Patents

Literature

39results about How to "The synthesis reaction process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyfunctional castor oil-based photo-cured resin as well as preparation method and application thereof

InactiveCN106866929AFast cross-linking and curingImprove curing efficiencyAdditive manufacturing apparatusInksOptical radiationPolymer science

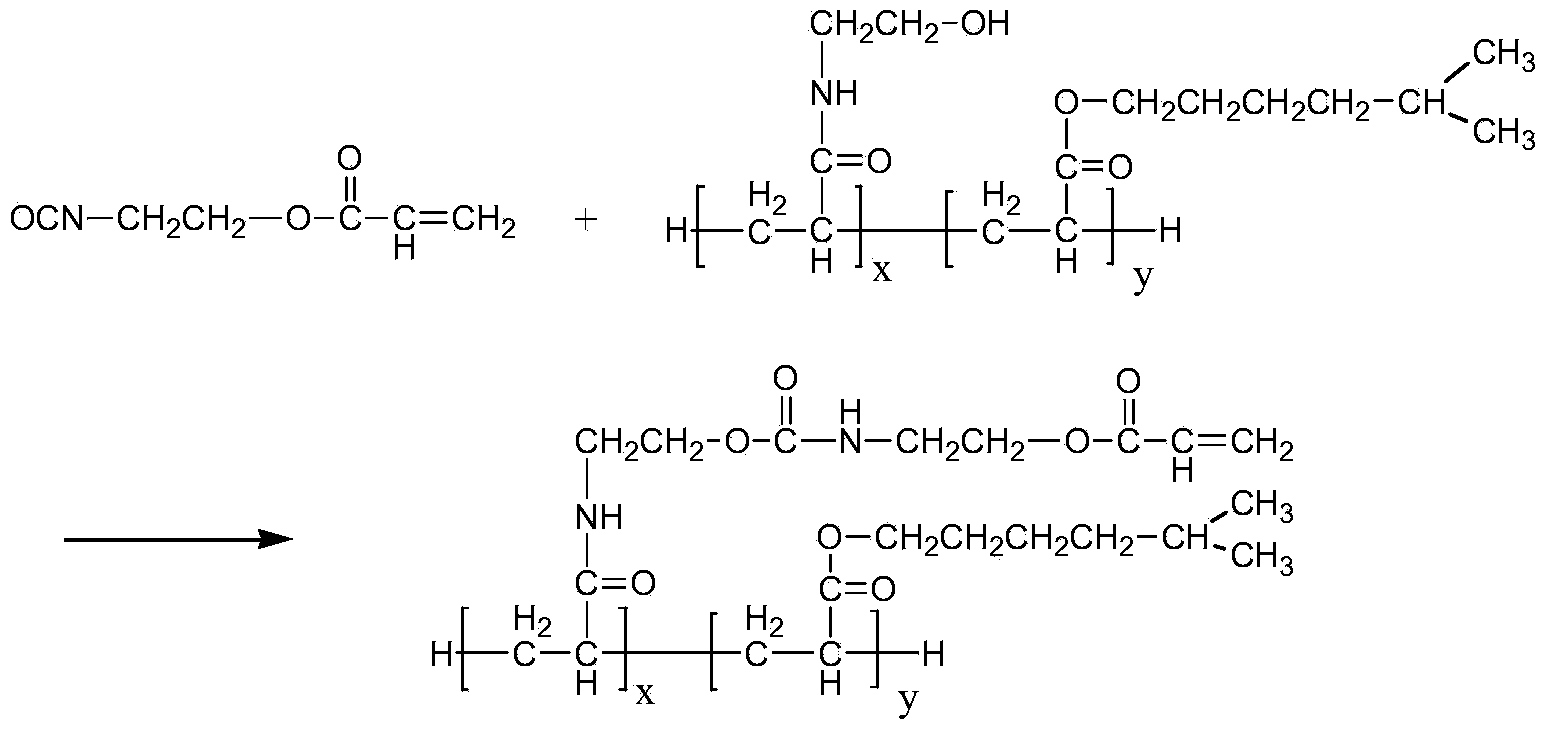

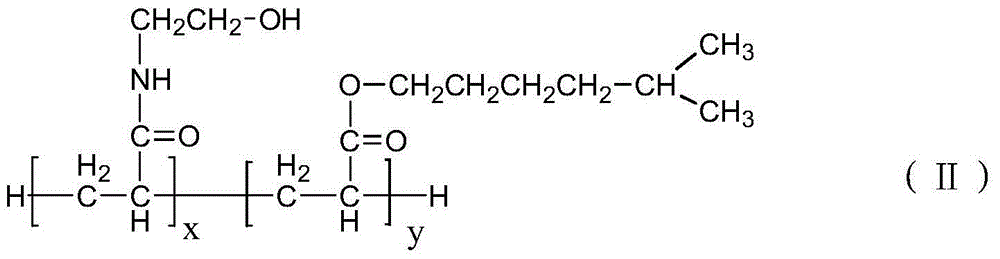

The invention relates to a polyfunctional castor oil-based photo-cured resin as well as a preparation method and application thereof. The preparation method comprises the following steps: with isocyanate and hydroxyl acrylate as raw materials, adding a polymerization inhibitor and a catalyst, introducing nitrogen for protection, and reacting for a certain period of time, so as to obtain an intermediate isocyanate semi-blocked prepolymer; adding castor oil into the prepared isocyanate semi-blocked prepolymer, so as to obtain castor oil-based urethane acrylate resin; and mixing the castor oil-based urethane acrylate resin with a photoinitiator and a diluent, and carrying out ultraviolet light radiation, so as to obtain UV castor oil-based resin with excellent performance. The photo-cured resin synthesized by virtue of the preparation method has relatively high molecular weight and viscosity, so that the interaction among resin molecules is enhanced, and the photo-crosslinking reaction efficiency of the resin is improved; the photo-cured resin contains more terminal double bonds, can be rapidly photo-cured and is suitable for being used as UV cured coatings, 3D printing materials and the like; and the prepared photo-cured resin has the beneficial effects that the water absorption rate and volume shrinkage rate of a cured film are substantially increased, meanwhile, the cost is low, the process is simple and controllable, and a product is relatively environment-friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

