Patents

Literature

38results about How to "Fast phosphating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphatizing liquid and preparation method thereof

InactiveCN101935831AReduce construction difficultyIncrease productivityMetallic material coating processesSodium fluoridePhosphoric acid

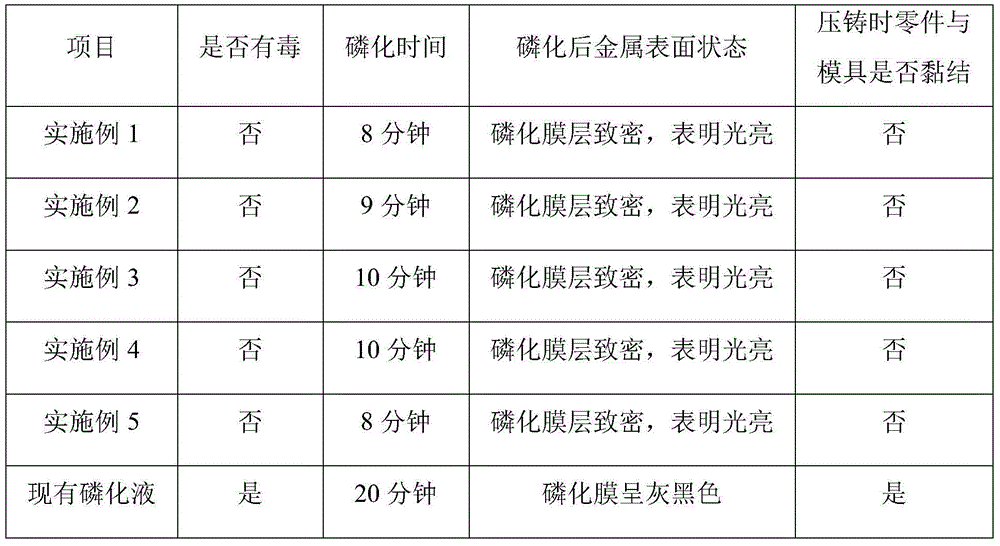

The invention discloses phosphatizing liquid. The phosphatizing liquid comprises the following components in percentage by weight: 7 percent of starter liquid, 0.38 to 0.4 percent of neutralizer, 0.2 to 0.6 percent of accelerator and the balance of water, wherein the starter liquid comprises the following components in percentage by weight: 30 to 36 percent of 85 percent phosphoric acid, 16 to 20 percent of 68 percent nitric acid, 15.6 to 18.4 percent of 99.7 percent zinc oxide, 0.4 to 0.6 percent of citric acid, 0.4 percent of sodium fluoride, 0.6 to 1 percent of nickel nitrate, 0.16 to 0.24 percent of ferric nitrate, 0.004 to 0.01 percent of copper nitrate and the balance of water.

Owner:景阳富

Magnetic material phosphating solution

ActiveCN104962895AImprove corrosion resistanceFast phosphatingMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a magnetic material phosphating solution, which consists of the following components: 20-200g / L of zinc dihydrogen phosphate, 50-200g / L of manganous dihydrogen phosphate, 50-200g / L of zinc nitrate, 100-303g / L of phosphoric acid, 100-303g / L of nitric acid, 5-20g / L of complexing agent, 50-100g / L of a buffering agent, 10-30g / L of an auxiliary film-forming agent and 50-120g / L of a promoting agent. A phosphating film formed by the phosphating solution disclosed by the invention is high in corrosion resistance and can be used as an ultimate treatment protection film layer, and no subsequent coating treatment is required. The phosphating speed of the phosphating solution is high, the film layer is fine in crystallization, the solution is stable, and sediment is settled; the shortcomings that too much sediment is settled in a high-temperature phosphating process of a common phosphating solution and the formed phosphating film is low in corrosion resistance are overcome.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Microcrystalline phosphating solution for brake block hardware

InactiveCN101348906AImprove pollutionLittle pollutionMetallic material coating processesPhosphateNitrobenzene

The invention provides a pollution-free microcrystalline phosphating treatment solution for brake pad hardware, which is mainly made from the following raw materials in portion by weight: 40 to 50 portions of zinc nitrate, 22 to 30 portions of zinc dihydrogen phosphate, 30 to 40 portions of Mazhev salt (manganous dihydrogen phosphate), 1.5 to 2 portions of guanidine nitrate, 1.5 to 2 portions of sodium m-nitrobenzene sulfonate, 1 to 2 portions of sodium tripolyphosphate, 2 to 4 portions of tartaric acid, 2 to 3 portions of sulfosalicylic acid, 1.5 to 2.5 portions of citric acid and 1,000 to 1,200 portions of water. The solution is used for the blackening-phosphating treatment of the surface of iron hardware, and has the characteristics of fast phosphorization, good performances, little environmental pollution, low cost, etc. The treatment solution has the advantages of fine phosphatized crystals of phosphating films, uniform color in consistent black and good corrosion resistance. Especially, as the treatment solution chooses the raw materials with little environmental pollution and high efficiency, the treatment solution acquires excellent effects in both phosphatization and environmental protection through optimized combination and reasonable proportioning.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Normal temperature electrolytic phosphating technology and phosphating solution

InactiveCN109056034APlay an environmental roleSave manpower and material costsPhosphatisationOrganic acidElectrolysis

The invention discloses a normal temperature electrolytic phosphating technology. A phosphating solution comprises 10-63 g / L of zinc ions, 10-100 g / L of calcium ions, 50-120 g / L of phosphate radical,40-200 g / L of nitrate radical, 10-50 g / L of organic acid and 1-45 g / L of an additive, wherein the phosphate radical is P2O5, the phosphating temperature is the normal temperature, and current with thedensity being 3-100 A / dm<2> is applied through direct-current power supplies; the phosphating time is 3-120 s; and the weight of phosphated film is 8-20 g / m<2>, the drawing speed is 4-10 m / s, the phosphating temperature is the normal temperature, no phosphated residue is produced, electrodes do not need to be cleaned periodically, the phosphating solution contains no heavy metal, and environmentprotection standards are met.

Owner:南京派诺金属表面处理技术有限公司

Cleaning, derusting and phosphating agent

InactiveCN104099594AFast phosphatingImprove phosphating effectMetallic material coating processesHydroxybenzoate EthersBetaine

The invention discloses a cleaning, derusting and phosphating agent. The cleaning, derusting and phosphating agent comprises the following formula components of raw materials in parts: 10-30 parts of phosphoric acid, 5-10 parts of metaphosphoric acid, 8-10 parts of hypochlorous acid, 5-10 parts of banana oil, 5-8 parts of dimethylbenzene, 5-12 parts of silicone oil, 5-10 parts of methyl ethyl ketone, 5-8 parts of isopropanol, 5-8 parts of diethyl ether, 3-5 parts of urea, 5-6 parts of m-dihydroxybenzene, 3-5 parts of p-hydroxyanisole, 5-8 parts of phenol, 5-8 parts of sodium polyacrylate, 2-3 parts of cocamidopropyl betaine, and 50-60 parts of de-ionized water. The cleaning, derusting and phosphating agent can be used at the normal temperature, has the advantages of quick phosphating speed, good phosphating effect, no corrosiveness, little waste residue discharge, combined completion of cleaning, derusting and phosphating at one step, easy production and low production cost, and can be applied to the degreasing, derusting and phosphating treatment of steel and cast iron products.

Owner:周彩球

Anti-seismic prefabricated house

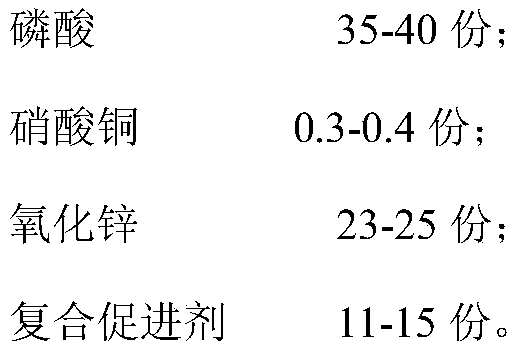

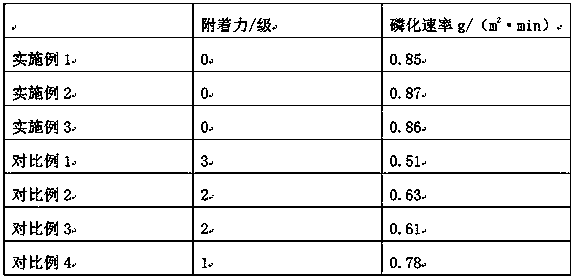

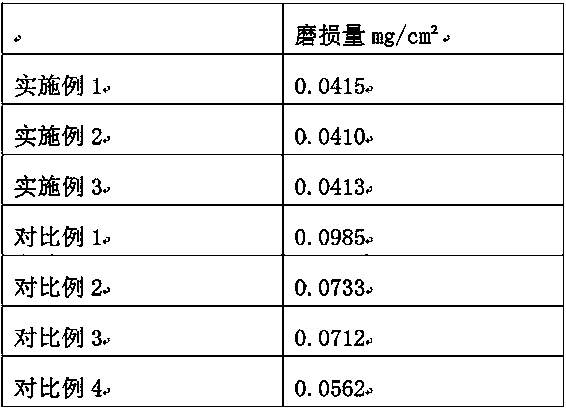

InactiveCN109778161AImprove film qualityPromotes electrochemical reactionsMetallic material coating processesElectrode potentialElectrochemical response

