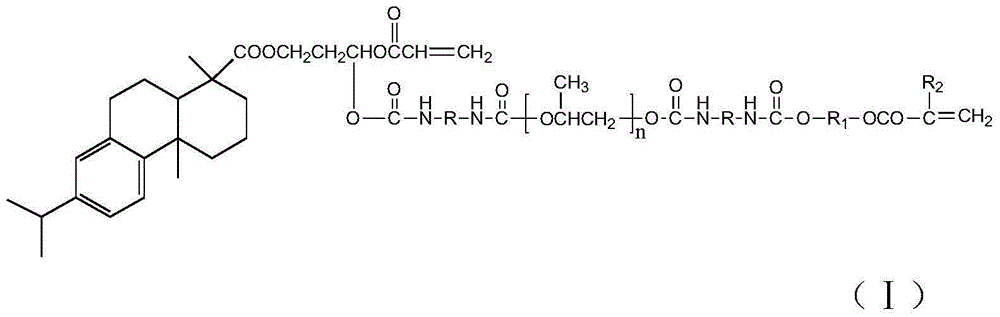

High-refraction-index and yellowing-resistant resin and synthesis method thereof

A synthesis method and high refractive index technology, applied in the field of optical resin and its synthesis, can solve the problem that the refractive index affects the contrast and clarity of flat panel displays, and achieve the effects of good application value, good yellowing resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

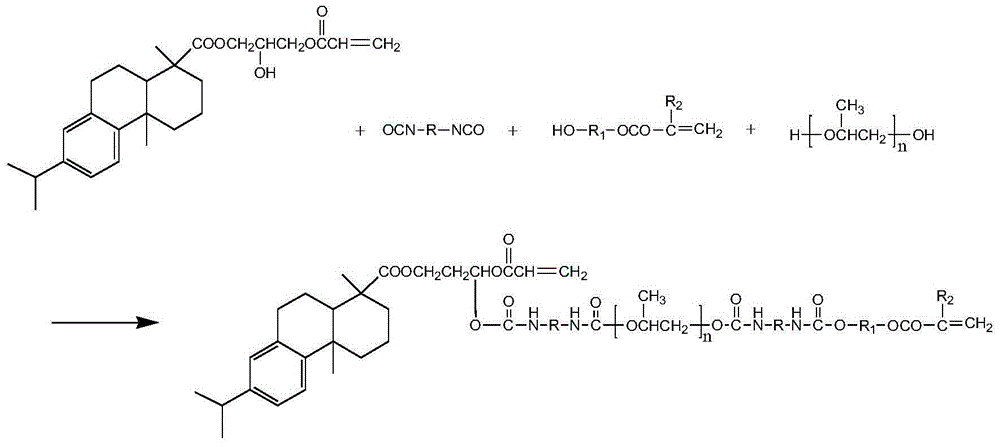

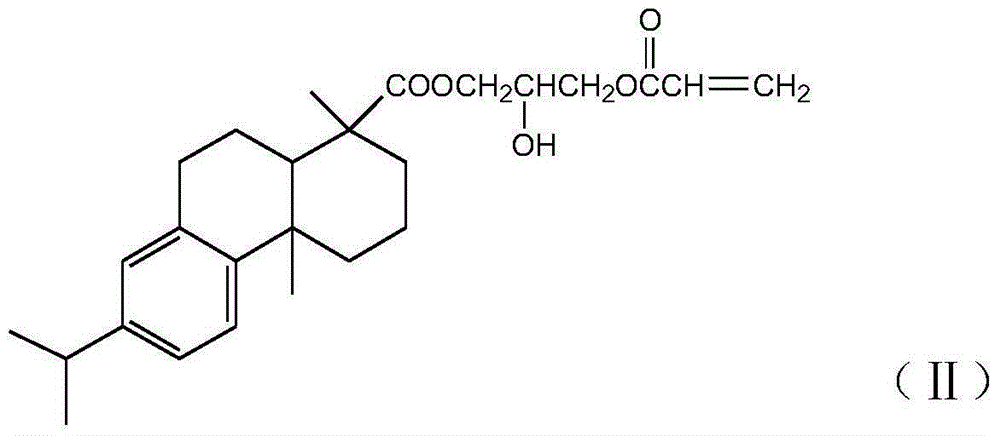

Method used

Image

Examples

Embodiment 1

[0032] Accurately weigh 100g of epoxy-modified rosin ester, 6g of hydroxyethyl acrylate, 500g of VORANOL8000LM from DOW Company, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate, and add them to a three-port thermometer with a thermometer. In the flask, the temperature was raised to 65 degrees, and 22 g of diisocyanate IPDI was added dropwise, and the temperature was controlled at 70-75 degrees, and the reaction was carried out for 2.5 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

Embodiment 2

[0034] Accurately weigh 100g of epoxy-modified rosin ester, 4g of hydroxyethyl methacrylate, 800g of ACCLAIM POLYOL 12200N from BAYER company, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate, and add to the mixture with In the three-necked flask with a thermometer, the temperature was raised to 65 degrees, and 25 g of diisocyanate TDI was added dropwise, the temperature was controlled at 70-75 degrees, and the reaction was carried out for 2 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

Embodiment 3

[0036] Accurately weigh 110g of epoxy-modified rosin ester, 10g of hydroxypropyl methacrylate, 600g of ACCLAIM POLYOL 12200N from BAYER company, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.01g of catalyst dibutyltin dilaurate, and add to the mixture with In the three-necked flask with a thermometer, the temperature was raised to 65 degrees, and 30 g of diisocyanate MDI was added dropwise, the temperature was controlled at 70-75 degrees, and the reaction was carried out for 3 hours. The content of the NCO group was analyzed by an infrared spectrometer, and when the peak of the NCO completely disappeared, the heating reaction was stopped to obtain a rosin ester modified polyurethane acrylate resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com