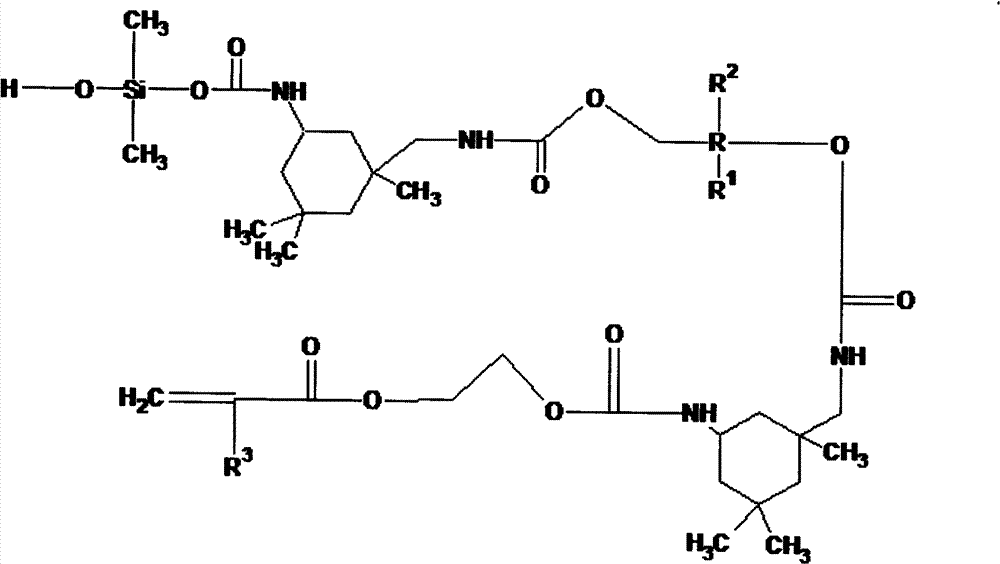

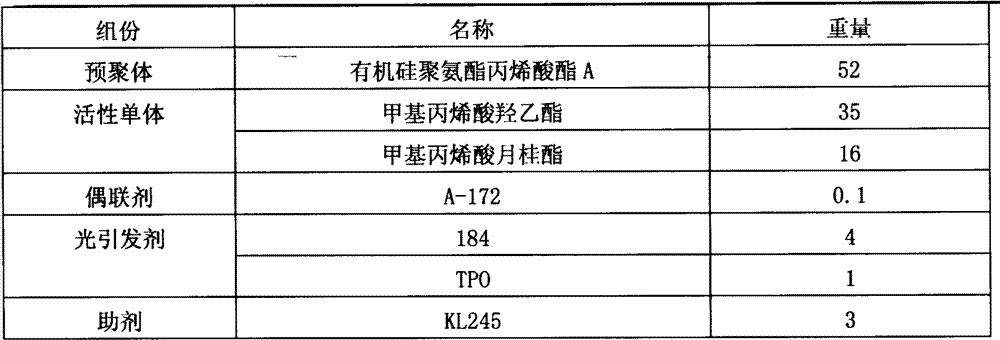

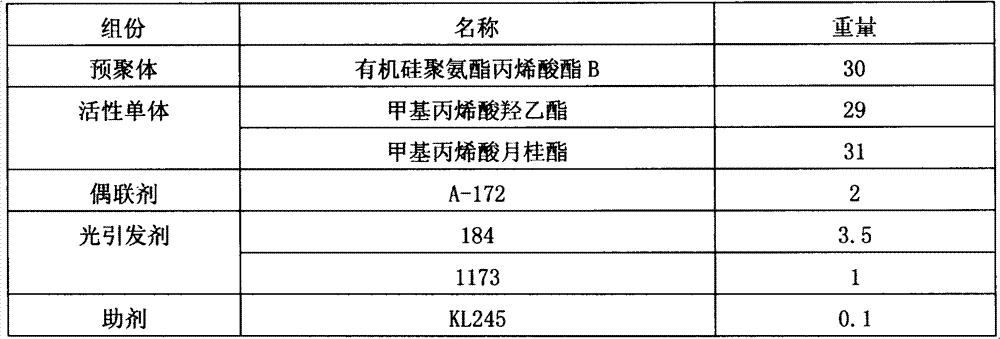

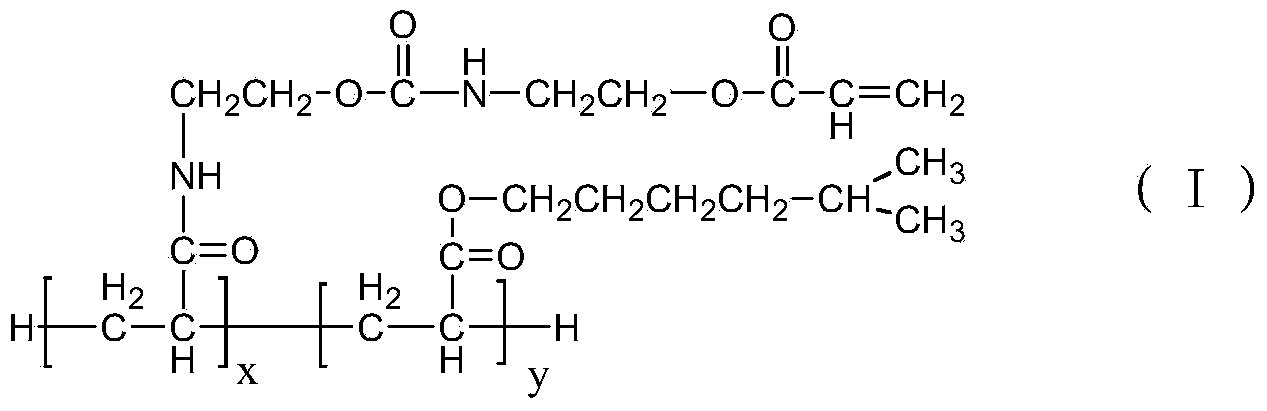

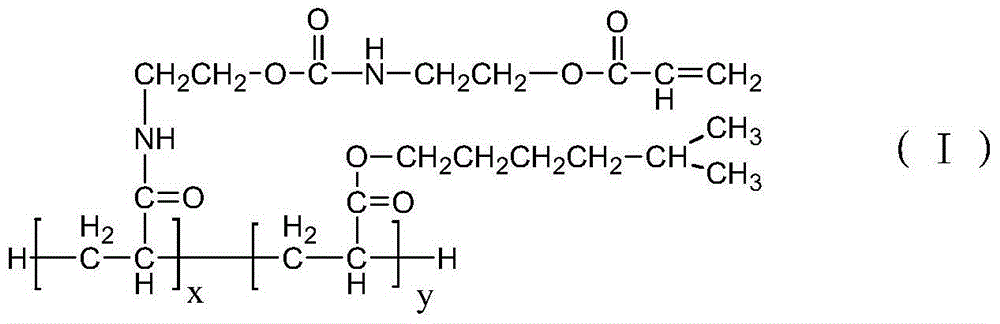

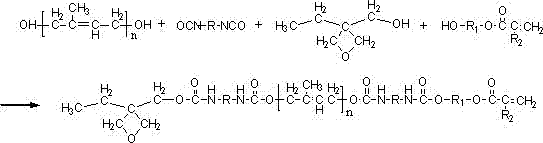

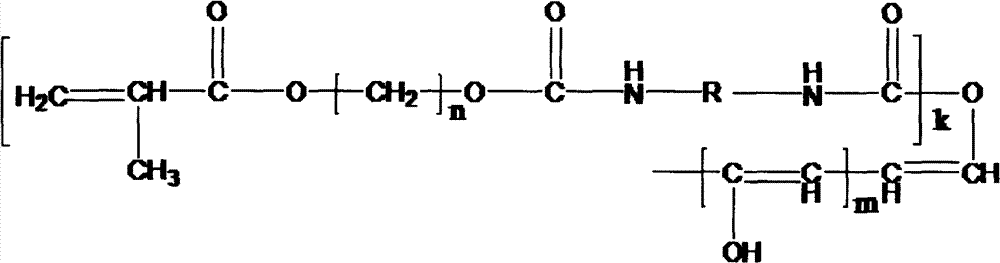

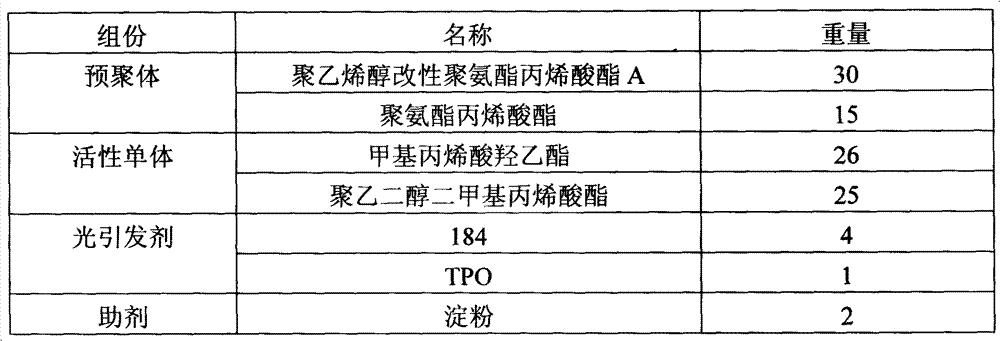

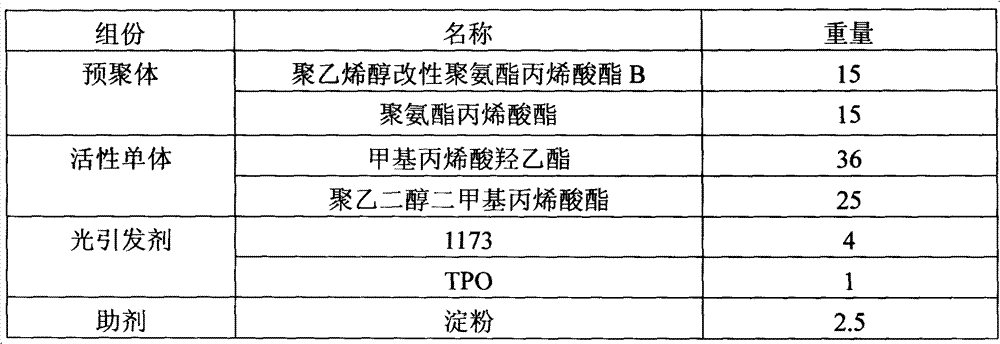

Ultraviolet (UV)-moisture double-curing liquid optical transparent adhesive and preparation method thereof

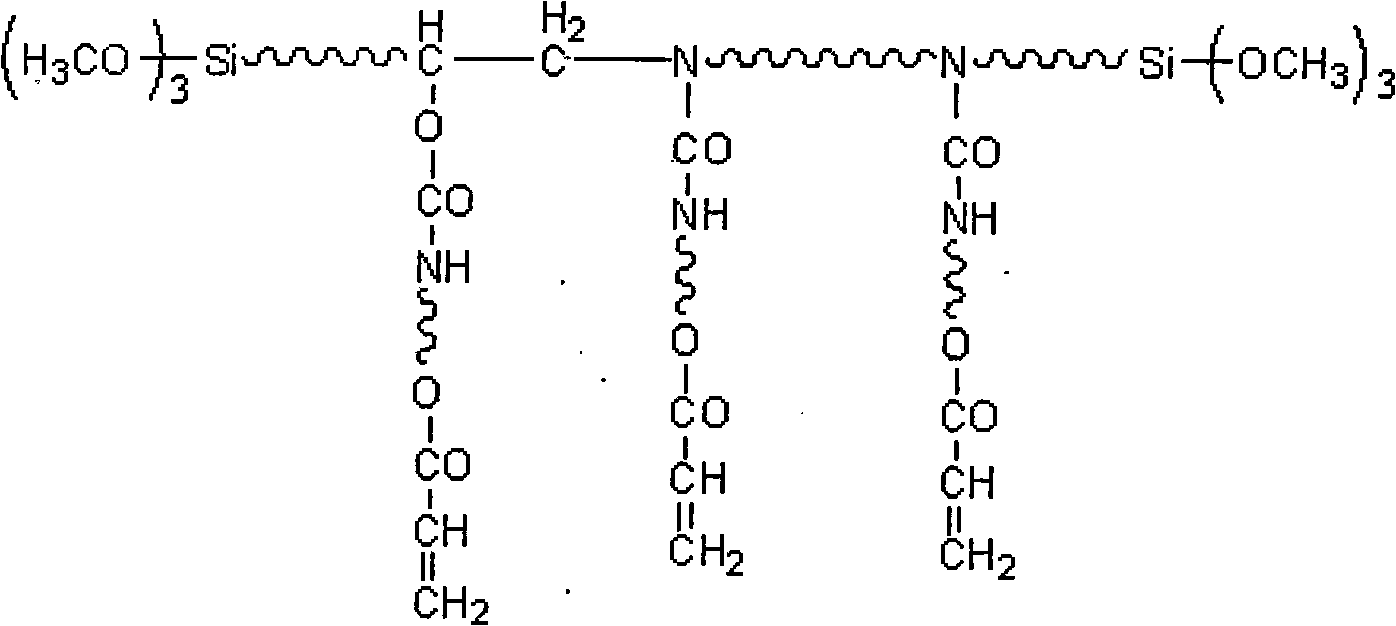

InactiveCN102816551AHigh transparencyHigh bonding strengthPolyureas/polyurethane adhesivesAdhesiveUltraviolet

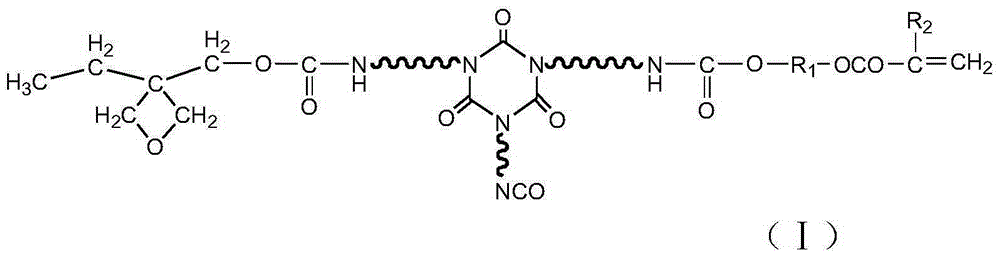

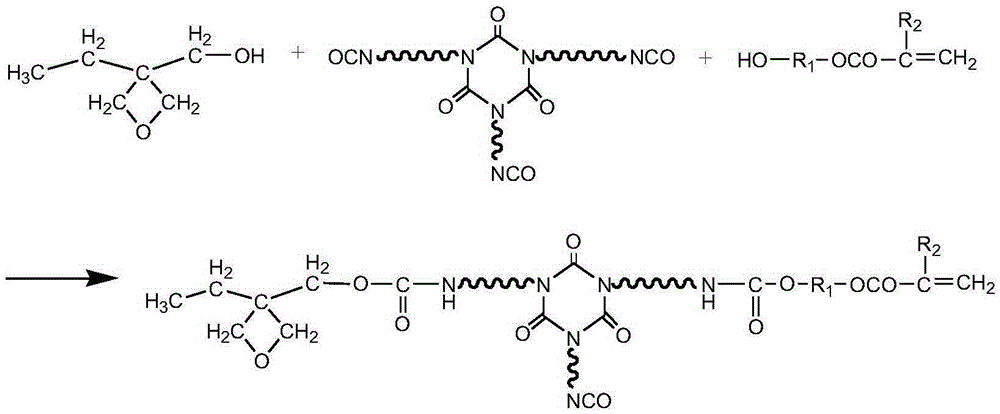

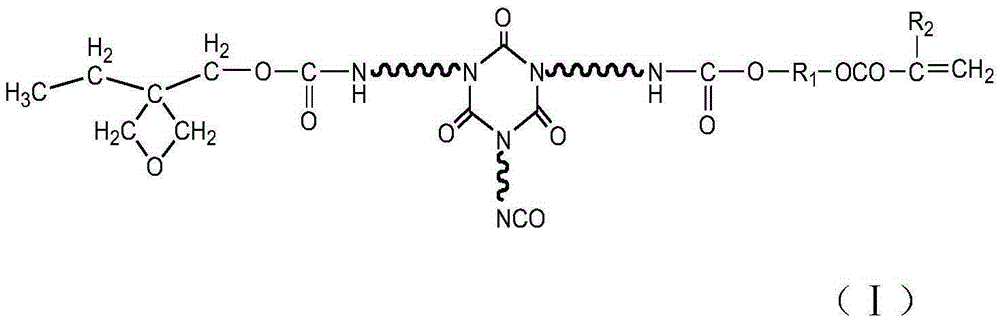

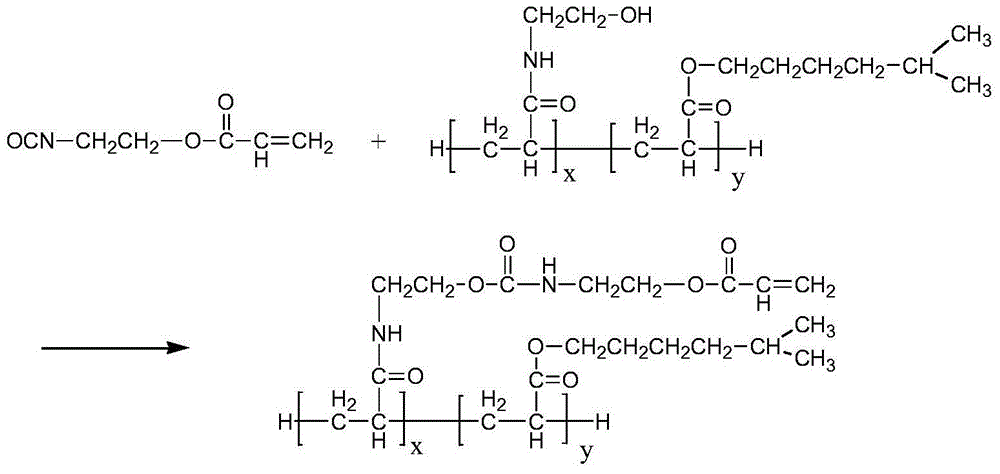

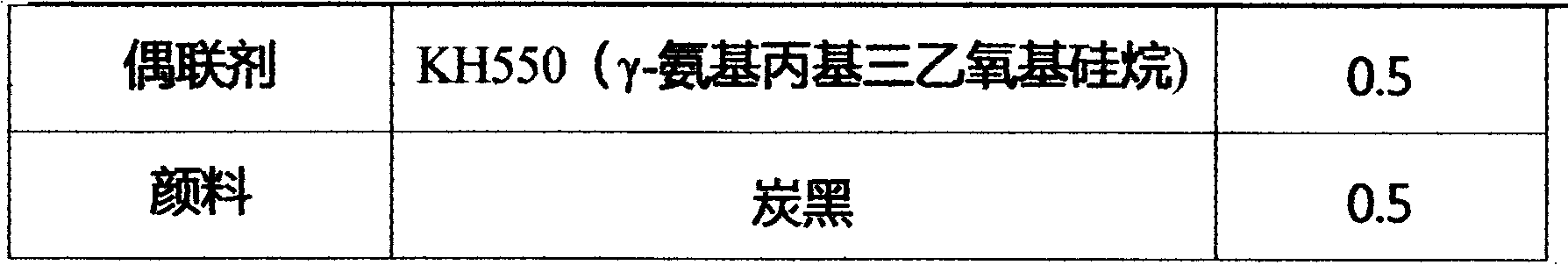

The invention relates to liquid optical transparent adhesive, in particular to ultraviolet (UV)-moisture double-curing liquid optical transparent adhesive and a preparation method thereof. The adhesive comprises, by weight, 30-60 parts of prepolymer, 5-50 parts of activated monomer, 0.1-7 parts of coupling agent, 1-10 parts of photoinitiator and 0.1-3 parts of auxiliaries. The prepolymer has a special molecular structural formula. The adhesive has the advantages of being good in transparency, adhesive strength and flexibility ductility, suitable for bonding of different materials, small in curing shrinkage percentage, resistant to yellowing and the like and can be used for attaching process on some special occasions such as touch screens. The preparation method includes: vacuum dewatering a reactive diluent for 1-2h at the temperature of 110-120 DEG C, cooling to room temperature, adding prepolymer, coupling agent and photoinitiator, stirring, dissolving, and adding auxiliaries to obtain the adhesive. The preparation method has the advantages of being simple in synthetic reaction process, easy to operate, low in cost and wide in product use range.

