Normal temperature environment-friendly phosphating solution for steel and application thereof

A kind of phosphating solution, an environment-friendly technology, applied in the direction of metal material coating process, etc., can solve the problems of high operating temperature, complex composition, and no disclosed accelerator composition, etc., achieve good corrosion resistance, simple phosphating process, phosphorus good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

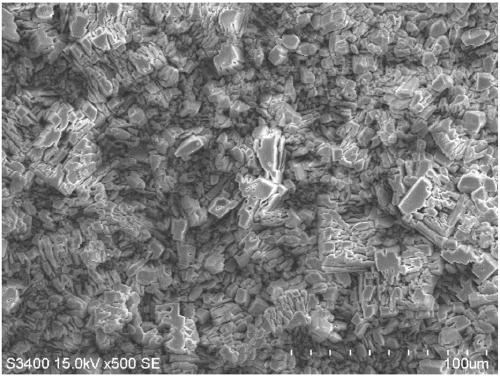

Image

Examples

Embodiment 1~ Embodiment 5

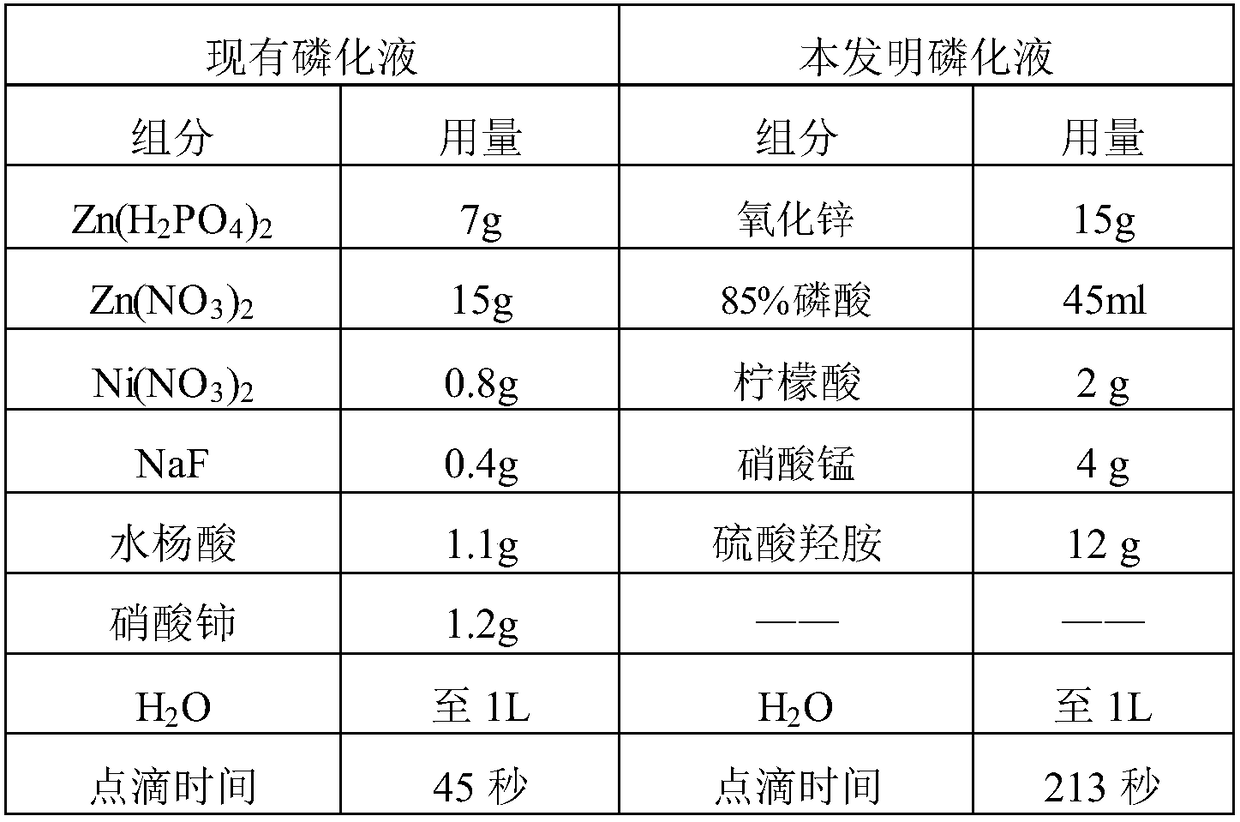

[0027] Example 1 to Example 5: Phosphating solution (see Table 1) using different amounts of zinc oxide and its phosphating effect experiment.

[0028] Table 1

[0029] Component

[0030] The five phosphating solutions in Examples 1 to 5 were used for the phosphating treatment of steel parts, and the pH value was adjusted to 2.4. The ultrasonic power is 210W, the phosphating temperature is 22℃, and the phosphating time is 30min. According to GB 6807-86 "Technical Conditions for Phosphating Treatment of Steel Parts Before Painting", the prepared phosphating film adopts copper sulfate drop test and 3% sodium chloride solution immersion test to judge the phosphating of steel parts by phosphating solution The performance and the results are shown in Table 2.

[0031] Table 2

[0032] project

[0033] It can be seen from Table 2 that when the zinc oxide concentration increases from 9g / L to 15g / L, the corrosion resistance of the phosphate coating gradually increases; when the mass c...

Embodiment 6~ Embodiment 11

[0034] Example 6 to Example 11: Phosphating solution (see Table 3) using different amounts of manganese nitrate and its phosphating effect experiment.

[0035] table 3

[0036] Component

[0037] The 6 phosphating solutions in Examples 6-11 were used for the phosphating treatment of steel parts, and the pH value was adjusted to 2.6. The ultrasonic power is 200W, the phosphating temperature is 30℃, and the phosphating time is 25min. According to GB 6807-86 "Technical Conditions for Phosphating Treatment of Steel Parts Before Painting", the prepared phosphating film adopts copper sulfate drop test and 3% sodium chloride solution immersion test to judge the phosphating of steel parts by phosphating solution The performance and the results are shown in Table 4.

[0038] Table 4

[0039] project

[0040] It can be seen from Table 4 that when the concentration of manganese nitrate is gradually increased from no addition to 4g / L, the corrosion resistance of the phosphating film gradu...

Embodiment 12~ Embodiment 17

[0041] Example 12 to Example 17: Phosphating solution (see Table 5) with different dosages of hydroxylamine sulfate and its phosphating effect experiment.

[0042] table 5

[0043] Component

[0044] The 6 phosphating solutions in Examples 12-17 were used for the phosphating treatment of steel parts, and the pH value was adjusted to 2.5. The ultrasonic power is 190W, the phosphating temperature is 35℃, and the phosphating time is 20min. According to GB 6807-86 "Technical Conditions for Phosphating Treatment of Steel Parts Before Painting", the prepared phosphating film adopts copper sulfate drop test and 3% sodium chloride solution immersion test to judge the phosphating of steel parts by phosphating solution The performance and the results are shown in Table 6.

[0045] Table 6

[0046] project

[0047] It can be seen from Table 6 that when the HAS concentration increases from 0g / L to 12g / L, the corrosion resistance of the phosphating film also increases, and when it is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com