Patents

Literature

94results about How to "Improve phosphating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

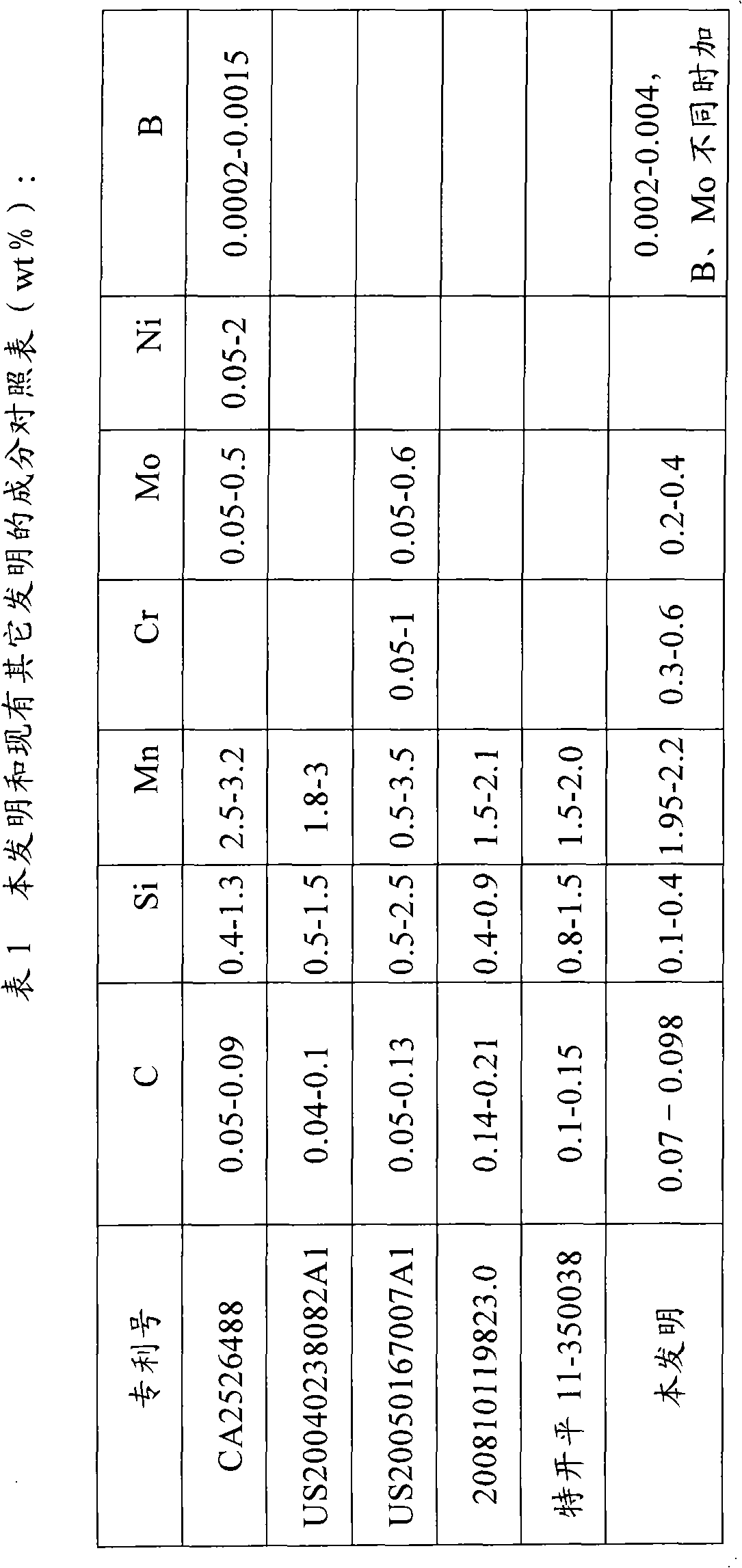

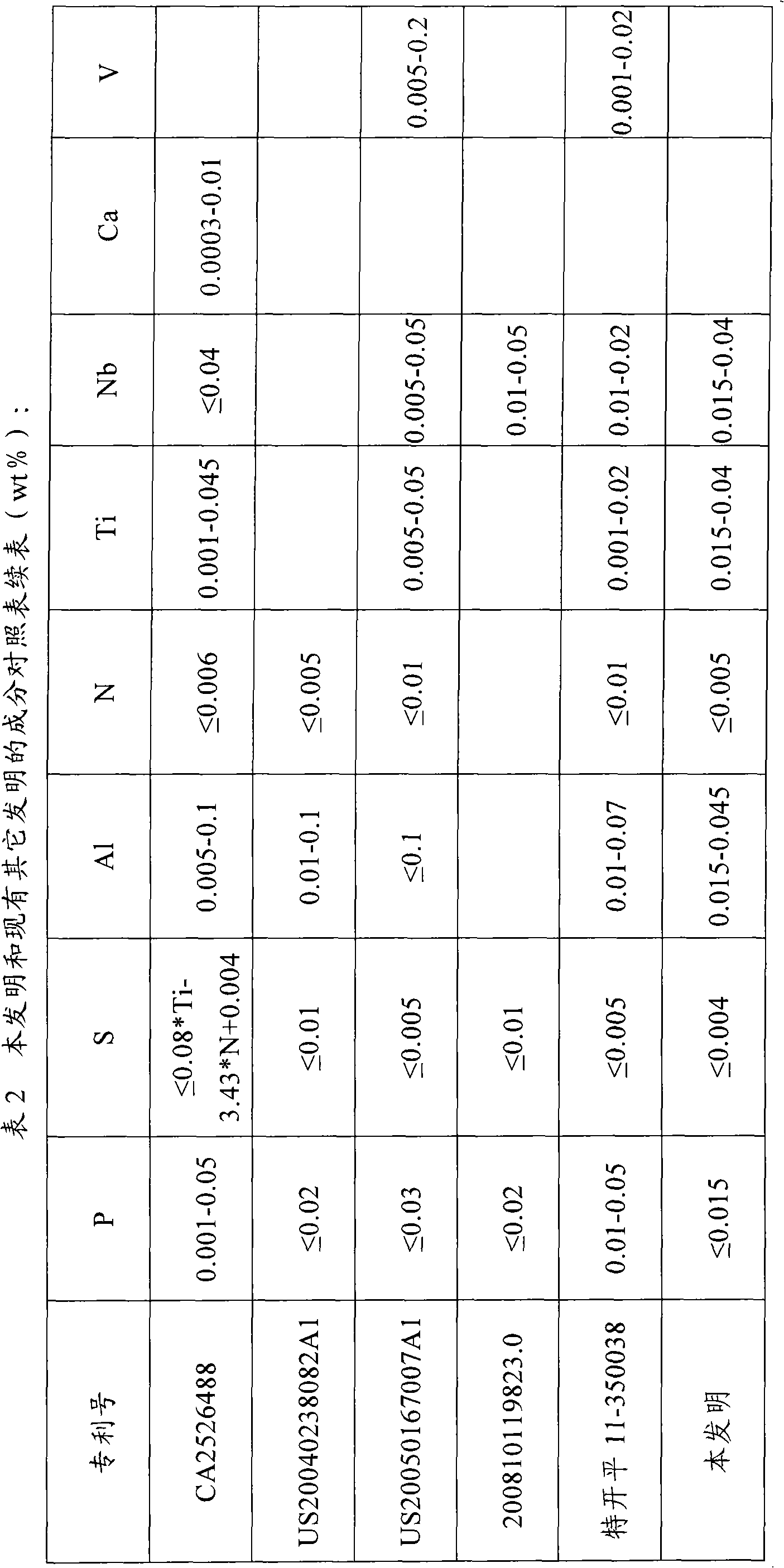

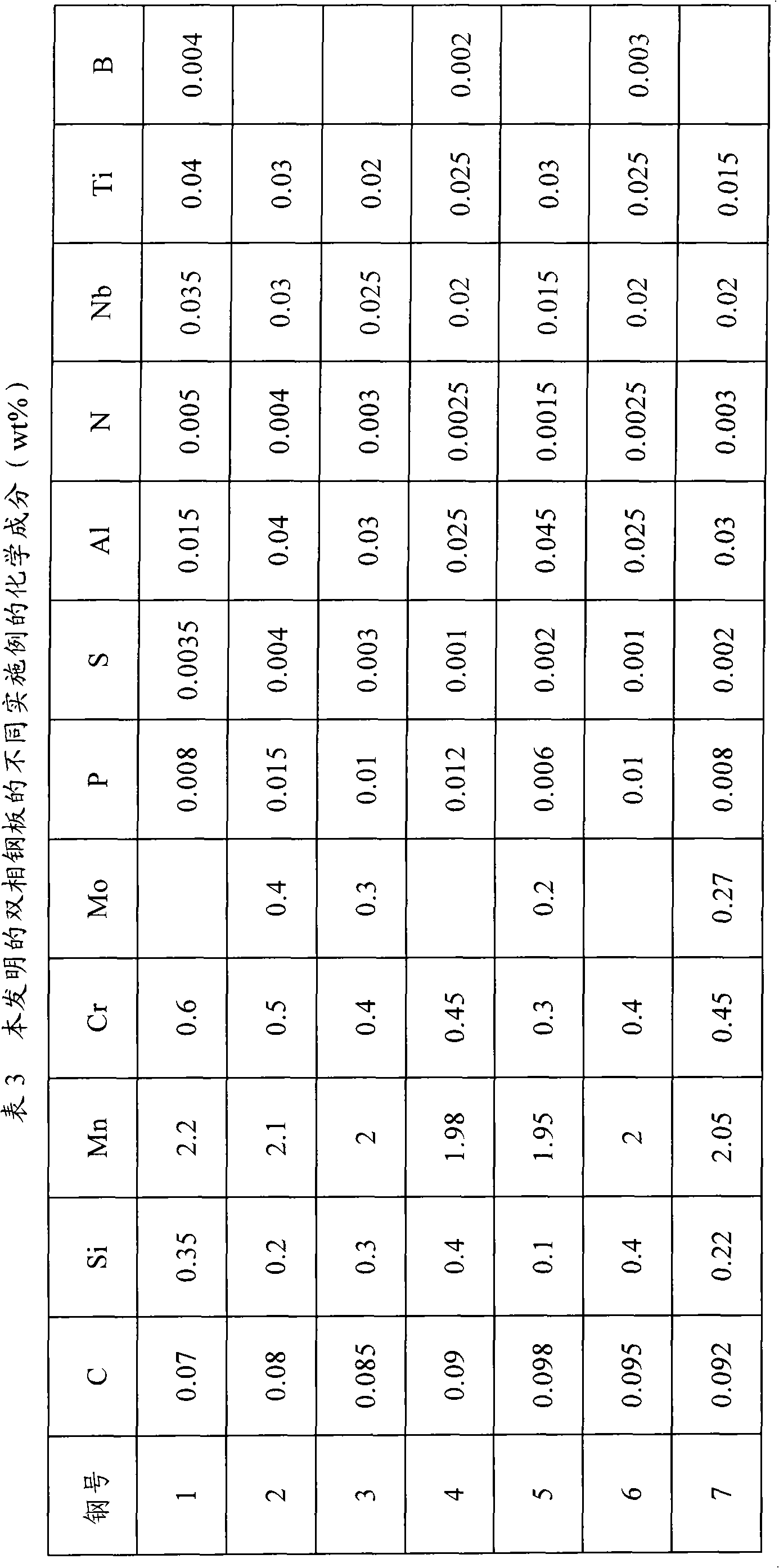

Double-phase steel plate and manufacturing method thereof

ActiveCN102586688AReduce the degree of enrichmentReduce defects such as red rustManufacturing technologyDouble phase

The invention provides a double-phase steel plate which comprises 0.07-0.098 of C, 0.1-0.4 of Si, 1.95-2.2 of Mn, 0.3-0.6 of Cr, less than or equal to 0.015 of P, less than or equal to 0.004 of S, less than or equal to 0.005 of N, 0.015-0.04 of Nb, 0.015-0.04 of Ti, 0.015-0.045 of Al, and 0.002-0.004 of B or 0.2-0.4 or Mo, wherein Pcm equals to C+Si / 30+Mn / 20+2P+4S which is less than or equals to 0.24; and the double-phase steel plate also comprises the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the double-phase steel plate. The high-strength uniform-performance double-phase steel plate can be obtained by the proper composition design and manufacturing technology, and the manufacturing requirements on parts of a high-strength automobile body can be better met.

Owner:BAOSHAN IRON & STEEL CO LTD

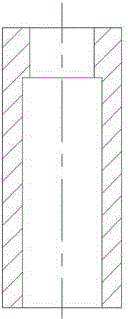

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

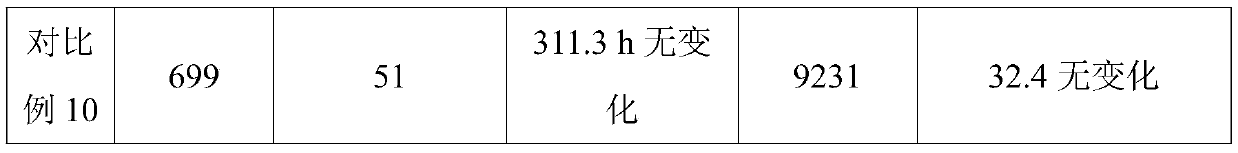

Cold-roll steel sheet with good phosphorization performance and production method

The invention provides a cold-roll steel sheet with the good phosphorization performance and a production method. The cold-roll steel sheet contains, by weight, smaller than or equal to 0.10% of C, smaller than or equal to 0.030% of Si, smaller than or equal to 0.50% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.080% of Al, smaller than or equal to 0.0080% of N, smaller than or equal to 0.10% of Ti and the balance Fe and unavoidable impurities. Compared with the prior art, the cold-roll steel sheet is characterized by being produced through the procedures of hot rolling, acid pickling, five-rack complete-six-roll cold continuous rolling and continuous annealing and levelling by precisely controlling the components in steel. After the produced steel sheet is phosphorized, a phosphorization film is uniform, the film weight is larger than or equal to 2.5 g / m<2>, the copper sulfate drop experiment time in corrosion resistance evaluation is longer than or equal to 60 s, the time that the steel sheet is soaked in a 3 wt% NaCl solution before the steel sheet starts to be rusted is longer than or equal to 75 min, and the requirements of steel downstream users on the high appearance quality and the good corrosion resistance of the phosphorized cold-roll steel sheet are met.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