Owner:HB FULLER CO

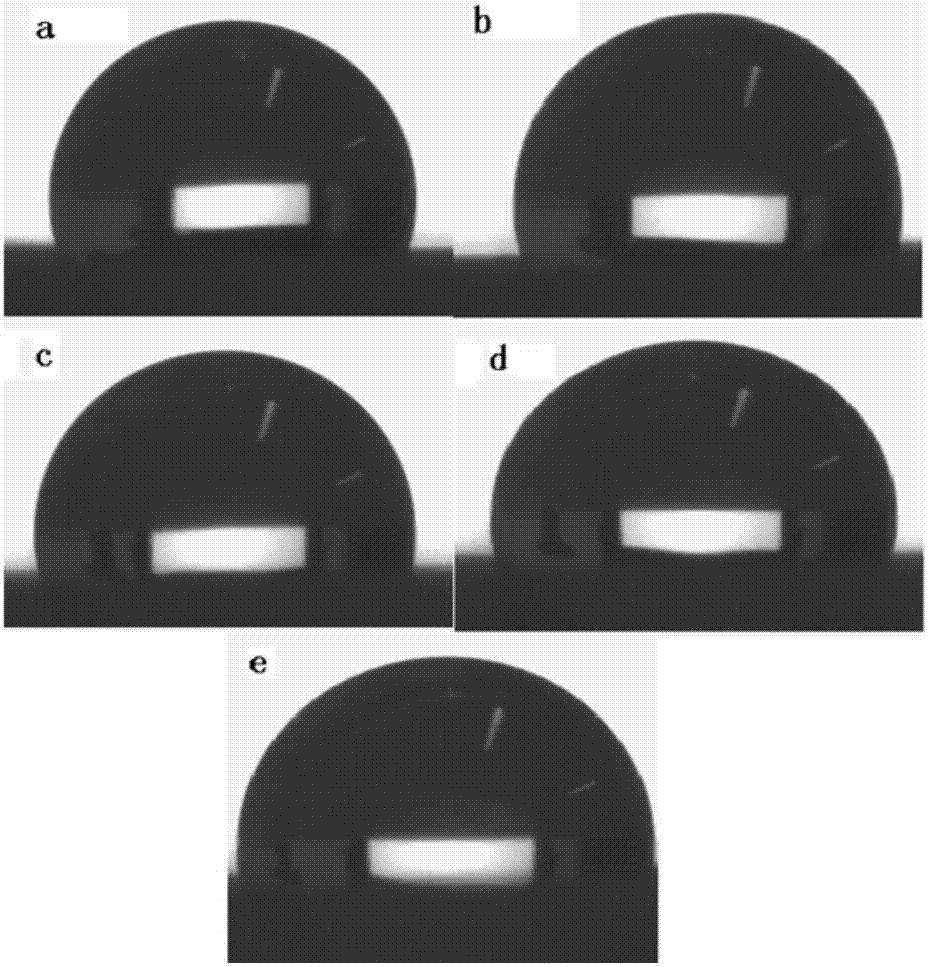

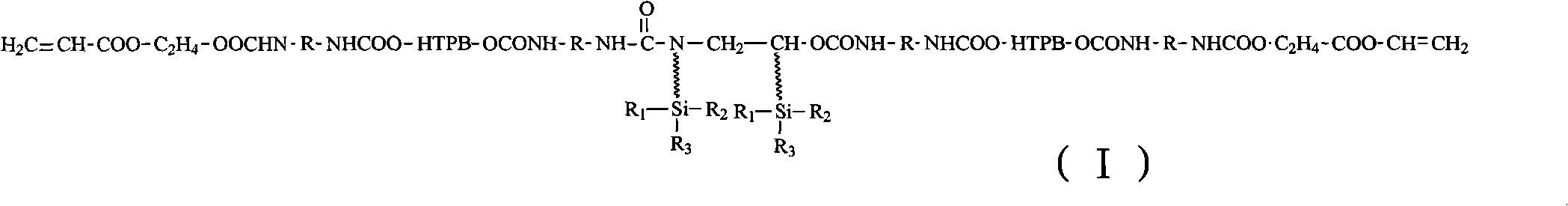

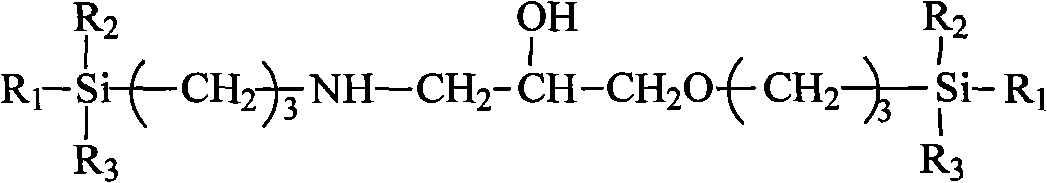

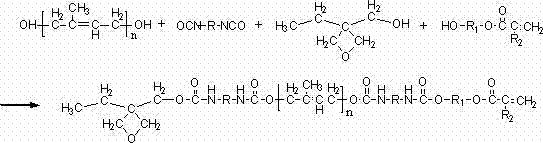

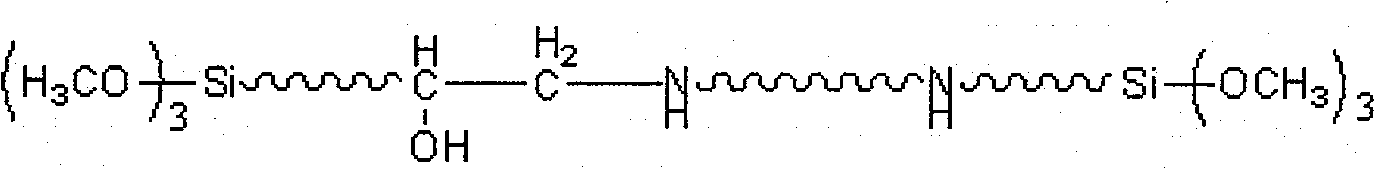

Light-cured resin with low water absorption and preparation method thereof

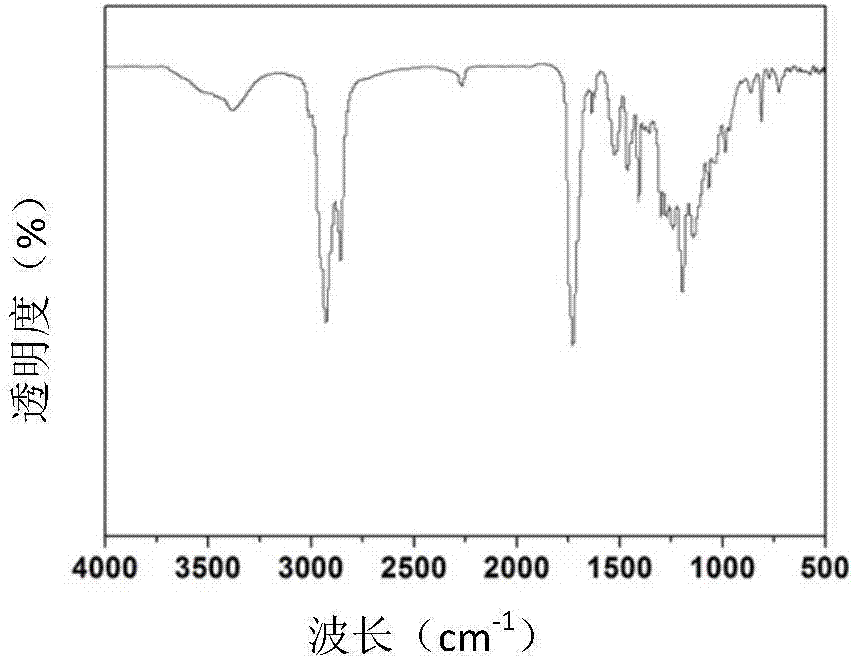

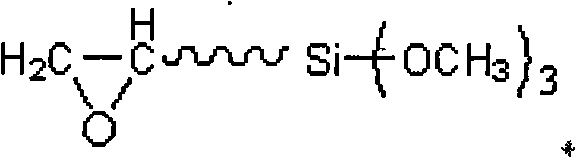

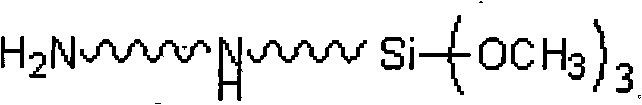

InactiveCN102010494ALow water absorptionReduce manufacturing costUrethane acrylateHydroxyl-terminated polybutadiene

The invention relates to a light-cured resin with low water absorption and a preparation method thereof. The light-cured resin is silicane modified hydroxyl-terminated polybutadiene type urethane acrylate. The preparation method comprises the following steps of: 1) reacting an epoxy silicane coupling agent with a primary amine silicane coupling agent to generate a modified silicane chain extender; 2) reacting hydroxyl-terminated polybutadiene with diisocyanate to generate polyurethane prepolymer 1; 3) reacting the modified silicane chain extender with the polyurethane prepolymer 1 to generate polyurethane prepolymer 2; and 4) reacting the polyurethane prepolymer 2 with hydroxyl acrylate to generate the silicane modified hydroxyl-terminated polybutadiene type urethane acrylate.

