Light-cured resin with low water absorption and preparation method thereof

A light-curing resin, low water absorption technology, applied in the field of light-curing materials, can solve the problems of poor product compatibility, poor control of the reaction, small molecular weight of the product, etc., and achieves a structure with regular structure, easy control and narrow molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

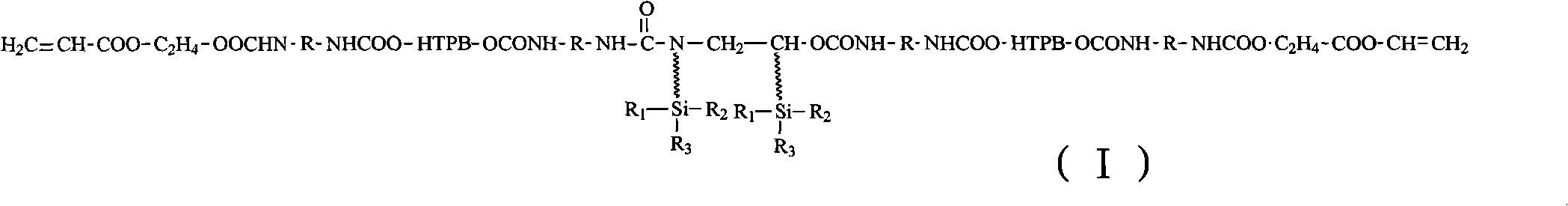

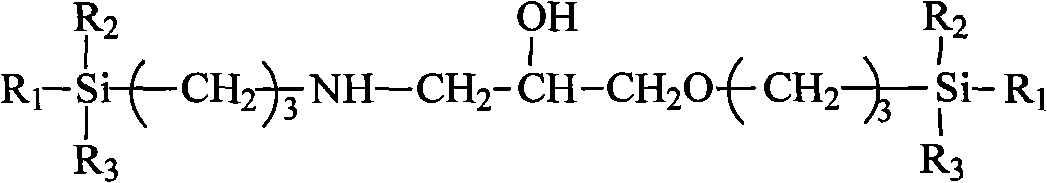

[0030] Weigh 10g of γ-aminopropyltriethoxysilane (KH-550) and add it to 11g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560) in a three-necked flask, mix well Then heat up to 70°C and react for 2 hours to obtain a modified silane chain extender containing secondary amino and hydroxyl functional groups, whose structural formula is:

[0031]

[0032] Among them, R 1 , R 2 , R 3 stands for CH 3 -, C 2 h 5 O- or CH 3 O-;

[0033] Vacuumize 100g of HTPB at 110°C (vacuum degree ≤ -0.08MPa) for 2 hours to remove the doped water; then cool down to 50°C, add 28.5g of TDI, and heat up to 85°C for 2 hours after the temperature is constant , and stop heating until the NCO content reaches the design value, that is, a polyurethane prepolymer with NCO groups at both ends is obtained, and its structural formula is: ,

[0034] Wherein, R represents toluene diisocyanate;

[0035] After mixing 100g of polyurethane prepolymer 1 and 5.6g of modified silane chain extender, react...

Embodiment 2

[0041]Weigh 10g of γ-aminopropyltriethoxysilane (KH-550) and add it to 11g of γ-(2,3-epoxypropoxy)propylmethyldimethoxysilane (WD-61) in a three-necked flask , after mixing evenly, heat up to 50°C and react for 3 hours to obtain a modified silane chain extender containing secondary amino and hydroxyl functional groups, which is the same as in Example 1;

[0042] Vacuumize 100g of HTPB at 100°C (vacuum degree ≤ -0.08MPa) for 3 hours to remove the doped water; then cool down to 60°C, add 24g of IPDI, and heat up to 80°C for 3 hours after the temperature is constant. Stop heating until the NCO content reaches the design value, and obtain polyurethane prepolymer 1 with NCO groups at both ends. Its structural formula is the same as that of Example 1, and R represents isophorone diisocyanate.

[0043] Mix 100g of polyurethane prepolymer 1 and 4.6g of modified silane chain extender, and react at 70°C for 3 hours to obtain polyurethane prepolymer 2 with NCO groups at both ends. Its st...

Embodiment 3

[0046] Weigh 10g of γ-aminopropylmethyldiethoxysilane (WD-57) and add it to 10g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560) in a three-necked flask, After mixing evenly, heat up to 90°C and react for 1 hour to obtain a modified silane chain extender containing secondary amino and hydroxyl functional groups, which is the same as in Example 1;

[0047] Vacuumize 100g of HTPB at 115°C (vacuum degree ≤ -0.08MPa) for 1.5 hours to remove the doped water; then cool down to 40°C, add 31g of MDI, and heat up to 90°C for 1 hour after the temperature is constant. Stop heating until the NCO content reaches the design value, and obtain polyurethane prepolymer 1 with NCO groups at both ends. Its structural formula is the same as that of Example 1, and R represents diphenylmethane diisocyanate.

[0048] After mixing 100g of polyurethane prepolymer 1 and 4.9g of modified silane chain extender, react at 90°C for 1 hour to obtain polyurethane prepolymer 2 with NCO groups at both ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com