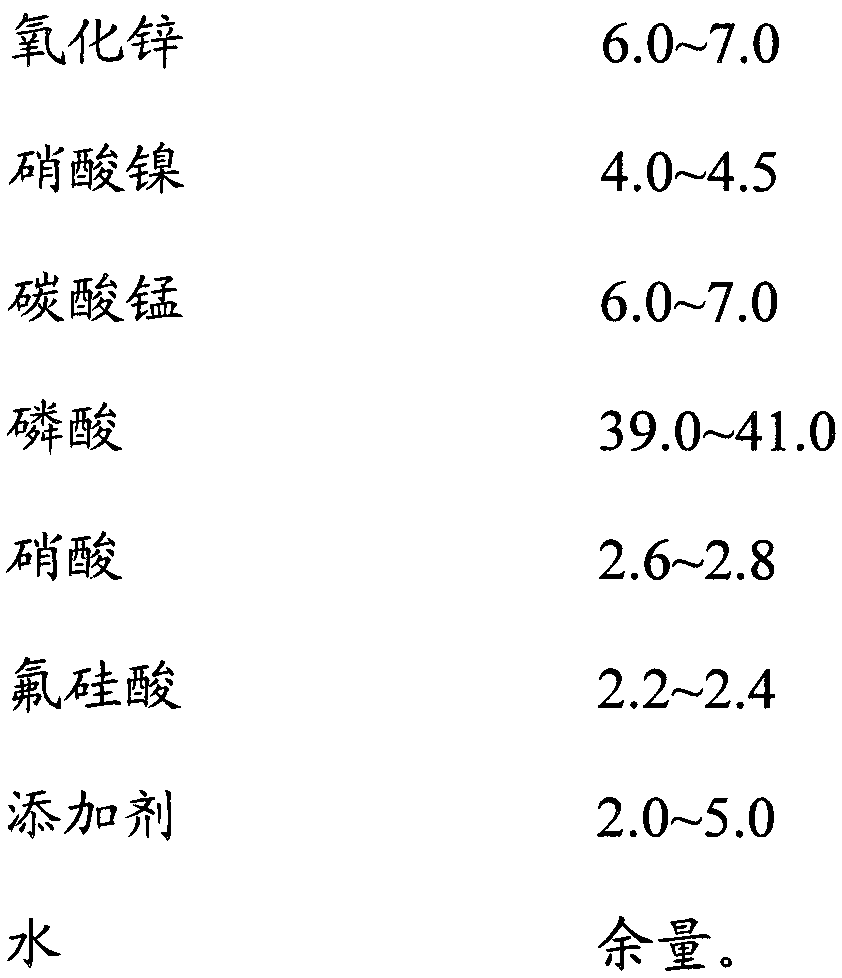

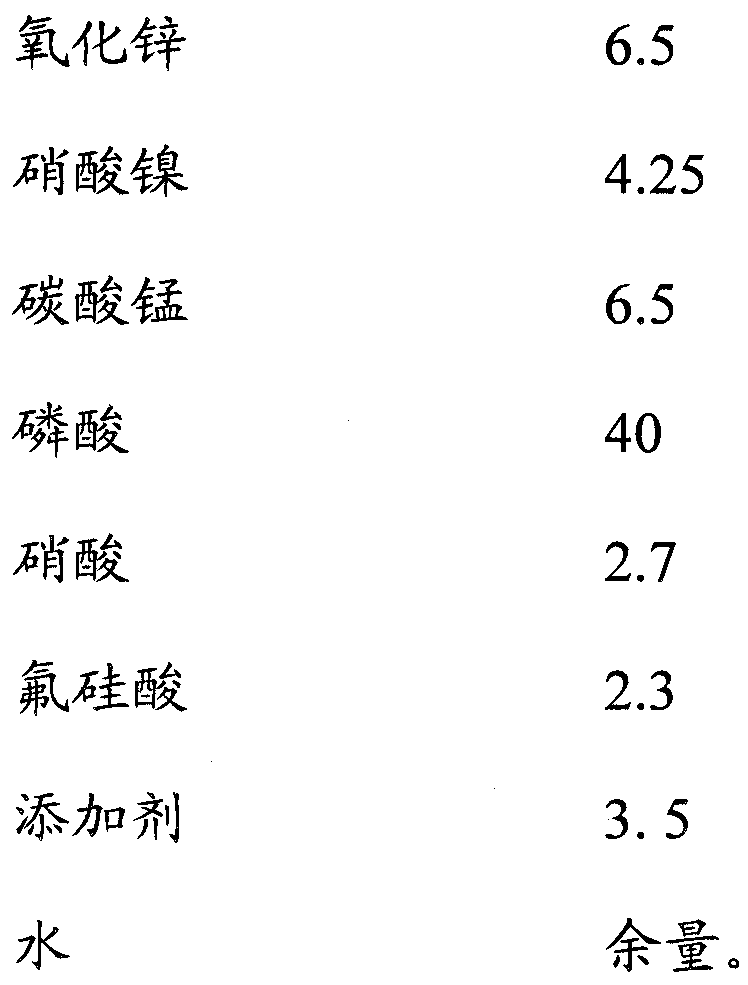

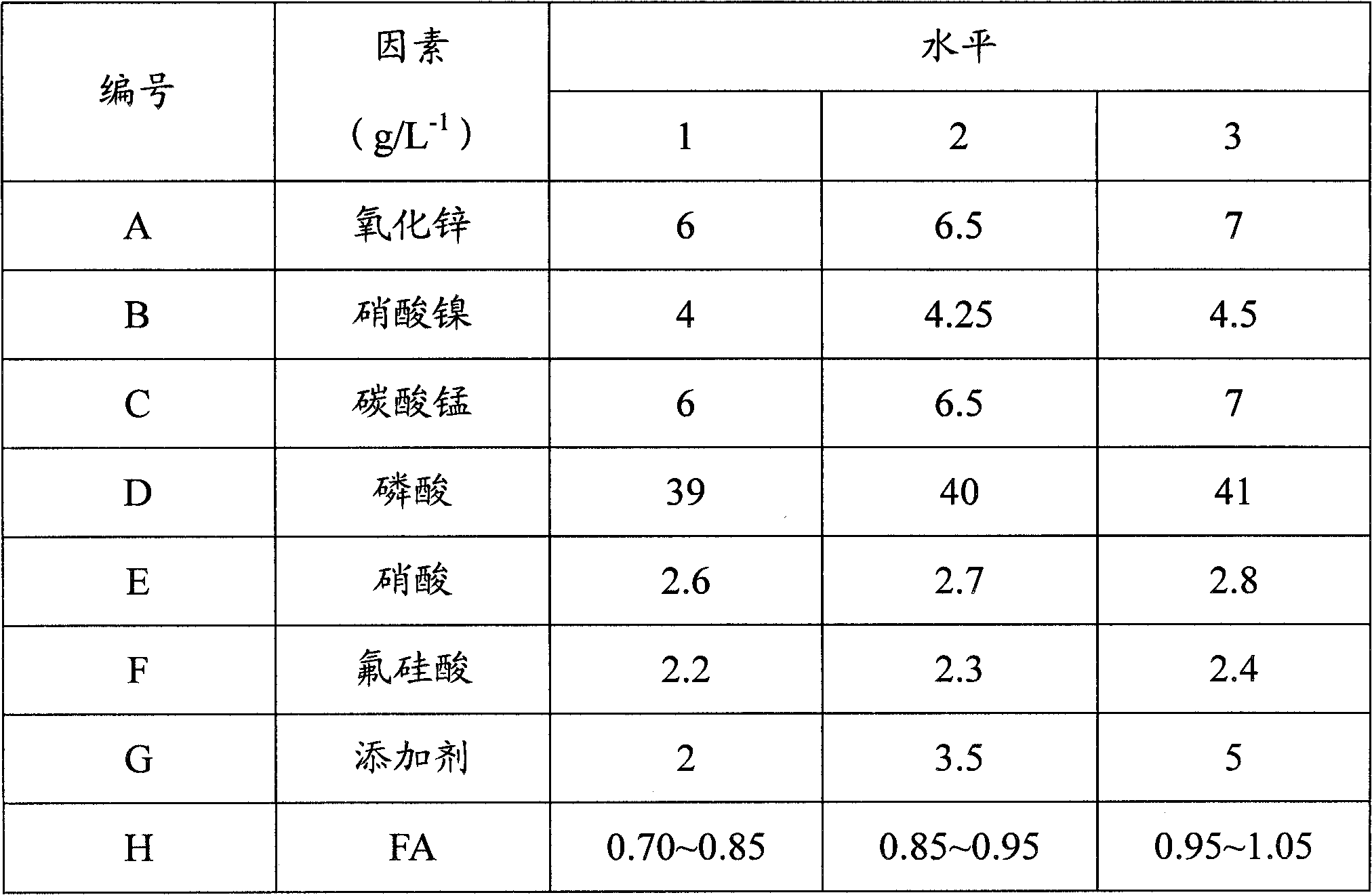

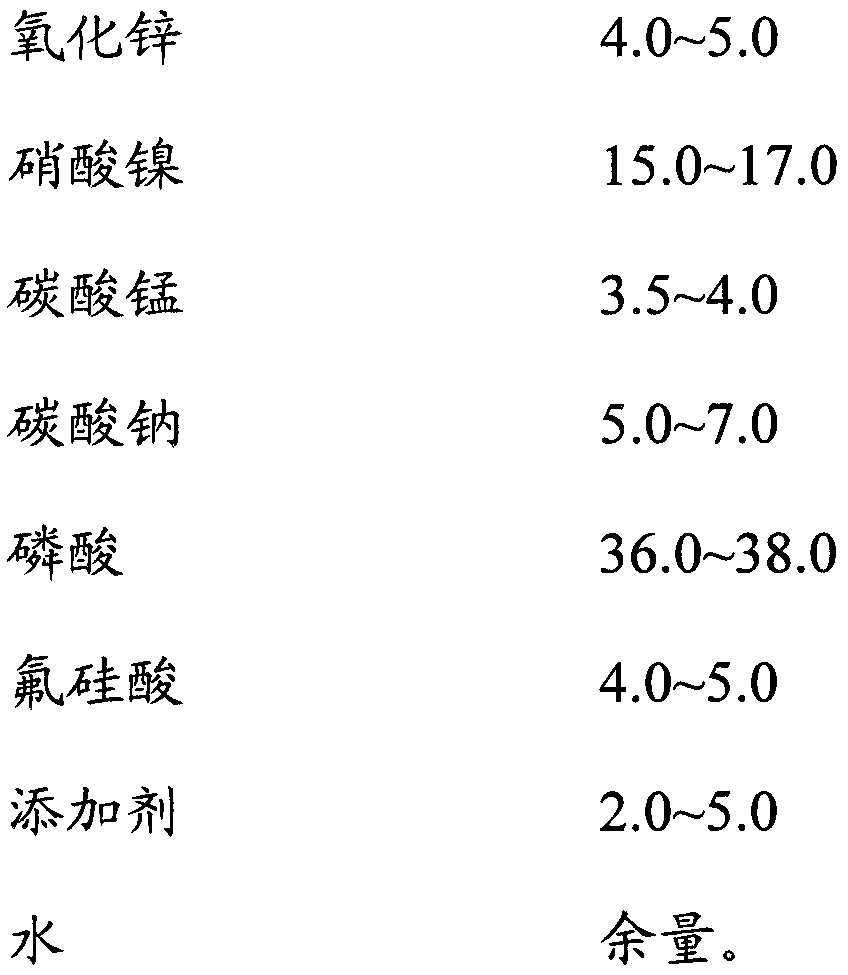

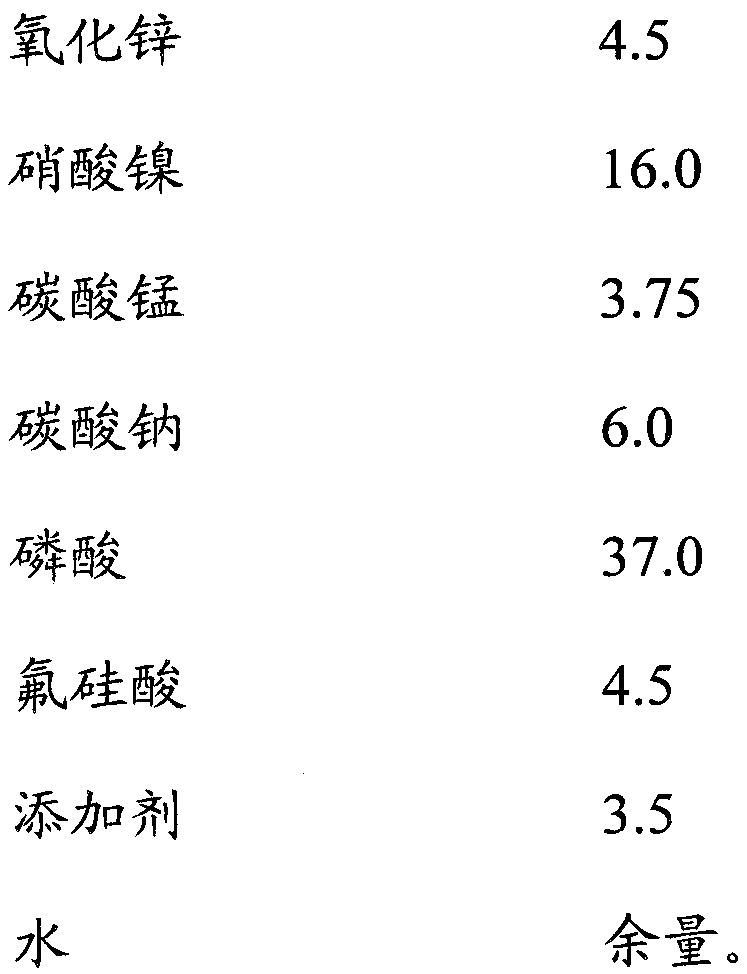

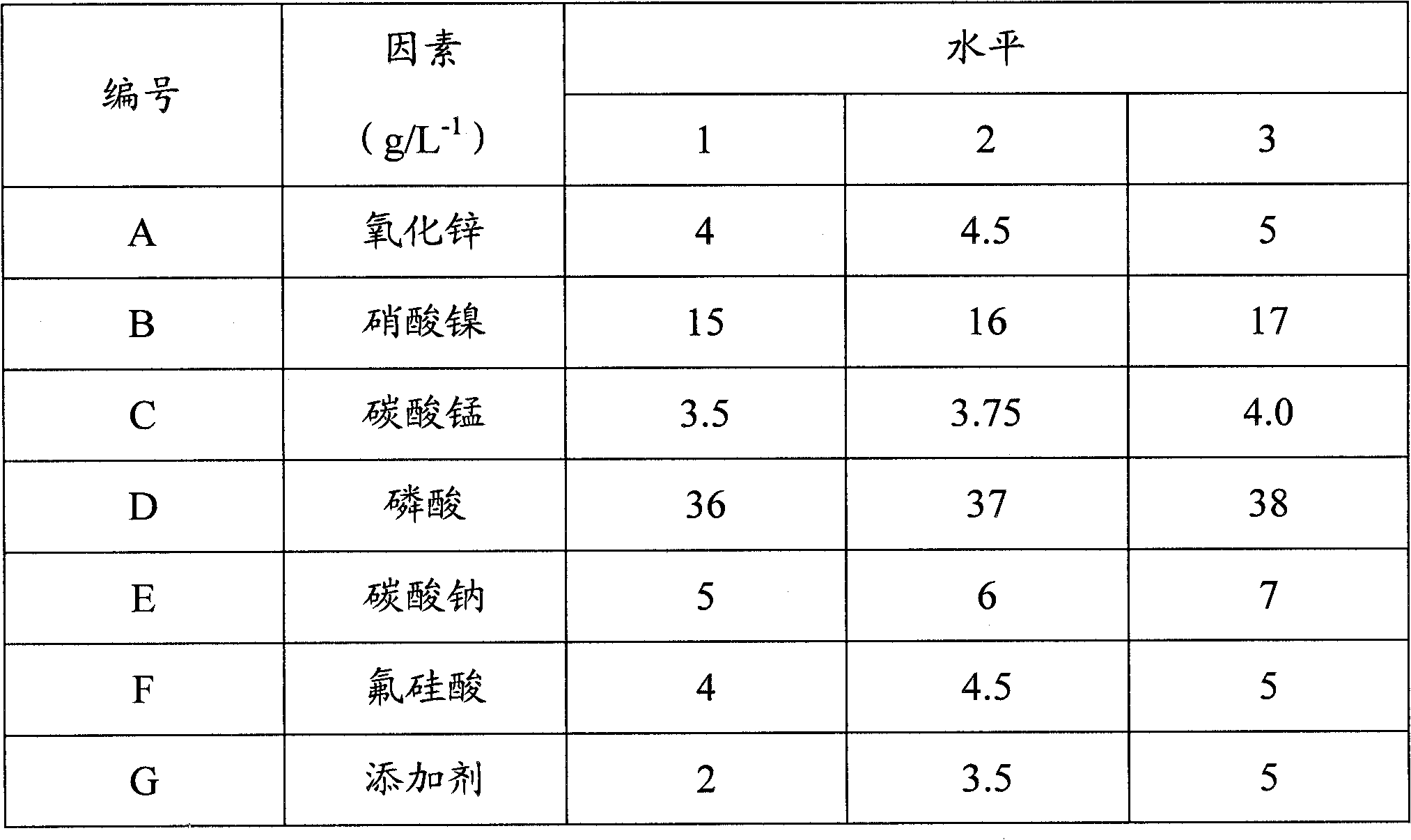

General phosphating agent

InactiveCN102719819AEasy to handlePrevent rustMetallic material coating processesNitratePhosphoric acid

The invention relates to the technical field of surface treatment technologies of metal materials and discloses a general phosphating agent which is suitable for surface treatment of metal materials such as steel, aluminium, zinc and the like. The general phosphating agent contains the following components: zinc oxide, nicdel nitrate, manganese carbonate, phosphoric acid, nitric acid, fluosilicic acid, an additive and water. The invention aims to provide the general phosphating agent with good versatility. The general phosphating agent can be widely used in surface treatment of metal such as steel, aluminium, zinc and the like and can be used to raise anticorrosion performance of metal surface.

