A normal-temperature phosphating solution for forming a high-corrosion-resistant phosphating film, a preparation method and a phosphating process

A technology of phosphating film and phosphating solution, which is applied in the direction of metal material coating process, can solve the problems of high energy consumption, long processing time, and increased phosphating cost for phosphating treatment, so as to reduce the cost of phosphating and increase the cost of phosphating. Protective, time-saving phosphating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

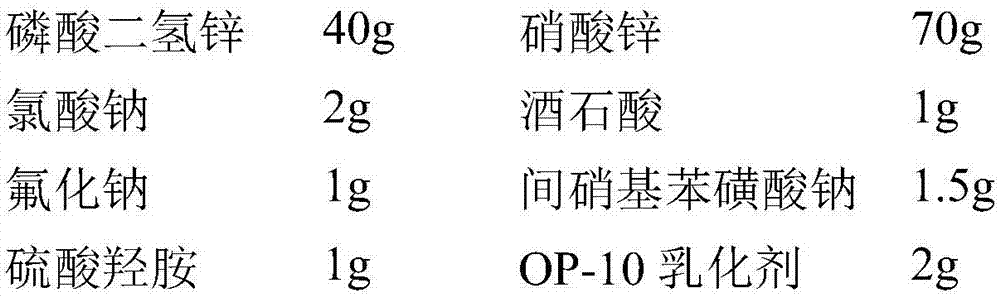

[0038] Weigh the corresponding components according to the following proportions:

[0039]

[0040] Then add the above components into deionized water one by one to make a 1L solution, stir evenly to dissolve completely, and make a room temperature phosphating solution for forming a high corrosion-resistant phosphating film.

[0041] The phosphating solution is: zinc dihydrogen phosphate 40g / L, zinc nitrate 70L, sodium chlorate 2 / L, sodium m-nitrobenzenesulfonate 1.5g / L, hydroxylamine sulfate 1g / L, tartaric acid 1 / L, fluoride Sodium 1g / L, OP-10 emulsifier 2g / L, the balance is water.

[0042] With the phosphating solution at a temperature of 25°C, the iron and steel workpieces were soaked (or sprayed) for 10 minutes, and then dried naturally to obtain a uniform, compact, and corrosion-resistant phosphating film.

[0043] The phosphating film film thickness that embodiment 1 obtains is 2-3.5g / m 2 , the phosphating film and the paint film are closely combined, and the result...

Embodiment 2

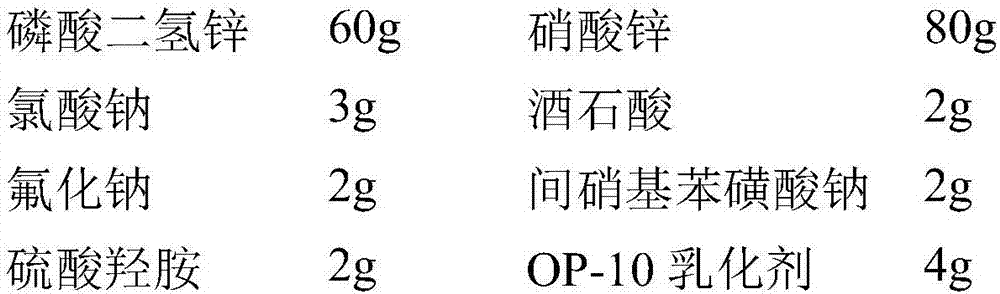

[0045] Weigh the corresponding components according to the following proportions:

[0046]

[0047] Then add the above components into deionized water one by one to make a 1L solution, stir evenly to dissolve completely, and make a room temperature phosphating solution for forming a high corrosion-resistant phosphating film.

[0048] The phosphating solution is: zinc dihydrogen phosphate 60g / L, zinc nitrate 80L, sodium chlorate 3 / L, sodium m-nitrobenzenesulfonate 2g / L, hydroxylamine sulfate 2g / L, tartaric acid 2 / L, sodium fluoride 2g / L, OP-10 emulsifier 4g / L, and the balance is water.

[0049] Apply the phosphating solution to the iron and steel workpiece at a room temperature of 25-30°C by brushing, brushing twice, and drying naturally to obtain a uniform and compact phosphating film with good corrosion resistance.

[0050] The phosphating film film thickness that embodiment 2 obtains is 2-3.5g / m 2 , Phosphate film neutral salt spray test 10 hours without corrosion.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com