Phosphating solution for corrosion prevention of iron towers and preparation method thereof

A phosphating solution and iron tower technology, applied in the coating process of metal materials, etc., can solve problems such as affecting adhesion and whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 Phosphating solution composition primary selection single factor experiment of the present invention

[0044] The on-site process requires that the phosphating solution used should be able to quickly form a film (rust layer conversion, zinc layer phosphating) at room temperature, and the rust removal and phosphating process can be completed in one step. At the beginning of the development process, H 3 PO 4 , ZnO, H 2O is the base solution, and different accelerators and chelating agents are added to prepare different phosphating solutions, and single-factor variable experiments are performed to determine the appropriate additives and dosage one by one. Observe the color of the conversion coating on the rust layer and the phosphating coating on the zinc layer and the ash on the surface. The conversion coating on the rust layer should be black, the phosphating coating on the zinc layer should be dark gray, and there should be no ash on the surface of the tw...

Embodiment 2

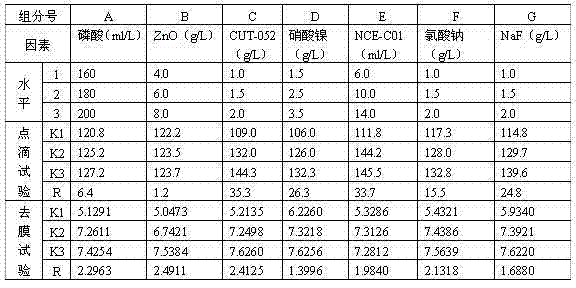

[0055] Embodiment 2 Phosphating solution orthogonal experiment of the present invention

[0056] According to the results obtained from the single factor experiment, an orthogonal design table was established, and seven factors and three levels were selected to do the orthogonal experiment, and the copper sulfate spot test was used as a method to quickly test the corrosion resistance of the rust conversion coating, with its corrosion resistance as the main Index, with the film weight of the phosphating film on the zinc layer as a reference, determine the optimal reagent dosage. Orthogonal experiment table and experimental results are shown in Table 1.

[0057] Table 1 Orthogonal experiment table and experimental results

[0058]

[0059] Graphics can be used to intuitively describe the relationship between factor levels and indicators. When drawing, the abscissa takes the actual value of each factor level, and the ordinate takes the mean value corresponding to this factor ...

Embodiment 3

[0076] Embodiment 3 Phosphating solution single factor variable experiment of the present invention

[0077] In order to further clarify the influence of each component of the phosphating solution on the phosphating performance, a single factor variable experiment of the phosphating solution was done, and the influence of each component on the performance of the phosphating solution was obtained as follows:

[0078] (1) Phosphoric acid. Phosphoric acid is a non-volatile non-oxidizing weak acid with triple ionization, which is graded ionized in aqueous solution and is the main component of phosphating solution. When phosphoric acid is in contact with the rust layer and zinc layer, three types of phosphates can be generated: ferrous, iron and zinc normal salt, hydrogen salt, and dihydrogen salt. Hydrogen phosphate and phosphate are insoluble and form a film layer, while dihydrogen phosphate quickly converts into two types of phosphates, hydrogen salt and normal salt, and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com