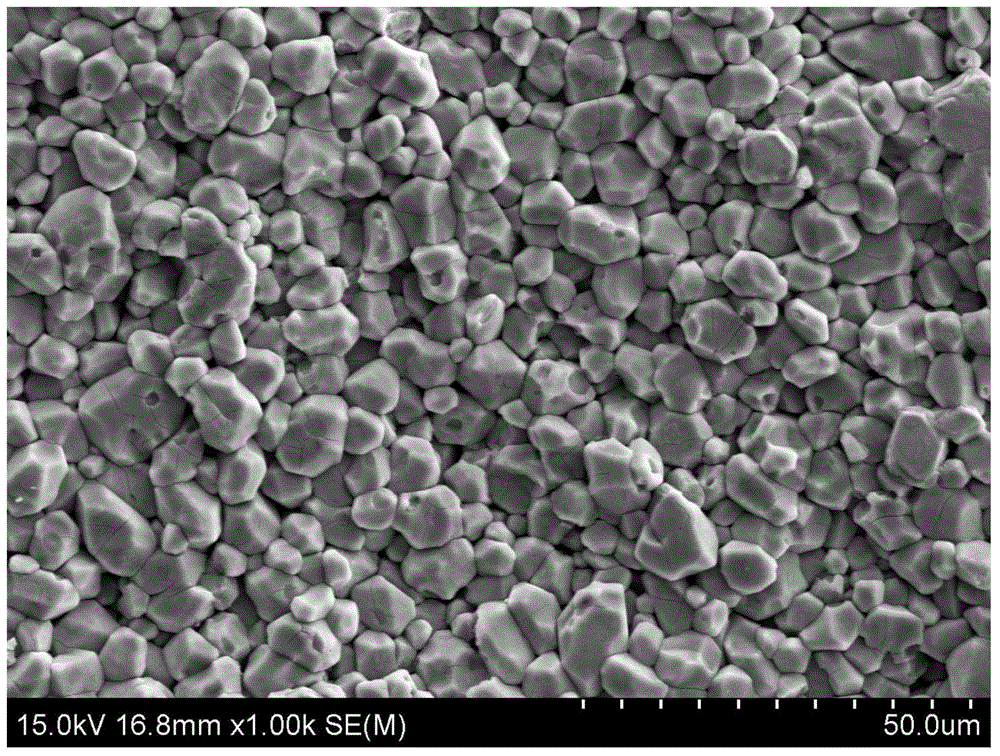

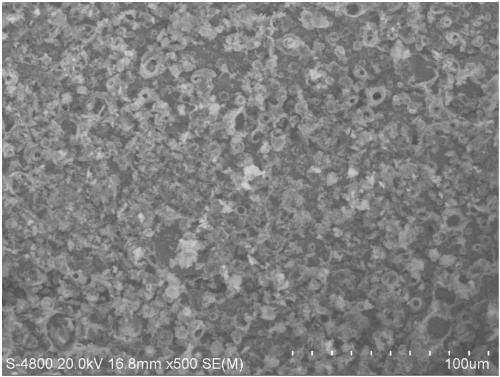

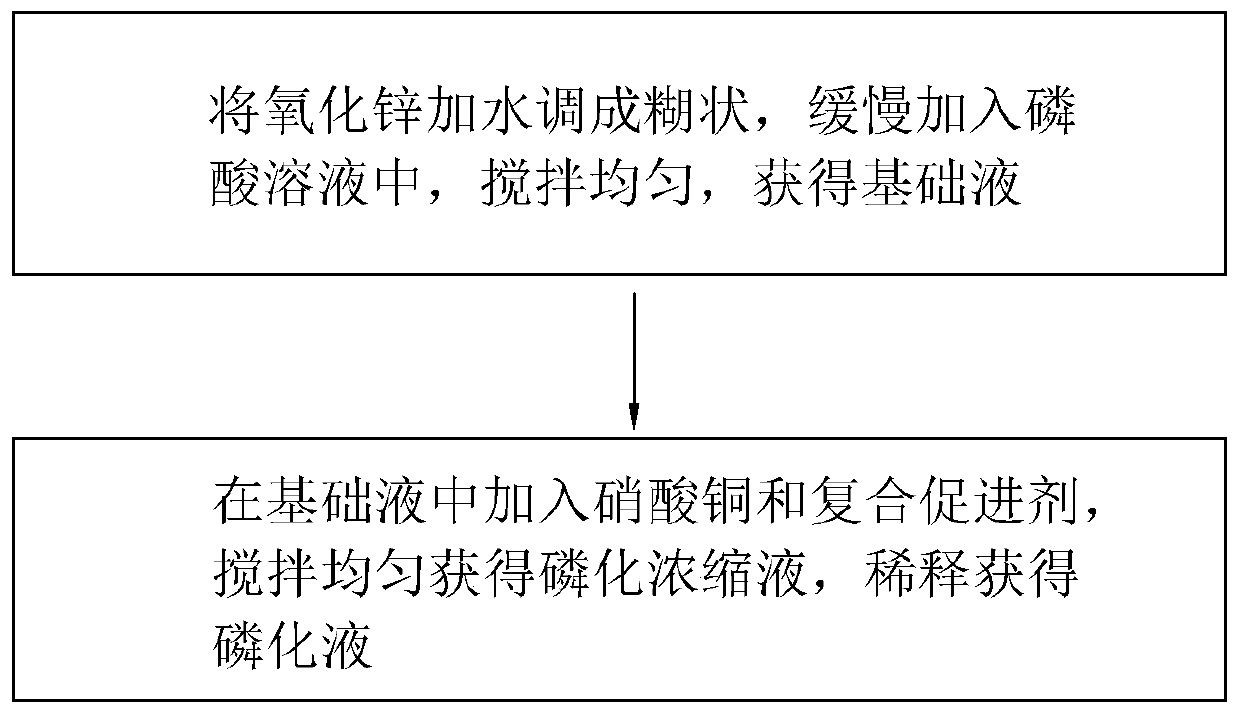

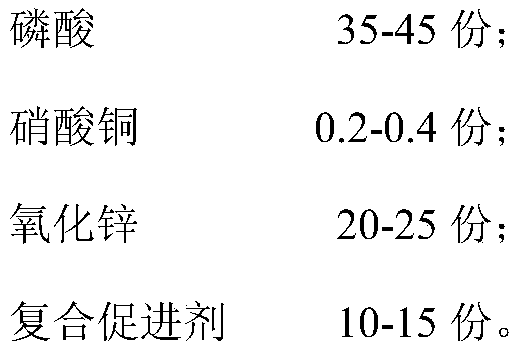

The invention discloses an anti-seismic prefabricated house, comprising a plurality of steel plates, wherein the outer side of each steel plate is treated by a phosphating solution to form a phosphating film, and the phosphating solution comprises the following components in parts by weight: 35-45 parts of phosphoric acid, 0.2-0.4 parts of copper nitrate, 20-25 parts of zinc oxide, and 10-15 partsof compound accelerant. The anti-seismic prefabricated house provided by the invention has the advantages: as the main film-forming materials, the phosphoric acid and zinc oxide can form a continuous and uniform phosphating film on the surface of the processed. Meanwhile, the addition of the compound accelerator further improves the film forming speed and film forming quality of the phosphatingfilm. In addition, because the electrode potential of copper is higher than that of iron, copper ions are reduced and deposited on the surface of a phosphated hinge body, so the cathode area on the surface is increased; the electrochemical reaction of phosphating is further promoted, the formation of phosphating crystal nucleus is accelerated, crystal grains are refined, and the phosphating film is compact and uniform; meanwhile, the phosphating speed is improved, the phosphating temperature is reduced, and finally the phosphating film has the advantages of compact film formation and strong adhesive force.

Owner:浙江华锦建筑装饰设计有限公司

Normal temperature quick phosphorizing agent for metal plastic deformation and preparation method thereof

InactiveCN1807683AFast phosphatingLow priceMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a normal temperature fast bonderite and producing method of metal plastic deformation, which is characterized by the following: the bonderite is composed of phosphoric acid, methyl ethyl ketone or acetone, eldopaque, manganese dihydrogen phosphate, calcium nitrate, zinc nitrate and water; the method comprises the following steps: mixing, emulsifying, restirring; the raw materials of bonderite is at a low price, which can be used at normal temperature. The method is easy to product, which reduces the costs of conversion.

