Polyfunctional castor oil-based photo-cured resin as well as preparation method and application thereof

A light-curing resin, castor oil-based technology, used in applications, inks, household appliances, etc., can solve the problems of UV resin dependence and low hydrophobicity, and achieve the effects of improved curing efficiency, improved comprehensive performance, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

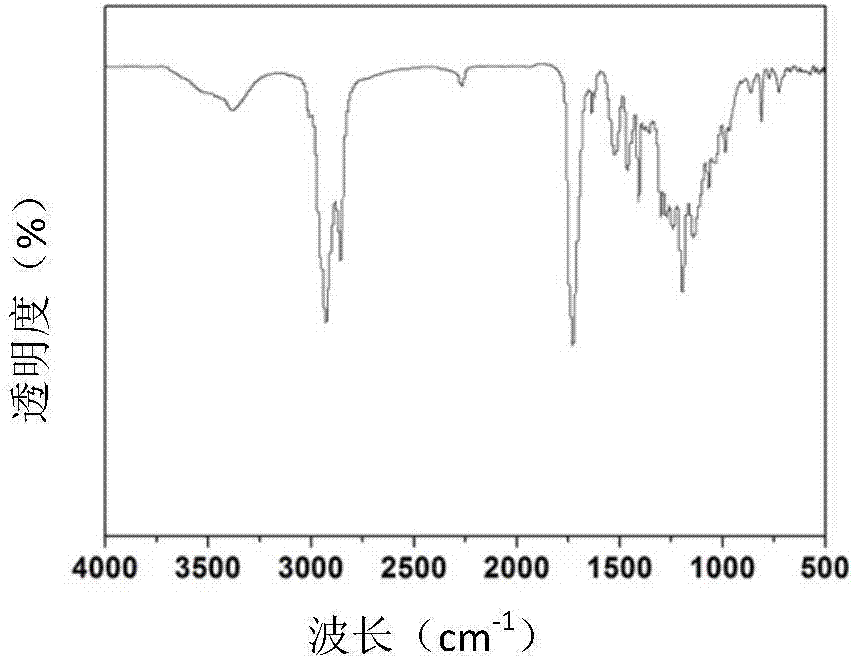

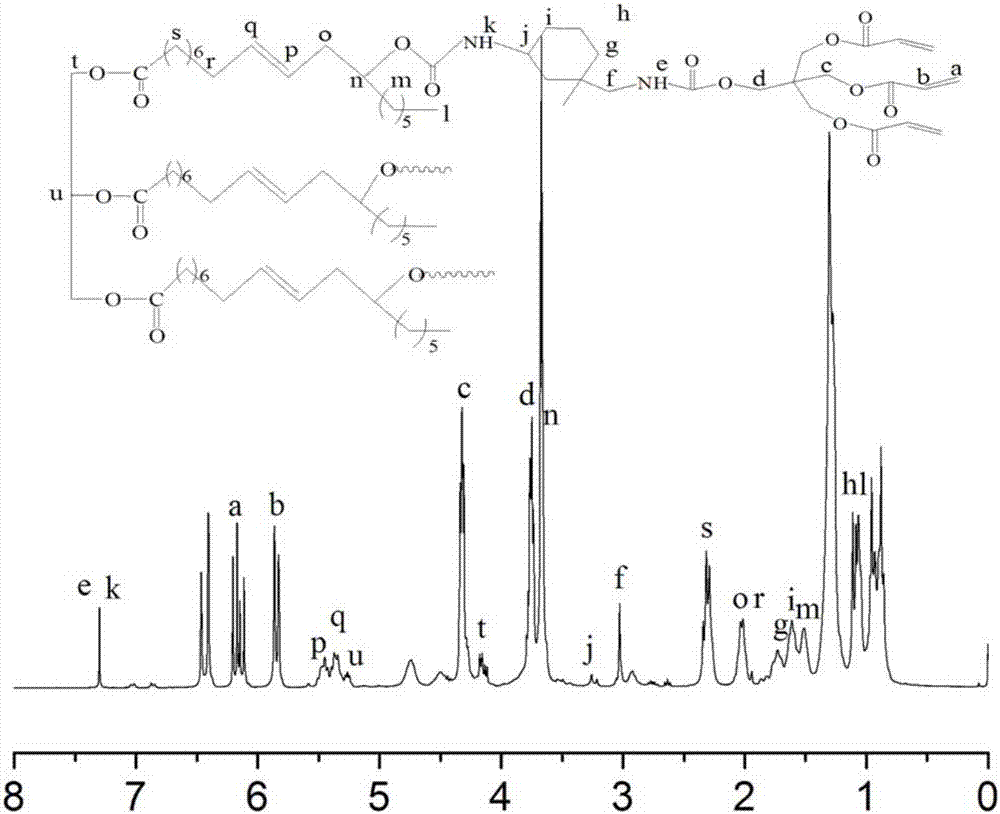

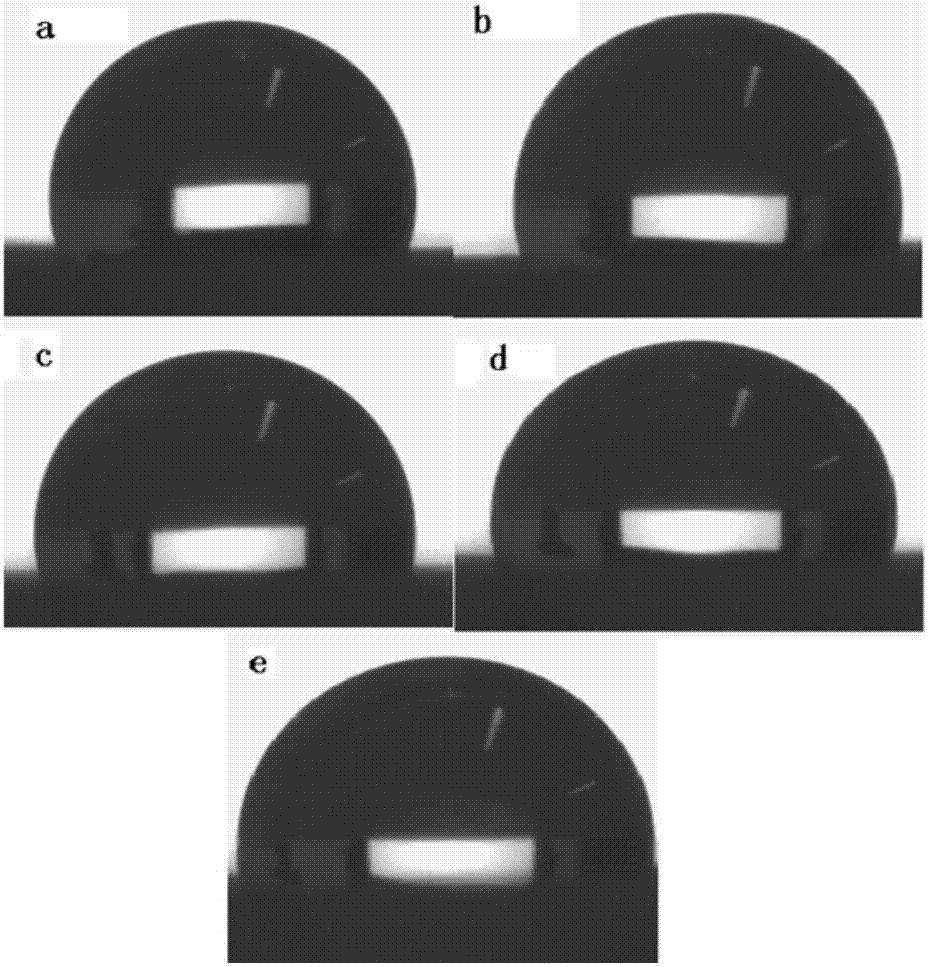

Method used

Image

Examples

Embodiment 1

[0022] (1) In the presence of the solvent n-hexane, using isocyanate and pentaerythritol triacrylate as raw materials (the molar ratio of isocyanate and acrylate is 0.8:1), add catalyst dibutyltin dilaurate (the total mass of reactants 2%) and the polymerization inhibitor p-hydroxyanisole (1% of the total mass of the reactants), under the protection of nitrogen, react at 30°C for 4 hours until the NCO content reaches 7%, and the isocyanate semi-blocked intermediate is obtained;

[0023] (2) React the semi-blocked isocyanate intermediate obtained in step (1) with castor oil (the molar ratio of materials is 0.9:1), the temperature is 40°C, and the reaction time is 10 hours until the NCO content is lower than 0.5%, to obtain polyurethane Acrylate prepolymer, solvent removed by rotary evaporation.

[0024] (3) Mix the urethane acrylate prepolymer with the photoinitiator 2-hydroxy-2-methylpropiophenone and the diluent hydroxyethyl acrylate in a ratio of 78%: 2%: 20% by mass fractio...

Embodiment 2

