Preparation method of conductive adhesive with high thermal conductivity and used for high-power LED package

A technology of LED packaging and high thermal conductivity, applied in the direction of conductive adhesives, adhesives, adhesive additives, etc., can solve the problems of poor electrical conductivity, low thermal conductivity of adhesives, high bonding strength, etc., and achieve good compatibility , low cost, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

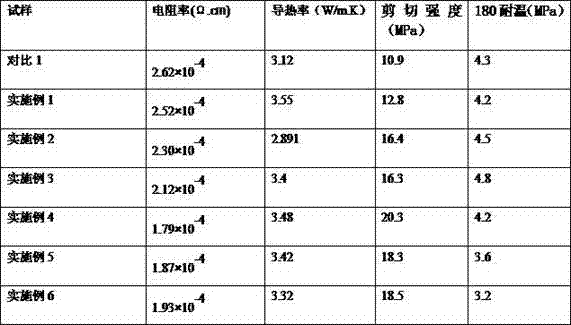

Examples

Embodiment 1

[0040] Add 5 parts of 3,4-epoxy cyclohexyl carboxylate, 30 parts of bisphenol A epoxy resin, and 4 parts of core-shell toughening agent Kane Ace@MX-125 into the double planetary dynamic mixing kettle in turn, and start the revolution Stirring and high-speed dispersion, at a temperature of 25°C, stir for 1 hour, add 5 parts of self-made functionalized graphene material, stir for 1 hour, add 45.5 parts of conductive silver powder, stir for 30 minutes, add 10 parts of Adico latent curing agent EH-4360S , stirred for 1 hour, added 0.5 parts of fumed silica, stirred for 1 hour, turned on the vacuum pump to vacuum for 1 hour, and the vacuum pressure was 0.0988MPa, and the high thermal conductivity conductive adhesive for high-power LED packaging was obtained. The revolution stirring speed is 20r / min, high-speed dispersion speed is 800r / min.

[0041] The self-made functionalized graphene material is carried out according to the following steps:

[0042] 1) Preparation of flake graphen...

Embodiment 2

[0051] Add 5 parts of 3,4-epoxy cyclohexyl carboxylate, 30 parts of bisphenol A epoxy resin, and 4 parts of core-shell toughening agent Kane Ace@MX-125 into the double planetary dynamic mixing kettle in turn, and start the revolution Stirring and high-speed dispersion, at a temperature of 25°C, stir for 1 hour, add 6 parts of self-made functionalized graphene material, stir for 1 hour, add 44.5 parts of conductive silver powder, stir for 30 minutes, add 10 parts of Adico latent curing agent EH-4360S , stirred for 1 hour, added 0.5 parts of fumed silica, stirred for 1 hour, turned on the vacuum pump to evacuate for 1 hour, and the vacuum pressure was 0.0988 MPa to obtain a high thermal conductivity conductive adhesive for high-power LED packaging; the revolution stirring speed is 20r / min, high-speed dispersion speed is 800r / min.

[0052] The self-made functionalized graphene material is carried out according to the following steps:

Embodiment 3

[0062] Add 5 parts of 3,4-epoxycyclohexyl carboxylate, 30 parts of bisphenol A epoxy resin, and 4 parts of core-shell toughening agent Kane Ace@MX-125 into the double planetary dynamic mixing kettle in sequence, and start Revolutionary stirring and high-speed dispersion, at a temperature of 25°C, stir for 1 hour, add 7 parts of self-made functionalized graphene material, stir for 1 hour, add 43.5 parts of conductive silver powder, stir for 30 minutes, add Adico latent curing agent EH-4360S 10 part, stirred for 1 hour, added 0.5 part of fumed silicon dioxide, stirred for 1 hour, turned on the vacuum pump to evacuate for 1 hour, and the vacuum pressure was 0.0988MPa, and the high thermal conductivity conductive adhesive used for high-power LED packaging was obtained; the revolution stirring speed The speed is 20r / min, and the high-speed dispersion speed is 800r / min.

[0063] The self-made functionalized graphene material is carried out according to the following steps:

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com