A kind of polyacrylate pressure-sensitive adhesive emulsion for polyethylene protective film and preparation method thereof

A polyethylene protective film, polyacrylate technology, used in adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as poor adhesion of pressure-sensitive adhesives, achieve fast curing, Well-balanced, non-migrating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

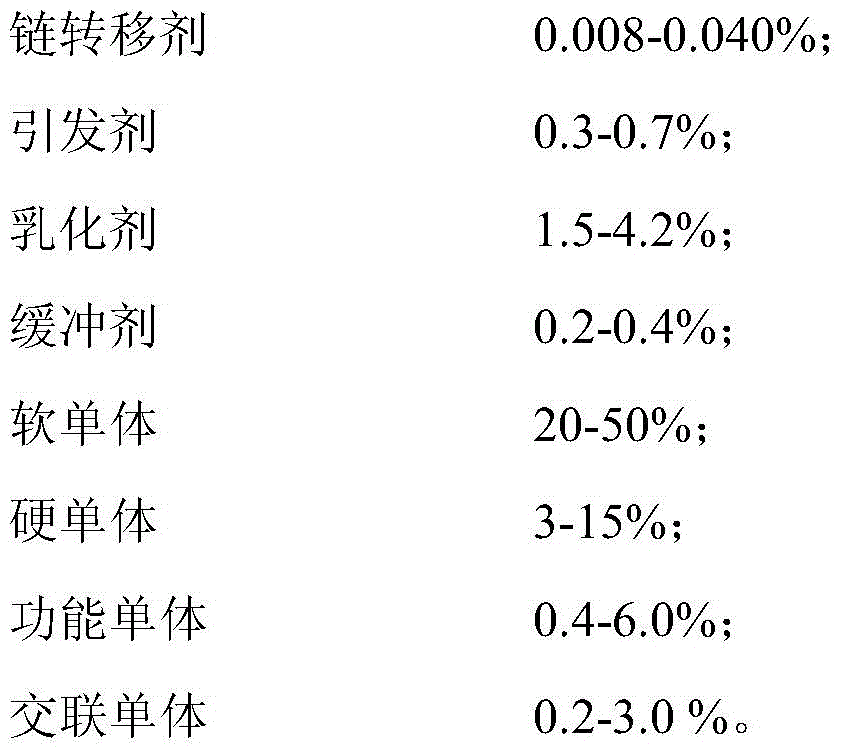

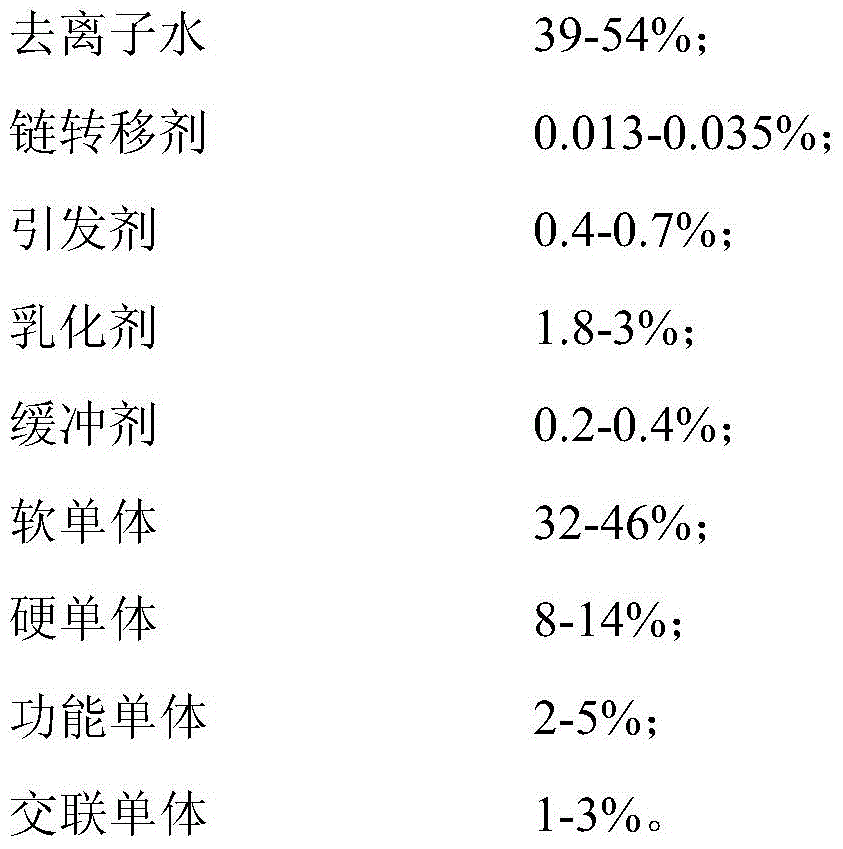

Method used

Image

Examples

Embodiment 1

[0029] 1. Synthetic pre-emulsion

[0030] With 100g of deionized water, 18g of ER-30 and 9g of SR-10 compound emulsifier, 3g of ammonium persulfate, 1.5g of sodium bicarbonate, 0.3g of n-dodecyl mercaptan, 12g of acrylic acid, 75g of methyl Methyl acrylate, 172.5g butyl acrylate, 160g isooctyl acrylate, 10.5g glycidyl methacrylate, 7.5g diacetone acrylamide, 4.5g adipate dihydrazide and 3g ethylene glycol methacrylate Disperses into a stable pre-emulsion.

[0031] 2. Preparation of Seed Emulsion

[0032] Add the remaining 2.5g of emulsifier, 0.3g of sodium bicarbonate and 130g of deionized water into the reactor, add 15g of pre-emulsion when the temperature rises to 75°C, and add 2g of ammonium persulfate and Mixed solution of 10g deionized water.

[0033] 3. Preparation of Polyacrylate PSA Emulsion

[0034] After 15 minutes of polymerization reaction, slowly add the remaining amount of pre-emulsion dropwise, and finish dropping in about 3 hours; after the dropwise additio...

Embodiment 2

[0046] 1. Synthetic pre-emulsion

[0047] 1.2g ammonium persulfate, 2.8g sodium bicarbonate, 0.08g n-dodecyl mercaptan and 10g acrylic acid, 16g Methyl methacrylate, 88g methyl acrylate, 30g ethyl acrylate, 60g butyl acrylate, 80g isooctyl acrylate, 8g glycidyl methacrylate, 5g diacetone acrylamide and 3g adipate dihydrazide are dispersed into Stable pre-emulsion.