[0026] (1) In the absence of solvent, using isocyanate and pentaerythritol triacrylate as raw materials (the molar ratio of isocyanate and acrylate is 0.9:1), add catalyst dibutyltin dilaurate (2% of the total mass of reactants %) and polymerization inhibitor p-methoxyphenol (1.5% of the total mass of the reactants), under nitrogen protection, react at 20°C for 5 hours until the NCO content reaches 6.5%, and the isocyanate semi-blocked intermediate is obtained;

[0027] (2) React the semi-blocked isocyanate intermediate obtained in step (1) with castor oil (the molar ratio of materials is 0.9:1), the temperature is 50°C, and the reaction time is 8 hours until the NCO content is lower than 0.5%, to obtain polyurethane Acrylate prepolymer;

[0028] (3) Mix the urethane acrylate prepolymer with the photoinitiator 2-hydroxy-2-methylpropiophenone and the diluent hydroxyethyl methacrylate at a mass fraction of 83%: 2%: 15%, and stir thoroughly After ultrasonic dispersion for 30 min...

Embodiment 3

[0030] (1) Under the condition of n-butyl ketone as solvent, isocyanate and pentaerythritol triacrylate are used as raw materials (the molar ratio of isocyanate and acrylate is 0.7:1), and the catalyst dibutyltin dilaurate (total mass of reactants 3%) and the polymerization inhibitor hydroquinone (2% of the total mass of the reactants), under the protection of nitrogen, react at 20°C for about 7 hours until the NCO content reaches 7.8%, and the isocyanate semi-blocked intermediate is obtained;

[0031] (2) React the semi-blocked isocyanate intermediate obtained in step (1) with castor oil (the molar ratio of materials is 0.9:1), the temperature is 40°C, and the reaction time is 5 hours, until the NCO content is lower than 0.5%, and polyurethane is obtained Acrylate prepolymer;

[0032] (3) Mix the urethane acrylate prepolymer with the photoinitiator 2-hydroxy-2-methylpropiophenone and the diluent triethylene glycol diacrylate at a mass fraction of 78%: 2%: 20% , fully stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com