Owner:CHONGQING RONGSHI METAL SURFACE TREATMENT AGENT

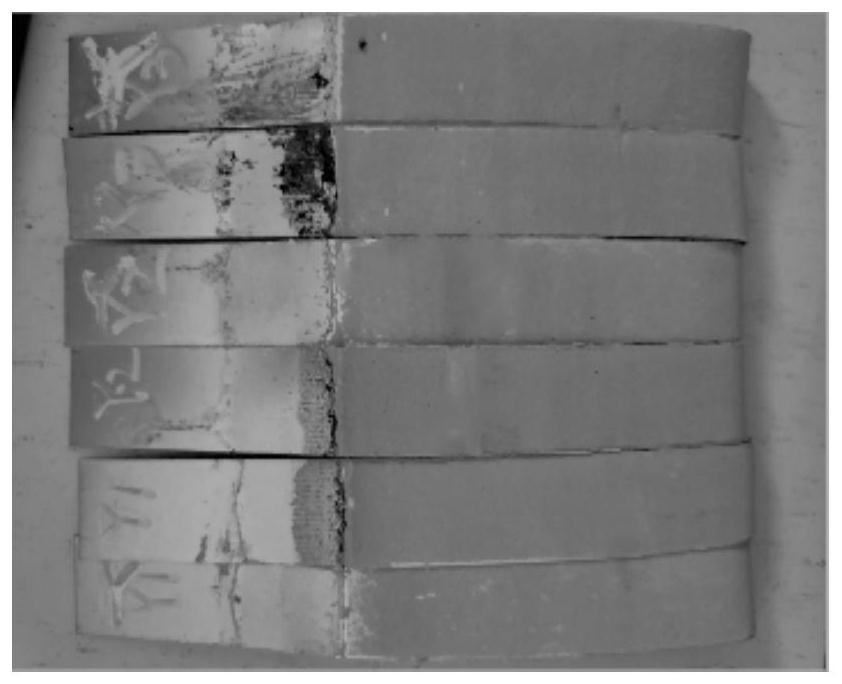

590MPa-grade cold-rolled dual-phase steel without surface stripe defect and production method thereof

The invention provides a 590MPa grade cold-rolled dual-phase steel without surface stripe defect and a production method thereof. The steel comprises the following components by weight percentage: 0.050% to 0.100% of C, less than or equal to 0.25% of Si, 1.20% to 2.00% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 0.05% to 0.10% of Al, 0.015 to 0.050% of Sb, and thebalance being Fe and other unavoidable impurities; The production method comprises the steps of smelting, continuous casting, hot charging heating, high pressure water descaling and rough rolling, finishing rolling, laminar cooling, reeling, hot rolling sheet pickling cold rolling, continuous annealing, air cooling, and leveling reeling, the 590MPa grade cold-rolled dual-phase steel produced by the invention has bright surface, no streaky defects, good corrosion resistance and coating adhesion, and excellent mechanical properties.

Owner:ANGANG STEEL CO LTD

High-strength hot-rolled steel sheet excellent in chemical treatability

ActiveUS20090032148A1Improve phosphating effectHigh strengthSynthetic resin layered productsRecord information storageHigh intensityHot rolled

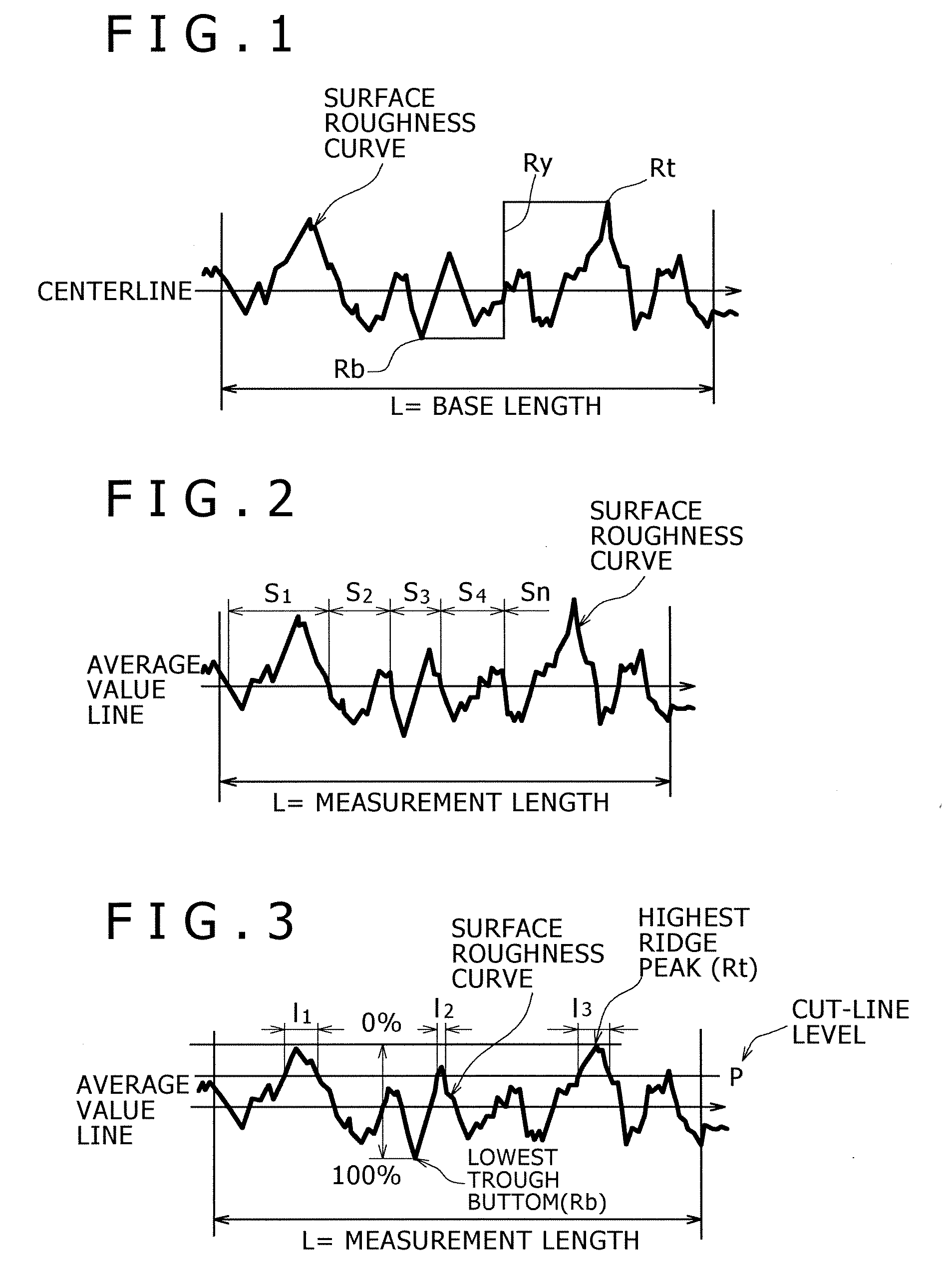

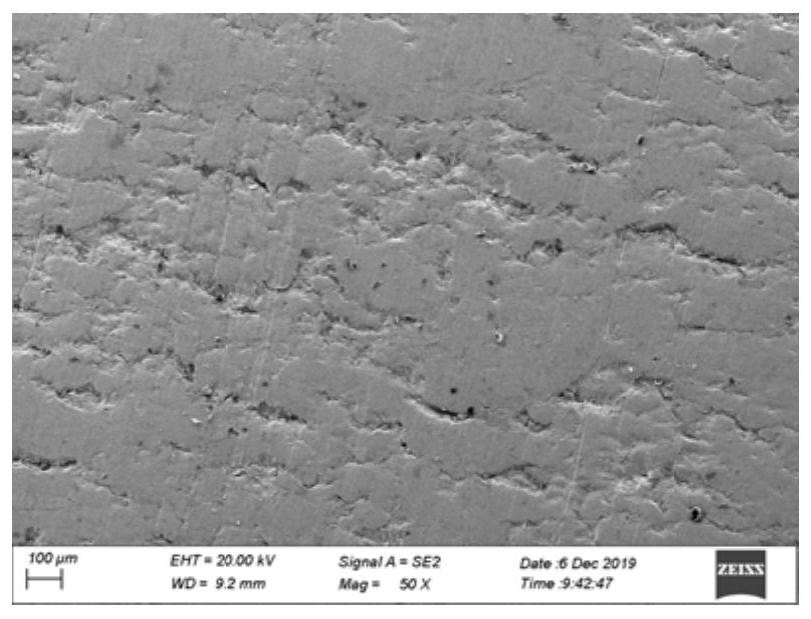

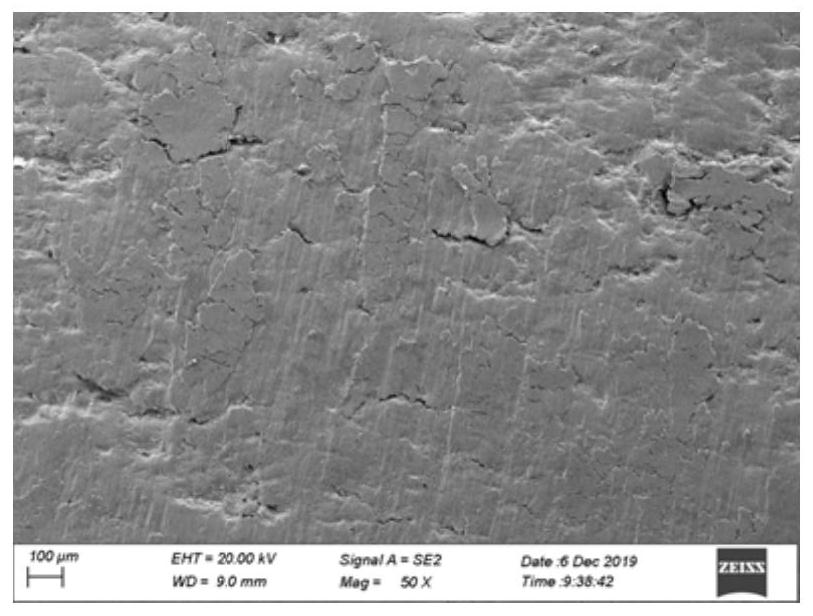

There is provided a high-strength hot rolled steel sheet excellent in phosphatability, wherein a maximum depth (Ry) of pits and bumps, existing on a surface thereof, is not less than 10 μm, and an average interval (Sm) of the pits and the bumps is not more than 30 μm, meeting either a requirement for a load length ratio (tp40) of the pits and the bumps on the surface at not more than 20%, or a requirement for a difference between a load length ratio (tp60) and the load length ratio (tp40), at not less than 60%, or both thereof. The high-strength hot rolled steel sheet is capable of exhibiting stable and excellent phosphatability even if Mo highly effective for reinforcement in strength is added thereto in expectation of a higher strength.

Owner:KOBE STEEL LTD

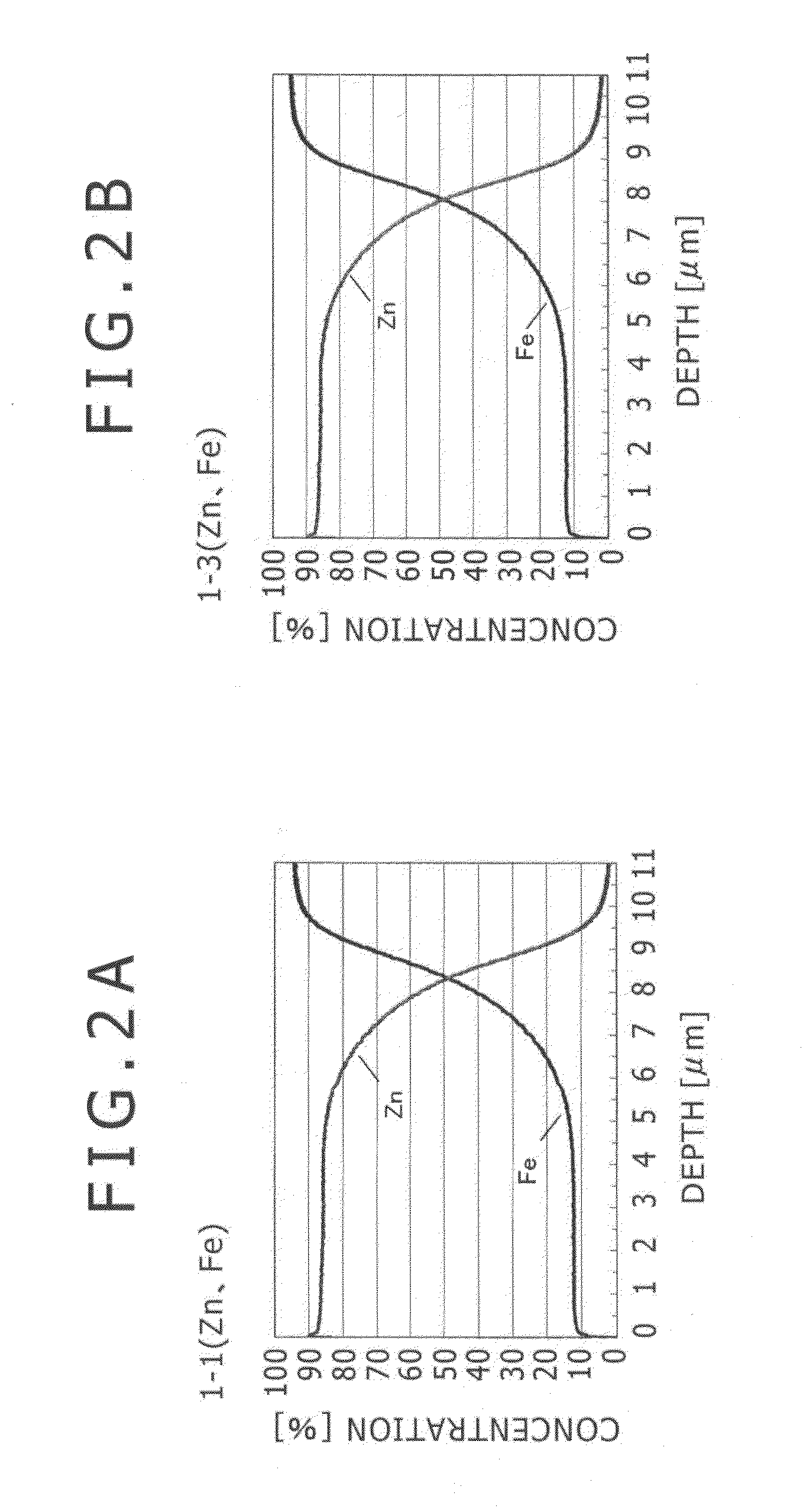

High strength hot dip galvannealed steel sheet of excellent phosphatability and ductility, and a production process therefor