Owner:YANTAI DARBOND TECH

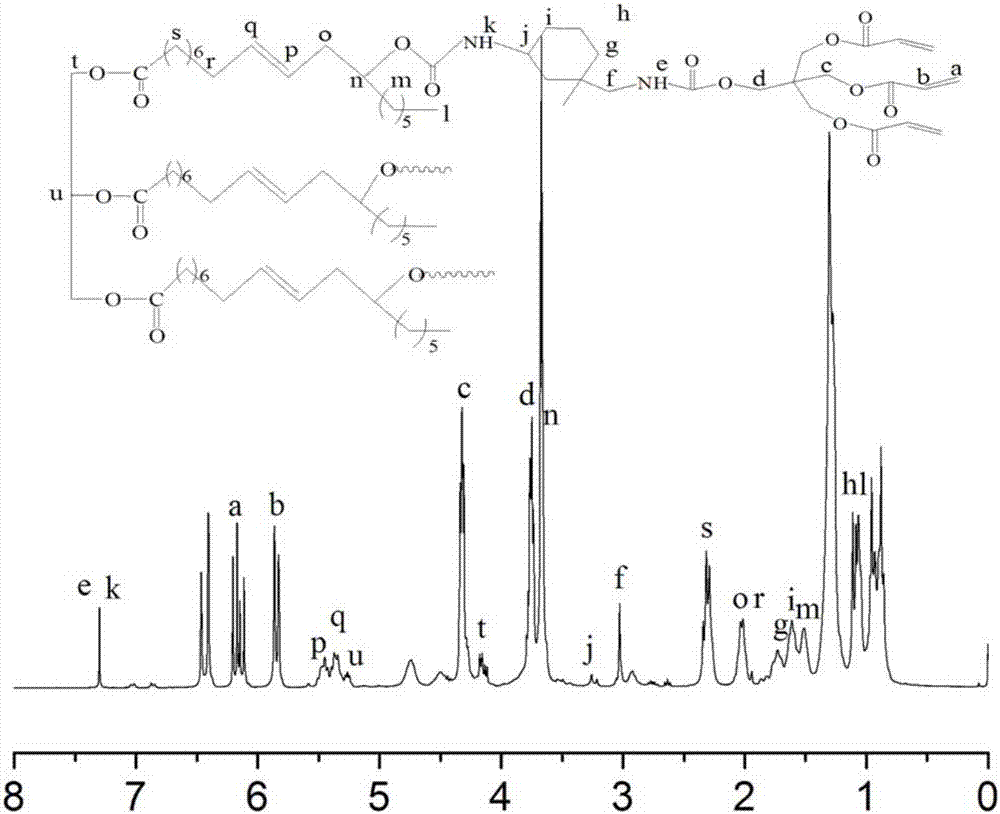

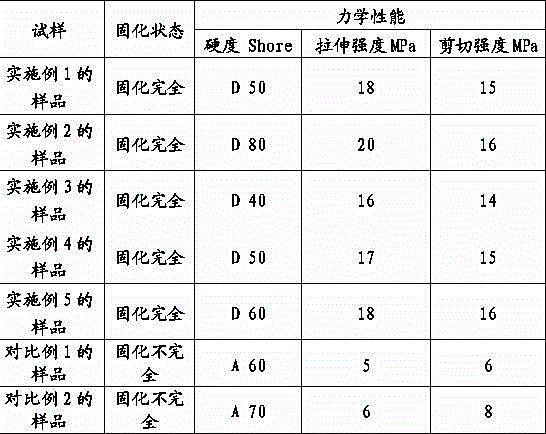

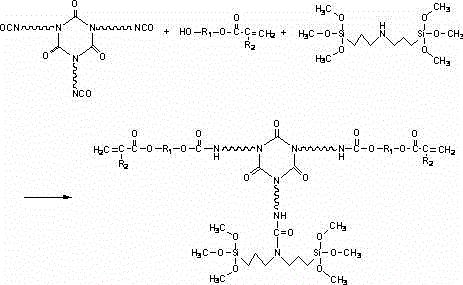

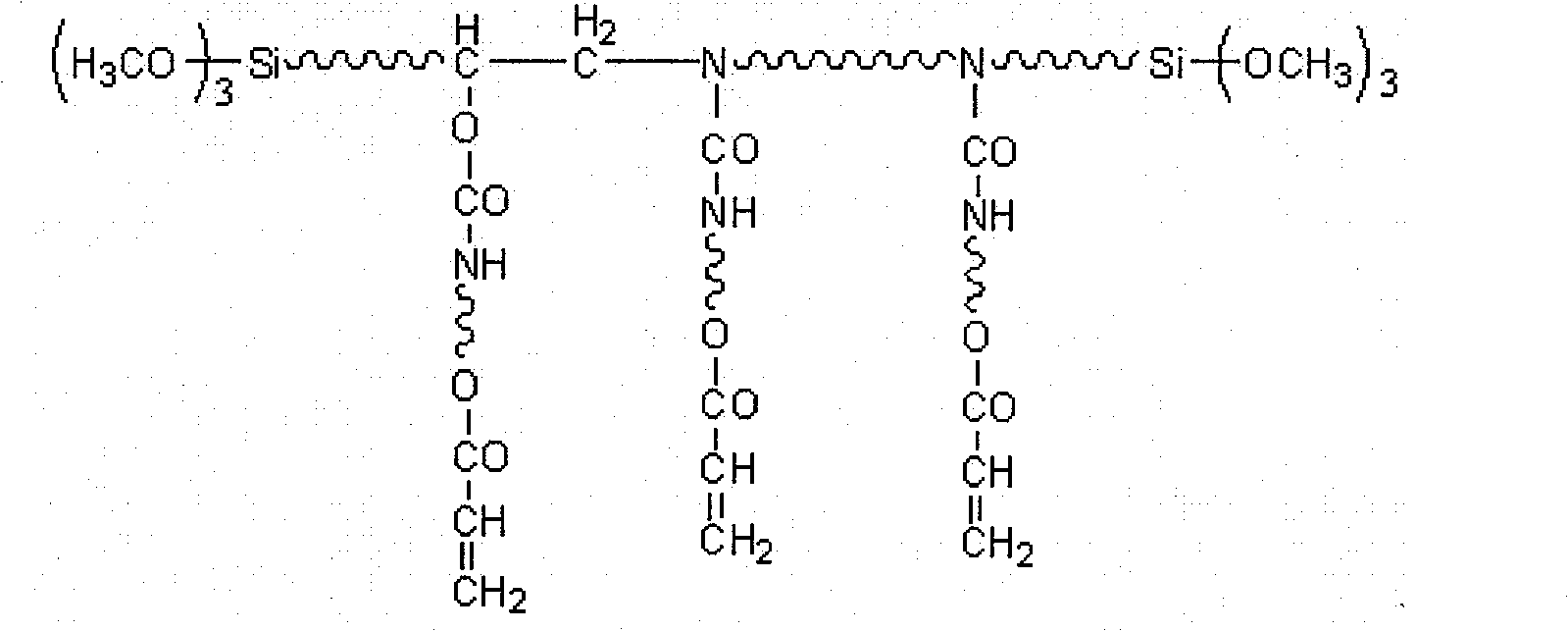

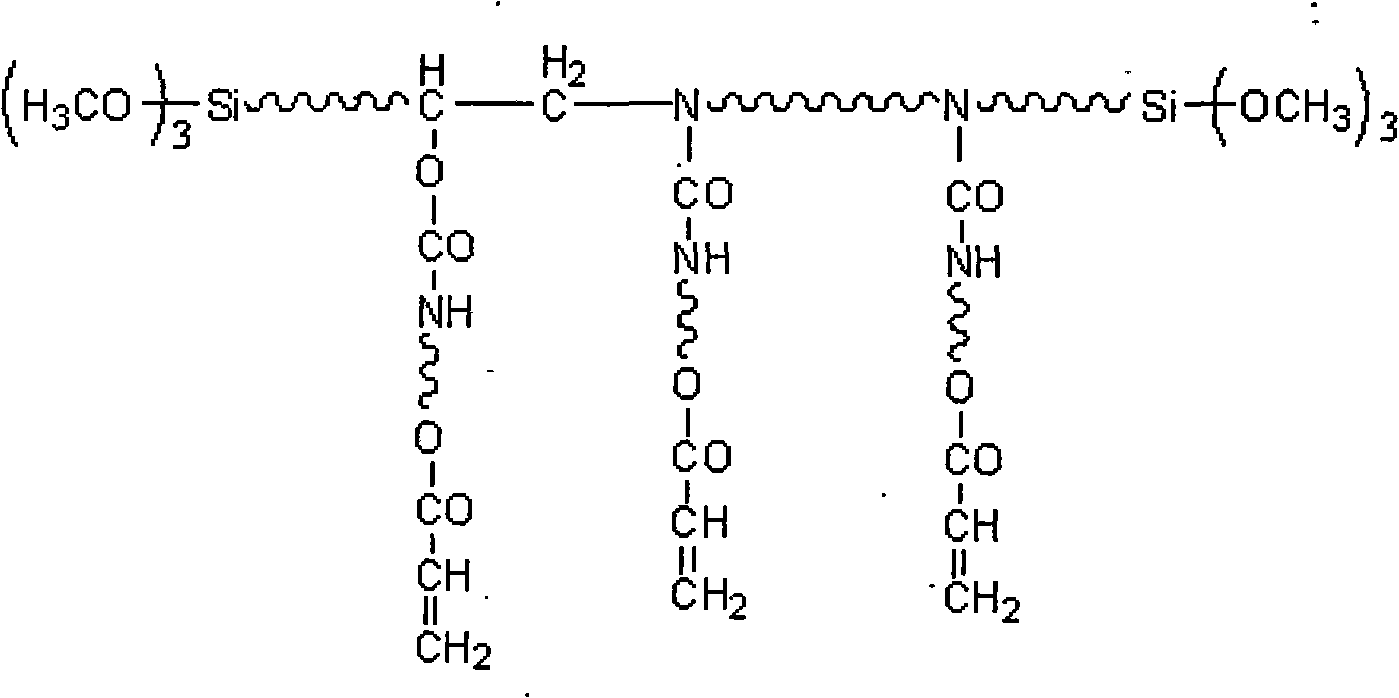

Three-functionality-degree organosilicon polyurethane acrylate and synthetic method thereof

The invention discloses three-functionality-degree organosilicon polyurethane acrylate and a synthetic method thereof. The invention is characterized in that an epoxy radical silane coupling agent is used for modifying a primary amino radical parhelium radical silane coupling agent to obtain a modified silane coupling agent containing three functional groups with active hydrogen; vulcabond and polymer dihydric alcohol are used for carrying out a reaction to obtain a polyurethane performed polymer (1) with NCO radical groups on both ends; then, hydroxy acrylic acid ester and the polyurethane performed polymer (1) are used for carrying out a reaction to obtain a polyurethane performed polymer (2) with an NCO radical group on one end; and finally, the polyurethane performed polymer (2) and the modified silane coupling agent react to obtain the three-functionality-degree organosilicon polyurethane acrylate. The invention has simple technology of the synthetic process and easy control, a product has regular structure, narrower molecular weight distribution and good consistency, the materials have the excellent properties of humidity resistance, heat resistance, weather resistance, oil resistance, good flexibility and low surface energy, and the invention can be applied to the industries of paint and adhesives.

Owner:YANTAI DARBOND TECH

UV/moisture dual-curing resin and synthesis method thereof

ActiveCN104788644ASpecial chemical structureSolve problems that cannot be curedPtru catalystSpectrograph

The invention provides a synthesis method of UV / moisture dual-curing resin. The method comprises the following steps: placing HDI tripolymer, hydroxied acrylates, polymerization inhibitor hydroquinone monomethylether and catalyst dibutyltin dilaurate into a three-mouth flask with a thermometer, heating the three-mouth flask to 65 DEG C, dropwise adding bis(gamma-trimethoxysilyl propyl)amine, controlling the temperature at 70 to 75 DEG C, and carrying out the reaction for 2 to 3 hours; analyzing NCO groups by utilizing an infrared spectrograph, and stopping the heating reaction when the NCO value is not changed, thereby obtaining the UV / moisture dual-curing resin. The resin can be optically cured by virtue of UV and also can be cured by virtue of moisture, so that the problem that a shadow part cannot be cured in the optical polymerization process; moreover, compared with the resin adopting isocyanate as a reaction group curing-sealing end, the resin adopting methoxylsilane as the moisture curing reaction group is more stable in reaction speed and cured resin effect, and the further curing effect of the product is better.

Owner:YANTAI DARBOND TECH

Resin with mixing and solidification functions and synthetic method thereof

The invention provides a synthetic method of resin with mixing and solidification functions. The synthetic method of the resin with the mixing and the solidification functions comprises the steps that 80-110 g of polyisoprene dibasic alcohol, 4-10 g of 3-ethyl-3-hydroxymethyleneoxetane, 5-12 g of hydroxyl acrylate, 0.1 g of polymerization inhibitor para hydroxybenzene methyl ether and 0.01 g of catalyst dibutyltin dilaurate are added into a three-mouth flask with a thermometer, the temperature is raised to 65 degrees, then 18-32 g of diisocyanate starts to be dropwise added, the temperature is controlled to be 70-75 degrees, and reaction is performed for 2-3 h. The content of NCO perssad is analyzed by an infrared spectrometer, until the NCO peak disappears completely, the heating reaction is stopped, and the urethane acrylate modified by oxetane can be obtained. The resin with the mixing and the solidification functions can manufacture three-dimensional products with low shrinking percentage, low warping, good flexibility, ageing resistance, high machining precision, good photocuring performance and excellent mechanical strength; in addition, the synthetic reaction is simple in technology and easy to control, no special equipment is needed to be used, no solvent is needed, and the production cost is low.

