Grain size controllable monodisperse polyvinyl alcohol gel microsphere, preparation method thereof

A technology of polyvinyl alcohol gel microspheres and polyvinyl alcohol gel, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of wide particle size distribution, difficulty, and difficulty in obtaining monodisperse microspheres with uniform size. and other issues to achieve the effect of broadening applications, short time consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 0.5g of borax to the mixture of 10mL of isoamyl alcohol and 5mL of triethanolamine, magnetically stir and slowly heat to 60°C to dissolve it, and prepare a coagulation bath solution.

[0040] Add 1.0g of polyvinyl alcohol into a beaker containing 12.5mL of deionized water, stir magnetically and slowly heat to 90°C to dissolve it to obtain a dispersed phase solution; mix 30mL of silicone oil and 20mL of isooctyl alcohol evenly to obtain a continuous phase solution.

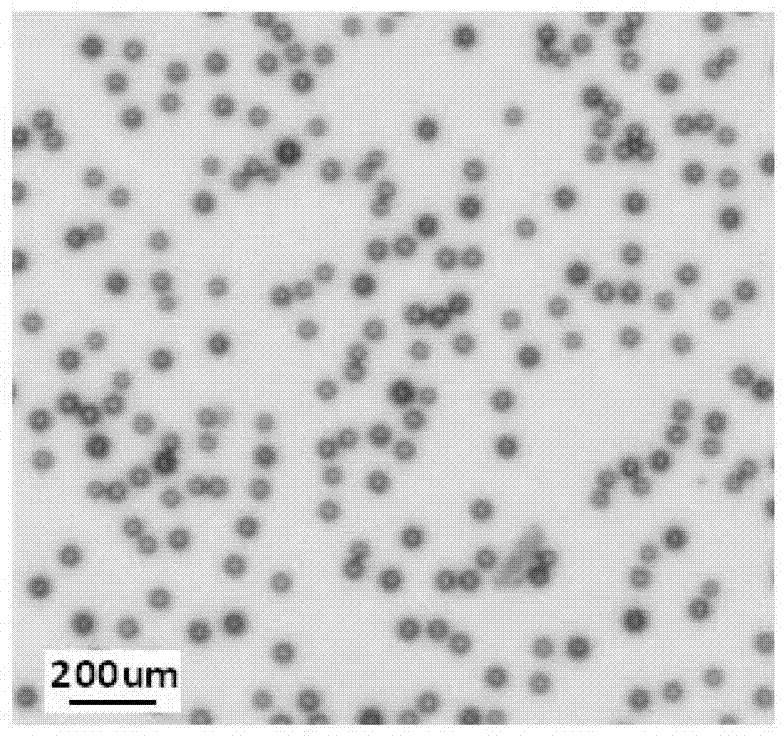

[0041] Put the above-mentioned dispersed phase solution and continuous phase solution into 1mL and 50mL syringes respectively, place them on two propulsion pumps, connect the microfluidic controller, and set the flow rate of the dispersed phase to 26mm min -1 , the viscosity is 160mPa·s, the continuous phase flow rate is 200mm·min -1 , viscosity 540mPa s, capillary size: outer diameter / inner diameter 165 / 98μm, turn on the microfluidic control device, and prepare monodisperse polyvinyl alcohol solution d...

Embodiment 2

[0043] Add 0.5g of borax to the mixture of 10mL of isoamyl alcohol and 5mL of triethanolamine, magnetically stir and slowly heat to 60°C to dissolve it, and prepare a coagulation bath solution.

[0044] Add 1.0g of polyvinyl alcohol into a beaker containing 12.5mL of deionized water, stir magnetically and slowly heat to 90°C to dissolve it to obtain a dispersed phase solution; mix 30mL of silicone oil and 20mL of isooctyl alcohol evenly to obtain a continuous phase solution.