Owner:赵惠霖

Rust-removing phosphating solution for wire rod drawing, and preparation method thereof

ActiveCN108048826AHigh hardnessImprove adhesionMetallic material coating processesPhosphatePhosphoric acid

The invention aims to solve the problems that wire rod pickling and phosphating procedures are implemented separately, resulting high treatment cost of waste water generated by washing, phosphating films are not secure enough, the fracture phenomenon occurs during drawing, and the content of corrosive components in phosphating agents is high. The invention provides a rust-removing phosphating solution for wire rod drawing, and a preparation method thereof, and belongs to the technical field of rust removal and phosphating treatment of metal surfaces. The rust-removing phosphating solution forthe wire rod drawing comprises, by mass, 20%-50% of concentrated phosphoric acid, 1%-10% of concentrated nitric acid, 1%-10% of zinc oxide, 2%-10% of dihydric phosphate, 1%-10% of nitrate, 0.5%-5% ofmanganese carbonate, 0.2%-5% of complexing agents, 0.05%-1% of fluorine-containing surfactants and the balance water. After treatment by the rust-removing phosphating solution provided by the invention, a gray-black uniform and dense phosphating film is formed on the surfaces of steel wires and welded steel tubes, and has better lubrication effects in the drawing and cold working process.

Owner:鞍山晨雷科技有限公司

Phosphatization technology for hot rolling steel plate under normal temperature

InactiveCN104250776ALow costReduce the use temperatureMetallic material coating processesPhosphateManganese

The invention discloses a phosphatization technology for a hot rolling steel plate under normal temperature, a phosphatization liquid employed in the technology comprises the following components: 34-38g / L of manganese dihydrogen phosphate, 44-48g / L of zinc nitrate, 5-7g / L of 85% of phosphoric acid, 3-4g / L of dibismuth trimolybdenum dodecaoxide, 5-7g / L of sodium tungstate, 1-3g / L of sodium chlorate, 4-6g / L of ammonium citrate, 24-28g / L of sodium nitrate, 2-4g / L of cupric nitrate, 8-10g / L of tartrate, 3-5g / L of ethylene diamine tetraacetic acid, 2-4g / L of urotropine and the balance of water. The phosphatization technology comprises the following steps: performing alkali washing to remove oil stain, flushing by clear water for 2-3 times after being removed from a lye tank, then placing in a phosphatization groove filled with the phosphatization liquid composed of the above components, controlling pH value of the phosphatization liquid at 3.5-4.5 and the temperature of 10-30 DEG C, immersing for 8-12 minutes; flushing for 2-3 times by clear water after being removed from the phosphatization groove, and then drying in air or naturally dying.

Owner:WUXI LUOSHE TECH VENTURE

Steel rim vehicle wheel surface phosphating treatment method

InactiveCN108914110AImprove compactnessImprove uniformityAnti-corrosive paintsMetallic material coating processesHigh phosphateWear resistance

The invention discloses a steel rim vehicle wheel surface phosphating treatment method and relates to the technical field of steel treatment. The method comprises: (1) grinding, (2) cleaning, (3) plasma treatment and (4) phosphating treatment. The method can well protect the steel rim vehicle wheel surface, improve the film forming stability, greatly improve the compactness and uniformity of the phosphated film, realize high phosphated film adhesion, improve the corrosion resistance and wear resistance of the surface of the steel rim vehicle wheel surface, realize high phosphated film purity,facilitate precipitate removal, shorten the conventional high-temperature surface phosphating treatment time, realize fast phosphating treatment at the normal temperature, prevent heating, solve the problem that the conventional high-temperature phosphating treatment method easily causes phosphated film impurities and precipitates difficult to remove, and improve the phosphating efficiency.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Method for using single component low-temperature zinc-based phosphatization liquid

InactiveCN102051613AImprove bindingImprove corrosion resistanceMetallic material coating processesToxic materialBond Force

The invention relates to a method for using single component low-temperature zinc-based phosphatization liquid, comprising the steps of removing oil, rinsing,, removing rust, rinsing, tempering, parkerising, rinsing, drying and coating, wherein the tempering technology is as follows: firstly, using a frosting material to frost the surface, then using a fan to blow the frosted fragments on the surface away, using magnet to further absorb the fragments on the surface, and finally, using an air-heater or a thermal radiation device to heat the surface to at least 35 DEG C is ordinarily reached to prepare for phosphatization treatment. The method has the beneficial effects that the phosphatization speed is fast: phosphatization is carried out for 2-5 minutes to obtain high quality phosphatization film with the depth of 1-3 microns / cm<2> under the tempering process condition of 25-40 DEG C; the single component is supplied, the same liquid is adopted during tanking and replenishing, and the regulation is extremely convenient; the bonding force between the phosphatization film and a paint film is firm, and a coating layer has good corrosion resistance; and the phosphatization liquid does not contain toxic substances such as heavy metals, nitrites and the like, is in favor of worker health and environment protection, has the characteristic of less sediment amount, and can be used for a long term.

Owner:缪克忠

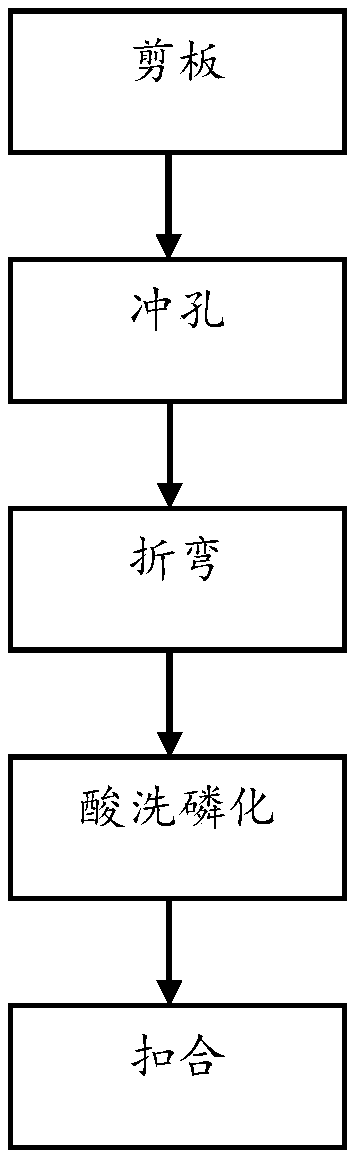

Door leaf manufacturing technique

InactiveCN107931989AImprove product qualityIncrease productivityMetallic material coating processesWing framesPunchingPoor quality

The invention relates to a door leaf manufacturing technique, relates to the technical field of furniture manufacturing technique, and solves the problems of complexity and poor quality in conventional door leaf manufacturing technique. The door leaf manufacturing technique provided by the invention comprises the following steps: step 1, plate shearing, shearing a plate to be a preset shape; step2, punching, after plate shearing, using a punching device for punching the plate; step: bending, using a bending machine for bending; step 4, pickling and phosphating, removing grease and corrosive materials, and carrying out surface adjustment; step 5, fastening, fastening a door leaf onto a door frame; the door leaf manufactured through the door leaf manufacturing technique provided by the invention has a simple structure, the door leaf manufacturing technique is simple in production process, repeated procedures are avoided, the production efficiency is improved, and the door leaf quality is improved.

Owner:广元市家福门业有限责任公司

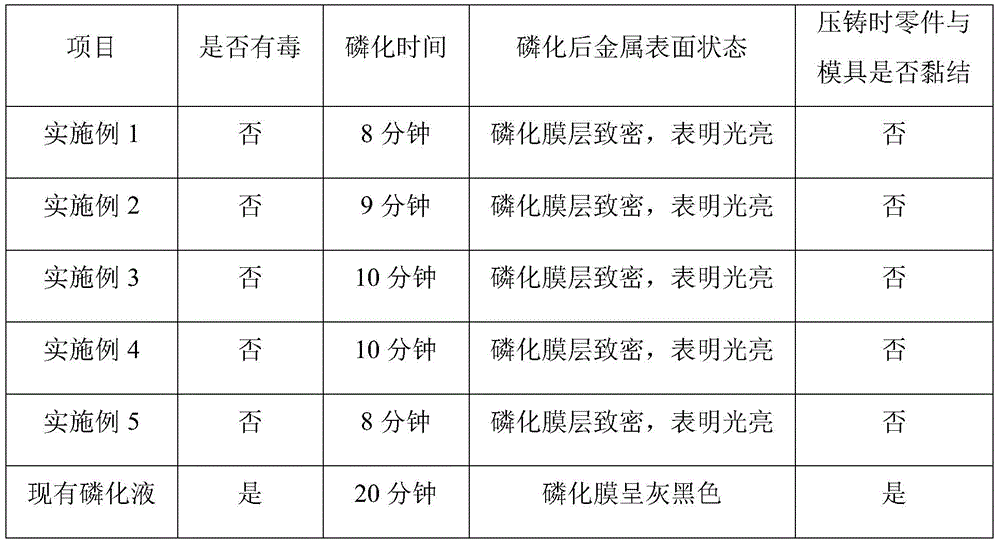

Composition for steel phosphating and preparation method thereof

ActiveCN104357818ABright colorFast phosphatingMetallic material coating processesPhosphatePolyethylene glycol

The invention discloses a composition for steel phosphating and a preparation method thereof. The composition is composed of the following components in parts by mass: 2-6 parts of sodium nitrate, 2-4 parts of sodium citrate, 15-25 parts of iron manganese dihydrogen phosphate, 5-10 parts of magnesium oxide, 10-20 parts of nickel nitrate, 2-5 parts of copper sulfate, 1-3 parts of sulfosalicylic acid, 2-5 parts of polyethyleneglycol and 500-900 parts of deionized water. The preparation method comprises the following steps: a. weighing the components according to parts by mass; b. adding the sodium citrate, sulfosalicylic acid and polyethyleneglycol into another deionized water; and c. uniformly mixing the solutions obtained in the step a and step b. The composition for steel phosphating can complete phosphating within 8-10 minutes, and has the advantages of high phosphating speed and short required lime for phosphating; and the surface of the phosphated steel has bright color.