Owner:YANTAI DARBOND TECH

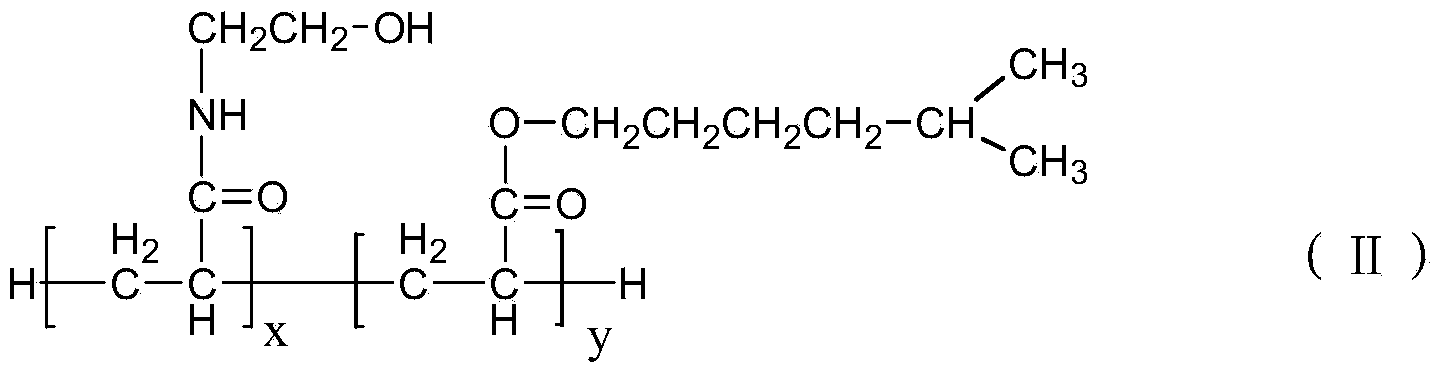

Optical pressure-sensitive resin and preparation method thereof

ActiveCN103524665AGood adhesionFast responseEster polymer adhesivesHydroxybenzoate EthersOCTYL ACRYLATE

The invention relates to optical pressure-sensitive resin and a preparation method thereof. The optical pressure-sensitive resin is polyacrylate-modified polyurethane acrylate resin. The preparation method comprises the following steps of: adding iso-octyl acrylate, N-ethoxyl acrylamide, p-hydroxyanisole, 1-dodecanethiol and ethyl acetate to a three-neck flask, and increasing temperature to 65 DEG C; starting dropping an azoisobutyronitrile-containing ethyl acetate solution, controlling the temperature at 70-80 DEG C, and reacting for 2-3 hours to obtain a polymer I; adding isocyanate ethyl acrylate to the polymer I, controlling the temperature at 70-80 DEG C, and reacting for 2-3 hours; analyzing the content of an NCO group by using an infrared spectrometer; stopping heating reaction when the peak of NCO completely disappears. The optical pressure-sensitive resin prepared through the method disclosed by the invention is fast in curing, achieves the curing energy less than 1000 mj / cm<2> and has the advantages of excellent adhesive force on a base material, very good application value and suitability for the full-lamination process of a capacitive touch screen.

Owner:YANTAI DARBOND TECH

Single-component shock-resistant low-viscosity structural adhesive and preparation method thereof

InactiveCN104087223ALow viscosityImproves flexibility and impact resistanceMacromolecular adhesive additivesEpoxy resin adhesivesPliabilityChemistry

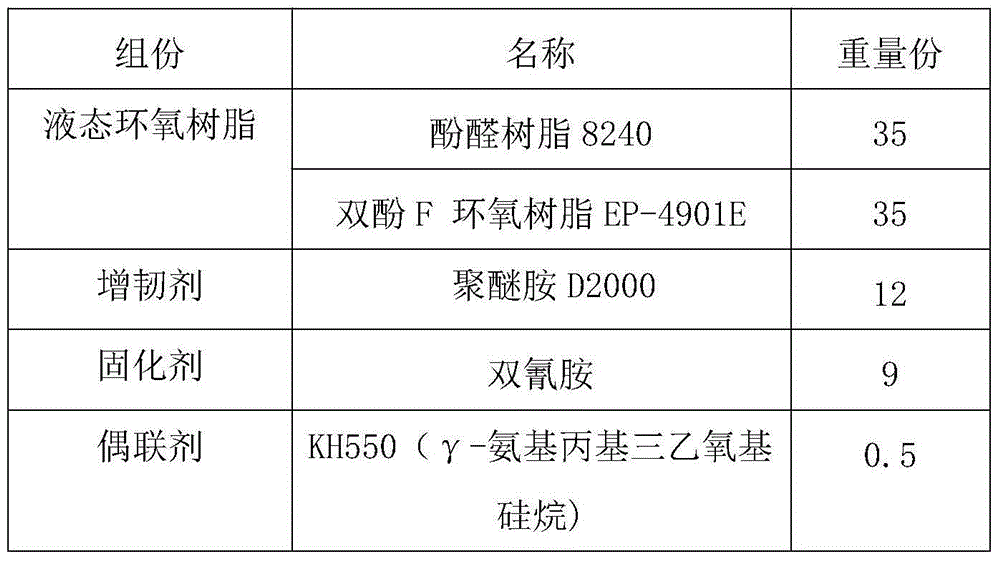

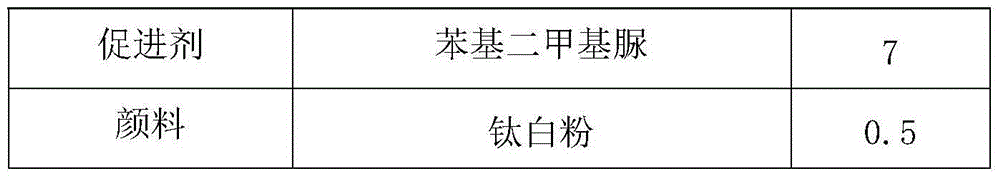

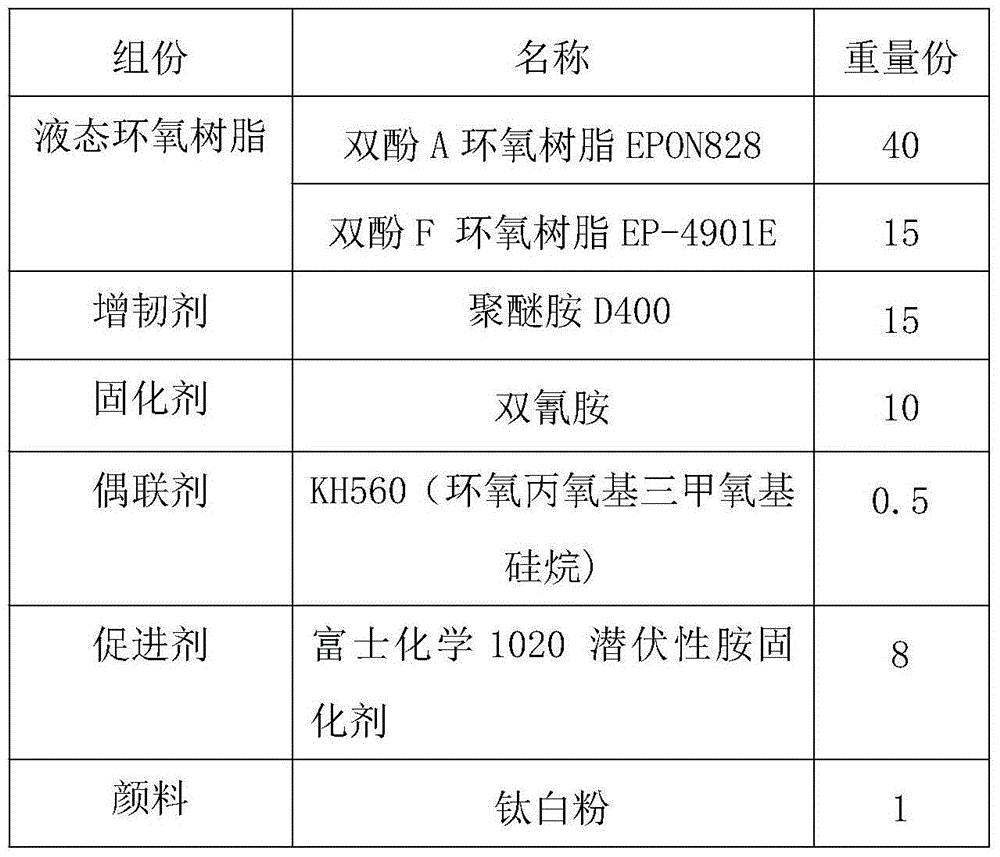

The invention relates to a structural adhesive and particularly relates to a single-component shock-resistant low-viscosity structural adhesive and a preparation method thereof, wherein the single-component shock-resistant low-viscosity structural adhesive is suitable for bonding motors and other structures. The preparation method comprises the following steps of (1) mixing liquid epoxy resin (40-80 parts) and a toughening agent (7-15 parts), and stirring at the temperature of 15-30 DEG C for 1h; (2) adding a curing agent (9-13.5 parts) while stirring, and continuing to stir at the temperature of 15-30 DEG C for 1h until uniformly mixing; (3) adding an accelerant (7-8 parts) while stirring, and continuing to stir at the temperature of 15-30 DEG C for 0.5h until uniformly mixing; and (4) adding a coupling agent (0-0.5 part) and pigment (0-1 part), and stirring at the temperature of 15-30 DEG C for 1h until uniformly mixing. Compared with the prior art, the single-component shock-resistant low-viscosity structural adhesive has the advantages that the toughening agent used by the invention is polyether amine, so that the high adhesive strength and temperature resistance of an epoxy system are remained, the viscosity of the system is reduced, and the flexibility and impact resistance of the adhesive are improved. The single-component shock-resistant low-viscosity structural adhesive is low in viscosity, and the adhesive can be coated on elements which are small in bonding gap and not easy to coat through self-permeation, so that the work efficiency can be greatly increased. A synthesis reaction process is simple, easy to operate and low in cost, and a product is wide in application range.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Multi-cured optical resin and synthesizing method thereof

InactiveCN106543154ASpecial chemical structureSolve problems that cannot be curedOrganic chemistryOrganic non-macromolecular adhesive4-MethoxyphenolHydroxybenzoate Ethers

The invention provides a synthesizing method for multi-curing available optical resin. The method comprises the following steps: adding 80-110g of HDI tripolymer, 5-10g of 3-ethyl-3-(hydroxymethyl) oxacyclobutane, 4-10g of hydroxyl acrylate, 0.1g of polymerization inhibitor 4-methoxyphenol and 0.01g of catalyst dibutyltin dilaurate into a three-necked flask with a thermometer, and heating to 65 DEG C; controlling the temperature to be 60-75 DEG C, reacting for 2-3 hours, analyzing NCO group with an infrared infrared spectrometer; and stopping the heat reaction when the NCO peak does not change so as to obtain the multi-cured functional resin capable of free radical+cation+moisture reaction.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

