A kind of hybrid curable resin and its synthesis method

A hybrid curing and resin technology, applied in the field of hybrid curable resin and its synthesis, can solve the problems of lack of appearance, large shrinkage, and large deformation and warpage of three-dimensional objects, and achieve excellent photocurability and low shrinkage. Good efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

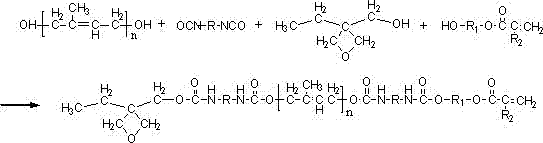

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 100g of polyisoprene diol, 6g of 3-ethyl-3-oxetanemethanol, 6g of hydroxyethyl acrylate, 0.1g of polymerization inhibitor p-hydroxyanisole, catalyst dibutyltin dilaurate Add 0.01g into a three-necked flask with a thermometer, raise the temperature to 65°C, start adding 22g of diisocyanate IPDI dropwise, control the temperature at 70-75°C, and react for 2.5 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the NCO peak completely disappeared, the heating reaction was stopped to obtain an oxetane-modified polyurethane acrylate resin.

Embodiment 2

[0031] Accurately weigh 100 g of polyisoprene diol, 4 g of 3-ethyl-3-oxetanemethanol, 12 g of hydroxyethyl methacrylate, 0.1 g of inhibitor p-hydroxyanisole, and catalyst dilauric acid Add 0.01 g of dibutyltin into a three-necked flask with a thermometer, raise the temperature to 65 degrees, start adding 25 g of diisocyanate TDI dropwise, control the temperature at 70-75 degrees, and react for 2 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the NCO peak completely disappeared, the heating reaction was stopped to obtain an oxetane-modified polyurethane acrylate resin.

Embodiment 3

[0033] Accurately weigh 110g of polyisoprene diol, 10g of 3-ethyl-3-oxetanemethanol, 5g of hydroxypropyl acrylate, 0.1g of polymerization inhibitor p-hydroxyanisole, catalyst dibutyltin dilaurate Add 0.01g into a three-necked flask with a thermometer, raise the temperature to 65°C, start adding 30g of diisocyanate MDI dropwise, control the temperature at 70-75°C, and react for 3 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the NCO peak completely disappeared, the heating reaction was stopped to obtain an oxetane-modified polyurethane acrylate resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com