Modified hydrogen-containing cyclotetrasiloxane bonding accelerant as well as preparation method and application thereof

A technology of adhesion promoter and cyclotetrasiloxane, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of decreased mechanical properties of silicone rubber, complex synthesis process, harsh vulcanization conditions, etc. , to achieve the effect of improving the bonding performance, the raw materials are cheap and easy to obtain, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

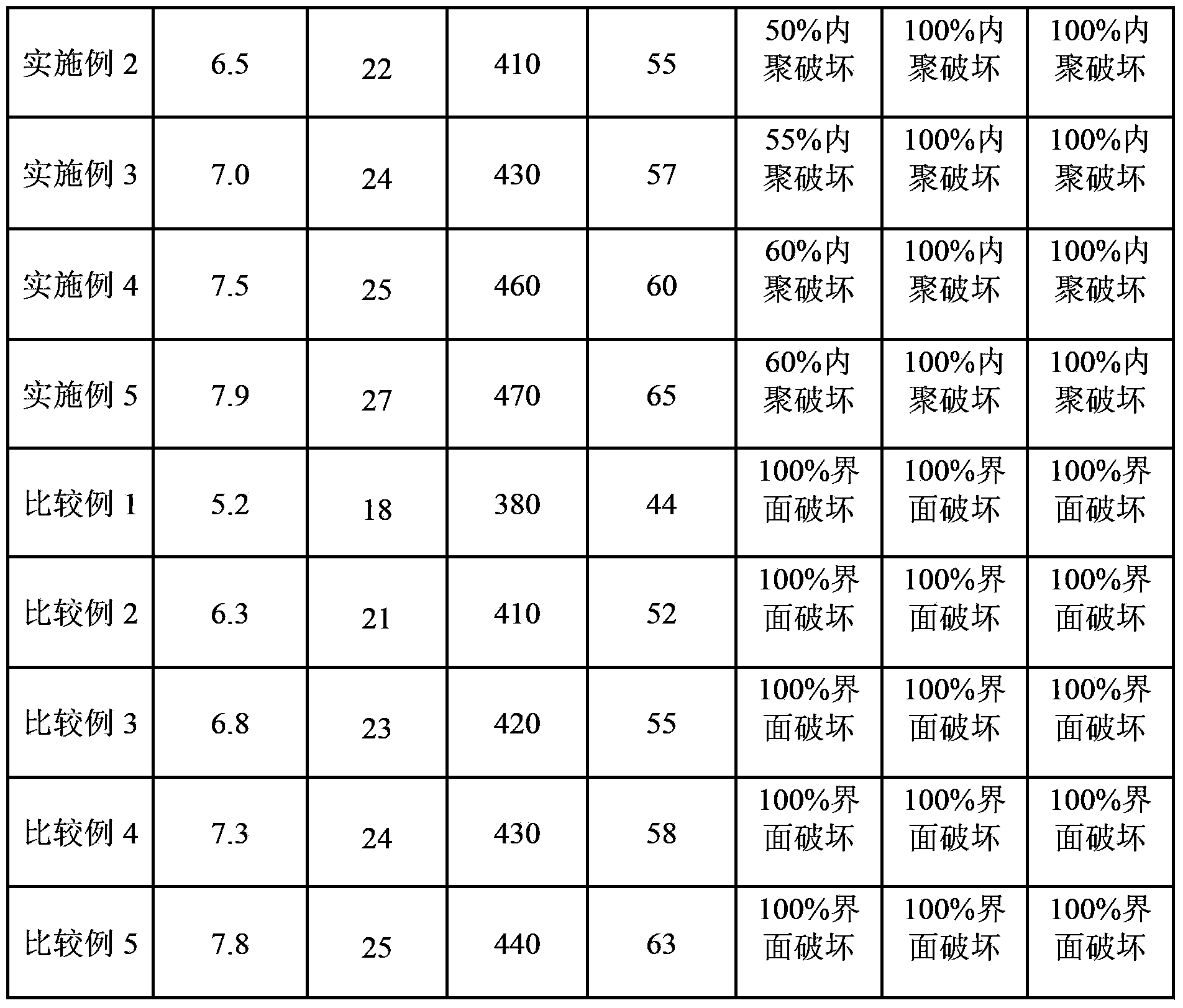

Embodiment 1

[0024] (1) Synthesis of adhesion promoter

[0025] 22.6g of 1,6-hexanediol diacrylate and 0.02g of silica-supported chloroplatinic acid catalyst with a platinum concentration of 0.5% were mixed in a flask and heated at 60°C for 30min. The claims define that the platinum catalyst is chloroplatinic acid or platinum-vinylsiloxane complex dissolved in isopropanol or tetrahydrofuran solvent, loaded on silicon dioxide or activated carbon. Here is only the isopropanol solution of chloroplatinic acid. Does it still need to be supported on silica or activated carbon? (No support is required, this is a separate type of catalyst, chloroplatinic acid is directly supported on silica or activated carbon)

[0026] 24g1,3,5,7-Tetramethylcyclotetrasiloxane, 40g toluene and 0.1g p-hydroxyanisole were added to a four-necked flask with a thermometer and a condensing reflux tube, and the temperature was raised while stirring. When the temperature in the reactor reached 60°C, the mixture of prehe...

Embodiment 2

[0035] Mix 20.8g of 1,5-pentanediol diacrylate, 14.2g of hydroxypropyl methacrylate and 0.02g of tetrahydrofuran solution of chloroplatinic acid with a platinum concentration of 2000ppm in a flask, preheat at 50°C for 40min, and set aside . (no load required)

[0036] 24g1,3,5,7‐tetramethylcyclotetrasiloxane, 80g toluene and 0.1g p-hydroxyanisole were added to a four-necked flask with a thermometer and a condensing reflux tube, and the temperature was raised while stirring. When the temperature in the four-necked flask reached 60°C, the mixture of preheated 1,5-pentanediol diacrylate, hydroxypropyl methacrylate and tetrahydrofuran chloroplatinate solution was added dropwise to the four-necked flask, and the dropping time was for 2h. After the dropwise addition, the reaction temperature was controlled at 80° C. for 3 h. Then add 5g of activated carbon into the four-necked flask, and the adsorption time is 0.5h. Finally, the reacted solution was subjected to suction filtrati...

Embodiment 3

[0042] 19.8 g of 1,4-butanediol diacrylate, 24.8 g of γ-(methacryloxy)propyltrimethoxysilane and 0.03 g of platinum(0)-1,3-diethylene at a platinum concentration of 3200 ppm The base‐1,1,3,3‐tetramethyldisiloxane complex was mixed in a flask and preheated at 40°C for 50min, and then set aside.

[0043] Add 24g of 1,3,5,7‐tetramethylcyclotetrasiloxane (viscosity of 8mPa), 60g of toluene and 0.2g of p-hydroxyanisole into a four-necked flask with a thermometer and a reflux tube while stirring While raising the temperature, when the temperature in the four-necked flask reached 60°C, the preheated 1,4-butanediol diacrylate, γ-(methacryloyloxy)propyltrimethoxysilane and platinum (0) The mixture of ‐1,3‐divinyl‐1,1,3,3‐tetramethyldisiloxane complex was added dropwise into a four-neck flask, and the dropping time was 1.5h. After the dropwise addition, the reaction temperature was controlled at 90° C. for 2.5 h. Then add 5g of activated carbon into the four-necked flask, and the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com