Cathode electrophoretic phosphatizing agent

A cathodic electrophoresis and phosphating agent technology, which is applied in electrophoretic plating, electrolytic coating, metal material coating technology, etc., can solve the problems of unsuitable automatic assembly line coating, complex composition of multi-component phosphating solution, narrow control range of process parameters, etc. problems, to achieve the effect of shortening the film forming time, satisfying the film quality and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

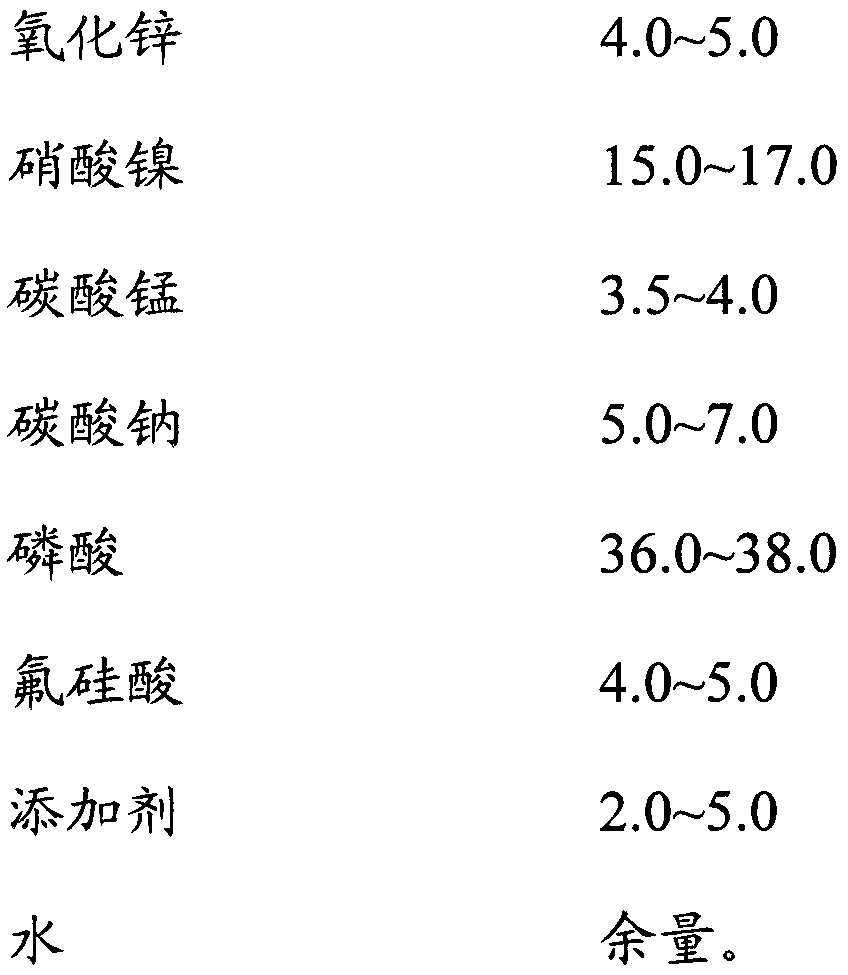

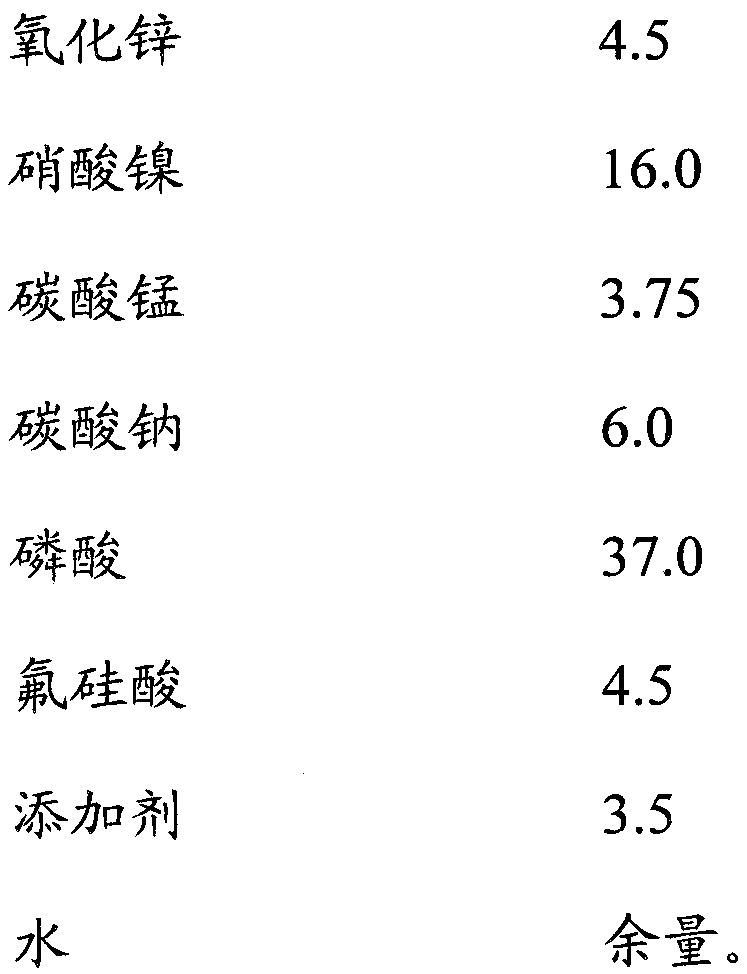

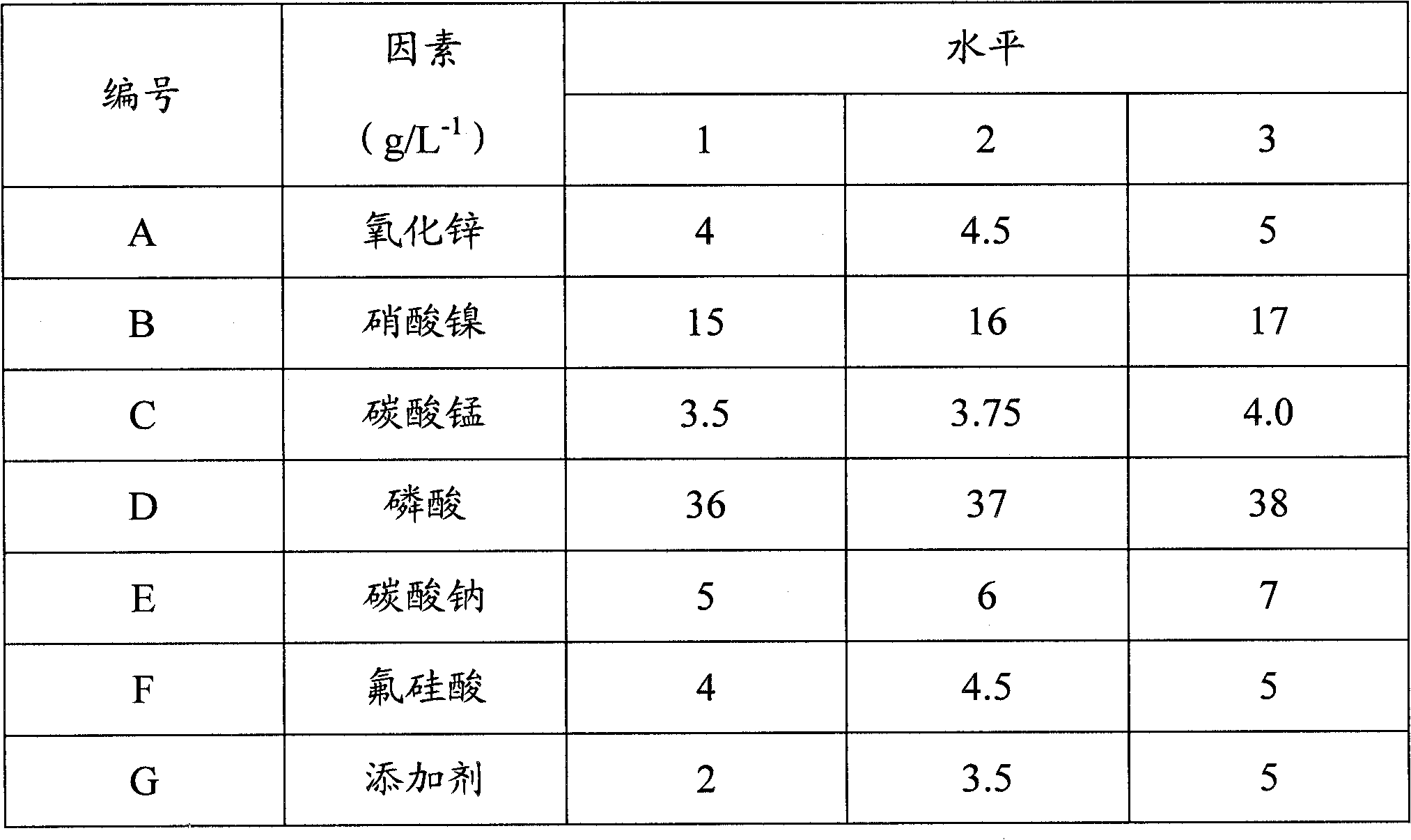

[0022] An embodiment of a cathodic electrophoretic phosphating agent described in the present invention includes zinc oxide, nickel nitrate, manganese carbonate, sodium carbonate, phosphoric acid, fluosilicic acid, additives, and water.

[0023] The principle of phosphating film formation is as follows:

[0024] Macha (Zeng Hualiang, Yang Jiachang "Electrolysis and Chemical Conversion Film", Light Industry Press, 1983, P205-206) believes that phosphating is a typical local reaction, which is an electrochemical reaction in nature.

[0025] (1) Iron is corroded and dissolved by phosphoric acid on the anode of the microbattery: Fe→Fe 2+ +2e;

[0026] (2) Hydrogen discharge on the cathode: 2H + +2e→H 2 ↑;

[0027] (3) Due to the H at the metal-solution interface + Descending, the reaction proceeds to the right:

[0028] 2Me II (H 2 PO 4 ) → Me 3 II (PO 4 ) 2 ↓+4H 3 PO 4 .

[0029] Generated Zn 2 Fe(PO 4 ) 2 4H 2 O is deposited in the cathode area, and as the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com