Ultraviolet (UV)-moisture double-curing liquid optical transparent adhesive and preparation method thereof

An optically clear adhesive, dual-curing technology, used in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve problems such as poor curing of glue, and achieve a wide range of products with good transparency and curing shrinkage. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

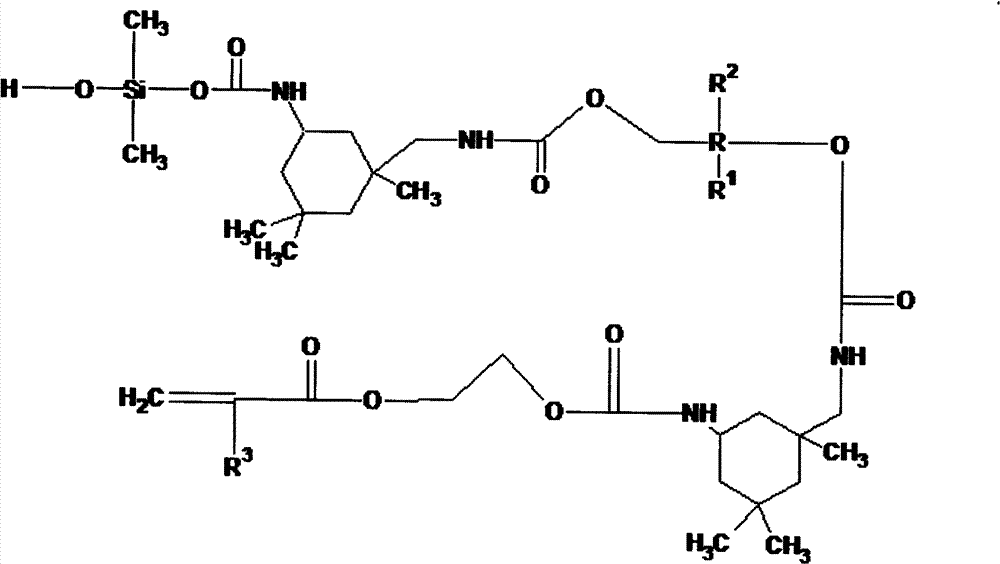

[0028] Preparation of prepolymer A: Weigh 65g of hydroxyethyl methacrylate and put it in a three-necked flask, raise the temperature to 110°C for 2 hours of vacuum dehydration, then lower it to 35°C, add 116.6g of 3-isocyanate methylene-3, 5 , 5-trimethylcyclohexyl isocyanate (IPDI), heated to 70 degrees for 2 hours to obtain a polyurethane prepolymer.

[0029] Weigh 200g of hydroxyalkyl silicone oil with a viscosity of 4000 and place it in a three-necked flask, raise the temperature to 110°C for 2 hours, vacuumize and dehydrate it, then lower it to 40°C, add 18.2g of polyurethane prepolymer, stir well, and heat to 85°C for 2 hours , to obtain polyurethane prepolymer II.

[0030] Add 11.7 g of isocyanate methylene-3,5,5-trimethylcyclohexyl isocyanate (IPDI) to 218.2 g of polyurethane prepolymer II, stir evenly, and react at 75°C for 3 hours to obtain polyurethane acrylate III.

[0031] Weigh 200g of hydroxyl silicone oil with a viscosity of 4000 and place it in a three-necked...

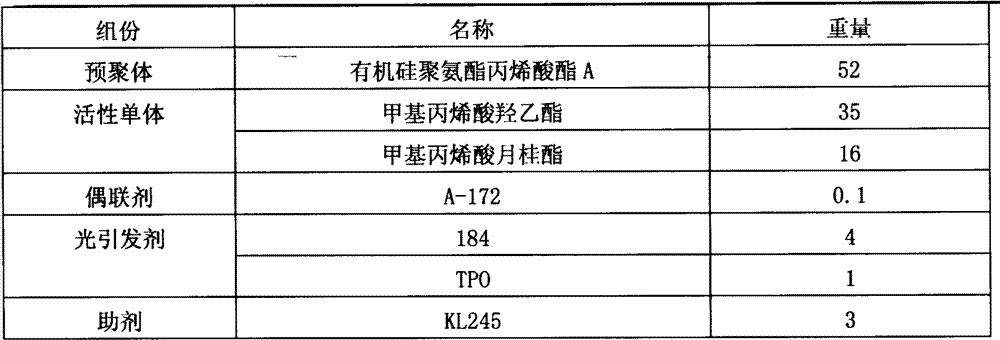

Embodiment 1

[0041] Embodiment 1: prepare UV adhesive according to the following table proportioning. Take 35g of hydroxyethyl methacrylate and 16g of lauryl methacrylate in a three-necked flask, raise the temperature to 115°C and vacuum dehydrate for 2 hours, cool down to room temperature, add 52g of silicone urethane acrylate A, 2g of coupling agent A-172 , 4g of photoinitiator 184 and 1g of TPO were stirred to dissolve, and finally 0.1g of substrate wetting agent KL-245 was added and stirred evenly to obtain a silicone urethane acrylate UV adhesive.

[0042]

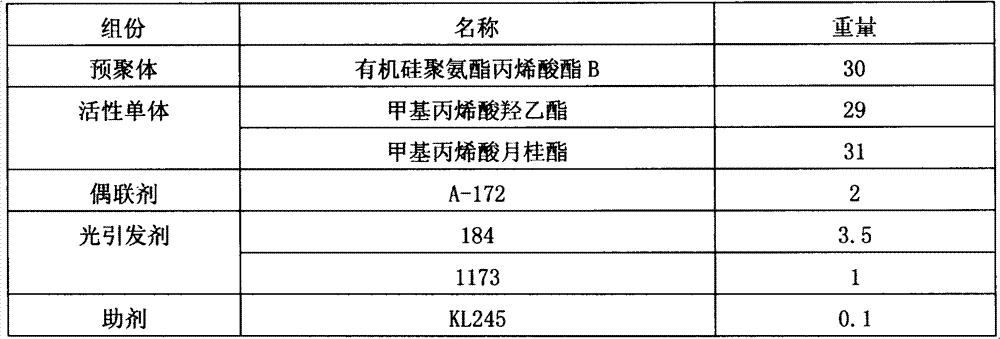

Embodiment 2

[0043] Embodiment 2: Prepare silicone polyurethane acrylate UV adhesive according to the ratio in the following table. Preparation method is with embodiment 1.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com