Optical resin and synthesis method thereof

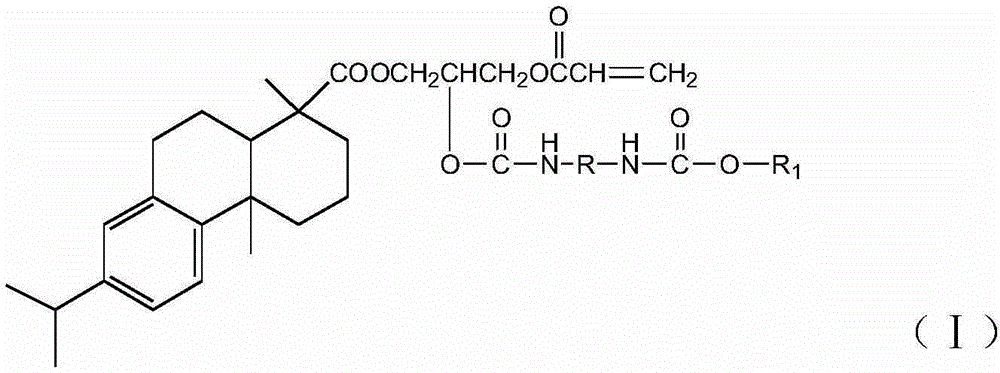

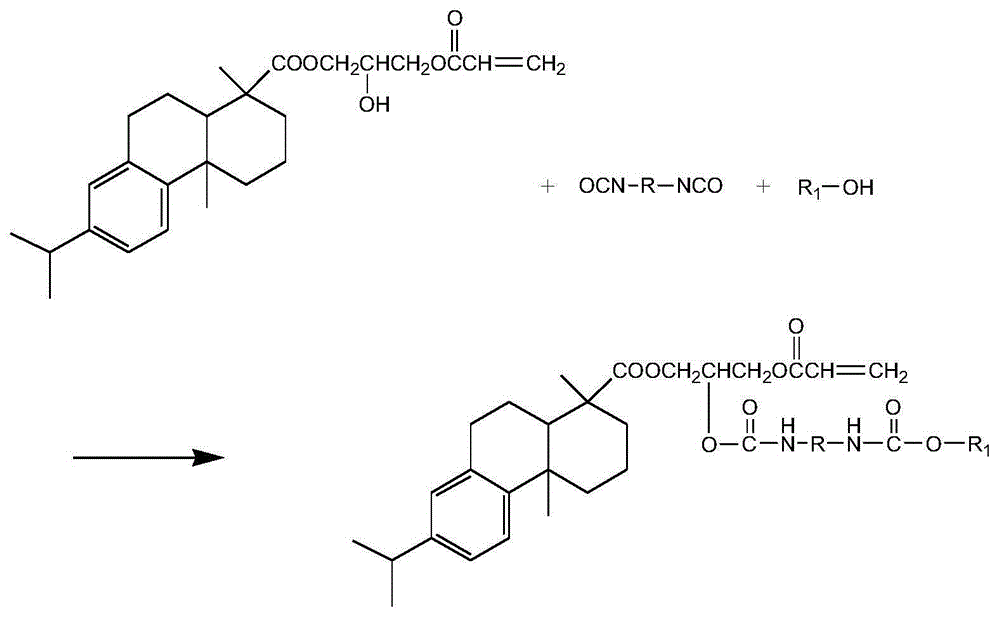

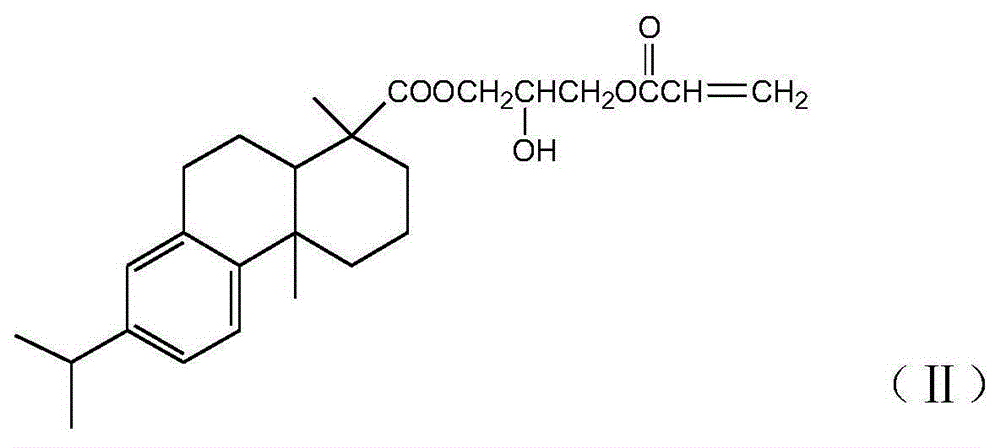

InactiveCN106543037AGood yellowing resistanceThe synthesis reaction process is simpleCarbamic acid derivatives preparationOrganic compound preparationEpoxyHydroxybenzoate Ethers

The invention provides an optical resin synthesis method, which comprises: adding 80-110 g of an epoxy-modified rosin ester, 4-10 g of a monohydric alcohol, 0.1 g of a polymerization inhibitor p-hydroxyanisole, and 0.01 g of a catalyst dibutyltin dilaurate to a three-necked flask having a thermometer, heating to a temperature of 65 DEG C, adding 18-32 g of diisocyanate in a dropwise manner, controlling the temperature at 70-75 DEG C, carrying out a reaction for 2-3 h, analyzing the NCO group content by using an infrared spectrometer, and stopping the heating reaction when the peak of NCO completely disappears so as to obtain the rosin ester modified polyurethane acrylate resin. According to the present invention, the obtained resin is the high-performance optical resin, has the refractive index of 1.52-1.54, has the good yellowing resistance, can be used for producing the high-end liquid-state optical transparent glue, avoids the disadvantages of low refractive index and poor yellowing resistance of the traditional liquid-state optical transparent glue, and is suitable for the whole adhesion process of the capacitive touch screen.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

Preparation of low-viscosity organosilicon material

The invention relates to the preparation of a low-viscosity organosilicon material. The preparation comprises the following steps: accurately weighing 350-380 g of polyvinyl silicone oil, 4 g of a low hydrogen-containing silicone oil crosslinking agent, 20 g of a microcapsule platinum catalyst, 20 g of carbon black, 800 g of a modified silicon oxide powder with the average grain diameter of 5 mum, 600 g of a spheroid aluminum hydroxide powder with the average grain diameter of 40 mum, and 200 g of an aluminum hydroxide powder with the average grain diameter of 10 mum, sequentially adding the materials into a 2L double-planet power mixer, and stirring for 3-5 hours at the autorotation speed of 100 revolutions per minute and at the revolution speed of 8 revolutions per minute.

Owner:烟台鑫海耐磨胶业有限公司

Preparation of methylvinylsilane resin

The invention relates to preparation of methylvinylsilane resin. The methylvinylsilane resin is prepared through the following steps: adding 41 to 43 g of ethyl orthosilicate, 8 g of toluene, 9 g of hexamethyldisiloxane, 3 g of tetramethyldivinyldisiloxane, 10 to 20 g of absolute ethyl alcohol and 1.4 g of concentrated hydrochloric acid (wherein wt% is 36%) into a three-neck flask equipped with a stirrer, a thermometer and a condenser tube; adding 15 g of water in an ice water bath drop by drop at a rate of 1 d / s, carrying out stirring for 5 min after addition, and then carrying out heating to 35 DEG C for a preliminary reaction for 25 to 40 min; allowing the temperature of a system to rise to 78 DEG C, carrying out a reaction for 4 h, then terminating the reaction, adding 1.43 g of NaHCO3 and carrying out heating to 125 DEG C to evaporate water and ethanol; after evaporation, carrying out a reflux reaction at 125 DEG C for 4 h, then adding 0.3 g of hexamethyldisiloxane, carrying out a reaction at 125 DEG C for 1 h, and then carrying out washing until a pH value is 7; and carrying out filtering so as to obtain a colorless transparent filtrate, transferring the filtrate to a pyriform flask, and carrying out pressure-reduced distillation to remove low-boiling-point substances like xylene so as to obtain the methylvinylsilane resin.

Owner:烟台鑫海耐磨胶业有限公司

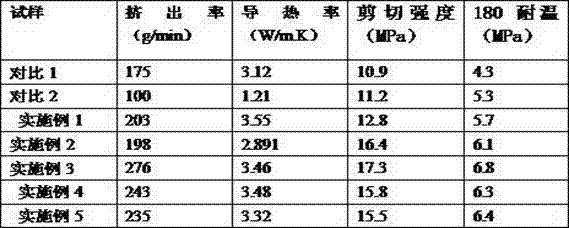

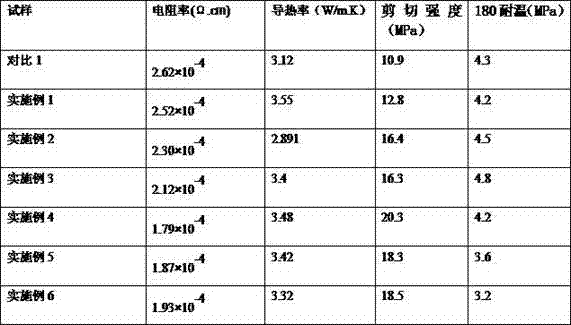

Single-component insulating structured adhesive with high thermal conductivity and preparation method of single-component insulating structured adhesive

InactiveCN107474770AHigh thermal conductivitySmall coefficient of thermal expansionNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal conductivityChemistry

The invention relates to a single-component insulating structured adhesive with high thermal conductivity and a preparation method of the single-component insulating structured adhesive. Epoxy resin, modified epoxy resin, a toughening agent and a coupling agent are sequentially added to a double-planet power mixing kettle in sequence, revolution stirring and high-speed dispersing are started, and the components are stirred for 1 h at certain temperature; modified thermally conductive and insulating packing is added, and stirring is performed for 1 h; a latent curing agent is added, and stirring is performed for 1 h; fumed silica is added, stirring is performed for 1 h, a product is kept at certain pressure for 1 h, and the single-component insulating structured adhesive with high thermal conductivity is obtained. The single-component insulating structured adhesive with high thermal conductivity has the characteristics of being low in viscosity, good in flowability, resistant to high temperature and excellent in thermal conductivity.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Preparation method of conductive adhesive with high thermal conductivity and used for high-power LED package

InactiveCN107513359AHigh thermal conductivityGood electrical conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesivePolymer science

The invention relates to a preparation method of conductive adhesive with high thermal conductivity and used for high-power LED package. The preparation method comprises the following steps: sequentially adding epoxy resin and a toughening agent into a double-planet power mixing kettle, starting revolution stirring and high-speed dispersion, at a certain temperature, stirring for 1h, adding a self-made functionalized graphene material and conductive silver powder, stirring for 1h, adding a latent curing agent, stirring for 1h, adding fumed silica, stirring for 1h, and maintaining for 1h at a certain pressure, thus obtaining the one-component conductive adhesive with high thermal conductivity. The conductive adhesive adopts a simple synthesis process, is low in cost and also has the characteristics of high strength, high temperature resistance, low shrinkage and excellent thermal conductivity and heat conductivity.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

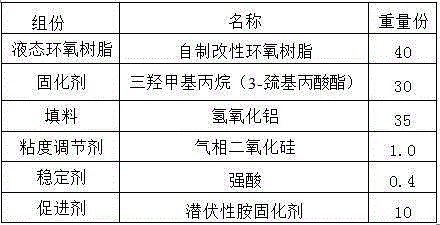

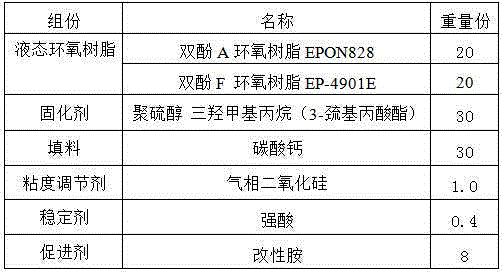

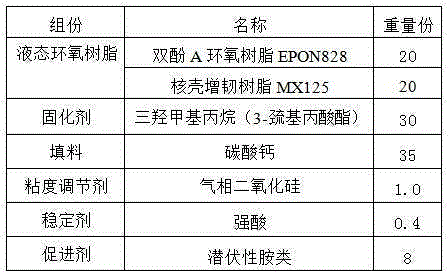

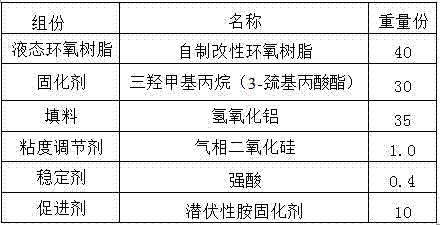

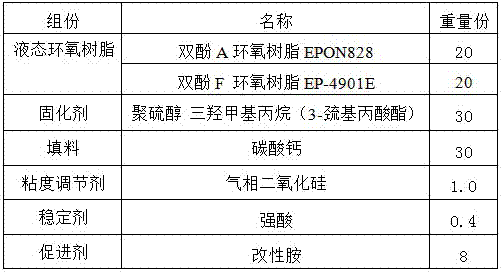

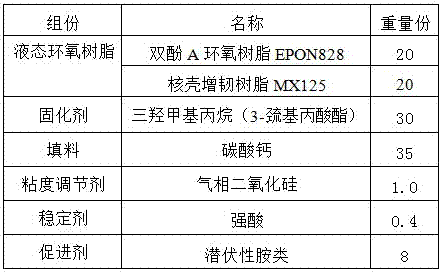

One-component flexible epoxy adhesive and preparation method thereof

ActiveCN105331316AGood flexibilityImprove performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention relates to a one-component flexible electronic adhesive and a preparation method thereof. The adhesive is characterized by being prepared from raw materials in parts by weight as follows: 20-50 parts of liquid-state self-made modified epoxy resin, 15-40 parts of a curing agent, 20-40 parts of filler, 0-3 parts of a viscosity regulator, 0.2-1 part of a stabilizer and 2-15 parts of an accelerator, wherein the curing agent adopts a sulfhydryl compound; the accelerator adopts an amine accelerator, an amine derivative accelerator or an imidazole accelerator; the liquid-state self-made modified epoxy resin adopts one or a mixture of bisphenol A epoxy resin, bisphenol F epoxy resin and phenol-formaldehyde resin and is prepared through the following steps: liquid-state epoxy resin and the curing agent are mixed and stirred in the ratio being 85:15, the temperature is controlled to be 75-80 DEG C, the accelerator is added during stirring, stirring is continued for 2 h after complete impregnation, and the temperature is controlled to be 75-80 DEG C; a product is cooled to 15-30 DEG C for standby application. A synthetic reaction process is simple and easy to operate, the cost is low, and the product has stable performance and wide application.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Synthesis of thiol-modified polyurethane resin

The present invention relates to synthesis of a thiol-modified polyurethane resin. The synthesis comprises: vacuumizing 100 g of HTPB for 2-4 h at a temperature of 110 DEG C to remove the doped water; cooling to a temperature of 50 DEG C, adding 29 g of HDI, heating to a temperature of 85 DEG C after the constant temperature is achieved, carrying out a reaction for 2.5-3.5 h, stopping the heating until the NCO content achieves a designed value, adding 3.9 g of hydroxypropyl methacrylate, 1.2 g of mercaptoethanol and 2.1 g of 16-mercapto hexadecan-1-ol, and uniformly mixing; and carrying out a reaction for 2.5-3.5 h at a temperature of 70 DEG C to obtain the thiol-modified polyurethane resin.

