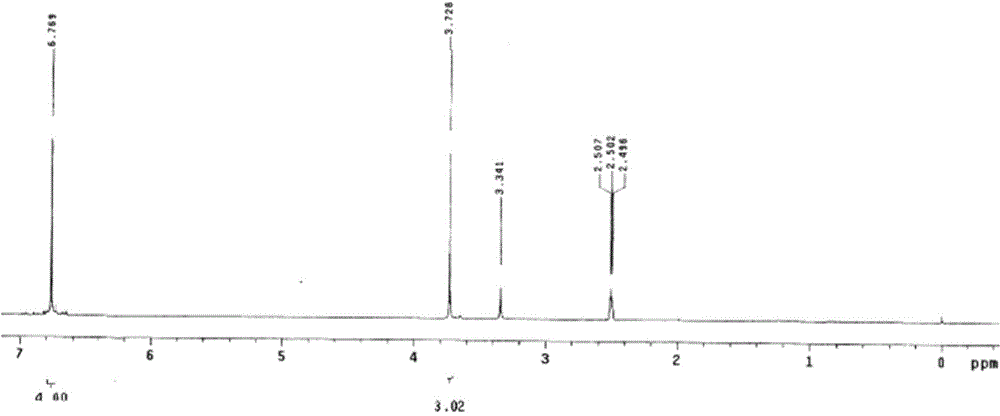

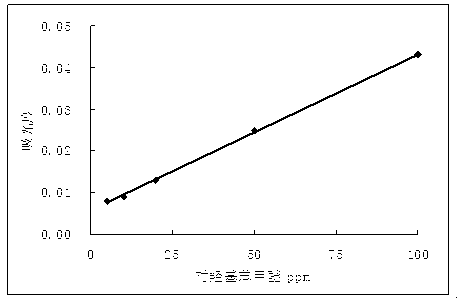

Method for determining 4-methoxyphenol in industrial acrylamide

InactiveCN102830076AAvoid security issuesAvoid accuracyColor/spectral properties measurementsHydroxybenzoate EthersPhysical chemistry

The invention discloses a method for determining 4-methoxyphenol in industrial acrylamide. The method comprises the following steps of: dissolving methoxyphenol dissolved in a glacial acetic acid solution, adding sodium nitrite to react, so as to generate yellow nitrous acid derivatives; and determining the absorbance of the yellow nitrous acid derivatives by using a spectrophotometer. With the adoption of the method provided by the invention, the problems of insecure operation and poor accuracy which are brought by using concentrated nitric acid to react can be solved. The method is simple and convenient to in operate, good in repeatability, high in sensitivity, and convenient for popularization and application.

Owner:江苏南天农科化工有限公司

Acid fuchsin writing liquid decolorizer

InactiveCN101709174AEasy to eraseWon't spreadChemical paints/ink removersHydroxybenzoate EthersSodium stearate

The invention provides acid fuchsin writing liquid decolorizer, comprising the following components by weight percent: 45-54% of gypsum, 15-18% of sodium stearate, 25-30% of magnesium sulfite, 0.5-1.5% of p-hydroxyanisole, 0.5-1.5% of pH modulator and 2-5% of metal ion removing complexing agent. The decolorizer of the invention is mainly used for wiping handwriting of teaching writing liquid, has good stability and no pollution, can rapidly discolor the handwriting of acid fuchsin writing liquid, and writing can be carried out again after discoloring without spreading handwriting. When in use, the writing liquid decolorizer is placed in tap water solution for half an hour, after that, can be used by dipping with an eraser. The writing liquid decolorizer also can be used for decoloring methyl blue writing liquid.

Owner:SHANXI UNIV

Cleaning, derusting and phosphating agent

InactiveCN104099594AFast phosphatingImprove phosphating effectMetallic material coating processesHydroxybenzoate EthersBetaine

The invention discloses a cleaning, derusting and phosphating agent. The cleaning, derusting and phosphating agent comprises the following formula components of raw materials in parts: 10-30 parts of phosphoric acid, 5-10 parts of metaphosphoric acid, 8-10 parts of hypochlorous acid, 5-10 parts of banana oil, 5-8 parts of dimethylbenzene, 5-12 parts of silicone oil, 5-10 parts of methyl ethyl ketone, 5-8 parts of isopropanol, 5-8 parts of diethyl ether, 3-5 parts of urea, 5-6 parts of m-dihydroxybenzene, 3-5 parts of p-hydroxyanisole, 5-8 parts of phenol, 5-8 parts of sodium polyacrylate, 2-3 parts of cocamidopropyl betaine, and 50-60 parts of de-ionized water. The cleaning, derusting and phosphating agent can be used at the normal temperature, has the advantages of quick phosphating speed, good phosphating effect, no corrosiveness, little waste residue discharge, combined completion of cleaning, derusting and phosphating at one step, easy production and low production cost, and can be applied to the degreasing, derusting and phosphating treatment of steel and cast iron products.