[0048] 2. Preparation of Seed Emulsion

[0049] Add the remaining 1.25g of emulsifier, 0.2g of sodium bicarbonate and 220g of deionized water into the reactor, add 15g of pre-emulsion when the temperature rises to 75°C, and add 0.9g of ammonium persulfate when the temperature rises to 82°C Mixed solution with 15g deionized water;

[0050] 3. Preparation of Polyacrylate PSA Emulsion

[0051] After 15 minutes of polymerization reaction, slowly add the remaining amount of pre-emulsion dropwise, and finish dropping in about 3 hours; after the dropwise addition, continue the reaction for 30 minutes; add 0.15g ammoni...

Embodiment 3

[0059] 1. Synthetic pre-emulsion

[0060] With 150g of deionized water, 8g of ER-30 and 13g of SR-10 compound emulsifier, 3g of ammonium persulfate, 1.8g of sodium bicarbonate, 0.06g of n-dodecyl mercaptan, 9g of acrylic acid, 6g of formaldehyde Glycidyl acrylate, 6g hydroxyethyl acrylate, 30g methyl methacrylate, 30g methyl acrylate, 98g butyl acrylate, 140g isooctyl acrylate, 7.5g diacetone acrylamide and 4.5g adipate dihydrazide Disperses into a stable pre-emulsion.

[0061] 2. Preparation of Seed Emulsion

[0062] Add the remaining 1.6g of emulsifier, 0.2g of sodium bicarbonate and 200g of deionized water into the reactor, add 15g of pre-emulsion when the temperature rises to 75°C, and add 2g of ammonium persulfate and 16g mixed solution of deionized water;

[0063] 3. Preparation of Polyacrylate PSA Emulsion

[0064] After 15 minutes of polymerization reaction, slowly add the remaining amount of pre-emulsion dropwise, and finish dropping in about 3 hours; after the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com