Owner:浙江迪特高强度螺栓有限公司

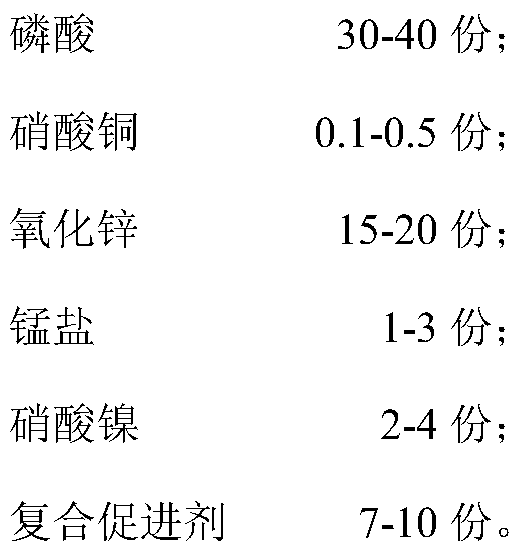

Car trunk hinge part and production process thereof

InactiveCN109706440AEffective complexationIncrease active pointMetallic material coating processesElectrode potentialElectrochemical response

The invention discloses a car trunk hinge part. The outer surface of the hinge part is treated with a phosphating solution to form a phosphating film, wherein the phosphating solution comprises the following components in parts by weight: 30-40 parts of phosphoric acid, 0.1-0.5 part of copper nitrate, 15-20 parts of zinc oxide, 1-3 parts of manganese salt, 2-4 parts of nickel nitrate, and 7-10 parts of a compound accelerant. The car trunk hinge part has the advantages that: phosphoric acid and zinc oxide are taken as main film-forming substances, so that a continuous and uniform phosphating film is formed on a treated metal surface. Meanwhile, the compound accelerant further can be added to increase film-forming speed of the phosphating film and improve film-forming quality of the phosphating film. Besides, electrode potential of copper is positive than that of iron, and copper ions are reduced for being deposited on the surface of a phosphated hinge body, so that a cathode region of the surface is increased, electrochemical reaction of phosphating is further promoted, formation of a phosphating crystal nucleus is accelerated, and crystalline grains are refined, and therefore, thephosphating film is compact and uniform, phosphating speed is reduced, and the phosphating film has the advantages of being tight in film-forming and strong in adhesive force.

Owner:温州疆昊汽车部件有限公司

Normal-temperature phosphating fluid for drawing steel

The invention discloses a normal-temperature phosphating fluid for drawing steel. The liquid is prepared by nitrate, nitrite, nitroguanidine, molybdate, phosphate, an accelerant and deionized water. The liquid can be used for performing normal-temperature phosphating on the steel for drawing, and can reach a same effect under a relatively-high-temperature phosphating; under the normal temperature, after 3 to 5 minutes, a layer of black, even and compact phosphating film can be formed on the surface of the steel, and the corrosion resistance is tested to be above the national standard. The problems of large high-temperature phosphating liquid consumption, high possibility in stripping, long phosphating time and the like are solved.

Owner:武汉金瑞欣精密工业设备有限公司

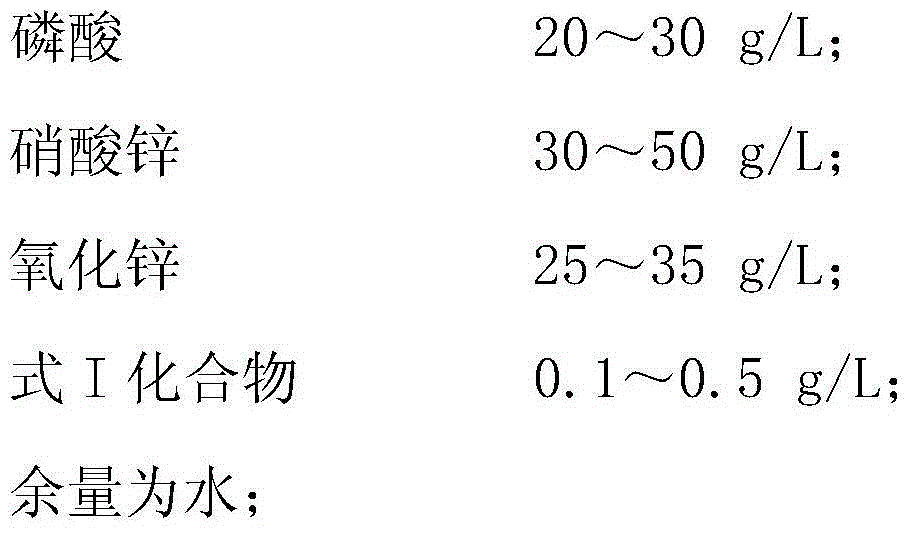

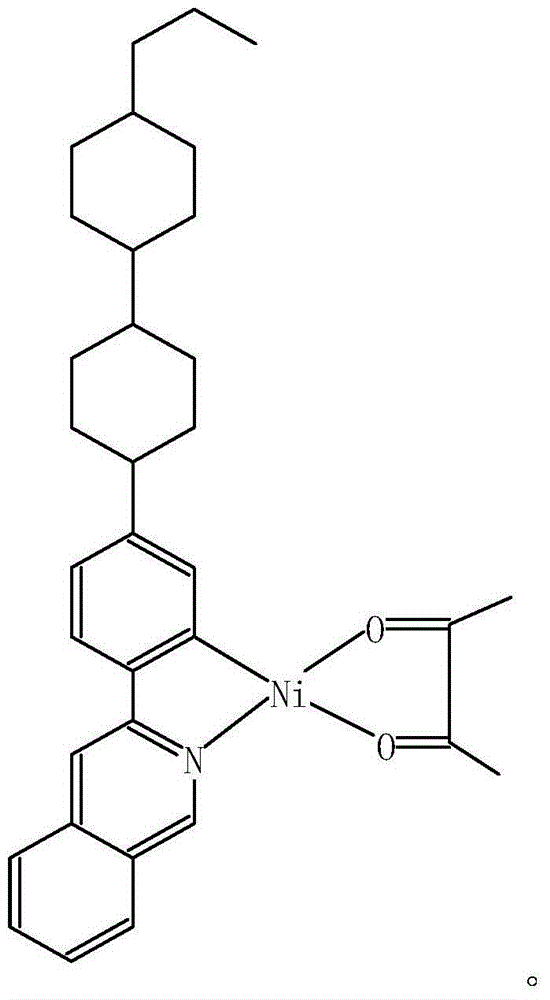

Phosphorizing liquid for pretreating high-carbon steel wire before drawing and preparation method of phosphorizing liquid

ActiveCN104878372AIncrease generation speedIncreasing the thicknessNickel organic compoundsMetallic material coating processesHigh carbonPhosphoric acid

The invention discloses phosphorizing liquid for pretreating a high-carbon steel wire before drawing and a preparation method of the phosphorizing liquid.The phosphorizing liquid is prepared from phosphoric acid, zinc nitrate, zinc oxide, a compound as shown in formula I, and water; zinc oxide is added to little water and mixed into paste; then phosphoric acid is added and agitated; zinc nitrate and the compound as shown in formula I are added after phosphoric acid is dissolved; water is added until reaching the use height; then the heating ad agitating are performed, and the volume is fixed; the temperature in phosphorizing liquid preparation is controlled to be 65 to 75 DEG C; the prepared phosphorizing film is thick, uniform, dense, high in corrosion resistance, fast to form, and wide in applicable scope of the steel wire according to the specification.

Owner:NINGBO BST METAL PROD

Four-in-one phosphating solution and preparation method thereof

InactiveCN109355647AFast degreasing, derusting and phosphatingFast phosphatingMetallic material coating processesPhosphoric acidRoom temperature

The invention discloses a four-in-one phosphating solution and a preparation method thereof. The four-in-one phosphating solution is composed of the following components including, by concentration, 10-30g / L of 85% phosphoric acid, 30-40 g / L of sodium dihydrogen phosphate, 0.5-1g / L of sodium tripolyphosphate, 0.1-0.3 g / L of a rust inhibitor, 0.33-0.46 g / L of a stabilizer, 0.8-1.2 g / L of ammonium molybdate, 1-2g / L of a pH conditioning agent and 1L of water. The four-in-one phosphating solution provided by the invention can be used for achieving four functions including deoiling, derusting, phosphorization and passivation in a tank under the room temperature, uniform, compact and corrosion-resistant color phosphating film is formed on the surface of a steel workpiece and can serve as a bottom layer before coating of paint spraying, powder coating and the like, and the coating adhesion is good.

