Single-component shock-resistant low-viscosity structural adhesive and preparation method thereof

An impact-resistant, low-viscosity technology, used in the field of structural adhesives, can solve the problems of high brittleness and high adhesive viscosity, and achieve the effect of reducing viscosity, low viscosity, and improving flexibility and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

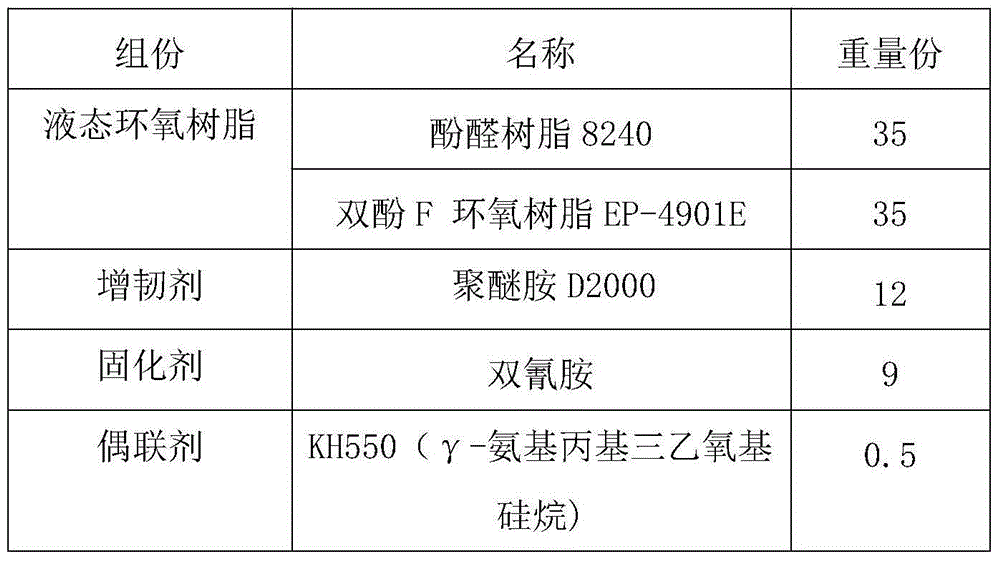

[0020] Example 1: Prepare a one-component impact-resistant low-viscosity structural adhesive according to the following table and the following steps.

[0021] (1) Mix 35g of phenolic resin, 30g of bisphenol F resin EP-4901E, and 18g of toughening agent polyetheramine D2000, stir for 1 hour, and control the temperature at 15°C-30°C.

[0022] (2) Add 9g of dicyandiamide curing agent while stirring, continue stirring for 1 hour after adding, and control the temperature at 15°C-30°C.

[0023] (3) Add 7g of benzyl dimethyl urea accelerator while stirring, stir for 0.5h, and control the temperature at 15°C-30°C.

[0024] (4) Add 8g of 1,6-hexanediol diglycidyl ether diluent, 0.5g of KH550 (γ-aminopropyltriethoxysilane) coupling agent and 0.5g of titanium dioxide to obtain an impact-resistant low-viscosity structural adhesive.

[0025]

[0026]

Embodiment 2

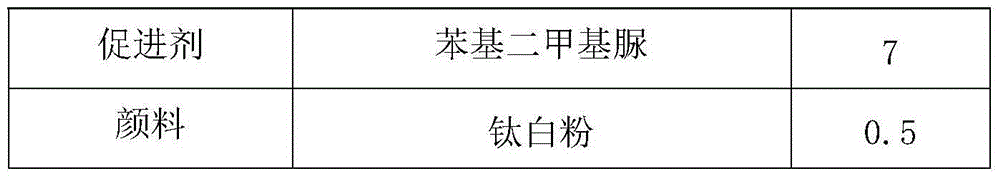

[0027] Example 2: Prepare a one-component impact-resistant low-viscosity structural adhesive according to the following table and steps.

[0028] (1) Mix 40g of bisphenol A epoxy resin EPON828, 10g of bisphenol F resin EP-4901E, and 20g of toughening agent polyetheramine D400, stir for 1 hour, and control the temperature at 15°C-30°C.

[0029] (2) Add 9g of dicyandiamide curing agent while stirring, continue stirring for 1 hour after adding, and control the temperature at 15°C-30°C.

[0030] (3) Add 8g of Fuji Chemical 1020 latent amine accelerator while stirring, stir for 0.5h, and control the temperature at 15°C-30°C.

[0031] (4) Add 0.5g KH560 (glycidoxytrimethoxysilane) coupling agent and 0.5g titanium dioxide to obtain impact-resistant low-viscosity structural adhesive.

[0032]

Embodiment 3

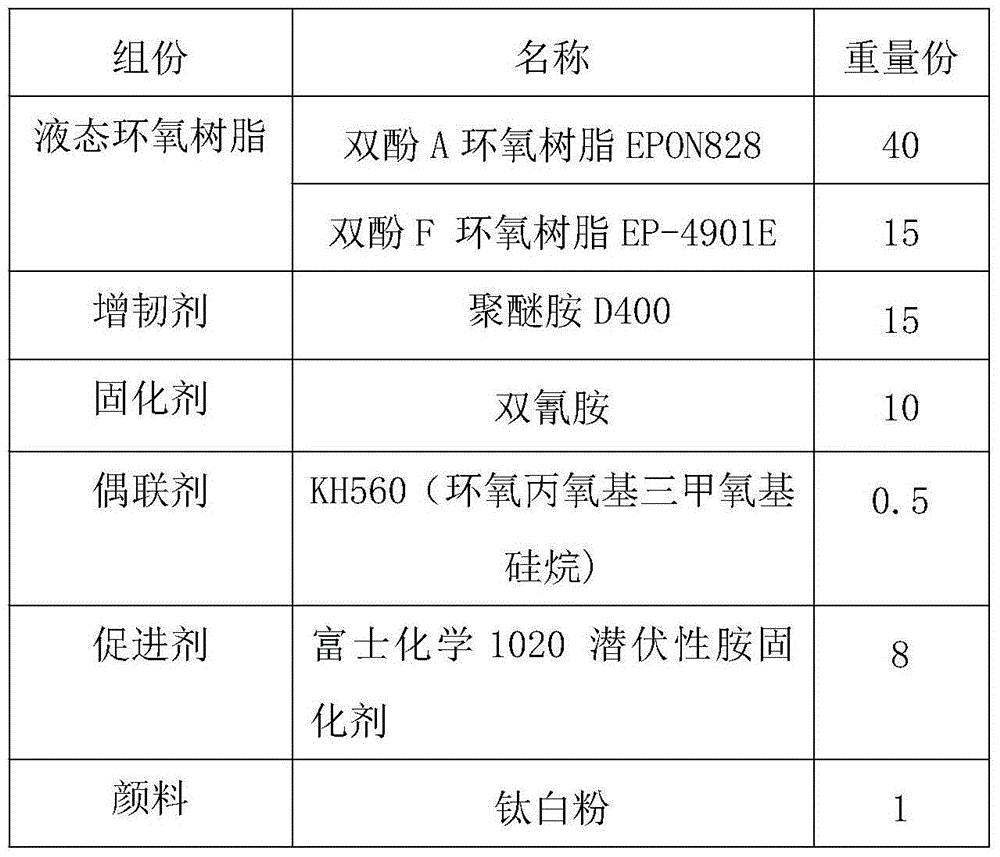

[0033] Embodiment 3: Prepare a one-component impact-resistant low-viscosity structural adhesive according to the ratio in the table below and the steps in Embodiment 1.

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com