Owner:周彩球

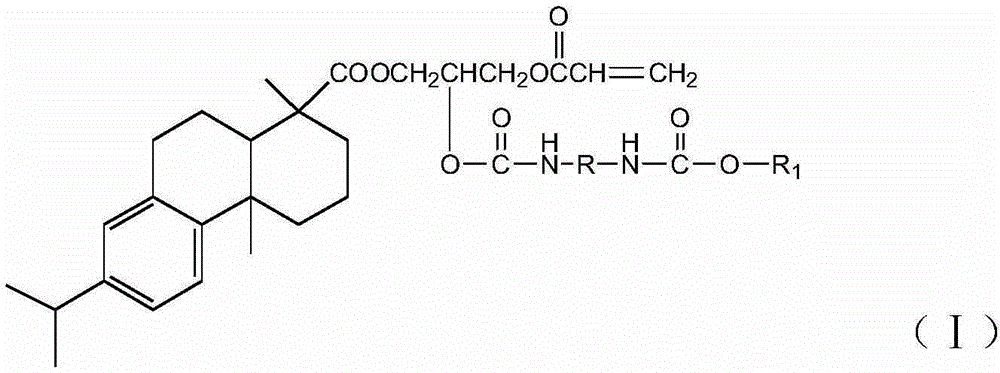

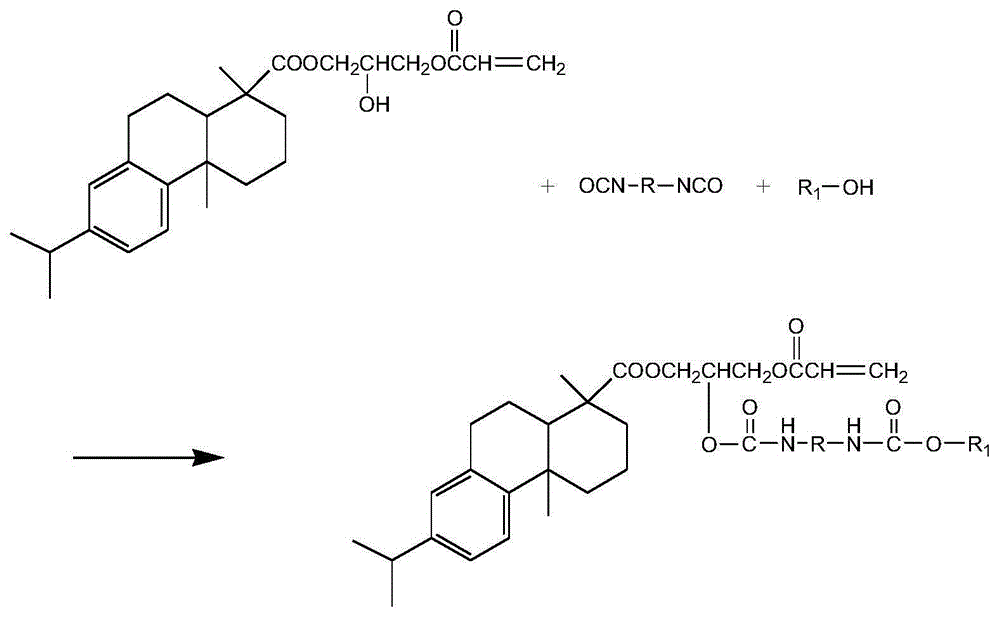

Optical resin and synthesis method thereof

InactiveCN106543037AGood yellowing resistanceThe synthesis reaction process is simpleCarbamic acid derivatives preparationOrganic compound preparationEpoxyHydroxybenzoate Ethers

The invention provides an optical resin synthesis method, which comprises: adding 80-110 g of an epoxy-modified rosin ester, 4-10 g of a monohydric alcohol, 0.1 g of a polymerization inhibitor p-hydroxyanisole, and 0.01 g of a catalyst dibutyltin dilaurate to a three-necked flask having a thermometer, heating to a temperature of 65 DEG C, adding 18-32 g of diisocyanate in a dropwise manner, controlling the temperature at 70-75 DEG C, carrying out a reaction for 2-3 h, analyzing the NCO group content by using an infrared spectrometer, and stopping the heating reaction when the peak of NCO completely disappears so as to obtain the rosin ester modified polyurethane acrylate resin. According to the present invention, the obtained resin is the high-performance optical resin, has the refractive index of 1.52-1.54, has the good yellowing resistance, can be used for producing the high-end liquid-state optical transparent glue, avoids the disadvantages of low refractive index and poor yellowing resistance of the traditional liquid-state optical transparent glue, and is suitable for the whole adhesion process of the capacitive touch screen.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com