Owner:山东泷瑞源电气科技有限公司

Production process of cold-drawn section steel

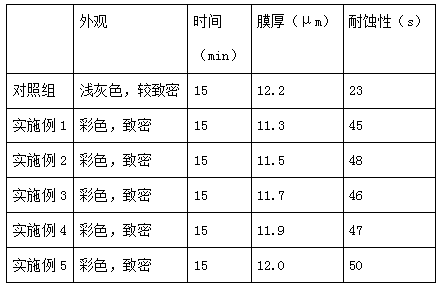

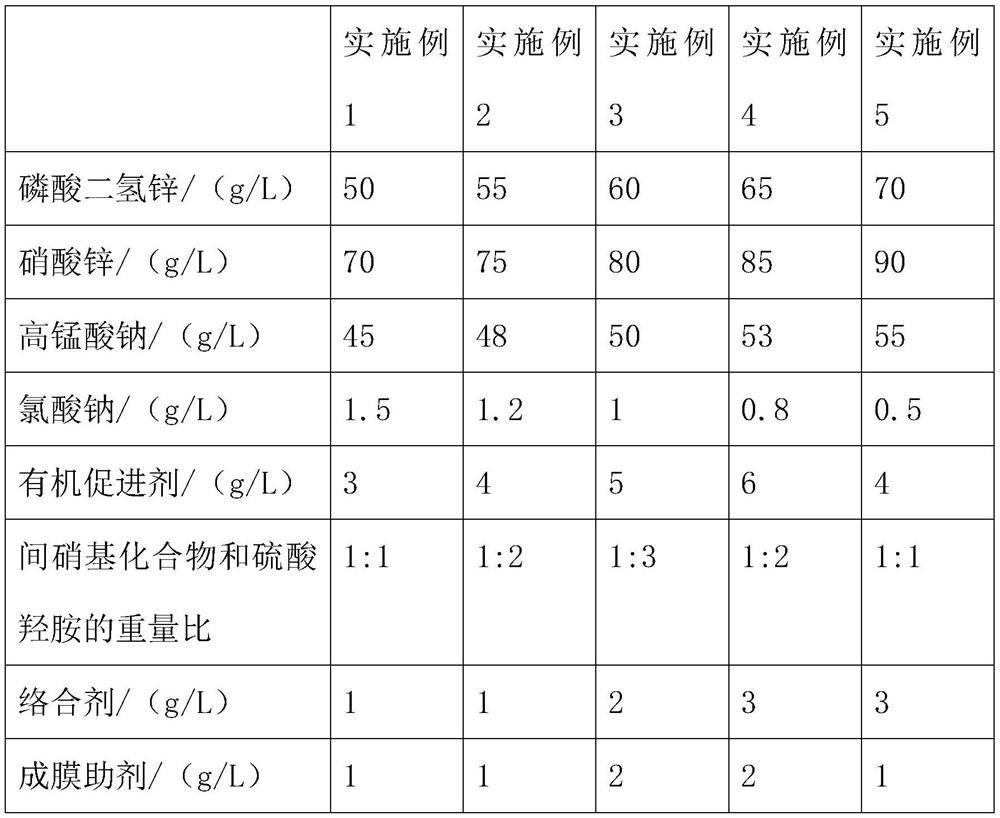

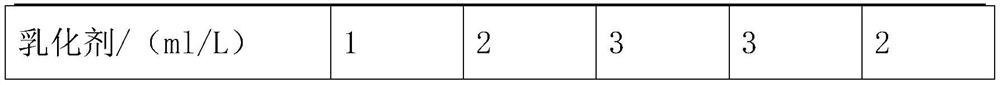

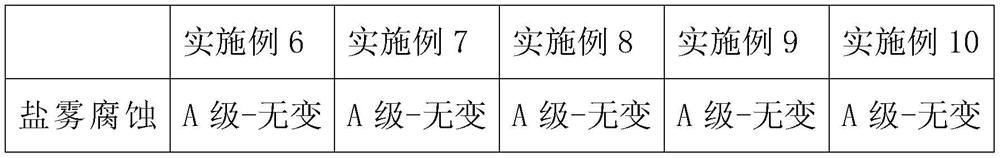

InactiveCN113174593AStable pHInhibition of suspended sedimentMetallic material coating processesPermanganate saltDusting powders

The invention discloses a production process of cold-drawn section steel. The production process comprises the following steps of step 1, grinding and removing a decarburized layer of a steel billet of which the surface is decarburized; step 2, alkali washing is conducted on the steel billet with the decarburized layer removed so as to remove oil stains and abrasive dust powder on the surface of the steel billet; step 3, the steel billet subjected to alkali washing is sequentially subjected to water washing, phosphorization, saponification and drying; and step 4, the dried steel billet is sequentially subjected to pointing, drawing, annealing and straightening. A phosphating solution used in the phosphating process comprises, by weight, 50-70 g / L of zinc dihydrogen phosphate, 70-90 g / L of zinc nitrate, 45-55 g / L of permanganate, 0.5-1.5 g / L of chlorate, 3-6 g / L of organic accelerant, 1-3 g / L of complexing agent, 1-2 g / L of coalescing agent, 1-3 ml / L of emulsifying agent and the balance water. The production process has the beneficial effect that the cold-drawn section steel produced by the production process has excellent corrosion resistance.

Owner:嵊州市裕盈金属冷拉型材有限公司

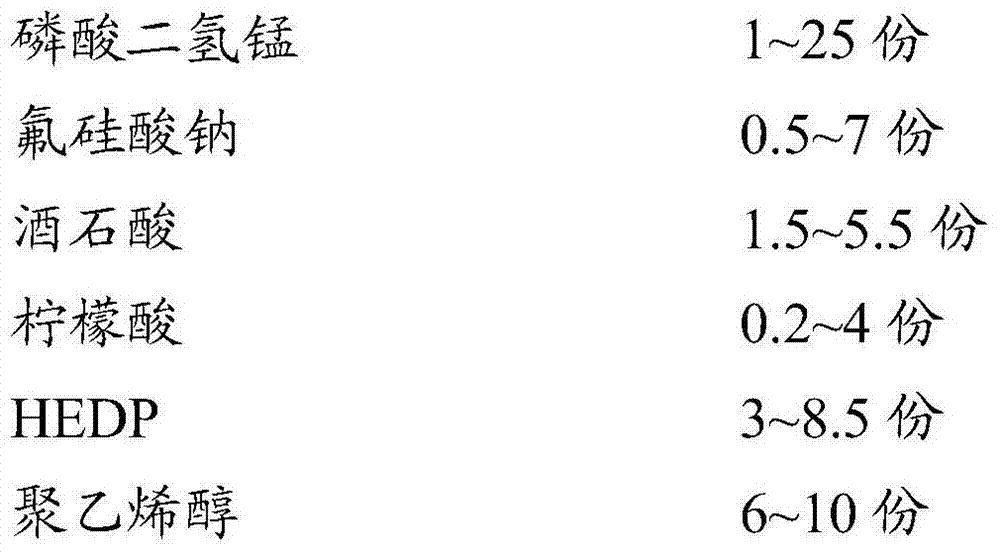

A kind of manganese series phosphating solution additive and using method thereof

ActiveCN104962898BStable pHGrain refinementMetallic material coating processesFluorosilicate saltPhosphate

The invention provides a manganese-based phosphating solution additive and a using method thereof, belonging to the field of industrial phosphating solutions. The additives include manganese dihydrogen phosphate, sodium fluorosilicate, tartaric acid, citric acid, HEDP, polyvinyl alcohol, starch phosphate monoester and gluconic acid; the degree of substitution of the starch phosphate monoester is 0.12. Compared with the prior art, the manganese-based phosphating solution additive of the present invention has the advantages of using tartaric acid instead of nitrite and cooperating with fluorosilicate to accelerate the film-forming speed; organic carboxylate is complexed with metal cations to make The crystal grains are refined, and the phosphating solution sediment is reduced at the same time to ensure the quality of the phosphating film. Coating adhesion; the additive has a wide application range, low cost, convenient use, energy saving and environmental protection, and is beneficial to industrial production.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of phosphating treatment solution for steel drawing at room temperature