InactiveUS20130236740A1Improve phosphating effectPhosphatability is deterioratedHot-dipping/immersion processesPretreated surfacesChemical compositionSheet steel

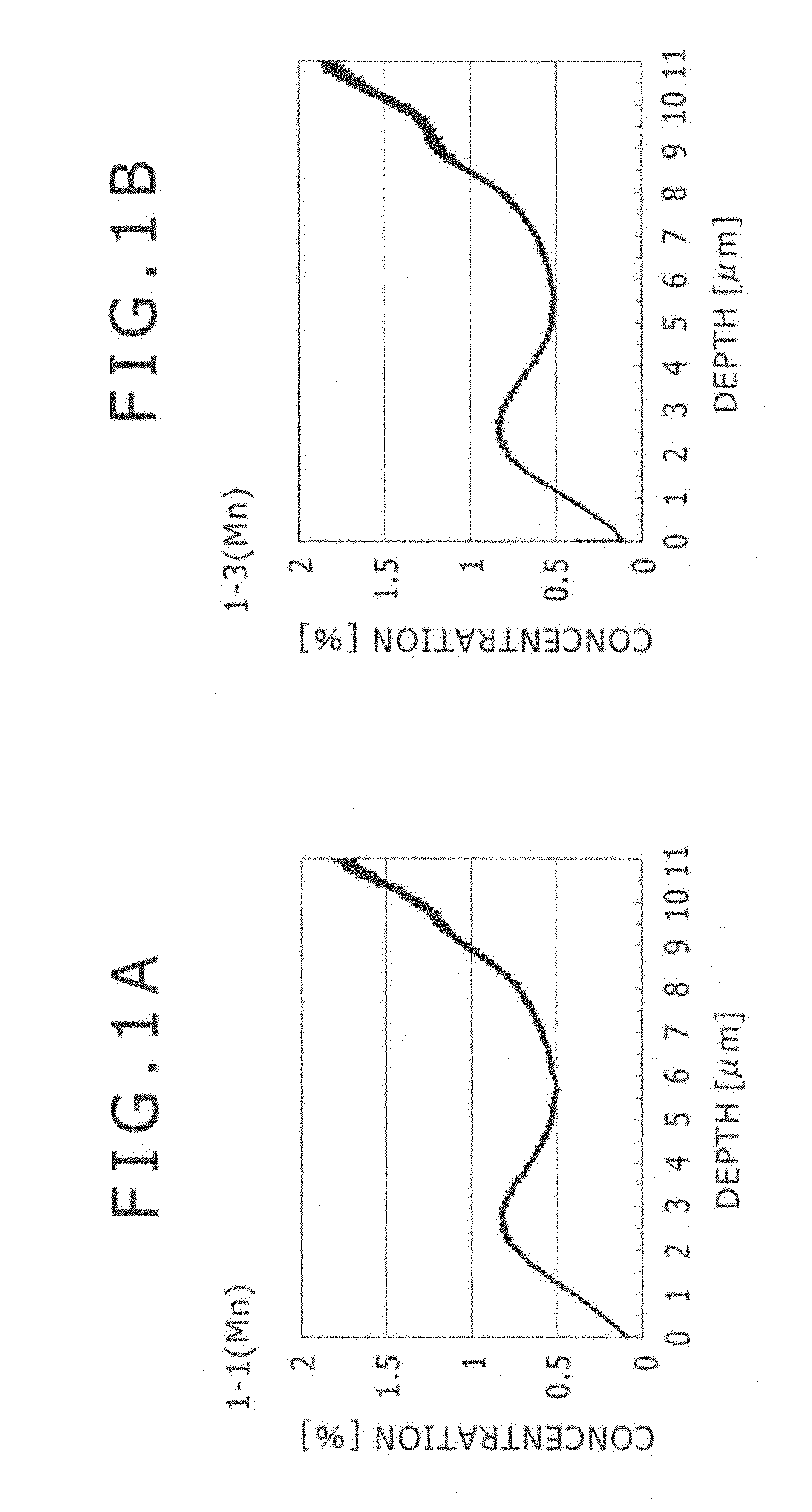

For obtaining a hot dip galvannealed steel sheet having high strength and high ductility and excellent phosphatability, a chemical composition of a material steel sheet for forming the hot dip galvannealed steel sheet comprises 0.4 to 2.0 mass % of Si and 1.0 to 3.5 mass % of Mn, and an average Mn concentration for a region from the uppermost surface to 0.01 μm depth in the coating layer is defined as 0.14% or more.

Owner:KOBE STEEL LTD

High strength steel sheet having superior ductility

ActiveUS7919194B2Improve ductilityHigh strengthHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A high strength steel sheet and a method for manufacturing the same has superior phosphatability properties and hot-dip galvannealed properties besides a tensile strength of 950 MPa or more and a high ductility, and also having a small variation in mechanical properties with the change in annealing conditions.

Owner:JFE STEEL CORP +1

Cathode electrophoretic phosphatizing agent

InactiveCN102719874AImprove corrosion resistancePromote formationElectrophoretic coatingsMetallic material coating processesPhosphateManganese

The present invention relates to a cathode electrophoretic coating technology field and discloses a cathode electrophoretic phosphatizing agent for pretreatment of cathode electrophoretic coating. The cathode electrophoretic phosphatizing agent comprises the following components: zinc oxide, nickel nitrate, manganese carbonate, sodium carbonate, phosphoric acid, fluosilicic acid, an additive and water. The invention aims to provide a cathode electrophoretic phosphatizing agent with high phosphorus ratio but simple components. When the Cathode electrophoretic phosphatizing agent is used in the pretreatment of cathode electrophoretic coating, a phosphate coating obtained has excellent adhesion and corrosion resistance.

Owner:CHONGQING RONGSHI METAL SURFACE TREATMENT AGENT

Surface treating agent for galvanized steel sheet, preparation method of surface treating agent, self-lubricating galvanized steel sheet, and preparation method of steel sheet

ActiveCN112410768AIncrease costGood compatibilityMetallic material coating processesPyrrolidinonesMaterials science

The invention discloses a surface treating agent for a galvanized steel sheet, a preparation method of the surface treating agent, a self-lubricating galvanized steel sheet, and a preparation method of the steel sheet, and belongs to the field of surface treating agents. The surface treating agent is mainly prepared from the following components: 0.01 mol / L to 0.10 mol / L of Mn<2+>, 0.001 mol / L to0.020 mol / L of Ni<2+>, 0.002 mol / L to 0.040 mol / L of NH2SO3<->, 0.02 mol / L to 0.24 mol / L of PO4<3->, 0.1 g / L to 0.5 g / L of polyvinylpyrrolidone, and the balance water, wherein the pH value of the surface treating agent is 1.5 to 4.0. The preparation method of the surface treating agent comprises the following steps: dissolving Mn(H2PO4)2.4H2O, Ni(NH2SO3)2.4H2O and polyvinylpyrrolidone in water, uniformly mixing, and adjusting the pH value by using H3PO4. The self-lubricating galvanized steel sheet sequentially comprises a galvanized layer, a lubricating film and an antirust layer, the galvanized layer is a pure zinc layer, and the lubricating film is formed by forming a film through the surface treating agent. According to the invention, stripping of the zinc layer on the surface of the steel sheet is reduced, meanwhile, the steel sheet has good phosphatization performance, and the adhesive performance is not reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

Phosphatization technology for steel surface

InactiveCN107099792ALow costLow priceMetallic material coating processesMaterials scienceRoom temperature

The invention relates to phosphatization technology for a steel surface. The phosphatization technology comprises the following steps: (1) deslagging and polishing a steel material; (2) performing first washing with water; (3) removing oil from the surface of the steel material by using an oil-removing liquid; (4) performing second washing with water; (5) derusting the steel material with a derusting liquid; (6) performing third washing with water; (7) treating the steel material with a surface conditioning liquid; (8) performing fourth washing with water; (9) phosphatizing the steel material with a phosphatizing liquid; (10) performing fifth washing with water; and (11) allowing the steel material to stand at the room temperature and performing baking. The technology is low in cost and convenient and reliable to operate. Through washing with water for several times and treatment with the oil-removing liquid, the derusting liquid and the surface conditioning liquid, an obvious phosphatization effect is achieved.

Owner:CHENGDU HONGYU TIMES TECH CO LTD

Ultra-high strength steel sheet having excellent phosphatability and hole expandability and method for manufacturing same

InactiveUS20180355453A1Excellent hole expandabilityHigh phosphatabilityHot-dipping/immersion processesFurnace typesSulfurManganese

Provided is an ultra-high-strength steel sheet having high phosphatability and hole expandability, including, by wt %, carbon (C): 0.08% to 0.2%, silicon (Si): 0.05% to 1.3%, manganese (Mn): 2.0% to 3.0%, phosphorus (P): 0.001% to 0.10%, sulfur (S): 0.010% or less, aluminum (Al): 0.01% to 0.1%, chromium (Cr): 0.3% to 1.2%, boron (B): 0.0010% to 0.0030%, titanium (Ti): 0.01% to 0.05%, nitrogen (N): 0.001% to 0.01%, and a balance of iron (Fe) and inevitable impurities, satisfying 3.4≤Ti / N≤10, 1.0≤Mn / (Si+Cr), and 0.7≤Mn* / (Si*+Cr*)≤Mn / (Si+Cr) where Ti, N, Mn, Si, and Cr refer to a weight percent (wt %), and Mn*, Si*, and Cr* refer to an average of values obtained by GDS component analysis from the surface to the 0.1 μm position in the thickness direction.

Owner:POHANG IRON & STEEL CO LTD

High-strength hot-dip galvannealed steel sheet with superior phosphatability

ActiveUS8697252B2Improve phosphating effectHot-dipping/immersion processesThin material handlingManganeseAlloy

Disclosed is a hot-dip galvannealed steel sheet that stably exhibits satisfactory phosphatability. It is a high-strength hot-dip galvannealed steel sheet which includes a base steel sheet and, arranged on at least one side thereof, an Fe—Zn alloyed galvanized layer. The base steel sheet contains 0.03% to 0.3% of carbon, 0.5% to 3.0% of silicon, and 0.5% to 3.5% of manganese, with the remainder including iron and inevitable impurities. The Fe—Zn alloyed galvanized layer has a concentration of silicon present as an oxide of [Si] (percent by mass) and a concentration of manganese present as an oxide of [Mn] (percent by mass), and these parameters satisfy the following conditions (1) and (2):[Si]≦0.25 (1)[Mn] / [Si]≦3.0 (2).

Owner:KOBE STEEL LTD

Cleaning, derusting and phosphating agent

InactiveCN104099594AFast phosphatingImprove phosphating effectMetallic material coating processesHydroxybenzoate EthersBetaine

The invention discloses a cleaning, derusting and phosphating agent. The cleaning, derusting and phosphating agent comprises the following formula components of raw materials in parts: 10-30 parts of phosphoric acid, 5-10 parts of metaphosphoric acid, 8-10 parts of hypochlorous acid, 5-10 parts of banana oil, 5-8 parts of dimethylbenzene, 5-12 parts of silicone oil, 5-10 parts of methyl ethyl ketone, 5-8 parts of isopropanol, 5-8 parts of diethyl ether, 3-5 parts of urea, 5-6 parts of m-dihydroxybenzene, 3-5 parts of p-hydroxyanisole, 5-8 parts of phenol, 5-8 parts of sodium polyacrylate, 2-3 parts of cocamidopropyl betaine, and 50-60 parts of de-ionized water. The cleaning, derusting and phosphating agent can be used at the normal temperature, has the advantages of quick phosphating speed, good phosphating effect, no corrosiveness, little waste residue discharge, combined completion of cleaning, derusting and phosphating at one step, easy production and low production cost, and can be applied to the degreasing, derusting and phosphating treatment of steel and cast iron products.

Owner:周彩球

Phosphorization liquid for zinc or zinc-aluminium alloy

InactiveCN101289742APhosphating effect is goodReduce processing costsMetallic material coating processesOxideMetallic Nickel

The invention discloses a phosphating solution for zinc or allumen, belonging to the metal surface treatment technique. The phosphating solution comprises the following raw materials in percentage by weight: 0.1-0.5 percent of zinc oxide, 0.2-0.5 percent of nitric acid, 3-4 percent of phosphoric acid, 0.02-0.04 percent of nickel nitrate, 0.02-0.2 percent of sodium fluoride, and the balance being water. The phosphating solution is made by stirring the raw materials are stirred until solid substance is completely dissolved and then filtering the raw materials. The product is used at normal temperature, and has the free acidity between 1 and 4 points, the total acidity between 25 and 35 points and the phosphating time between 2 and 8 minutes; a phosphating film is uniform, dense, solid and strong in the binding force with a coating; the adhesive force of the coating is over Grade 1; in addition, excessive AL<3+> dissolved in phosphating process can be complexed by F<-> in a bath solution in time, so as to guarantee the normal proceeding of phosphating treatment. The invention has the advantages that: the phosphating solution is good in phosphating effect, low in processing cost, easy to have the process operated and regulated; a spray product treated with the phosphating solution is excellent in the adhesive force of coating and has good corrosion resistance as well as durability.

