Production process of electrodeposited copper foil with shiny surface subjected to roughening

A technology of electrolytic copper foil and production process, which is applied in the field of preparation of high-precision electrolytic copper foil, can solve the problems such as the unsatisfactory peeling resistance of electrolytic copper foil, improve the peeling resistance and corrosion resistance, improve the peeling strength, improve The effect of surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

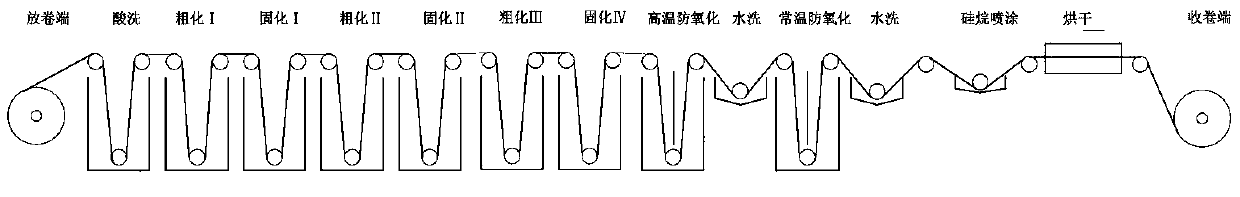

[0022] Such as figure 1 As shown, a production process of smooth surface roughened electrolytic copper foil, the 18μm copper foil with smooth surface roughness Rz of 1.62μm is pickled, roughened Ⅰ, cured Ⅰ, roughened Ⅱ, cured Ⅱ, cured Ⅲ in sequence , Curing Ⅳ, high temperature anti-oxidation, water washing Ⅰ, room temperature anti-oxidation, water washing Ⅱ, silane spraying and drying and other processes. The vehicle speed is 22m / min.

[0023] Among them, the pickling process conditions: temperature 30~40 ℃, sulfuric acid (H 2 SO 4 ) concentration of 100~170g / l, copper ion (Cu 2+ ) Concentration 25~45g / l.

[0024] Coarsening I and II process conditions: current density 28~33A / dm 2 , temperature 25~35℃, sulfuric acid (H 2 SO 4 ) concentration of 160~180g / l, copper ion (Cu 2+ ) concentration of 7~13g / l, chloride ion (Cl 2- ) concentration 15~30mg / l, sodium tungstate (Na 2 WO 4 2H 2 O) 0~90mg / l, sodium molybdate (Na 2 MoO 4 2H 2 O) 0~70mg / l and cobalt sulfate (CoSO...

Embodiment 2

[0032] A production process for roughening electrolytic copper foil on a smooth surface. The 18 μm copper foil with a smooth surface roughness Rz of 1.53 μm is pickled, roughened Ⅰ, cured Ⅰ, roughened Ⅱ, cured Ⅱ, cured Ⅲ, and cured Ⅳ in sequence. , high temperature anti-oxidation, water washing Ⅰ, room temperature anti-oxidation, water washing Ⅱ, silane spraying and drying processes. The vehicle speed is 22m / min.

[0033] Among them, the pickling process conditions: temperature 30~40 ℃, sulfuric acid (H 2 SO 4 ) concentration of 100~170g / l, copper ion (Cu 2+ ) Concentration 25~45g / l.

[0034] Coarsening I and II process conditions: current density 28~33A / dm 2 , temperature 25~35℃, sulfuric acid (H 2 SO 4 ) concentration of 160~180g / l, copper ion (Cu 2+ ) concentration of 7~13g / l, chloride ion (Cl 2- ) concentration 15~30mg / l, sodium tungstate (Na 2 WO 4 2H 2 O) 0~90mg / l, sodium molybdate (Na 2 MoO 4 2H 2 O) 0~70mg / l and cobalt sulfate (CoSO 4 ·7H 2 O) 0~45g / L. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com