Double-phase steel plate and manufacturing method thereof

A steel plate, mass percentage technology, applied in the field of dual-phase steel plate and its manufacturing, can solve the problem of not taking into account the balance of carbon equivalent, drawing performance and hole expansion rate, unfavorable weldability, surface quality and phosphating Performance, failure to take into account the surface and phosphating performance, etc., to achieve good uniformity of mechanical properties, achieve performance balance, and facilitate welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

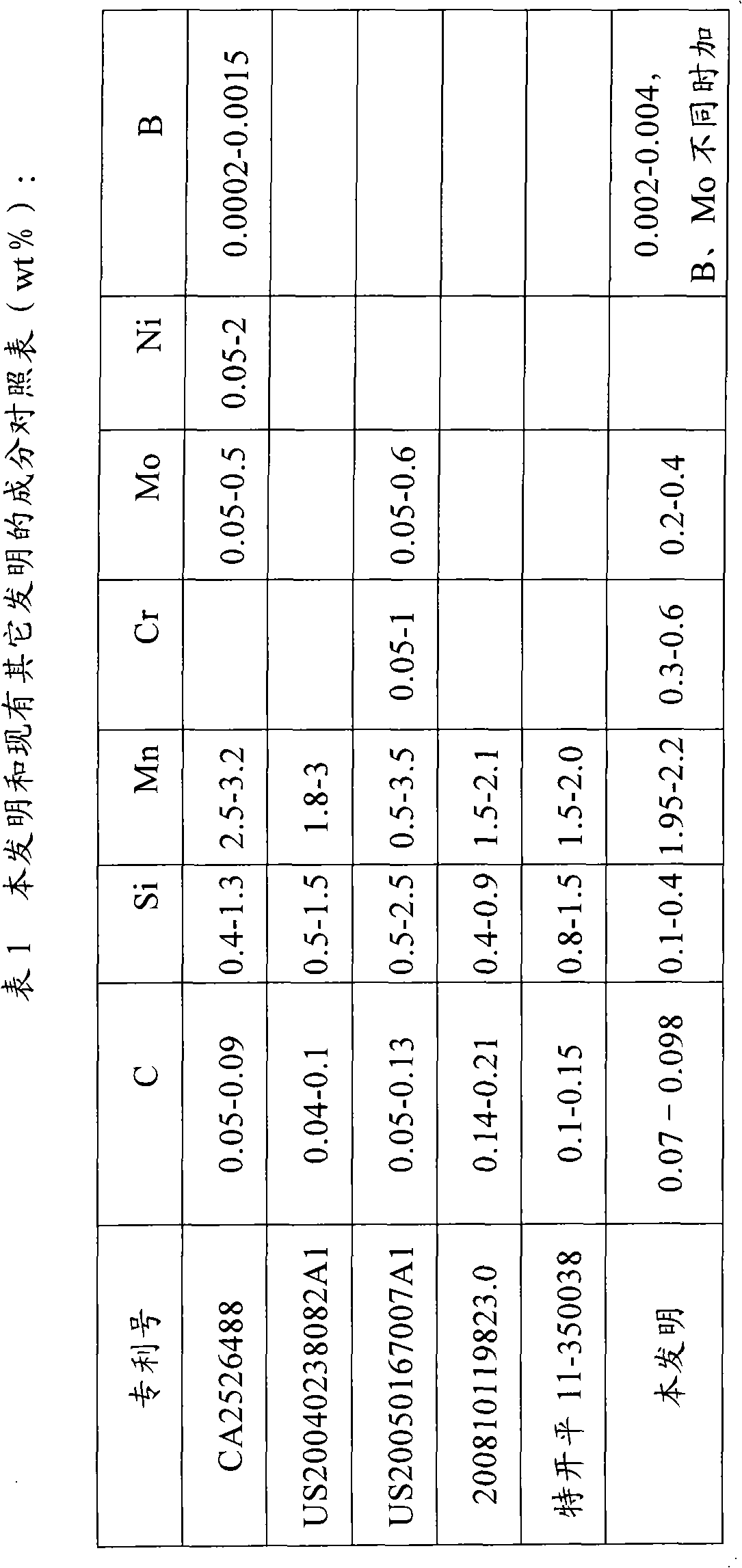

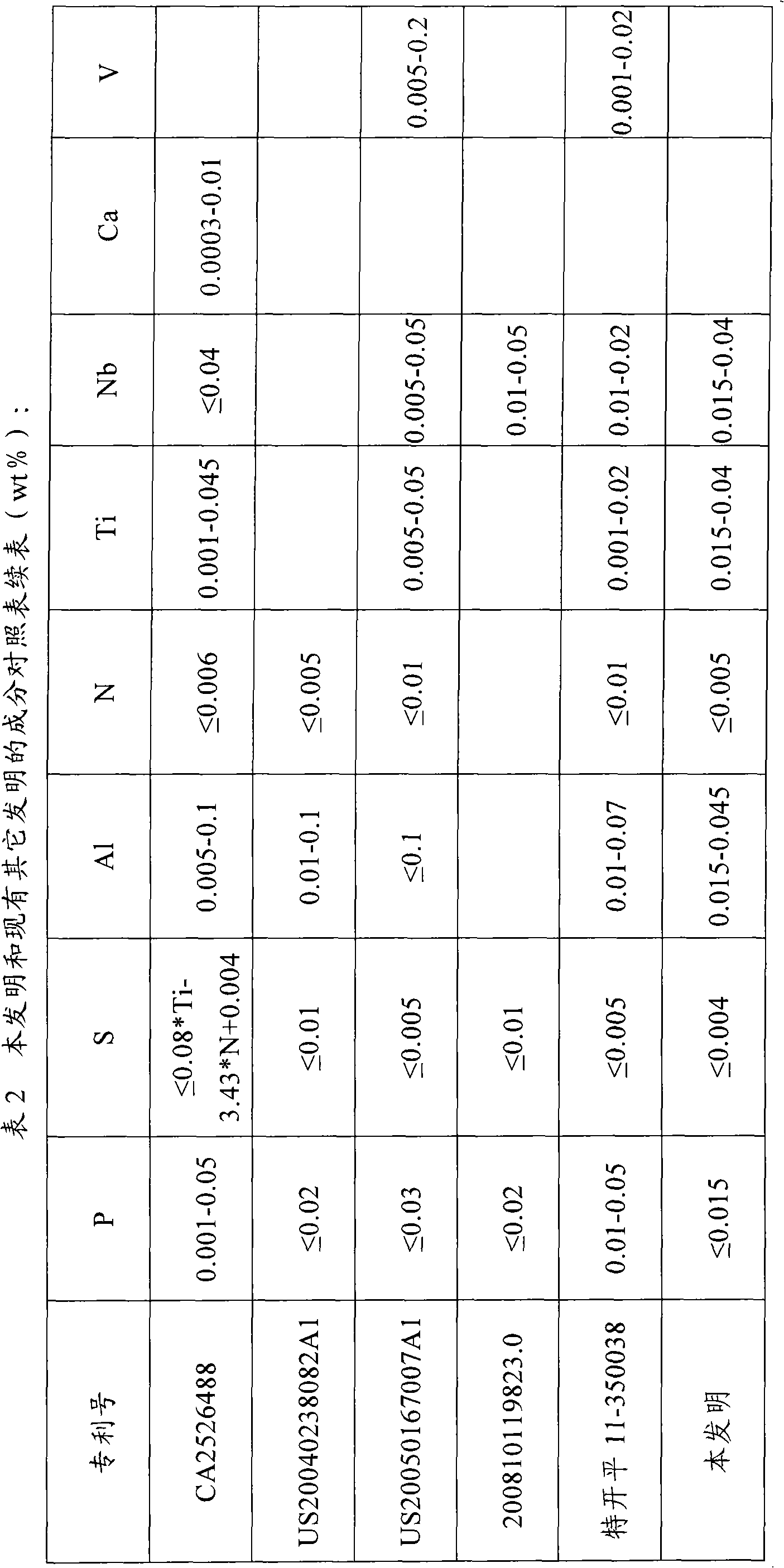

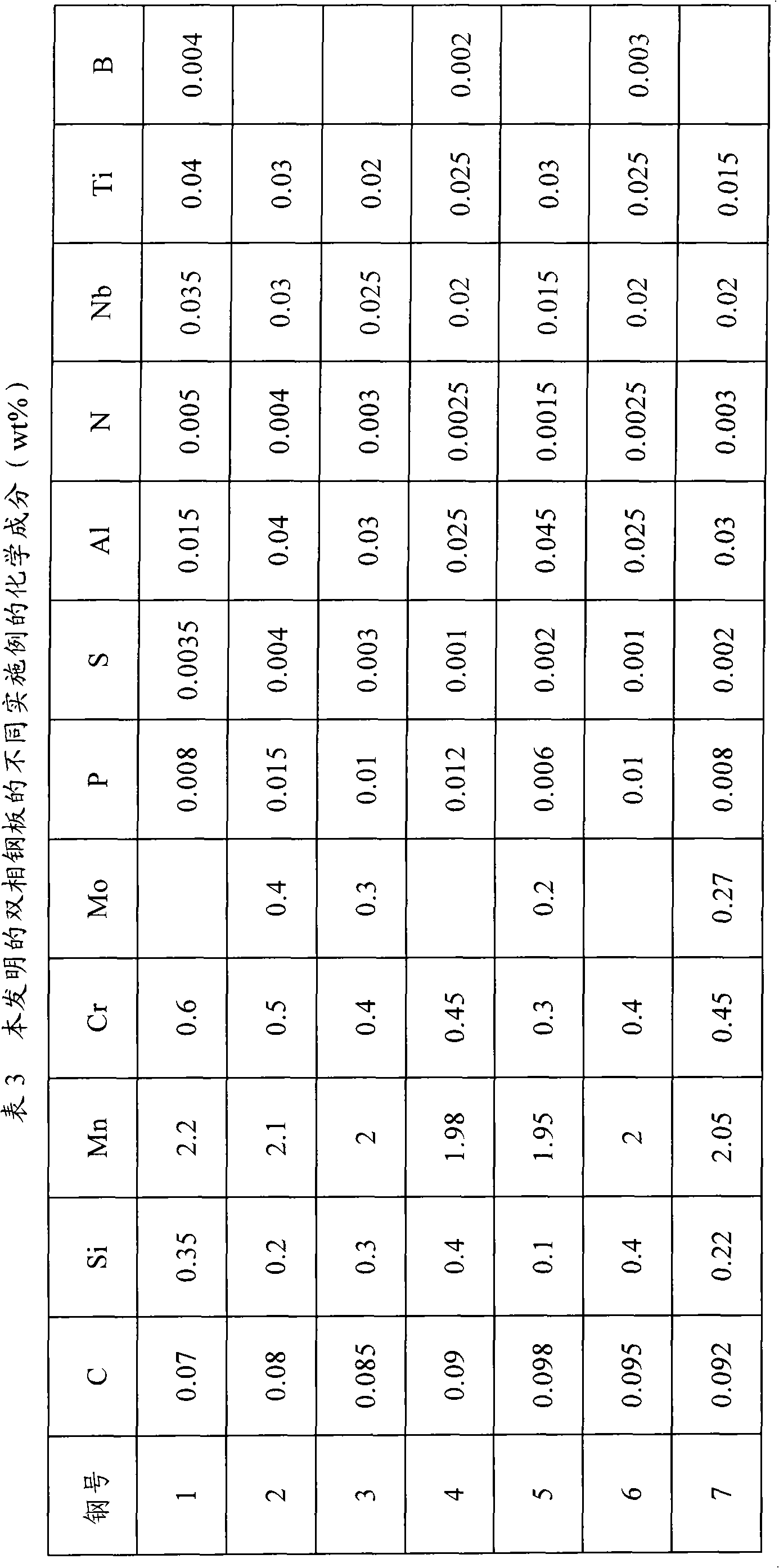

[0039] According to the present invention, the chemical composition mass percentage of the dual-phase steel sheet is:

[0040] C: 0.07~0.098; Si: 0.1~0.4;

[0041] Mn: 1.95~2.2; Cr: 0.3~0.6;

[0042] P: ≤0.015; S: ≤0.004;

[0043] N:≤0.005; Nb: 0.015~0.04;

[0044] Ti: 0.015~0.04; Al: 0.015~0.045;

[0045] Also contains B: 0.002 to 0.004 or Mo: 0.2 to 0.4;

[0046] Others are Fe and inevitable impurities,

[0047] Wherein, the mass percentage of the chemical composition of the dual-phase steel sheet satisfies:

[0048] Pcm=C+Si / 30+Mn / 20+2P+4S)≤0.24.

[0049] The effect of each main chemical component element in the dual-phase steel sheet of the present invention is as follows:

[0050] C: Improve the strength of martensite, affect the content of martensite, and have a great influence on the strength. The increase of carbon content is not good for weldability. Therefore, the carbon content should be selected between 0.07% and 0.098%. If it is lower than 0.07%, the stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com