Owner:烟台鑫海耐磨胶业有限公司

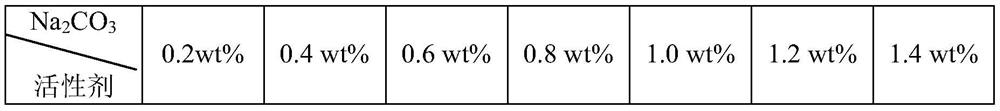

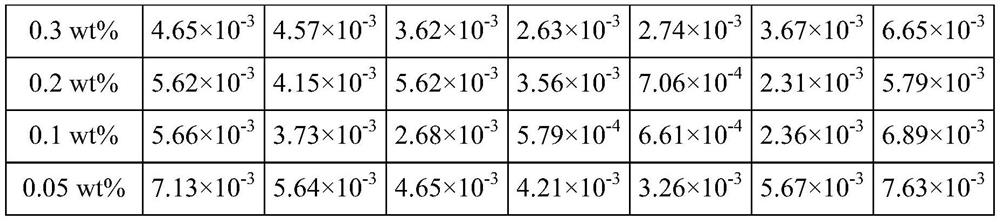

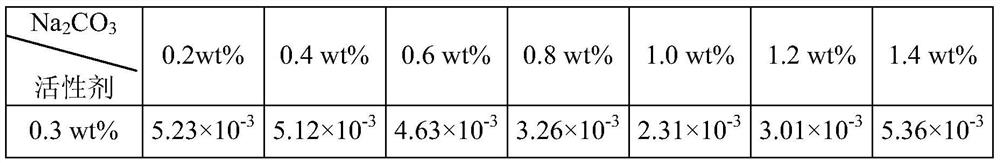

Petroleum sodium sulfonate composition as well as preparation method and application thereof

The invention provides a petroleum sodium sulfonate composition as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing 5 to 95weight percent of a fraction 1 of which the average molecular weight is 252 to 312, 5 to 95 weight percent of a fraction 2 of which the average molecular weight is 313 to 395 and 0 to 50 weight percent of a fraction 3 of which the average molecular weight is 396 to 490 according to 100 percent of the total weight of a mixed material, thus obtaining the mixed material; adding a diluent into the mixed material, thus obtaining a diluted product; carrying out sulfonation treatment on the diluted product by adopting an SO3 gas, thus obtaining a sulfonated product, wherein the diluent is prepared from one or a combination of several alcohols of which the carbon chain lengths are C3 to C10, and the dosage of the diluent is 0.1 to 10 percent of the weight of the mixed material; then neutralizing petroleum sulfonic acid in the sulfonated product by adopting a sodium hydroxide aqueous solution until the pH (Potential of Hydrogen) value of a system is 7 to 11, thus obtaining the petroleum sodiumsulfonate composition.

Owner:PETROCHINA CO LTD

Sodium alkylarylsulfonate surfactant composition and its preparation and application

ActiveCN107670581ALow viscosityLow aromatic contentTransportation and packagingMixingBenzeneReverse order

The invention provides a sodium alkylarylsulfonate surfactant composition and its preparation and application. The method comprises mixing a raw material 1 and a raw material 2 to obtain a mixed material, wherein the raw material 1 comprises one or more of reverse order dewaxed oil or distillate from a decompression second line, reverse order dewaxed oil or distillate from a decompression third line and reverse order dewaxed oil or distillate from a decompression forth line, the raw material 2 comprises one or more of light alkyl benzene, heavy alkyl benzene 1# and heavy alkyl benzene 2#, a weight ratio of each ingredients in the raw material 1 is 5-95wt% and a weight ratio of each ingredients in the raw material 2 is 5-95wt%, carrying out sulfonation treatment on the mixture through SO3 gas to obtain the sulfonated product and neutralizing the sulfonated product until system pH is 7-10 through a sodium hydroxide aqueous solution.

Owner:PETROCHINA CO LTD

High-refraction-index and yellowing-resistant resin and synthesis method thereof

InactiveCN106543404AGood yellowing resistanceThe synthesis reaction process is simpleEpoxyHydroxybenzoate Ethers

The invention provides a hgh-refraction-index and yellowing-resistant resin synthesis method, which comprises: adding 80-110 g of epoxy-modified rosin ester, 4-10 g of hydroxy acrylate, 500-800 g of high molecular weight polyether diol, 0.1 g of a polymerization inhibitor p-methoxyphenol, and 0.01 g of a catalyst dibutyltin dilaurate to a three-necked flask having a thermometer, heating to a temperature of 65 DEG C, adding 18-32 g of diisocyanate in a dropwise manner, controlling the temperature at 70-75 DEG C, carrying out a reaction for 2-3 h, analyzing the NCO group content by using an infrared spectrometer, and stopping the heating reaction when the peak of NCO completely disappears so as to obtain the rosin ester modified polyurethane acrylate resin.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

Three-functionality-degree organosilicon polyurethane acrylate and synthetic method thereof

The invention discloses three-functionality-degree organosilicon polyurethane acrylate and a synthetic method thereof. The invention is characterized in that an epoxy radical silane coupling agent is used for modifying a primary amino radical parhelium radical silane coupling agent to obtain a modified silane coupling agent containing three functional groups with active hydrogen; vulcabond and polymer dihydric alcohol are used for carrying out a reaction to obtain a polyurethane performed polymer (1) with NCO radical groups on both ends; then, hydroxy acrylic acid ester and the polyurethane performed polymer (1) are used for carrying out a reaction to obtain a polyurethane performed polymer (2) with an NCO radical group on one end; and finally, the polyurethane performed polymer (2) and the modified silane coupling agent react to obtain the three-functionality-degree organosilicon polyurethane acrylate. The invention has simple technology of the synthetic process and easy control, a product has regular structure, narrower molecular weight distribution and good consistency, the materials have the excellent properties of humidity resistance, heat resistance, weather resistance, oil resistance, good flexibility and low surface energy, and the invention can be applied to the industries of paint and adhesives.

Owner:YANTAI DARBOND TECH

Preparation of high-temperature-resistant epoxy structural adhesive

InactiveCN106854446AThe synthesis reaction process is simpleEasy to controlNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyTriethoxysilane

The invention relates to preparation of a high-temperature-resistant epoxy structural adhesive. The adhesive is prepared by adding 50 g of epoxy resin E-51, 50 g of epoxy resin F-51, 2.5 g of a flexibilizer KH-07A, 2.5 g of a flexibilizer KH-07B, 2.5 g of a flexibilizer KH-07C, 2.5 g of a flexibilizer KH-07D and 1 g of gamma-aminopropyltriethoxysilane into a mixing kettle and carrying out stirring at normal temperature for 1 to 2 h, with a rotating speed being 100 to 180 rpm; and adding 5 g of alumina powder, 10 g of spherical aluminum powder and 5 g of silica micropowder, carrying out stirring at a rotating speed of 1000 to 1200 rpm for 20 to 40 min, and carrying out cooling to normal temperature after uniform mixing; and adding 3 g of dicyandiamide, 1 g of 100A and 1 g of PN-23 carrying out stirring at a rotating speed of 100 to 180 rpm for 30 min, and then carrying out blanking.

Owner:烟台鑫海耐磨胶业有限公司

Preparation of heat-conducting joint-filling material

InactiveCN106854376AThe synthesis reaction process is simpleEasy to controlHeat-exchange elementsAluminium hydroxideResin matrix

The invention relates to preparation of a heat-conducting joint-filling material. The preparation comprises the following steps: accurately weighing 100 to 120 parts of a resin matrix, adding 25 to 30 parts of an aluminate coupling agent; adding the above substances into a mixer and carrying out stirring at a vacuum degree of -0.1 MPa for 40 to 50 min; after completion of stirring, adding 100 parts of aluminum hydroxide into a mixture obtained in the previous step and carrying out stirring at a vacuum degree of -0.1 MPa for 5 to 10 min; then adding 150 parts of the heat-conducting filler boron nitride, carrying out stirring at a vacuum degree of -0.1 MPa for 30 min and then carrying out blanking; and molding a mixture obtained in the previous step into a sheet material with a size of 5 mm and subjecting the sheet material to curing at 130 DEG C for 20 to 30 min so as to obtain the heat-conducting joint-filling material.

Owner:烟台鑫海耐磨胶业有限公司

Synthesis of diphenylether-formaldehyde resin

InactiveCN106811161AThe synthesis reaction process is simpleEasy to controlNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesives4-MethoxyphenolHydroxybenzoate Ethers

The invention relates to synthesis of diphenylether-formaldehyde resin. A process comprises the following steps that 80 to 90g of diphenylether-formaldehyde resin, 32 to 40g of HDI trimers, 5g of 3-ethyl-3-hydroxymethyleneoxetane, 10g of hydroxyethyl methylacrylate, 0.1g of polymerization inhibitors of 4-methoxyphenol and 0.01g of catalysts of dibutyl tin laurate are added into a three-opening flask with a temperature indicator; the temperature is raised to 80 to 90 DEG C; the temperature is controlled to be 80 to 90 DEG C; the reaction is taken for 3 to 6hours; the heating reaction is stopped, and the diphenylether-formaldehyde resin is obtained.

Owner:孙萌萍

A kind of optical pressure-sensitive resin and preparation method thereof

ActiveCN103524665BImprove adhesionQuick responseEster polymer adhesivesIsooctyl acrylateHydroxybenzoate Ethers

The invention relates to optical pressure-sensitive resin and a preparation method thereof. The optical pressure-sensitive resin is polyacrylate-modified polyurethane acrylate resin. The preparation method comprises the following steps of: adding iso-octyl acrylate, N-ethoxyl acrylamide, p-hydroxyanisole, 1-dodecanethiol and ethyl acetate to a three-neck flask, and increasing temperature to 65 DEG C; starting dropping an azoisobutyronitrile-containing ethyl acetate solution, controlling the temperature at 70-80 DEG C, and reacting for 2-3 hours to obtain a polymer I; adding isocyanate ethyl acrylate to the polymer I, controlling the temperature at 70-80 DEG C, and reacting for 2-3 hours; analyzing the content of an NCO group by using an infrared spectrometer; stopping heating reaction when the peak of NCO completely disappears. The optical pressure-sensitive resin prepared through the method disclosed by the invention is fast in curing, achieves the curing energy less than 1000 mj / cm<2> and has the advantages of excellent adhesive force on a base material, very good application value and suitability for the full-lamination process of a capacitive touch screen.