Owner:武汉金瑞欣精密工业设备有限公司

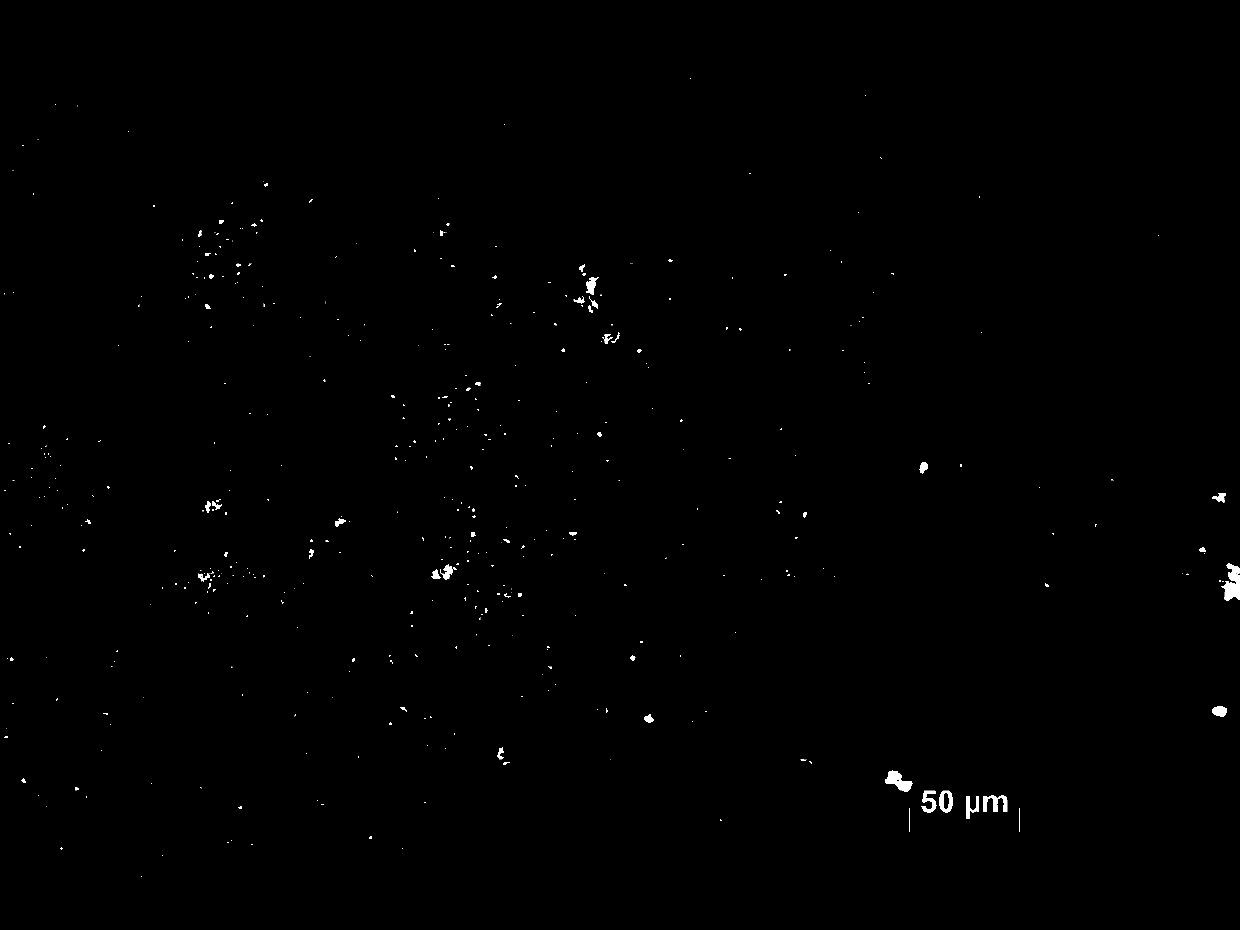

Novel efficient manganese-series surface conditioning agent as well as preparation method and application thereof

PendingCN114606488AChange the microstateOvercome coarseningMetallic material coating processesManganeseFluoride

The invention relates to a novel efficient manganese-series surface conditioning agent as well as a preparation method and application thereof. The manganese-series surface conditioning agent is prepared from the following components in percentage by weight: 20 to 40 percent of manganese salt, 3 to 5 percent of organic salt complex, 10 to 25 percent of fluoride, 15 to 35 percent of sodium carbonate and 2 to 15 percent of dispersion accelerant. According to the invention, a phosphating film which is fine in crystal, uniform and compact, high in protection performance and capable of being firmly combined with a matrix can be formed on the surface of a metal workpiece in a short time and at a lower temperature; according to the invention, the micro-state of the surface of the metal workpiece can be changed, the phenomenon of coarsening of the coating of the metal workpiece can be overcome, and the defects of uneven corrosion and the like caused by strong alkaline degreasing or strong acidic rust removal of the metal workpiece can be eliminated; the phosphating solution also can enhance the corrosion resistance of the surface of a metal workpiece, improve the adhesive force of a coating film, reduce the residue amount in the phosphating solution and reduce the consumption of the phosphating solution, and has the advantages of removing impurities brought by the workpiece, preventing the aging of the bath solution, prolonging the service life of the bath solution, improving the phosphating speed and shortening the treatment time.

Owner:东莞市精诚环保科技有限公司

Normal temperature quick phosphorizing agent for metal plastic deformation and preparation method thereof

InactiveCN100376718CFast phosphatingLow priceMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a normal temperature fast bonderite and producing method of metal plastic deformation, which is characterized by the following: the bonderite is composed of phosphoric acid, methyl ethyl ketone or acetone, eldopaque, manganese dihydrogen phosphate, calcium nitrate, zinc nitrate and water; the method comprises the following steps: mixing, emulsifying, restirring; the raw materials of bonderite is at a low price, which can be used at normal temperature. The method is easy to product, which reduces the costs of conversion.