Owner:XUZHOU ZENITH COATING

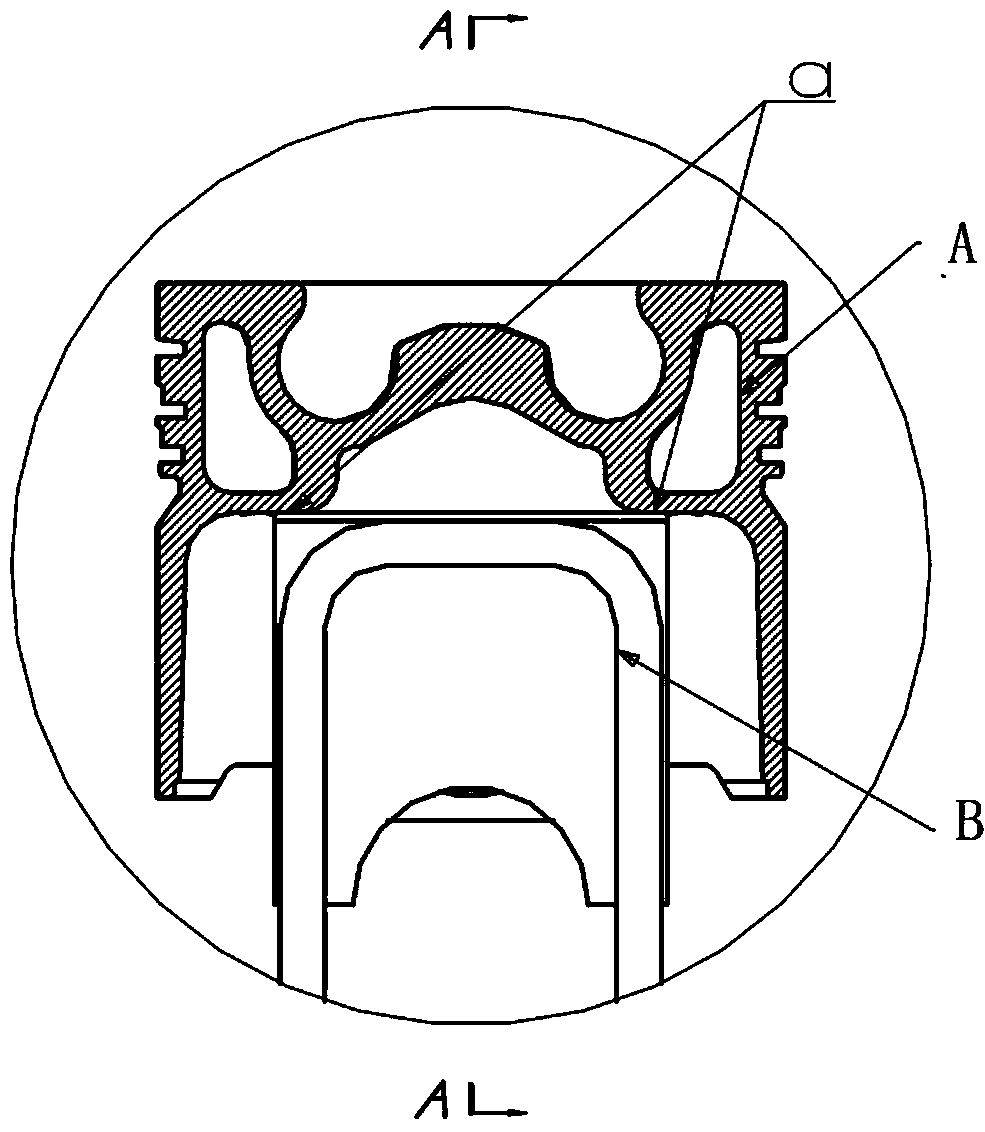

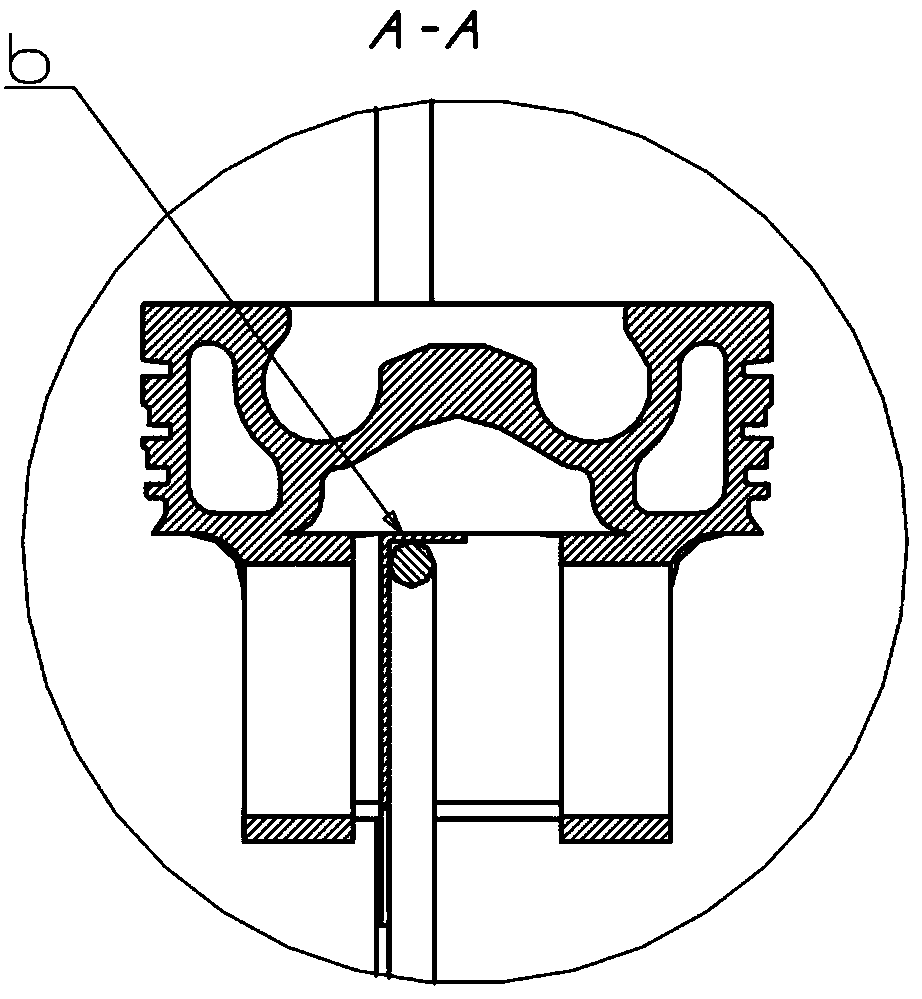

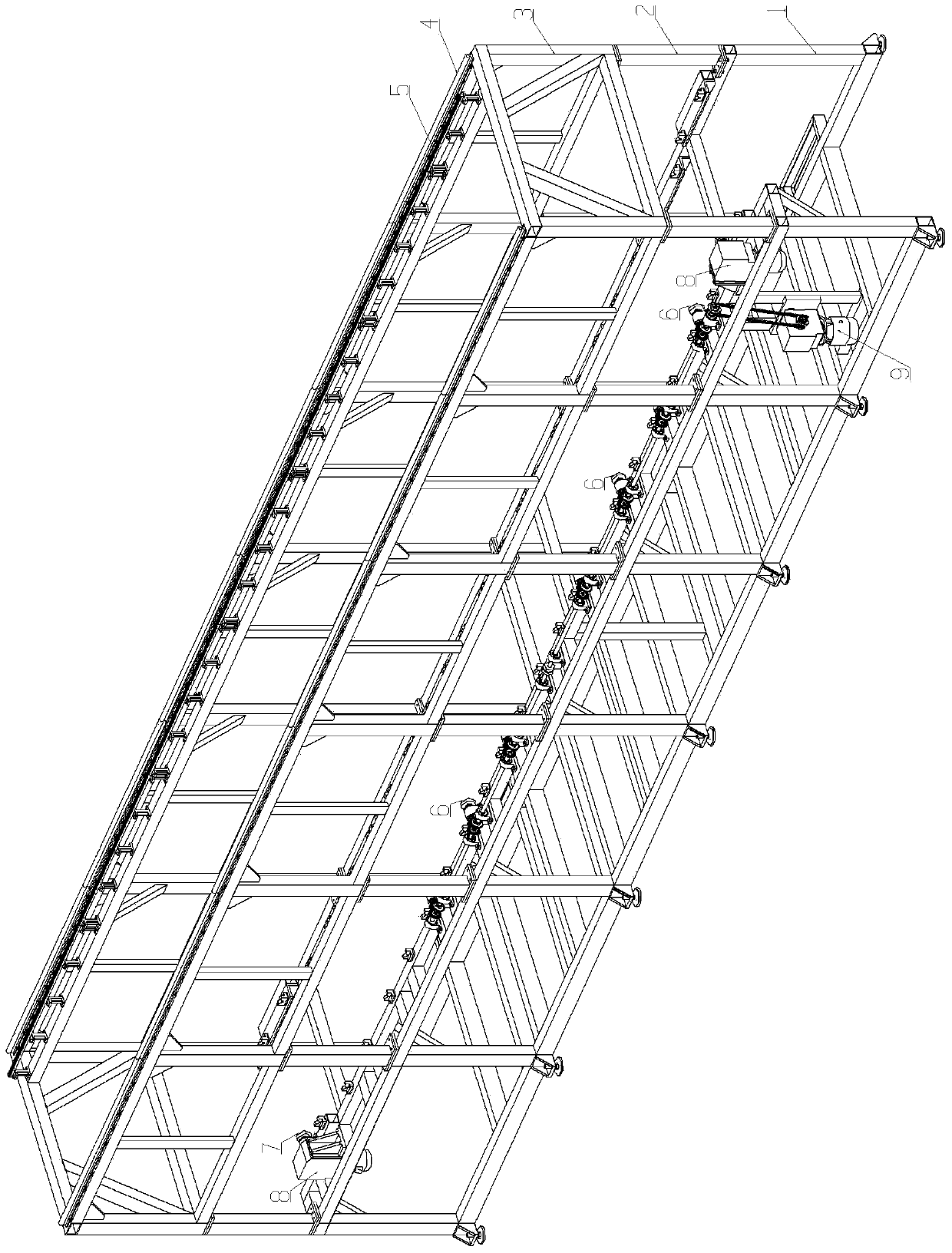

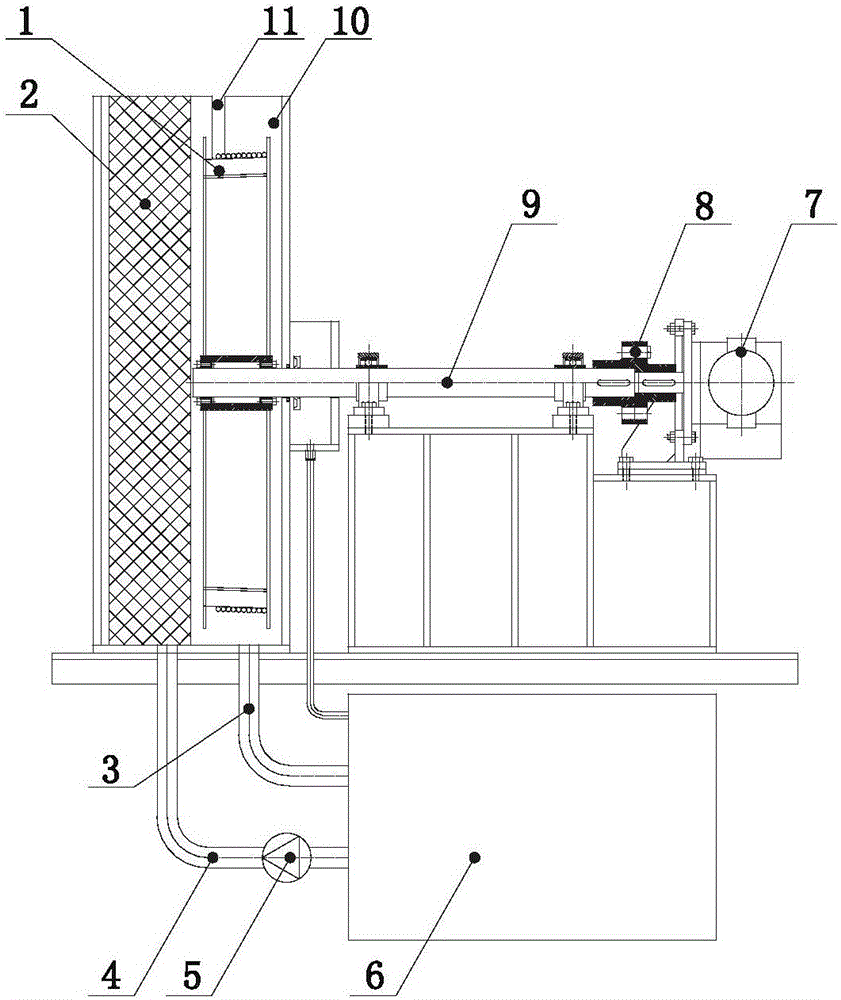

Rotary hanging tool suitable for piston phosphorization

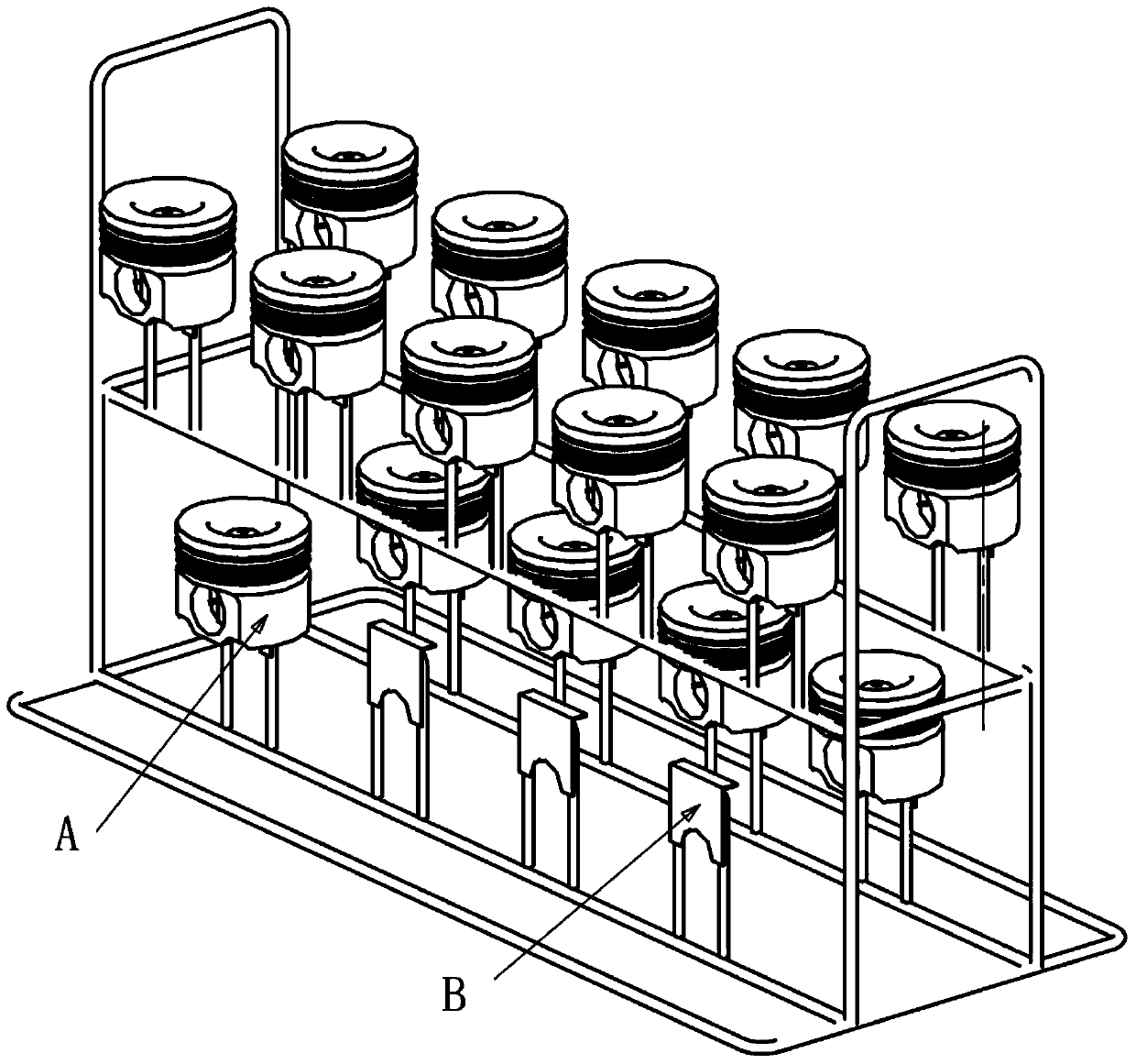

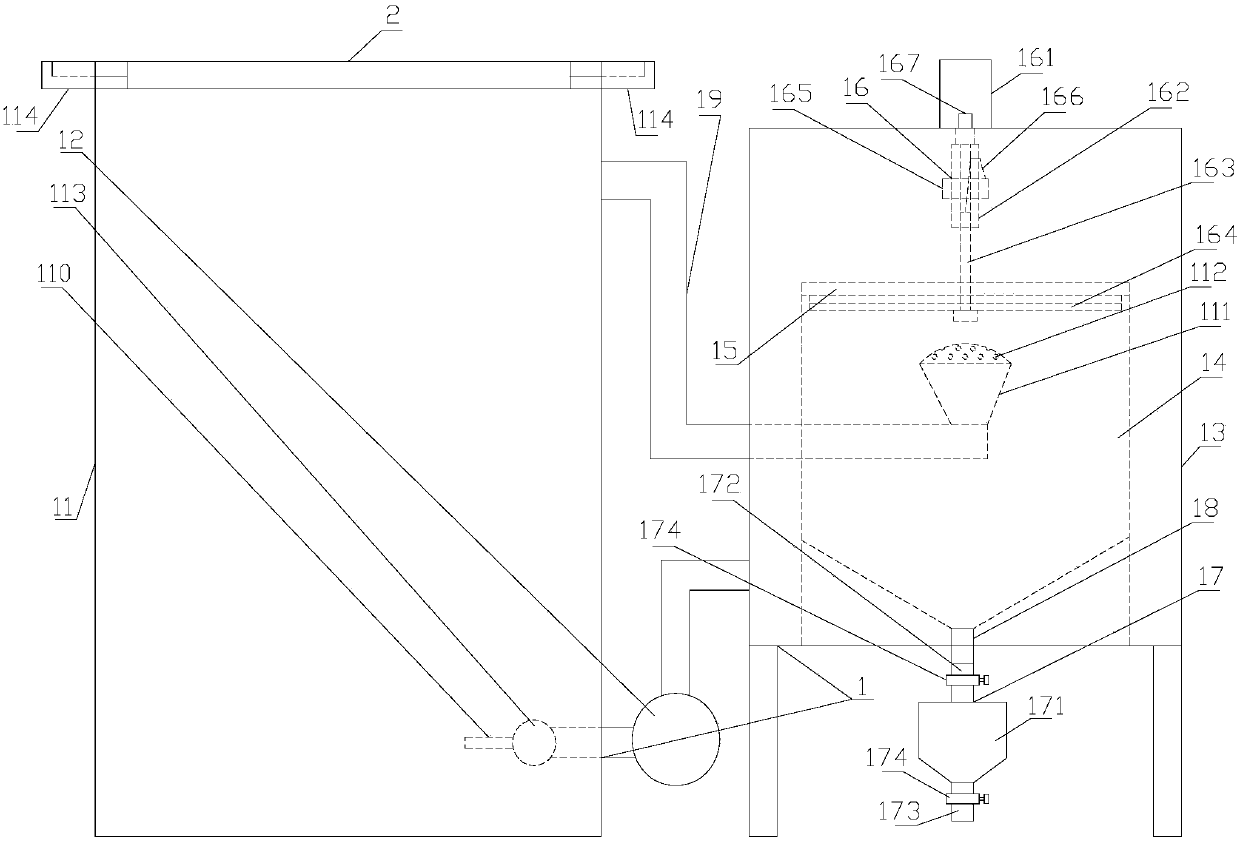

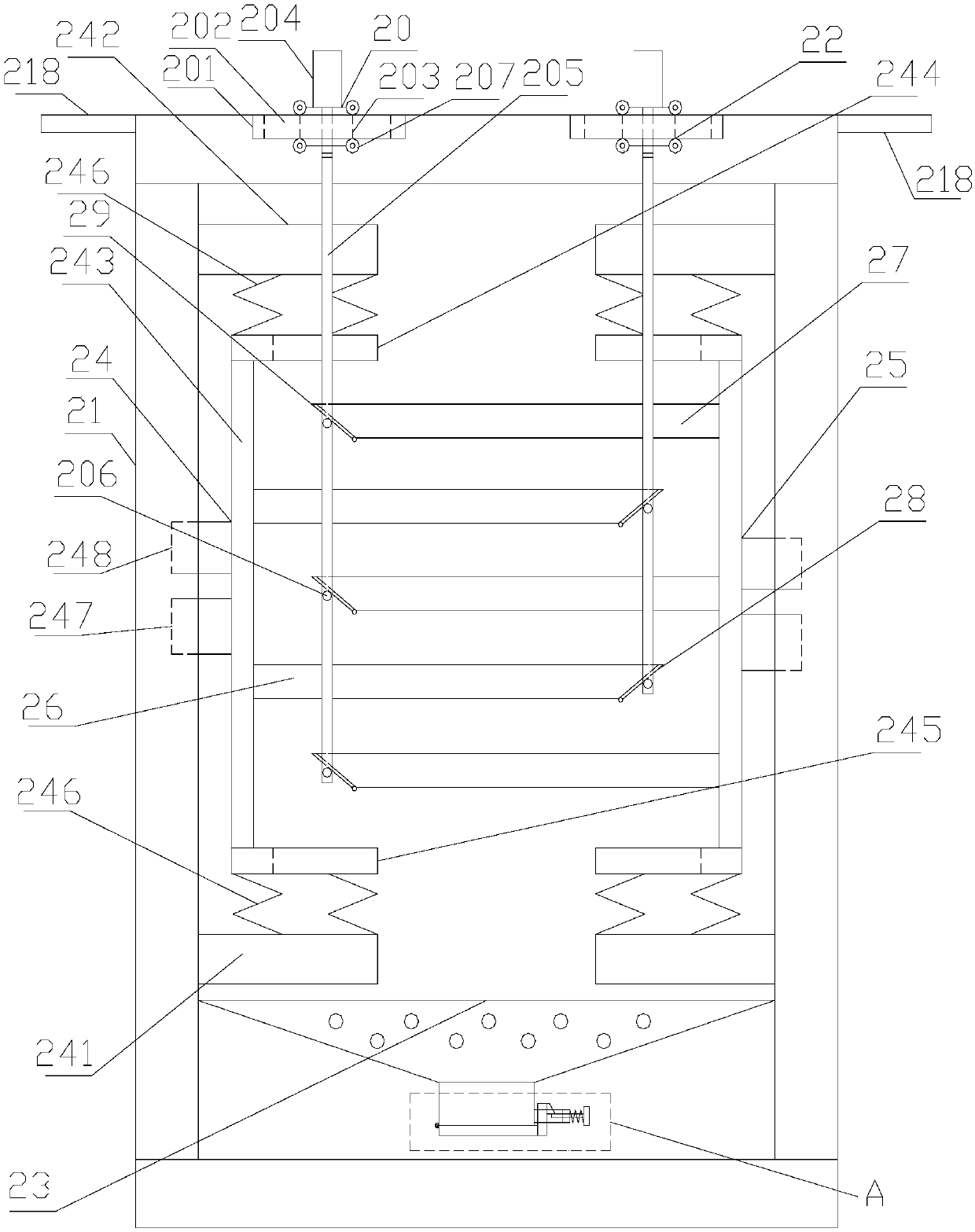

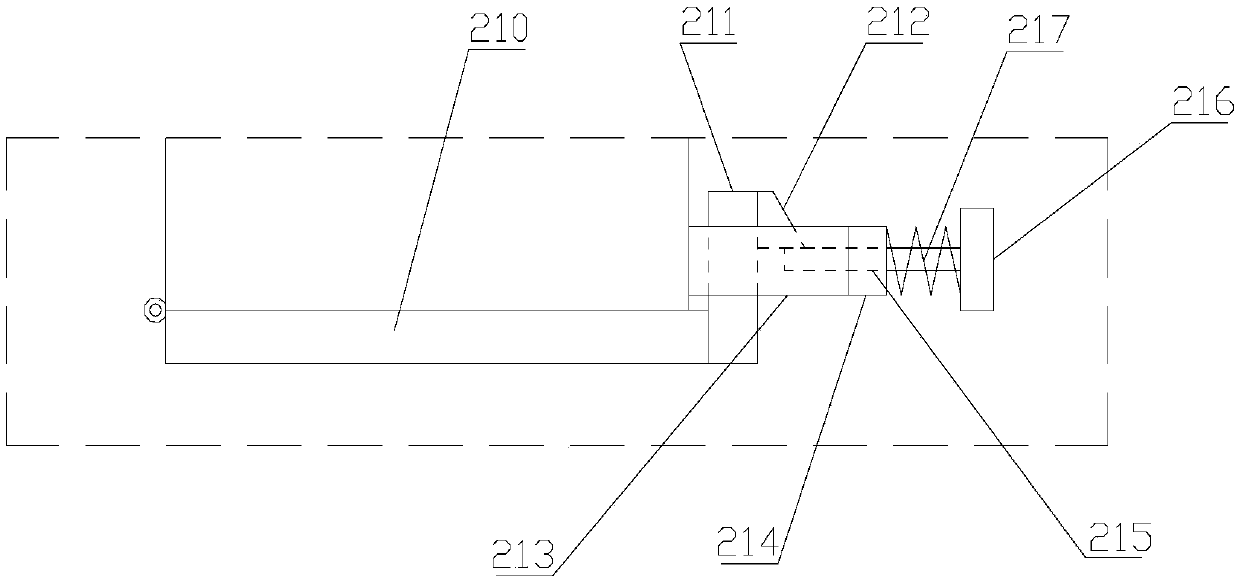

ActiveCN103695896ASmooth dischargeFully contactedElectrolysis componentsPhosphatisationEngineeringMechanical engineering

The invention particularly discloses a rotary hanging tool for piston phosphorization. The rotary hanging tool comprises a fixed bracket, wherein a drum box body is arranged in the fixed bracket; two rows of special tools are arranged in the drum box body in a longitudinal symmetry manner, and each row comprises multiple sets of special tools; a transmission device is arranged on one side of the fixed bracket; the lower trays of the two rows of special tools are symmetrically mounted on a tray bracket, the upper trays of the upper row of special tools are fixed at the top of the drum box body and correspond to the lower trays of the upper row of special tools, and the upper trays of the lower row of special tools are fixed at the bottom of the drum box body and correspond to the lower trays of the lower row of special tools. Due to the adoption of the structure, the rotary hanging tool has the benefits that phosphorization liquid comprehensively and fully makes contact with a piston and the best phosphorization effect is achieved.

Owner:BINZHOU BOHAI PISTON CO LTD +1

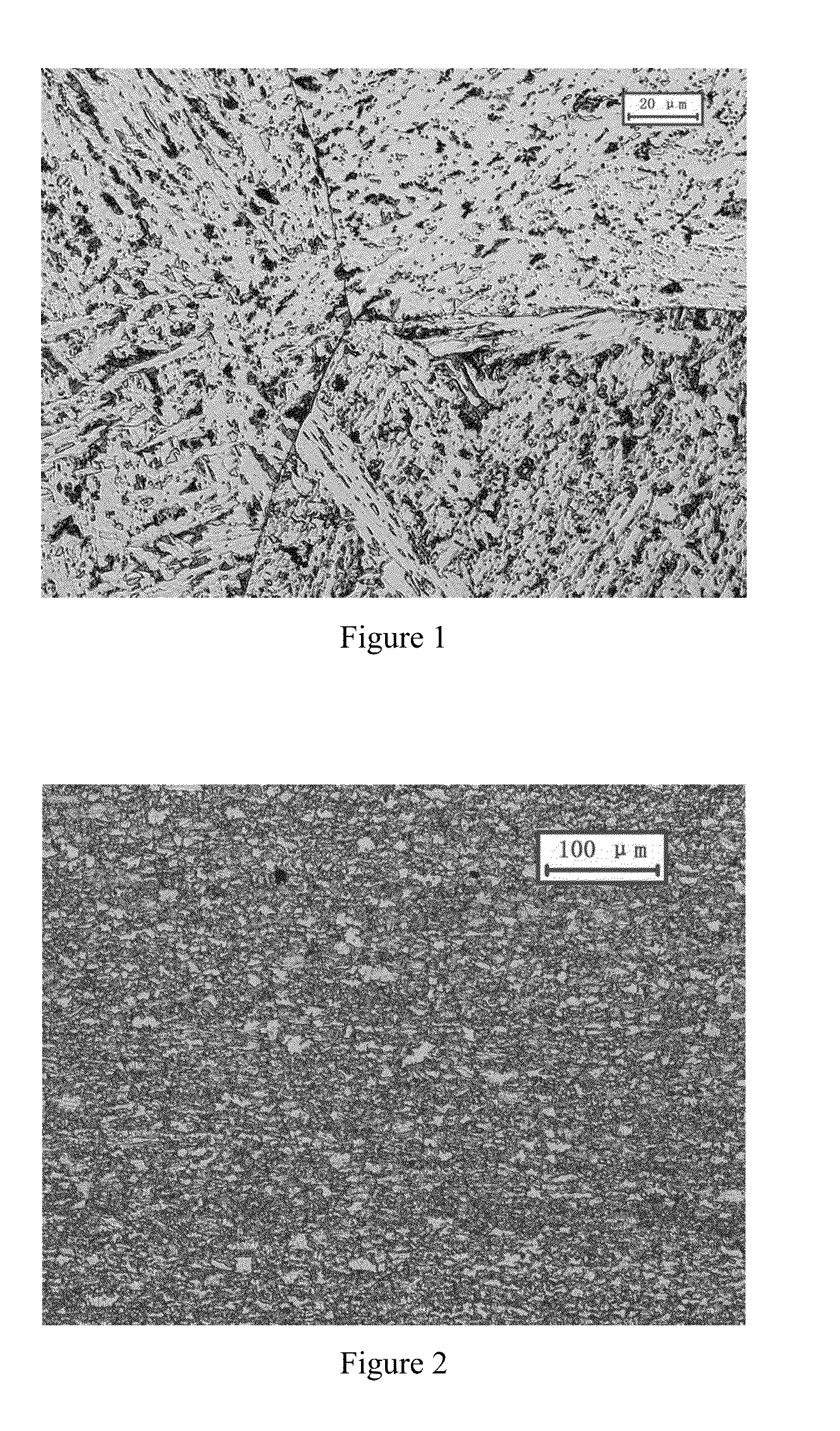

A 780mpa cold-rolled duel-phase strip steel and method for manufacturing the same