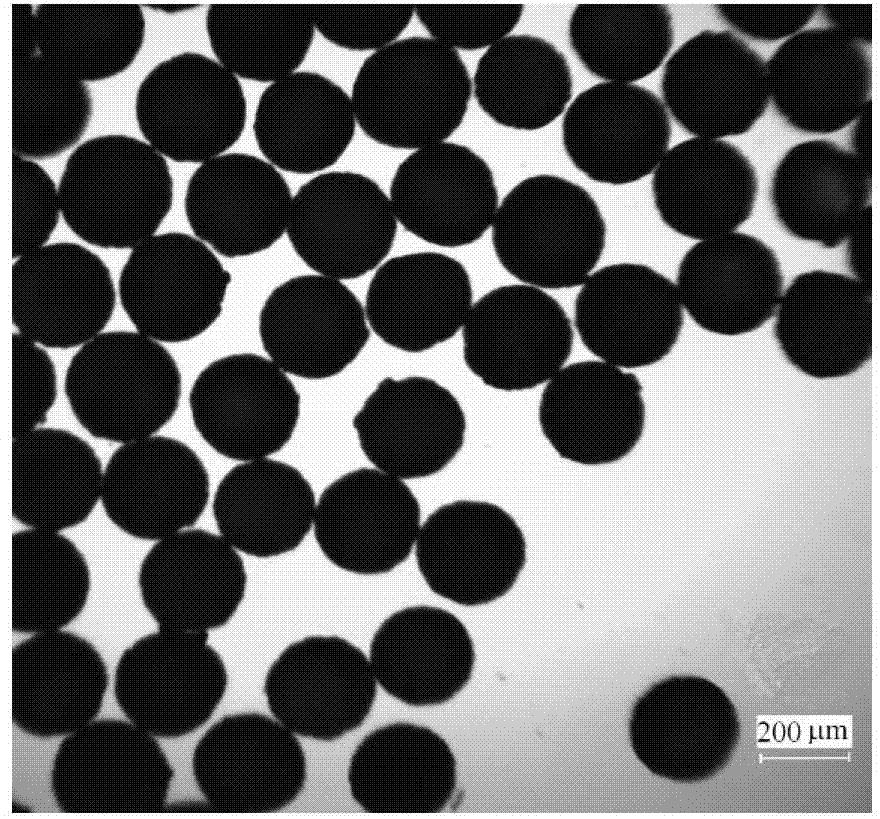

[0045] Put the above-mentioned dispersed phase solution and continuous phase solution into 1mL and 50mL syringes respectively, place them on two propulsion pumps, connect the microchannel reactor, and set the flow rate of the dispersed phase to 72mm min -1 , the viscosity is 160mPa·s, and the flow rate of the continuous phase is 127mm·min -1 , viscosity 540mPa s, capillary size: outer diameter / inner diameter 245 / 98μm, turn on the microfluidic control device, prepare monodisperse polyvinyl alcohol soluti...

Embodiment 3

[0047] Add 0.5g of borax to the mixture of 10mL of isoamyl alcohol and 5mL of triethanolamine, magnetically stir and slowly heat to 60°C to dissolve it, and prepare a coagulation bath solution.

[0048] Add 1.0g of polyvinyl alcohol into a beaker containing 12.5mL of deionized water, stir magnetically and slowly heat to 90°C to dissolve it to obtain a dispersed phase solution; mix 30mL of silicone oil and 20mL of isooctyl alcohol evenly to obtain a continuous phase solution.

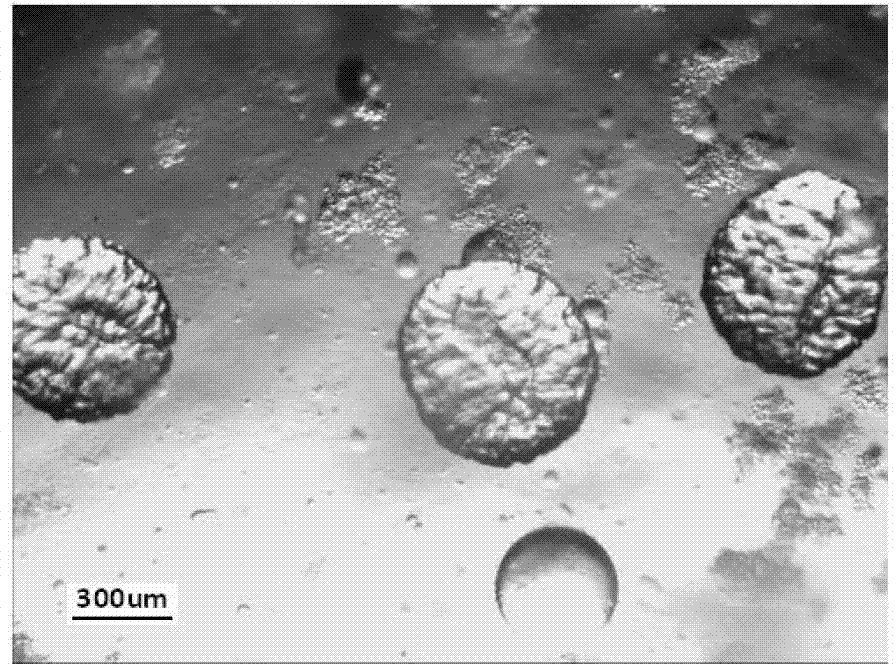

[0049] Put the above-mentioned dispersed phase solution and continuous phase solution into 1mL and 50mL syringes respectively, place them on two propulsion pumps, connect the microchannel reactor, and set the flow rate of the dispersed phase to 264mm min -1 , the viscosity is 160mPa·s, and the flow rate of the continuous phase is 46mm·min -1 , viscosity 540mPa s, capillary size: outer diameter / inner diameter 360 / 225μm, turn on the microfluidic control device, prepare monodisperse polyvinyl alcohol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com