Owner:赵惠霖

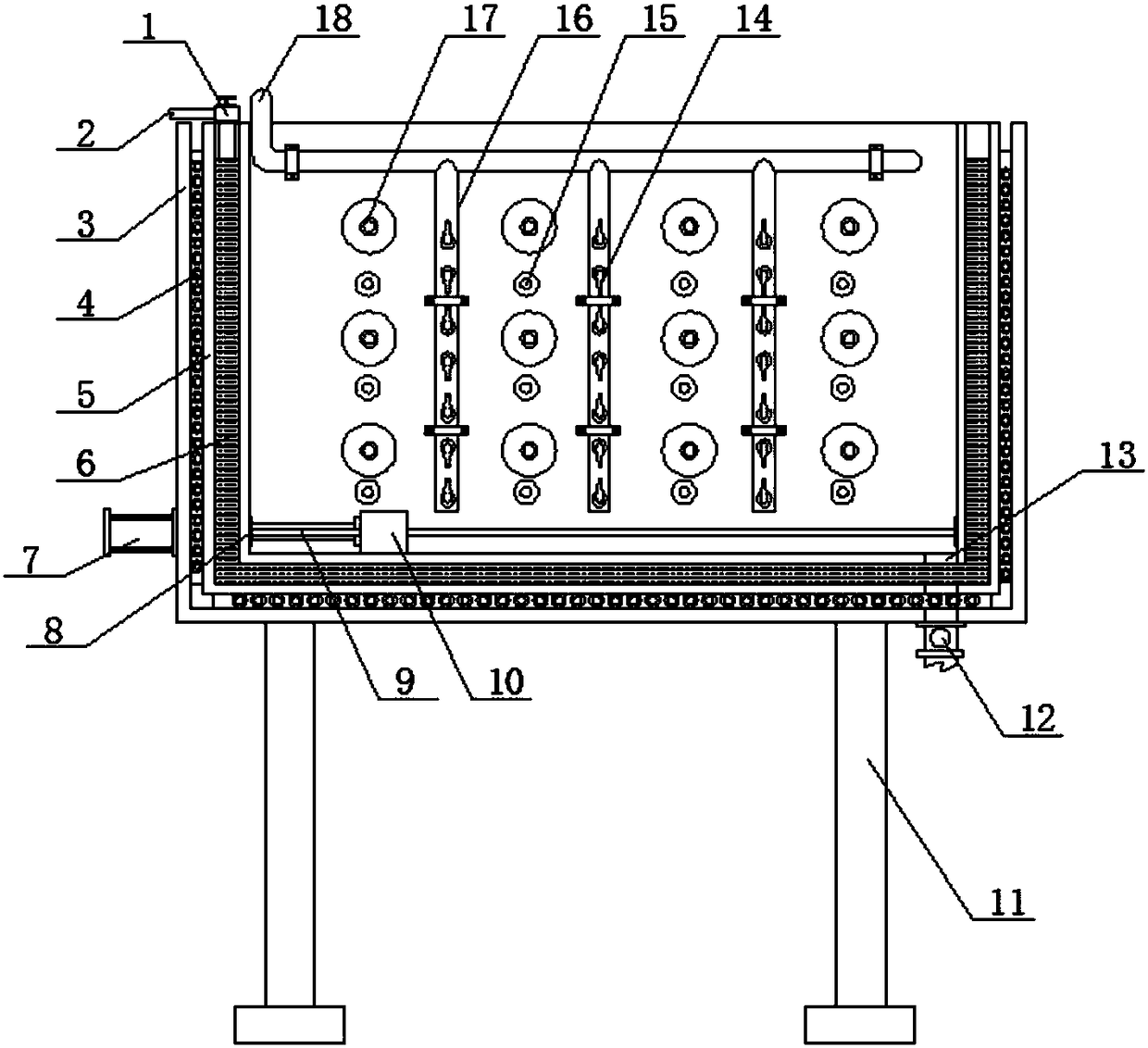

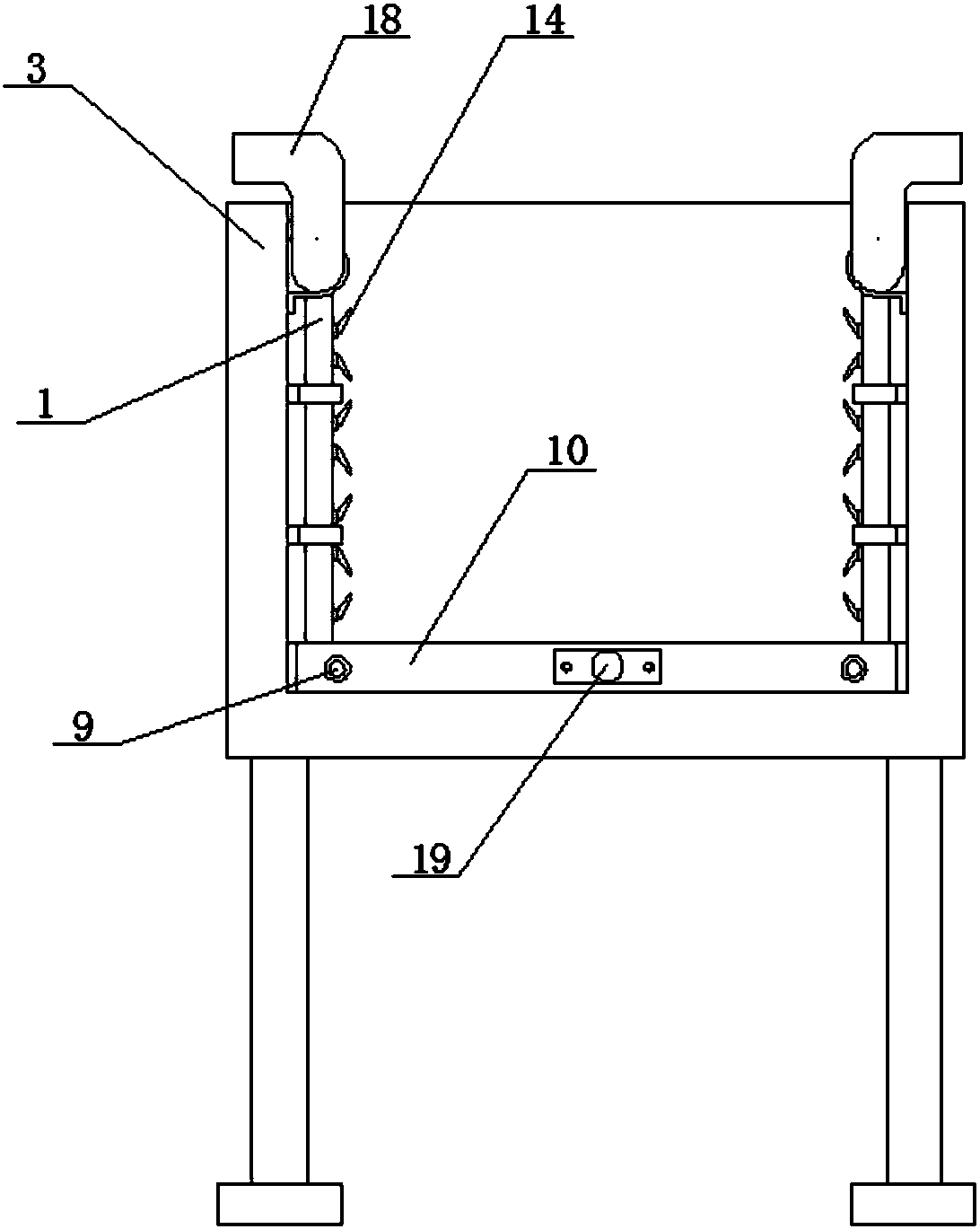

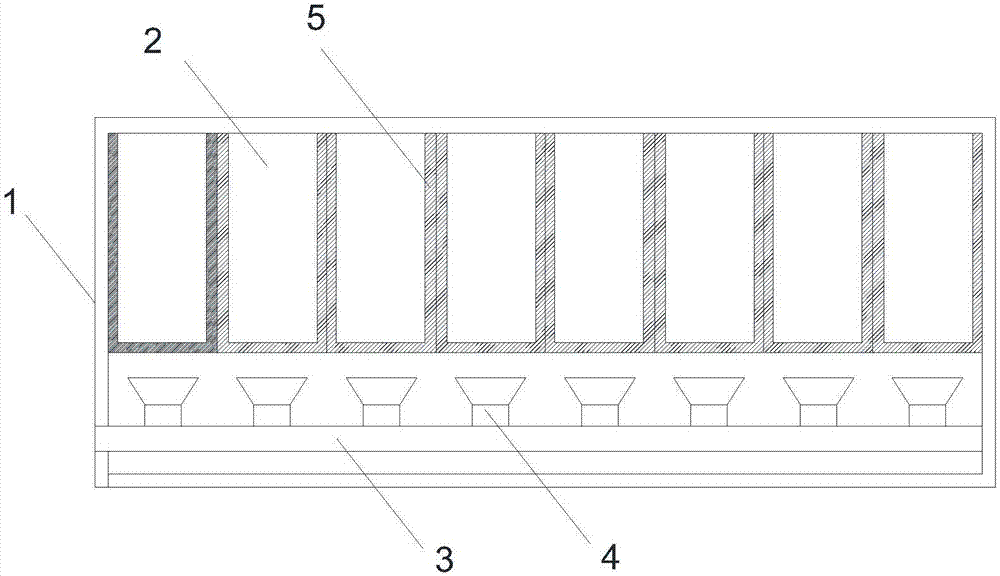

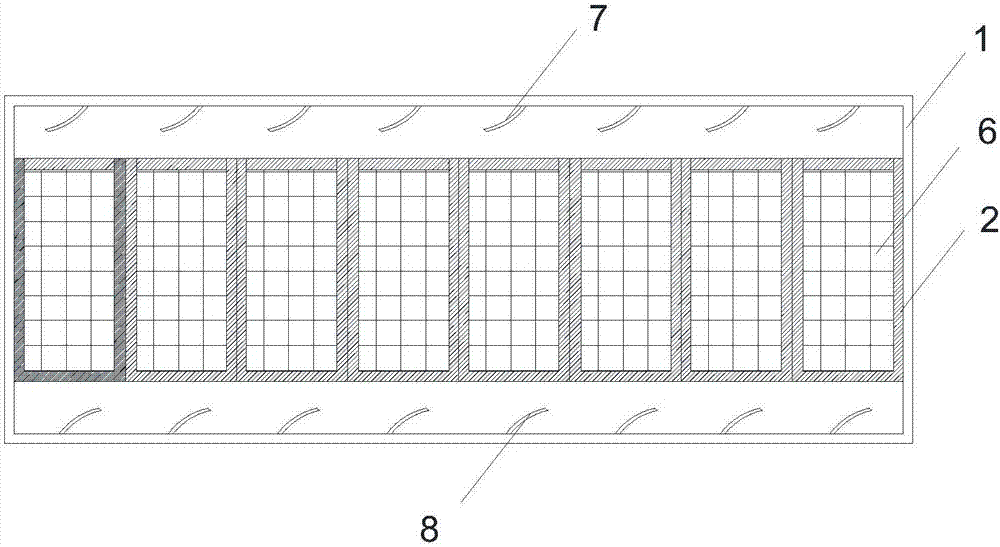

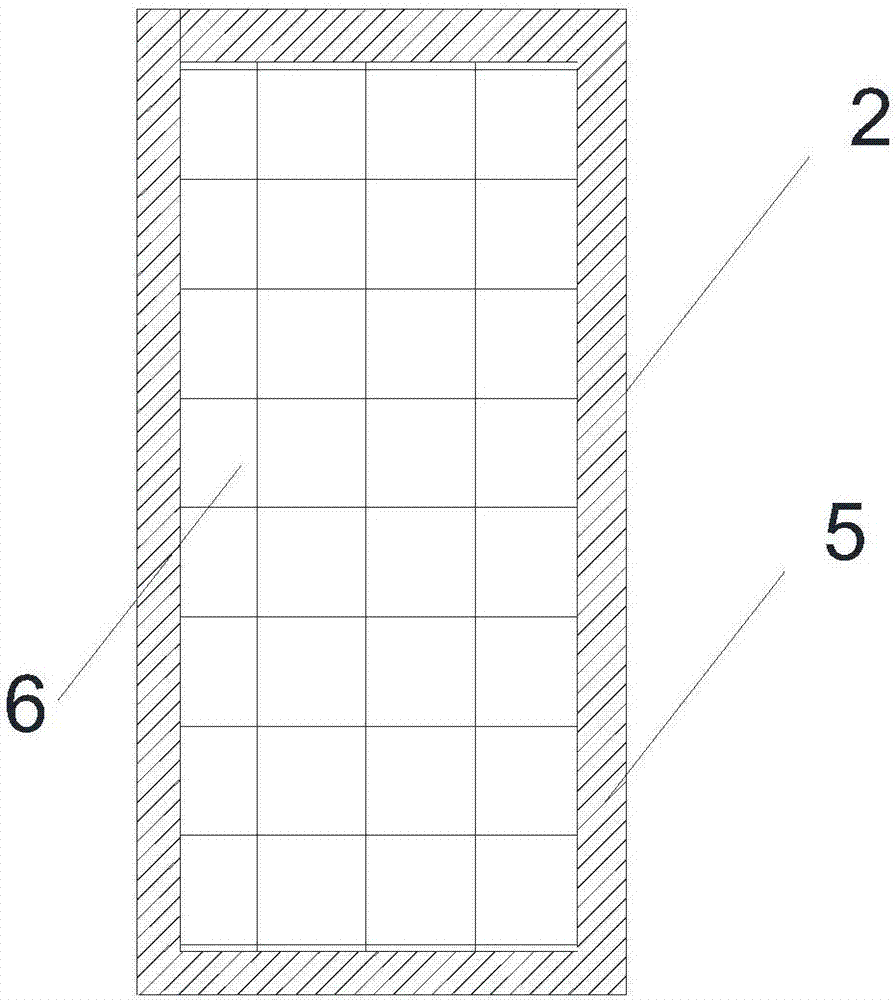

Ultrasonic phosphorizing device

PendingCN108425111ASolve problems such as rustImprove the quality of subsequent processingMetallic material coating processesUltrasonic sensorHeat conducting