ActiveUS20150361519A1Improve phosphating effectSmall anisotropyFurnace typesHeat treatment furnacesFerritic matrixHigh intensity

The invention discloses a 780 MPa cold-rolled duel-phase strip steel having a microstructure of fine equiaxed ferrite matrix and martensite islands distributed homogeneously on the ferrite matrix, and comprising the following chemical elements in mass percentage: C:0.06-0.1%; Si≦0.28%; Mn:1.8-2.3%; Cr:0.1-0.4%; Mo: not added when Cr≧0.3%; Mo=0.3-Cr when Cr<0.3%; Al: 0.015-0.05%; at least one of Nb and Ti elements, wherein Nb+Ti is in the range of 0.02-0.05%; and the balance amounts of Fe and other unavoidable impurities. Correspondingly, the invention also discloses a method for manufacturing the 780 MPa cold-rolled duel-phase strip steel. The 780 MPa cold-rolled duel-phase strip steel has high strength, superior elongation, good phosphating property and small anisotropy in mechanical properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Normal temperature quick phosphorizing agent for metal plastic deformation and preparation method thereof

InactiveCN1807683AFast phosphatingLow priceMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a normal temperature fast bonderite and producing method of metal plastic deformation, which is characterized by the following: the bonderite is composed of phosphoric acid, methyl ethyl ketone or acetone, eldopaque, manganese dihydrogen phosphate, calcium nitrate, zinc nitrate and water; the method comprises the following steps: mixing, emulsifying, restirring; the raw materials of bonderite is at a low price, which can be used at normal temperature. The method is easy to product, which reduces the costs of conversion.

