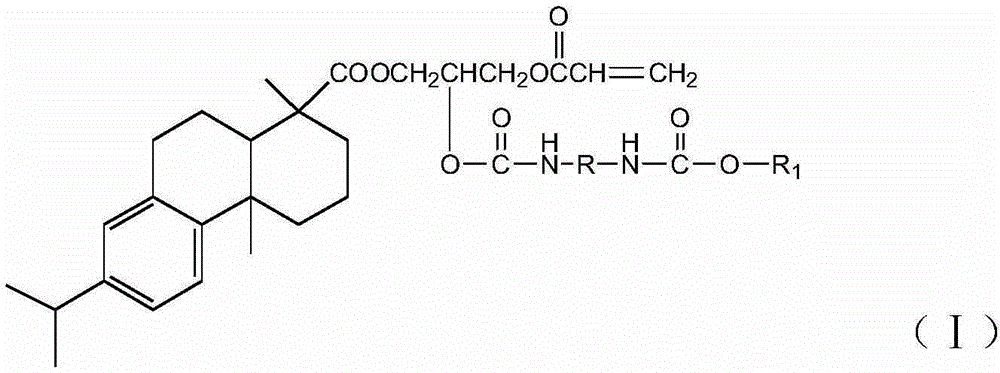

Optical resin and synthesis method thereof

A synthesis method and technology of optical resin, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problems that the refractive index affects the contrast and clarity of flat panel displays, etc., achieve good application value, simple reaction process, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

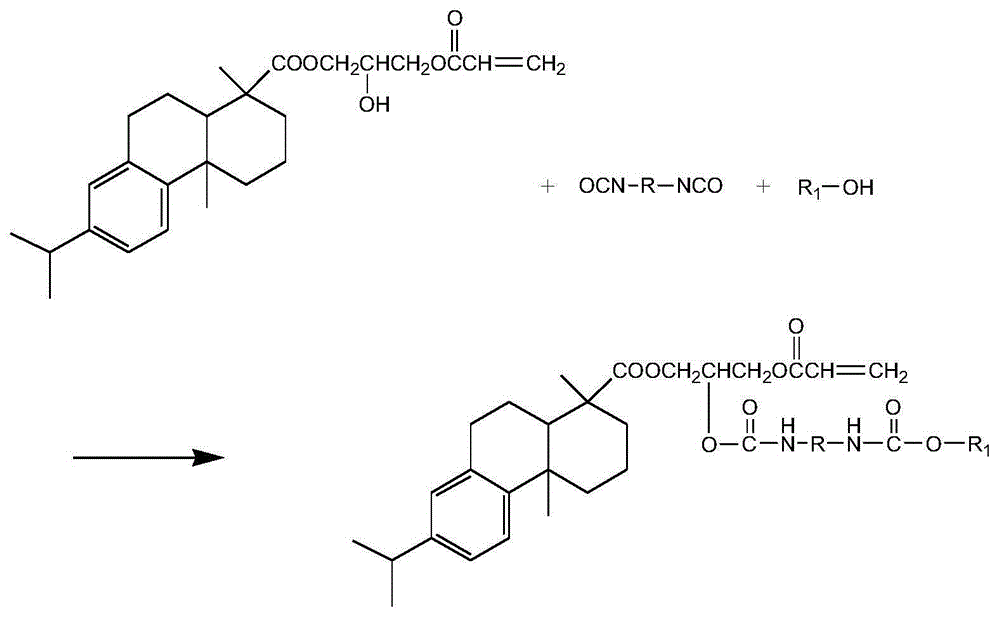

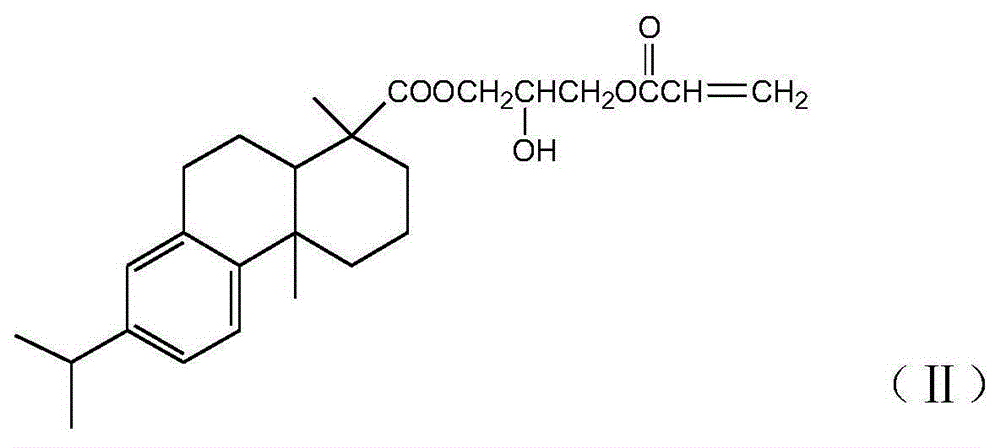

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 100g of epoxy-modified rosin ester, 6g of n-butanol, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate, add them to a three-necked flask with a thermometer, and heat up to 65 degrees , start to drop 22g of diisocyanate IPDI, control the temperature at 70-75 degrees, and react for 2.5h. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

Embodiment 2

[0031] Accurately weigh 100 g of epoxy-modified rosin ester, 4 g of isobutanol, 0.1 g of inhibitor p-hydroxyanisole, and 0.01 g of catalyst dibutyltin dilaurate, add them to a three-necked flask with a thermometer, and heat up to 65 degrees. Start to drop 25g of diisocyanate TDI, control the temperature at 70-75 degrees, and react for 2 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

Embodiment 3

[0033] Accurately weigh 110g of epoxy-modified rosin ester, 10g of neopentyl alcohol, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate, add them to a three-necked flask with a thermometer, and heat up to 65 degrees , start to drop 30g of diisocyanate MDI, control the temperature at 70-75 degrees, and react for 3h. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com