The invention discloses an ultrasonic phosphorizing device for goods shelf production. The ultrasonic phosphorizing device comprises an outer jacket and a phosphorizing tank, supporting feet are arranged at the bottom of the phosphorizing tank, the outer jacket is nested outside the phosphorizing tank, an electric heating resistance wire is paved on the outer surface of the phosphorizing tank andarranged between the phosphorizing tank and the outer jacket, and an ultrasonic transducer and a temperature sensor are mounted on the side wall of the phosphorizing tank in an embedded manner and arranged in an up-down staggered manner. Ultrasonic phosphorizing technology is adopted, so that easiness in adjustment and control is realized; a phosphorized film obtained by the method is uniform, thin, compact and high in phosphorizing speed and corrosion resistance, and subsequent processing quality of workpieces is improved; heat conducting liquid is utilized to uniformly heat the phosphorizingtank, so that the problem that the phosphorizing tank is too high in temperature locally caused by the electric heating resistance wire is avoided; a nozzle enables tank liquid to be quickly stirredwell, so that heating efficiency is improved; an automatic deslagging device is arranged, so that labor intensity of workers is lowered.

Owner:浙江剑麟金属制品有限公司

A kind of composition for iron and steel phosphating and preparation method thereof

Owner:浙江迪特高强度螺栓有限公司

Microcrystalline phosphating solution for brake block hardware

InactiveCN101348906BImprove pollutionLittle pollutionMetallic material coating processesPhosphateNitrobenzene

The invention provides a pollution-free microcrystalline phosphating treatment solution for brake pad hardware, which is mainly made from the following raw materials in portion by weight: 40 to 50 portions of zinc nitrate, 22 to 30 portions of zinc dihydrogen phosphate, 30 to 40 portions of Mazhev salt (manganous dihydrogen phosphate), 1.5 to 2 portions of guanidine nitrate, 1.5 to 2 portions of sodium m-nitrobenzene sulfonate, 1 to 2 portions of sodium tripolyphosphate, 2 to 4 portions of tartaric acid, 2 to 3 portions of sulfosalicylic acid, 1.5 to 2.5 portions of citric acid and 1,000 to 1,200 portions of water. The solution is used for the blackening-phosphating treatment of the surface of iron hardware, and has the characteristics of fast phosphorization, good performances, little environmental pollution, low cost, etc. The treatment solution has the advantages of fine phosphatized crystals of phosphating films, uniform color in consistent black and good corrosion resistance. Especially, as the treatment solution chooses the raw materials with little environmental pollution and high efficiency, the treatment solution acquires excellent effects in both phosphatization and environmental protection through optimized combination and reasonable proportioning.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Phosphorizing agent capable of cleaning and derusting synchronously and preparing process thereof

InactiveCN1219913CLow priceEasy dischargeMetallic material coating processesIonophoric ActivityActive agent

The invention discloses a normal temperature three-in-one phosphorizing agent capable of cleaning and derusting synchronously and preparing process thereof, wherein the bonderite comprises phosphorus acid, methyl ketone, ethanol, hydroquinone, non-ionic active agent and water as raw material, which is prepared through the steps of agitating, emulsifying and restirring.

Owner:赵惠霖

High-temperature phosphating tank for automobile hub

InactiveCN107974678APhosphating time is shortImprove phosphating effectMetallic material coating processesEngineeringGas-filled tube

The invention relates to the technical field of hub machining equipment and technologies, in particular to a high-temperature phosphating tank for an automobile hub. A main body of the high-temperature phosphating tank is a rectangular tank body; hub baskets are arranged in the middle position in the tank body side by side; the bottoms of the hub baskets are hollowed-out grids; an inflating pipe is arranged under the nub baskets, and aeration discs are vertically upwards arranged on the inflating pipe; and a left turbulence plate and a right turbulence plate are further arranged on the inner walls of the two sides of the tank body correspondingly. The phosphating tank is subjected to turbulence through the inflating pipe, the contact area and the contact degree between a phosphating solution and the automobile hub are increased, and the acting force of the phosphating solution on the hub is increased; and through the left turbulence plate and the right turbulence plate which are arranged on the inner walls of the tank body and by matching the effect of the inflating pipe, the phosphating solution can rotate in the tank body in the same direction and at different slow speeds, in this way, a reaction between the phosphating solution and the hub can be fully increased, and thus the effects that the function of full phosphating is achieved, and the phosphating speed is increased are achieved.

Owner:BENGBU FUWOTE WHEEL MFG TECH

Intermediate and phosphorizing agent prepared thereby and preparation process thereof

The invention discloses an intermediate, a phosphating agent prepared using the intermediate and a preparation method thereof. The intermediate uses manganese dihydrogen phosphate, zinc nitrate, ammonium ethylenediaminetetraacetate, calcium nitrate and water as raw materials, and is prepared by stirring and mixing. Phosphating agents prepared using intermediates are prepared by using zinc dihydrogen phosphate, zinc oxide, methyl ethyl ketone (or acetone), hydroquinone and water as raw materials, stirring and mixing, and then adding intermediates. The intermediate of the present invention can reduce transportation costs and warehousing costs. The phosphating agent prepared with it can be used in the coating process at normal temperature, and can also be used as a phosphating agent in the drawing process of steel wire ropes and special steel wires. It can also be used as a phosphating agent for cold extrusion and cold forging production. The raw materials prepared by the invention are cheap, can be used at normal temperature, have good phosphating effect, fast phosphating speed, which only takes a few seconds, are non-corrosive, non-toxic, harmless and pollution-free, have almost no waste residue emissions, and can be reused many times. ,long time.

Owner:赵惠霖

A kind of rust-removing phosphating solution for wire drawing and preparation method thereof

ActiveCN108048826BHigh hardnessImprove adhesionMetallic material coating processesO-Phosphoric AcidPhosphate

The purpose of the present invention is to solve the problem that the wire pickling and phosphating treatment processes are carried out separately, resulting in high cost of wastewater treatment caused by water washing, insufficient firmness of the phosphating film, fracture phenomenon in drawing, and high corrosive components contained in the phosphating agent. The problem is to provide a rust-removing phosphating solution for wire drawing and a preparation method thereof, belonging to the technical field of rust-removing and phosphating treatment of metal surfaces. The derusting and phosphating solution for wire drawing is composed of the following chemical components in mass percentage: concentrated phosphoric acid: 20~50%; concentrated nitric acid: 1~10%; zinc oxide: 1~10%; dihydrogen phosphate: 2~ 10%; nitrate: 1~10%; manganese carbonate: 0.5~5%; complexing agent: 0.2~5%; fluorine-containing surfactant: 0.05~1%; water: balance. After being treated by the rust-removing phosphating solution of the present invention, a layer of gray-black uniform and dense phosphating film is formed on the surface of the steel wire and welded steel pipe, which plays a better lubricating role in the drawing and cold working process.

Owner:鞍山晨雷科技有限公司

External thread ferrule connector

InactiveCN111394717APromotes electrochemical reactionsPromote formationMetallic material coating processesPhosphatePhysical chemistry

The invention discloses an external thread ferrule connector. The ferrule connector is characterized in that a phosphating film is formed on the outer surface of each part of the ferrule connector through phosphating solution treatment, wherein a phosphating solution comprises, by weight, 210-240 parts of phosphoric acid, 30-40 parts of zinc salt, 15-20 parts of manganese salt, 20-25 parts of a dispersant and 20-25 parts of an accelerant. After the ferrule connector is put into the phosphating solution, the anodic oxidation process of Fe occurs on the surface of the ferrule connector, and substances such as Fe (H2PO4) 2, Zn (H2PO4)2, Zn3 (PO4) 2.4H2O and Zn2Fe (PO4) 2.4H2O are generated; when phosphating reaction is carried out until the concentration of each substance correspondingly reaches respective solubility product, insoluble phosphates form crystal nucleuses on active points on the surface of the ferrule connector, and the crystal nucleuses are taken as the center to continuously extend and grow towards the periphery of the surface to form crystals until the continuous and uniform phosphating film is formed on a treated metal surface; and meanwhile, the manganese salt can accelerate the anodic oxidation process of Fe on the surface of the ferrule connector as well as the film forming speed of the phosphating film on the metal surface, so that the continuous, uniform andcompact phosphating film is formed on the surface of the ferrule connector, and a continuous protection effect is achieved.

Owner:ZHEJIANG FANGDUN INSTR VALVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com