Owner:赵惠霖

High-temperature manganese phosphating process

ActiveCN109082657AReduce corrosionReduce roughnessMetallic material coating processesManganeseHeavy load

The invention discloses a high-temperature manganese phosphating process which comprises the following steps that a, a workpiece is electrically de-oiled to obtain a A product.; b, the product A is washed with hot water to obtain a B product; c, the product B is washed with cold water to obtain a C product; d, the C product is washed with acid to obtain a D product; e, the D product is cleaned with cold water to obtain a E product; f, the E product is surface-adjusted by immersing the E product in the first surface conditioning liquid containing the saponifier surface conditioning agent to obtain a F product; g, the F product is surface-adjusted by immersing the F product in a second surface conditioning liquid containing a manganese phosphate surface conditioning agent to obtain a G product; h, the G product is phosphated to obtain a H product; i, the H product is washed with cold water to obtain a product I; j. the product I is washed with hot water to obtain a J product; k, and theproduct J is dried to obtain a finished product. The high-temperature manganese phosphating process has the advantages of short process time and small mechanical fit tolerance, and the phosphating workpiece can withstand high speed, heavy load and large impact.

Owner:AVIC LIYUAN HYDRAULIC

Device for automatic piston phosphatization

ActiveCN103695895AReduce labor intensityAchieve recyclingMetallic material coating processesWorking environmentFiltration mechanism

The invention discloses a device for automatic piston phosphatization. The device comprises a main frame, wherein two manipulators are arranged at the top of the main frame and can move back and forth along the main frame; a plurality of phosphatization process tank groups are arranged at the bottom of the main frame according to the technical process; the manipulators are matched with rotary hanging racks which can move among the phosphatization process tank groups; a filter press and a phosphatizing tank XI are arranged on the outer side of the main frame; the phosphatizing tank XI, the filter press and a phosphatizing tank VIII in the main frame are connected to form a circulating filtration mechanism for filtering a phosphatizing solution. The main body is frame-shaped; the device is simple in structure, convenient to mount, debug and protect and the working environment is safe and sanitary. The device adopts an automatic production manner to greatly improve the production efficiency and reduce the labor intensity of workers. The filter mechanism is used to filter the phosphatizing solution in order to implement recycling on the phosphatizing solution, and further reduce the use cost.

Owner:BINZHOU BOHAI PISTON CO LTD +1

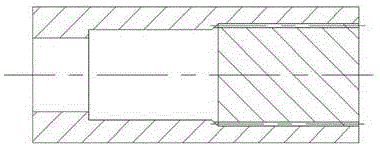

Machining method of hollow plunger

The invention discloses a machining method of a hollow plunger, and belongs to the technical field of hollow plunger machining. The machining method includes the sequentially-conducted steps that a bar material is selected; the bar material is subjected to softening processing after being subjected to blanking; surface processing is conducted on the bar material subjected to softening processing;lubricating processing is conducted on the bar material subjected to surface processing; cold extruding is conducted on the bar material subjected to lubricating processing to form a plunger body upper portion and a plunger body lower portion; a ball head and a lubrication hole of the plunger body upper portion are machined, and the plunger body lower portion and a middle lubrication hole are machined; the plunger body upper portion and the plunger body lower portion are welded in a friction welding manner; friction welding flashes are subjected to rough turning; hardening and tempering processing and nitriding processing are conducted on a plunger body obtained after welding is completed; and outer circles of the ball head and the plunger body are ground, and machining of the hollow plunger is completed. The plunger body machined and formed through the machining method is small in thermal expansion amount, the influence of temperature on changes of the fit clearance of the plunger outer diameter and a cylinder body is small, and therefore stability of a plunger pump is improved.

Owner:四川坤成润科技有限公司

Phosphating solution for corrosion prevention of iron towers and preparation method thereof

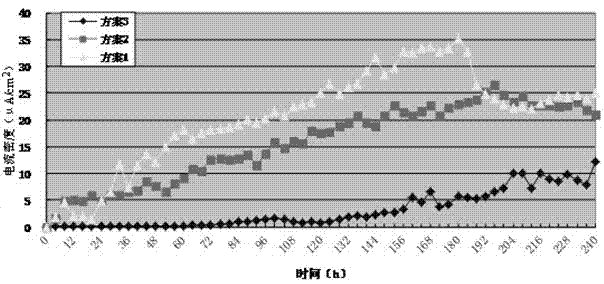

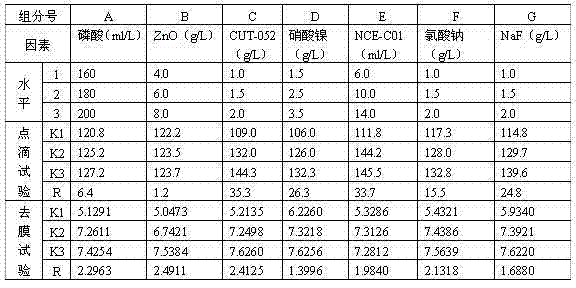

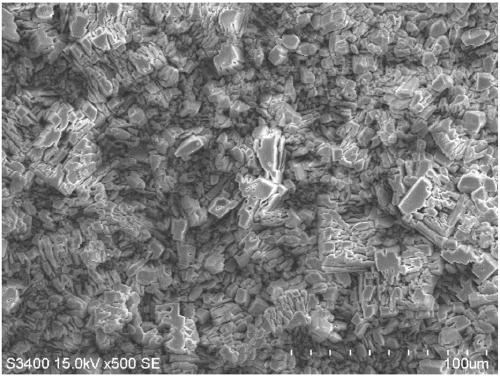

InactiveCN103088324AHigh speedImprove phosphating effectMetallic material coating processesNitrateSodium chlorate

The invention discloses a phosphating solution for corrosion prevention of iron towers and a preparation method thereof. The phosphating solution is prepared by using the following raw materials: 180-185 ml / L of phosphoric acid, 60-65 ml / L of ethanol, 3.0-3.5 ml / L of OP-10, 5.0-6.5 g / L of zinc oxide, 1.5-2.0 g / L of CUT-052, 2.5-3.5 g / L of nickel nitrate, 10.0-14.0 ml / L of NCE-C01, 1.5-2.0 g / L of sodium chlorate, and 1.5-2.0 g / L of NaF. According to the invention, operations of cleaning, rust-layer transformation, zinc-layer phosphorization and surface adjustment can be completed in one step; and the phosphating solution carries out rusty phosphorization and rust-layer transformation on iron towers, the construction process is simple, and the corrosion prevention effect is good.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

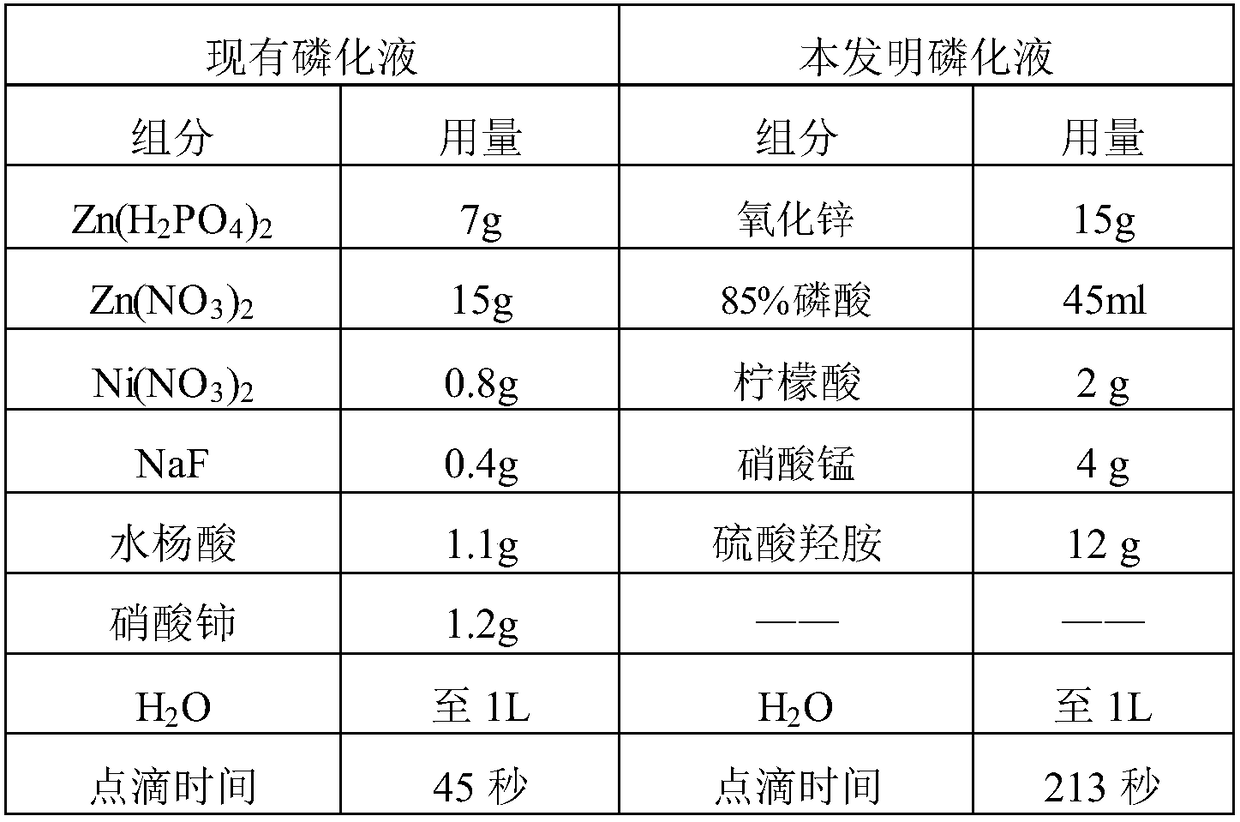

Normal temperature environment-friendly phosphating solution for steel and application thereof

InactiveCN109468622ASimplify the phosphating processEasy to operateMetallic material coating processesNitrateManganese

The invention relates to the technical field of steel surface treatment and a normal temperature environment-friendly phosphating solution for steel and an application thereof. Specifically, the phosphating solution provided by the invention comprises zinc oxide, phosphoric acid, manganese nitrate, reductive accelerant, citric acid and water; wherein each 1L of phosphating solution comprises 37-53ml of phosphoric acid, 9-21g of zinc oxide, 1-10g of manganese nitrate, 2-16g of reductive accelerant, 0.5-3.5g of citric acid and the balance of water. The phosphating solution provided by the invention has simple formula and low treatment cost; phosphorization can be carried out at normal temperature so as to save energy; without chromium in the phosphating solution, the toxic problem of chromium to environment and human body can be avoided; phosphating film layer formed by phosphorization under ultrasonic action is uniform and compact and has excellent corrosion resistance. The dropping time of the copper sulfate of the obtained phosphating film can reach 213s, the soaking time of 3% NaCl solution exceeds 6h, and the film weight can reach 6.5-7.3g / m2.

Owner:JIANGSU UNIV OF TECH

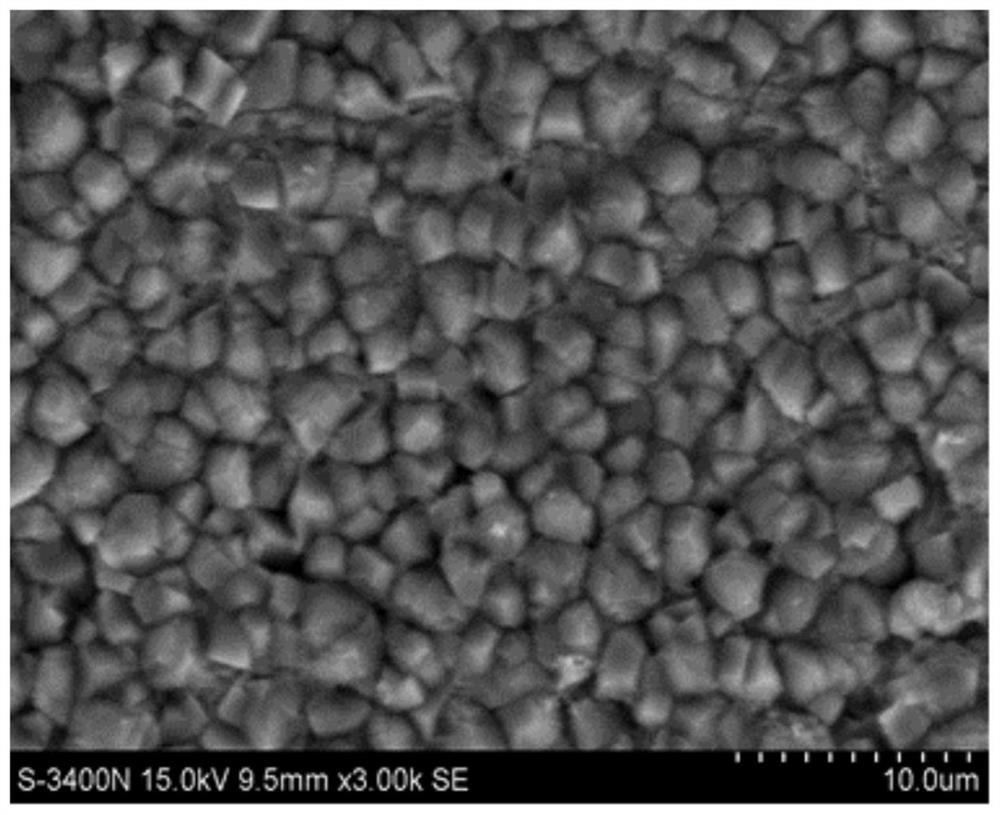

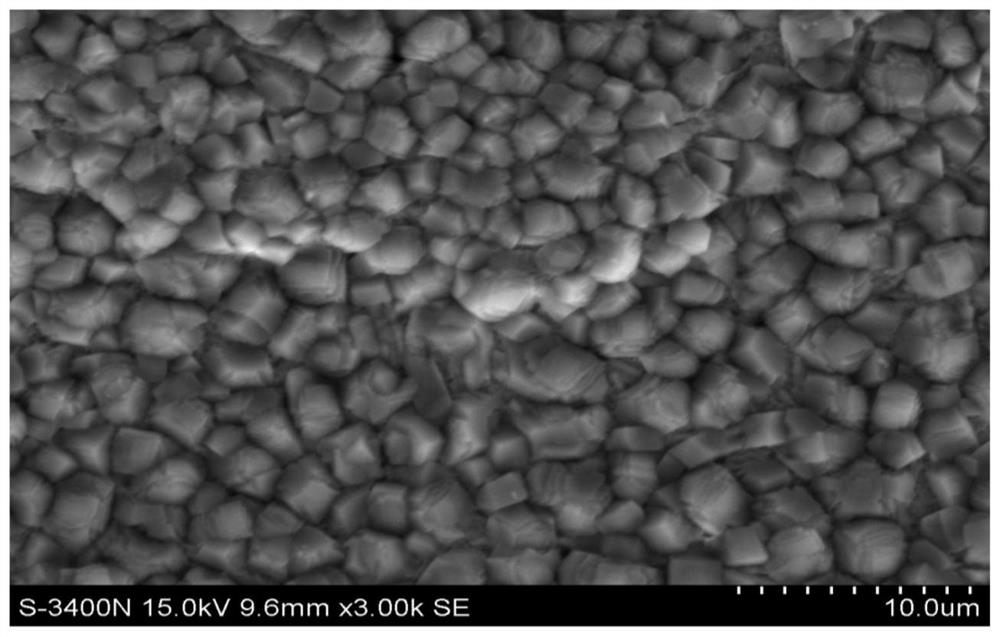

Method for improving phosphating performance of low-carbon aluminum killed steel automobile plate and automobile plate

ActiveCN111647733AQuality improvementMeet the requirements of phosphating performanceAluminiumSmelting

The invention particularly relates to a method for improving the phosphating performance of a low-carbon aluminum killed steel automobile plate and the automobile plate, and relates to the field of steel smelting. The method for improving the phosphating performance of the low-carbon aluminum killed steel automobile plate comprises the steps of casting blank component control, hot rolling, cold rolling, annealing and leveling; in the casting blank component control step, casting blank are controlled to comprise the following components of, in percentage by mass, 0.01% to 0.02% of C, smaller than or equal to 0.02% of Si, 0.10% to 0.30% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, 0.03% to 0.06% of Al, 0.001% to 0.003% of B, smaller than or equal to 0.005% of N and the balance Fe and inevitable impurities; in the hot rolling step, the tapping billet temperature is 1140 DEG C to 1240 DEG C, the rough rolling outlet temperature is 1020 DEG C to 1100 DEG C, the final rolling temperature is 900 DEG C to 960 DEG C; in the cold rolling step, the cold rolling reduction rate is 67.6% to 86.1%; and in the annealing step, the dew point temperature of a heating section of an annealing furnace is-30 DEG C to 0 DEG C. According to the embodiment of the method for improving the phosphating performance of the low-carbon aluminum killed steel automobile plate and the automobile plate, the low-carbon aluminum killed steel automobile has the advantages that the grain size of a phosphating film on the surface is less than 5 microns, the coverage rate is 100%, the P ratio is more than 85%, and the phosphating performance is excellent.

