Method for improving phosphating performance of low-carbon aluminum killed steel automobile plate and automobile plate

A low-carbon aluminum-killed steel and automobile sheet technology, applied in the field of steel smelting, can solve problems such as insufficient phosphating performance, and achieve the effect of improving surface quality and improving phosphating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] In the present embodiment, the billet component control is as shown in Table 1:

[0082] Table 1

[0083] C Si mn P S Al B N 0.0193 0.010 0.194 0.009 0.006 0.039 0.002 0.003

[0084] The steel billet temperature is 1190°C, the exit temperature of rough rolling is 1045°C, the final rolling temperature is 915°C, and the coiling temperature is 680°C.

[0085] Cold rolling reduction is 67.6%.

[0086] The continuous annealing process is controlled as follows: the dew point of the heating section in the furnace is -25°C, and the other sections are -46°C; the O content of each section is 10ppm; the H2 content is 5%.

[0087] The leveling process is controlled as follows: the Ra value of the steel plate surface after leveling is 1.2um, and the RPc is 93.

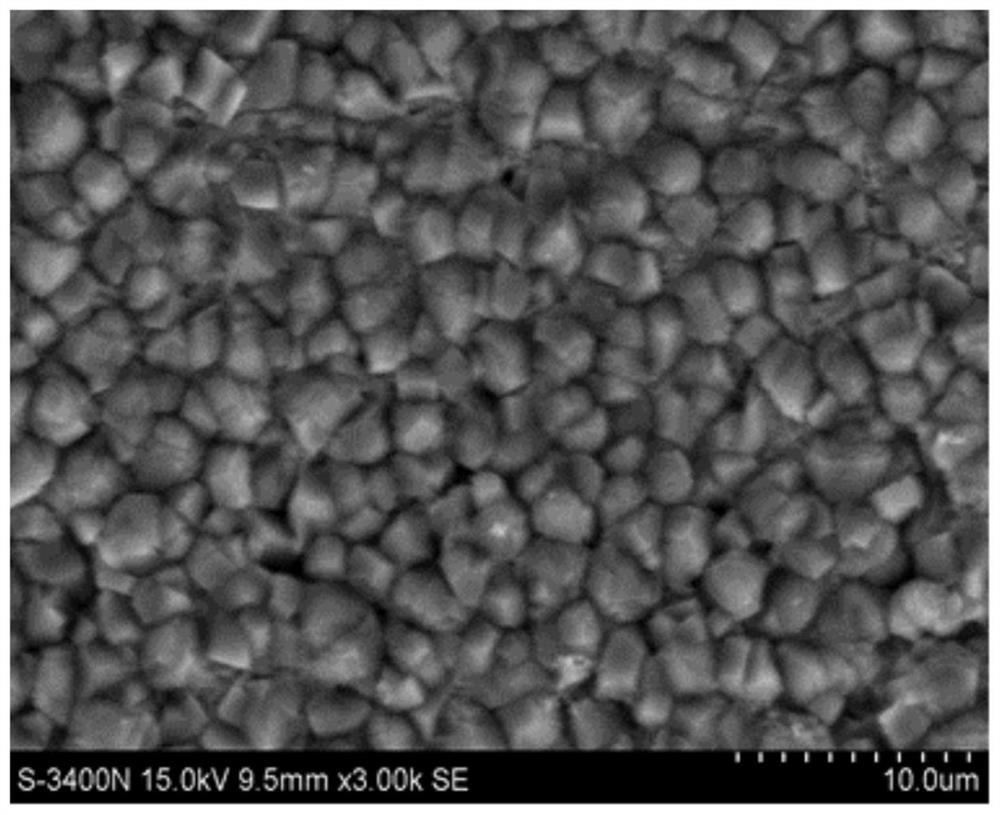

[0088] The topography of the phosphating film on the surface of the low-carbon aluminum-killed steel automobile sheet produced by this embodiment is as follows figure 1 shown, from figur...

Embodiment 2

[0090] In the present embodiment, the billet component control is as shown in Table 2:

[0091] Table 2

[0092] C Si mn P S Al B N 0.0190 0.013 0.199 0.006 0.005 0.043 0.003 0.003

[0093] The steel billet temperature is 1180°C, the rough rolling exit temperature is 1040°C, the final rolling temperature is 910°C, and the coiling temperature is 685°C.

[0094] The cold rolling reduction was 86.0%.

[0095] The continuous annealing process is controlled as follows: the dew point of the heating section in the furnace is -22°C, and the other sections are -49°C; the O content of each section is 13ppm; the H2 content is 7%.

[0096] The leveling process is controlled as follows: after leveling, the Ra value of the steel plate surface is 1.3um, and the RPc is 116.

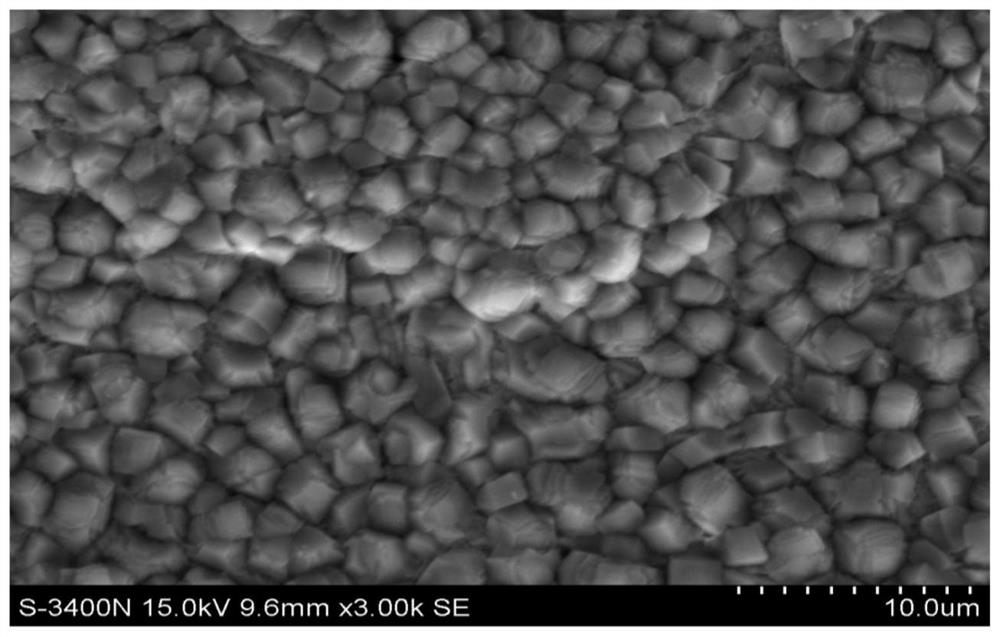

[0097] The topography of the phosphating film on the surface of the low-carbon aluminum-killed steel automobile sheet produced by this embodiment is as follows figure 2 shown, from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com