One-component flexible epoxy adhesive and preparation method thereof

An epoxy adhesive, one-component technology, applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of high brittleness of epoxy adhesive, high price, high viscosity of toughening resin, etc., to achieve Low cost, stable product performance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

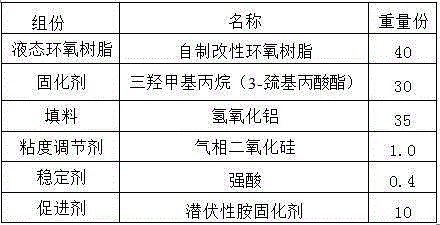

[0024] Embodiment 1: Prepare a one-component flexible epoxy curing agent according to the following table and the following steps.

[0025] (1) Mix 40 parts of self-made modified epoxy resin and 0.4 parts of stabilizer, stir for 1 hour, and control the temperature at 15-30°C

[0026] (2) Add 30 parts of mercapto compound, stir for 1 hour, and control the temperature at 15-30°C

[0027] (3) Add filler and viscosity regulator, stir for 30 minutes respectively, and control the temperature at 15-30°C

[0028] (4) Add stabilizer, continue to stir for 0.5 hours until the mixture is uniform, and control the temperature at 15-30°C

[0029] (5) Add 8 parts of accelerator while stirring, continue to stir for 0.5 hours until the mixture is uniform, and control the temperature at 15-30°C;

[0030]

Embodiment 2

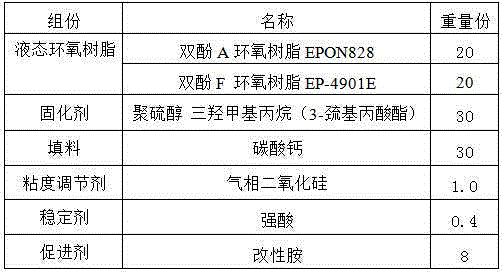

[0031] Embodiment 2: Prepare a one-component flexible epoxy adhesive according to the ratio in the table below and the steps in Embodiment 1.

[0032]

Embodiment 3

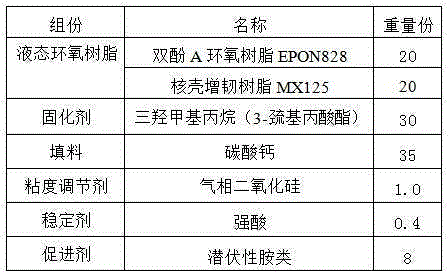

[0033] Embodiment 3: Prepare a one-component flexible epoxy adhesive according to the ratio in the table below and the steps in Embodiment 1.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com