Owner:YANTAI DARBOND TECH

Rapid permeation bottom underfill and preparation method thereof

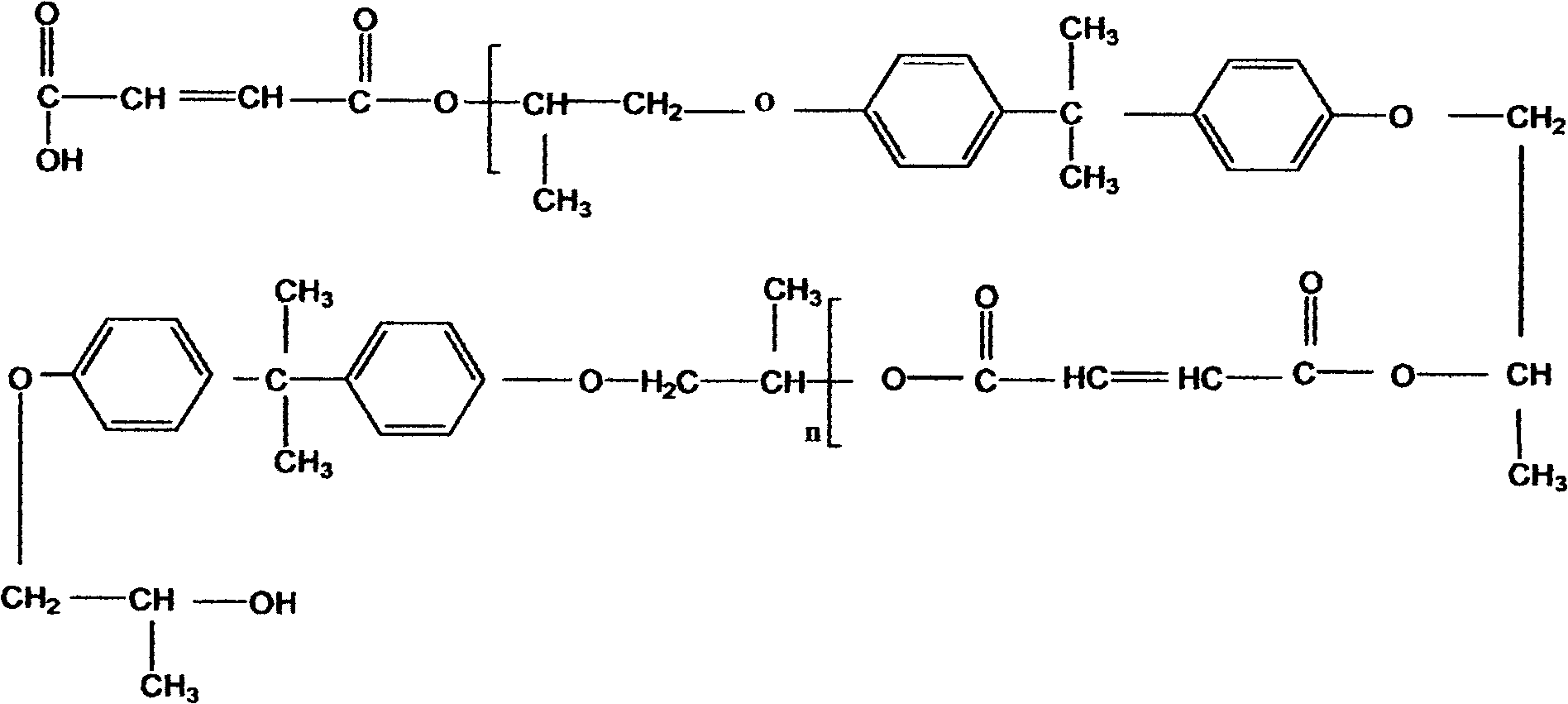

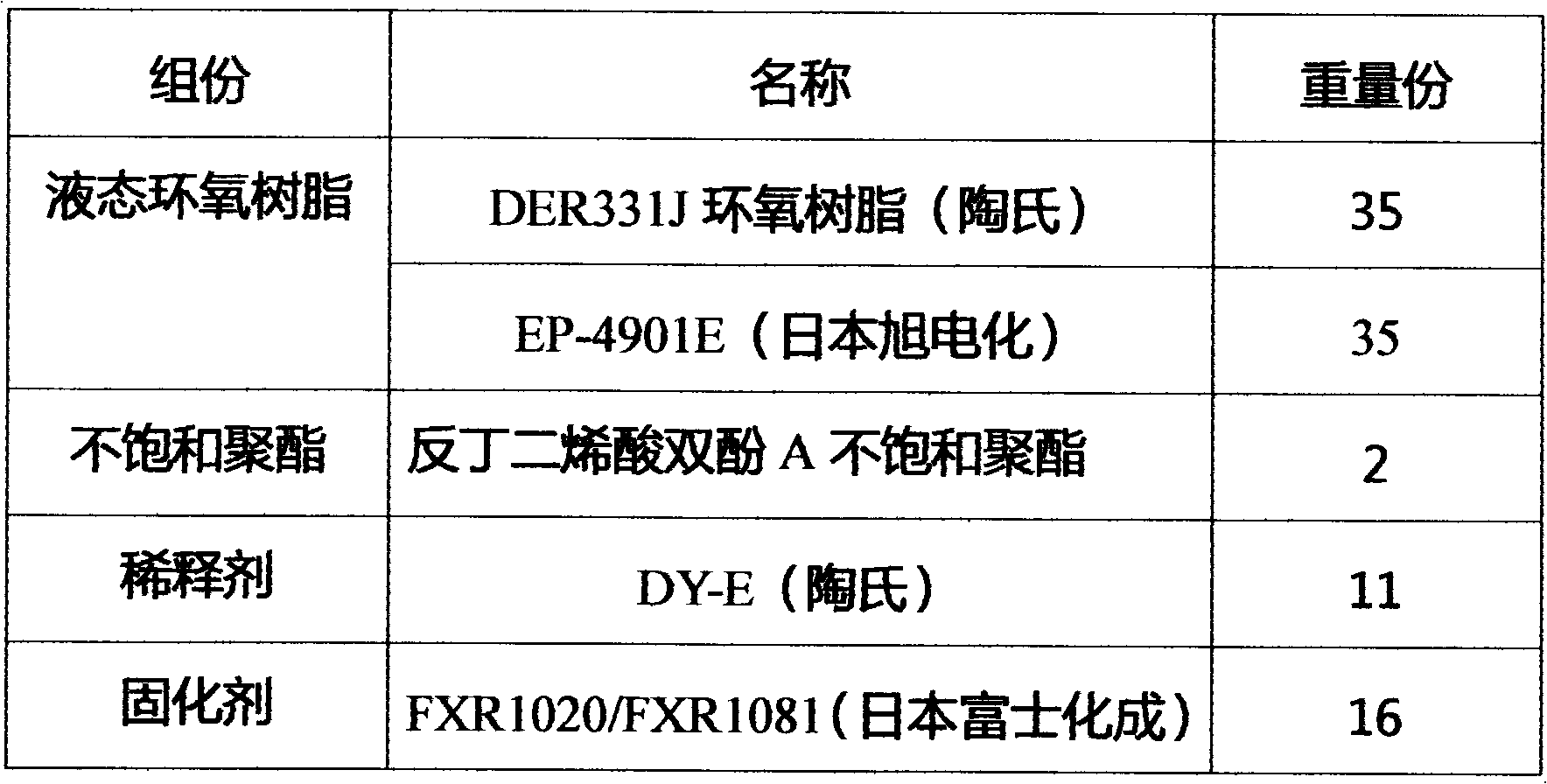

InactiveCN102732199BImprove work efficiencyWide range of usesOther chemical processesEpoxy resin adhesivesEpoxyPolyester

The present invention discloses a rapid permeation bottom underfill and a preparation method thereof. The underfill comprises, by weight, 2-10% of an unsaturated polyester, 20-80% of a liquid epoxy resin, 0-20% of a diluent agent, 5-20% of a curing agent, 0-5% of a coupling agent and 0-3% of a pigment. The preparation method comprises: carrying out a mixing pretreatment on the liquid epoxy resin and the unsaturated polyester, heating to a temperature of 80-100 DEG C, stirring for 1.5-2.5 hours, cooling to the temperature of 15-30 DEG C, adding the curing agent, stirring for 1 hour at the temperature of 15-30 DEG C, adding the diluent agent, the coupling agent and the pigment, and stirring for 1 hour at the temperature of 15-30 DEG C. The product of the present invention can rapidly and completely permeate under the high viscosity condition, no residue exists on the position of underfill applying, the underfill liquids on four edges of the chip present uniform and best fillets, and the production efficiency and the impact resistance are improved.

Owner:HB FULLER CO

One-component flexible epoxy adhesive and preparation method thereof

ActiveCN105331316BGood flexibilityImprove performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesLiquid stateFlexible electronics

The invention relates to a one-component flexible electronic adhesive and a preparation method thereof. The adhesive is characterized by being prepared from raw materials in parts by weight as follows: 20-50 parts of liquid-state self-made modified epoxy resin, 15-40 parts of a curing agent, 20-40 parts of filler, 0-3 parts of a viscosity regulator, 0.2-1 part of a stabilizer and 2-15 parts of an accelerator, wherein the curing agent adopts a sulfhydryl compound; the accelerator adopts an amine accelerator, an amine derivative accelerator or an imidazole accelerator; the liquid-state self-made modified epoxy resin adopts one or a mixture of bisphenol A epoxy resin, bisphenol F epoxy resin and phenol-formaldehyde resin and is prepared through the following steps: liquid-state epoxy resin and the curing agent are mixed and stirred in the ratio being 85:15, the temperature is controlled to be 75-80 DEG C, the accelerator is added during stirring, stirring is continued for 2 h after complete impregnation, and the temperature is controlled to be 75-80 DEG C; a product is cooled to 15-30 DEG C for standby application. A synthetic reaction process is simple and easy to operate, the cost is low, and the product has stable performance and wide application.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

A kind of hybrid curable resin and its synthesis method

The invention provides a synthetic method of a hybrid curable resin, comprising: polyisoprene diol 80-110g, 3-ethyl-3-oxetanemethanol 4-10g, hydroxyacrylate 5- 12g, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate were added in a three-necked flask with a thermometer, and the temperature was raised to 65 degrees, and 18-32g of diisocyanate was started to be added dropwise, and the temperature was controlled at 70 ‑75 degrees, reaction 2‑3h. Use an infrared spectrometer to analyze the content of the NCO group. When the peak of the NCO completely disappears, stop the heating reaction to obtain an oxetane-modified polyurethane acrylate resin. The resin of the present invention can be used to produce three-dimensional products with low shrinkage, low warpage, good flexibility, aging resistance, high processing accuracy, and excellent photocurability and excellent mechanical strength; in addition, the synthetic reaction process Simple, easy to control, no need to use special equipment, no solvent, low production cost.

Owner:YANTAI DARBOND TECH

Preparation of silver-copper powder electric conduction material

InactiveCN106854445AThe synthesis reaction process is simpleEasy to controlNon-macromolecular adhesive additivesEpoxy resin adhesivesTriethoxysilaneRoom temperature

The present invention relates to preparation of a silver-copper powder electric conduction material. The preparation comprises: mixing 15-25 parts of a bisphenol F type epoxy resin and 20 parts of neopentyl glycol glycidyl ether for 10-30 min to achieve a uniform state, adding 10 parts of diamino diphenyl methane and 8 parts of 3-aminopropyltriethoxysilane, mixing for 10-30 min at a room temperature to obtain a uniform mixture, grinding through a three-roller machine, adding 3-5 parts of silver plating copper powder and 5 parts of silver plating nickel powder, applying vacuum at a room temperature, and carrying out low speed mixing for 1-3 h so as to prepare the silver-copper powder electric conduction material.

Owner:烟台鑫海耐磨胶业有限公司

A kind of petroleum sulfonic acid sodium salt composition and its preparation method and application

The invention provides a petroleum sulfonic acid sodium salt composition, a preparation method and application thereof. The preparation method comprises taking the total weight of the mixture as 100%, 5wt%-95wt% fraction 1 with an average molecular weight of 252-312, 5wt%-95wt% fraction 2 with an average molecular weight of 313-395 and 0-50wt% % average molecular weight is that fraction 3 of 396-490 is mixed homogeneously, obtains mixture; Add diluent in mixture, obtain the product after dilution, adopt SO 3 The gas is subjected to sulfonation treatment on the diluted product to obtain a product after sulfonation treatment; wherein, the diluent includes one or a combination of alcohols with a carbon chain length of C3-C10, and the amount is the weight of the mixture 0.1%-10% of 0.1%-10%; and then use sodium hydroxide aqueous solution to neutralize the petroleum sulfonic acid in the product after sulfonation treatment until the pH value of the system is 7-10 to obtain the petroleum sulfonic acid sodium salt composition.

Owner:PETROCHINA CO LTD

A kind of hydrolyzable ultraviolet curable glue and preparation method thereof

InactiveCN102807835BLiquidityLow shrinkagePolyureas/polyurethane adhesivesPolyether adhesivesPolymer scienceAdhesive

The invention relates to the technical field of ultraviolet curing adhesive, in particular to a hydrolysable ultraviolet curing adhesive and a method for preparing the same. The curing adhesive comprises the following components in part by weight: 30 to 70 parts of prepolymer, 15 to 60 parts of reactive diluent, 0 to 10 parts of coupling agent, 1 to 10 parts of photoinitiator and 0.1 to 2.5 parts of auxiliary agent, wherein the prepolymer has a unique structural formula. The preparation method comprises the following steps of: performing vacuum dehydration on the reactive diluent at the temperature of between 110 and 120 DEG C for 1 to 2 hours; cooling the reactive diluents; adding the prepolymer, the coupling agent and the photoinitiator into the reactive diluents when the temperature is reduced to the room temperature; stirring the mixture for dissolution; and finally adding the auxiliary agent. The ultraviolet curing adhesive is high in fluidity, easy to coat and quick in curing, the curing matters have the characteristics of hardness, crispness and low shrinkage ratio, and the curing adhesive is suitable for mechanical processing; and the curing adhesive is high in water adsorption, susceptible to peptization in water, low in cost and wide in application range. The preparation method is characterized by simple synthetic reaction process, and is easy to operate.

Owner:HB FULLER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com