Owner:SHOUGANG CORPORATION

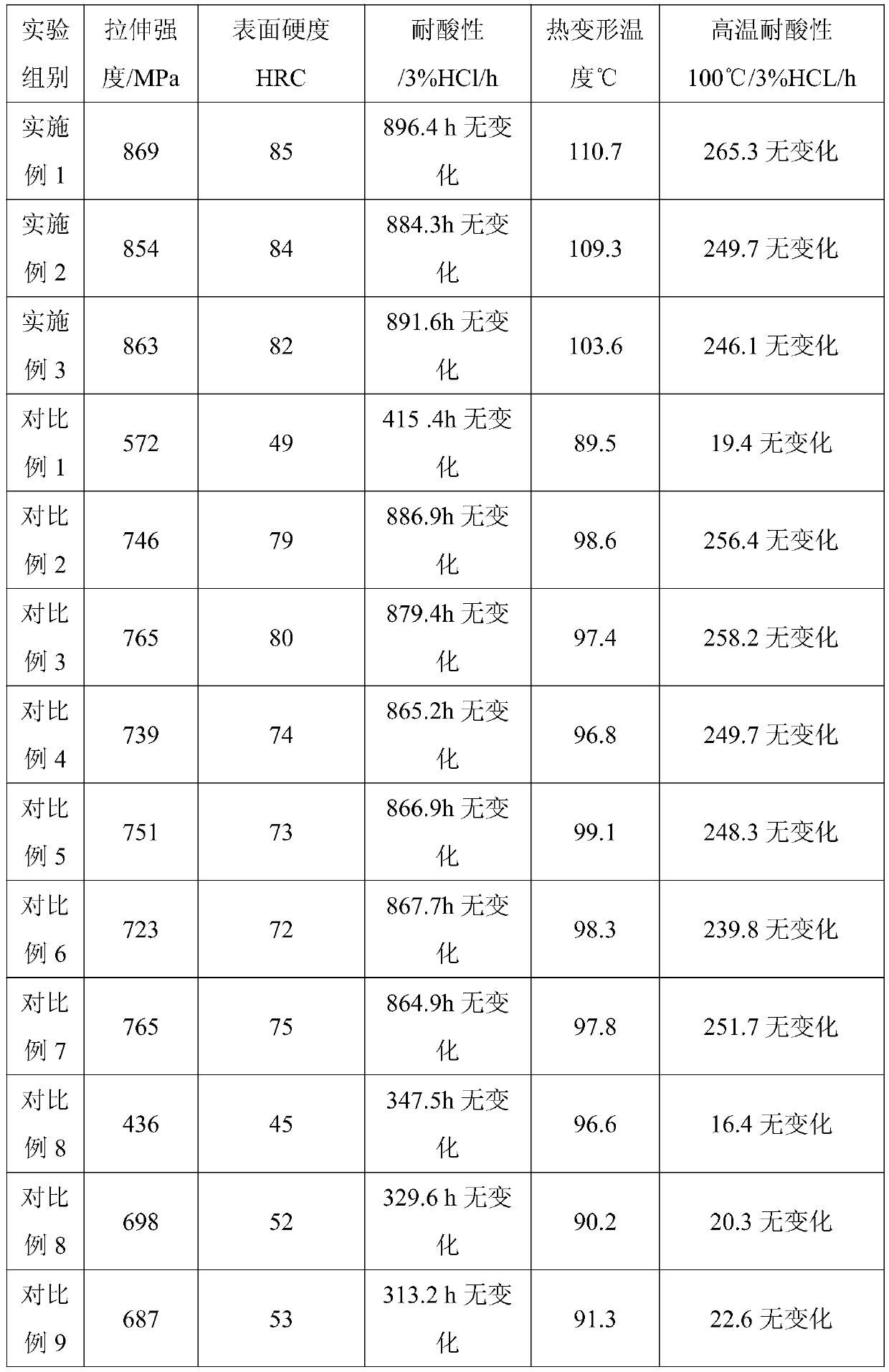

Stamping die surface phosphating processing method

InactiveCN110042376AExcellent high temperature corrosion resistanceGood adhesionMetallic material coating processesHigh-temperature corrosionHot Temperature

The invention discloses a stamping die surface phosphating processing method, and relates to the technical field of mold processing. The stamping die surface phosphating processing method includes thefollowing steps of polishing, heating, phosphating, twice soaking and twice drying processing and pressurizing processing. By means of the stamping die surface phosphating processing method, a uniform and compact phosphating film can be formed on the surface of a stamping die, the surface of the stamping die can be better protected, and the processed stamping die has excellent high-temperature corrosion-resistant performance.

Owner:长沙而道新能源科技有限公司

Spring phosphatization process

InactiveCN105755457AImprove phosphating effectSimplify the phosphating processMetallic material coating processesAir springPhosphate

The invention discloses a spring phosphatization process, which is characterized by comprising the steps of: 1) soaking a spring in a 20%NaCaco3 solution at 60-80DEG C for 15min; 2) taking the spring out, and rinsing the spring clean in 60-80DEG C hot water; 3) at room temperature, soaking the spring in a 20% hydrochloric acid solution for 15min; 4) taking the spring out, and immediately rinsing the spring clean in 80DEG C hot water; 5) putting the rinsed spring into a phosphatized container, pouring a well prepared phosphatization solution into the container to submerge the spring completely, turning on heating equipment, heating the phosphatization solution to 88-95DEG C for 8-15min, and rinsing the phosphatized spring with clean water to obtain a grey brown spring; and 6) after phosphorization, conducting filling and sealing treatment on the phosphate film, putting the spring into the filling solution, and performing heating to 90-98DEG C for 5-10min, taking the filled spring out of the filling solution and conducting rinsing, drying or airing the spring, and soaking the aired spring into TECH1300 antirust oil for 1min, then taking the spring out and performing airing. The phosphatization process is simple, and the spring phosphatization effect is better.

Owner:CHONGQING YINGRUISHENG DIE CASTING

Anhydrous phosphating agent

InactiveCN106399987ASimplify the painting processReduce processing timeMetallic material coating processesPolyvinyl butyralOrganic solvent

The invention discloses an anhydrous phosphating agent. The anhydrous phosphating agent is prepared from, by weight, 20 parts to 40 parts of phosphoric acid, 3 parts to 15 parts of polyvinyl butyral, 3 parts to 12 parts of silicone oil, 5 parts to 10 parts of sodium borate, 8 parts to 18 parts of resin, 3 parts to 14 parts of citric acid and 30 parts to 60 parts of organic solvents. A preparation method of the anhydrous phosphating agent includes the following steps that a, mixed liquid of polyvinyl butyral resin and the organic solvents is prepared; b, phosphoric acid and citric acid organic solvent mixed liquid is prepared; and c, mixing is performed, wherein the solutions obtained in the steps of a and b, silicone oil and sodium borate are mixed according to the formula, and the phosphating agent is prepared in a stirring manner. The phosphating agent is good in phosphating effect, small in sewage discharge amount, free of corrosivity, simple in preparation process and low in cost.

Owner:广州市汇盛金丰科技企业孵化器有限公司

No surface streak defect 590mpa grade cold-rolled dual-phase steel and production method

The invention provides a 590MPa grade cold-rolled dual-phase steel without surface stripe defect and a production method thereof. The steel comprises the following components by weight percentage: 0.050% to 0.100% of C, less than or equal to 0.25% of Si, 1.20% to 2.00% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 0.05% to 0.10% of Al, 0.015 to 0.050% of Sb, and thebalance being Fe and other unavoidable impurities; The production method comprises the steps of smelting, continuous casting, hot charging heating, high pressure water descaling and rough rolling, finishing rolling, laminar cooling, reeling, hot rolling sheet pickling cold rolling, continuous annealing, air cooling, and leveling reeling, the 590MPa grade cold-rolled dual-phase steel produced by the invention has bright surface, no streaky defects, good corrosion resistance and coating adhesion, and excellent mechanical properties.

Owner:ANGANG STEEL CO LTD

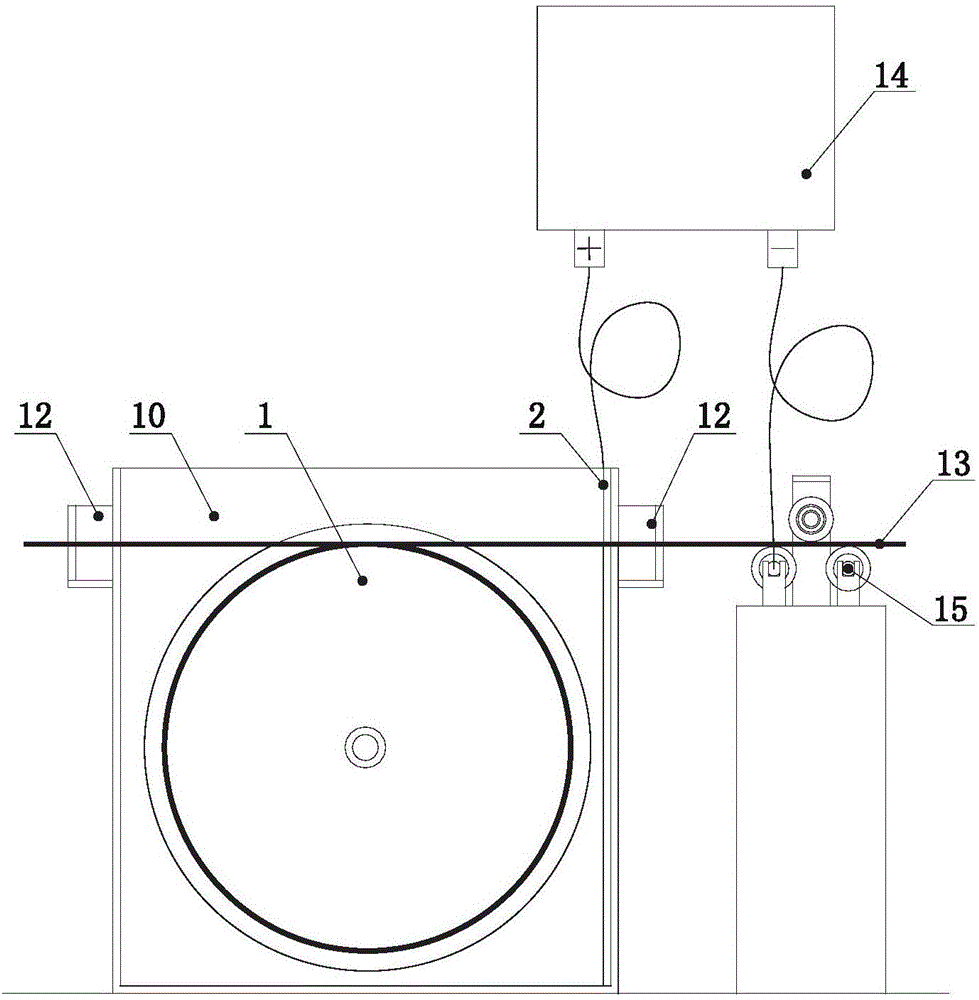

Dynamic phosphorization device and method for metal wires

ActiveCN106399985AIncrease phosphating timePhosphating effect is goodPhosphatisationMetallic material coating processesPipingEngineering

The invention provides a dynamic phosphorization device and method for metal wires and solves the technical problems that the existing phosphorization device occupies a large space, is low in phosphorization efficiency, is poor in phosphorization effect and cannot meet later drawing acceleration requirements. The dynamic phosphorization device is provided with a phosphorization trough, a power supply and a liquid storing tank and is further provided with a conducting device and a wire coiling device, wherein the conducting device is close to the wire inlet position of the phosphorization trough, and the liquid storing tank is arranged below the phosphorization trough and connected with the phosphorization trough through a water inlet pipe and a water return pipe; the wire coiling device comprises a winding drum and a wire coiling driving device, the winding drum is arranged in the phosphorization trough, the winding drum is connected with the wire coiling driving device through a winding drum shaft, and the winding drum shaft penetrates through the side wall of the phosphorization trough; and the inner surface of the phosphorization trough is provided with a metal electrode plate, the metal electrode plate is connected with a positive electrode of the power supply through a cable, and the conducting device is connected with a negative electrode of the power supply through a cable. The dynamic phosphorization device and method are widely applied to the non-acid-pickling drawing field of the metal wires.

Owner:威海银兴预应力线材有限公司

Improved screw phosphorizing device

InactiveCN107893221AAvoid cloggingEasy to discharge slagMetallic material coating processesSlagBiochemical engineering

The invention discloses an improved screw phosphating device, which comprises a phosphating tank and a loading mechanism placed in the phosphating tank, and the phosphating tank includes a main body of the phosphating tank, a pump group, a first tank body and a second tank body , a filter body, a cleaning mechanism, a collecting mechanism and a slag outlet, the inner bottom surface of the first tank body is provided with a second tank body, the bottom of the second tank body is conical, and the first tank body The bottom of the tank is provided with a slag outlet connected to the bottom of the second tank, the output end of the slag outlet is provided with a collecting mechanism, the upper end of the second tank is provided with a filter body, and the first tank The body is provided with a cleaning mechanism for cleaning the inner wall of the filter. The output end and input end of the pump group are respectively connected with the main body of the phosphating tank and the first tank body, and the main body of the phosphating tank is connected with the second tank body through a pipeline. Compared with the prior art, the screw can be turned and bounced continuously, the phosphating effect is greatly improved, and the phosphating slag can be separated without affecting the production.

Owner:海盐创通技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com