Patents

Literature

36results about How to "Simplify the painting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for decorating fingernails with multicolored designs

InactiveUS20070092634A1Simplify the painting processShorten the timePerson identificationTypewritersEngineeringBody region

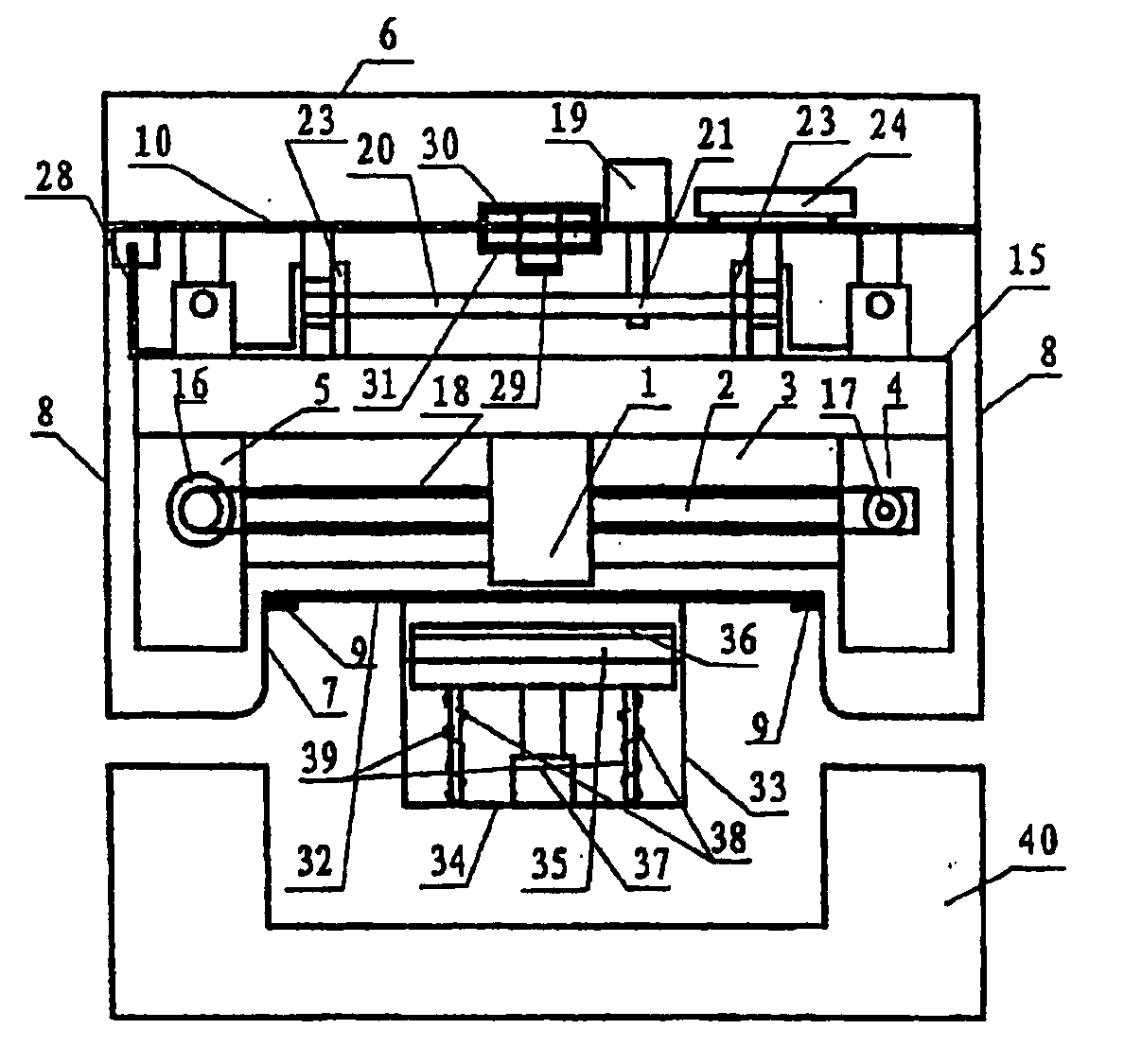

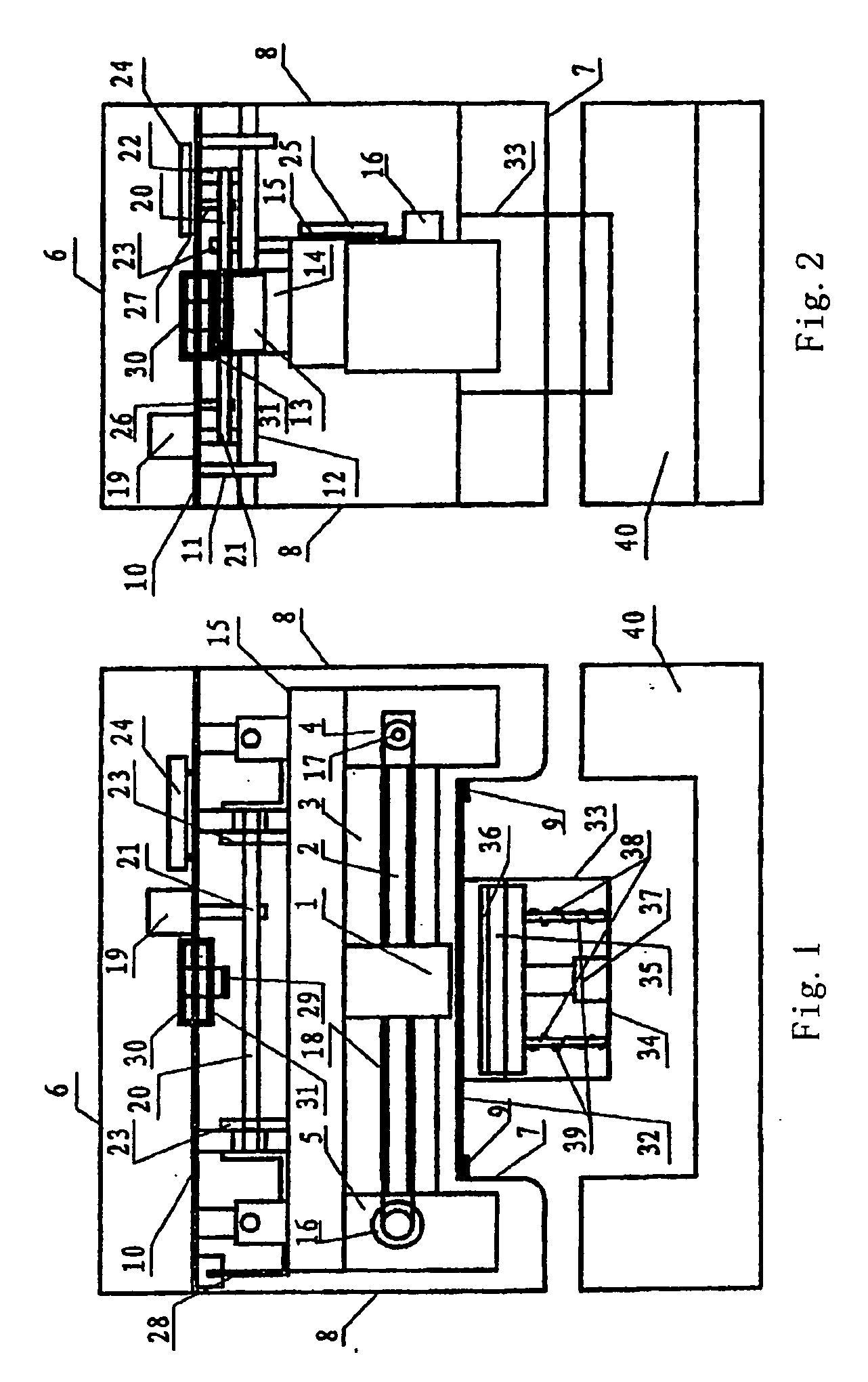

The present invention relates to a body painting method mainly used in nail beautifying for simultaneously creating a plurality of patterns, and a specialized computer-controlled body-painting machine for realizing the method. In use, a plurality of target body parts to be painted are simultaneously placed onto the clamp of the body-painting machine after necessary preprocesses have been preformed to the target body parts; then a plurality of pictures for said body parts are simultaneously opened with a computer and the body parts are displayed on the screen of the computer by the camera, the pictures will be printed as one pattern simultaneously after the sizes and printing locations of these pictures have been adjusted, resulting in each of the pictures being printed at its corresponding printing location; the body-painting machine is operated by the computer, and its printing head is connected to a transverse moving mechanism and a longitudinal moving mechanism; the camera head is fixedly mounted above the printing head; the clamp can be inserted into the space between the upper casing and the base of the machine body. According to present invention, a plurality of body-painting patterns can be printed at one time, thereby the painting process is greatly simplified and the painting time is significantly reduced.

Owner:ZHANG XINGZHU

Painting method for plastic casing

The invention refers to a paint-spraying method of plastic shell, especially for the shell of electronic equipments: mobile phone, PDA and so on, making the shell show at least two colors. The method includes: produce one shell with at least two colors by injection moulding, spray bottom paint with low covering performance on its surface, and then spray a layer of transparent surface paint. The light beam produces refraction and transmission by the layer of paint, different shells can absorb visible lights in different wave band and accordingly shows at least two new colors different from material color of the shell and the paint color.

Owner:诺基亚西门子通信系统技术(北京)有限公司

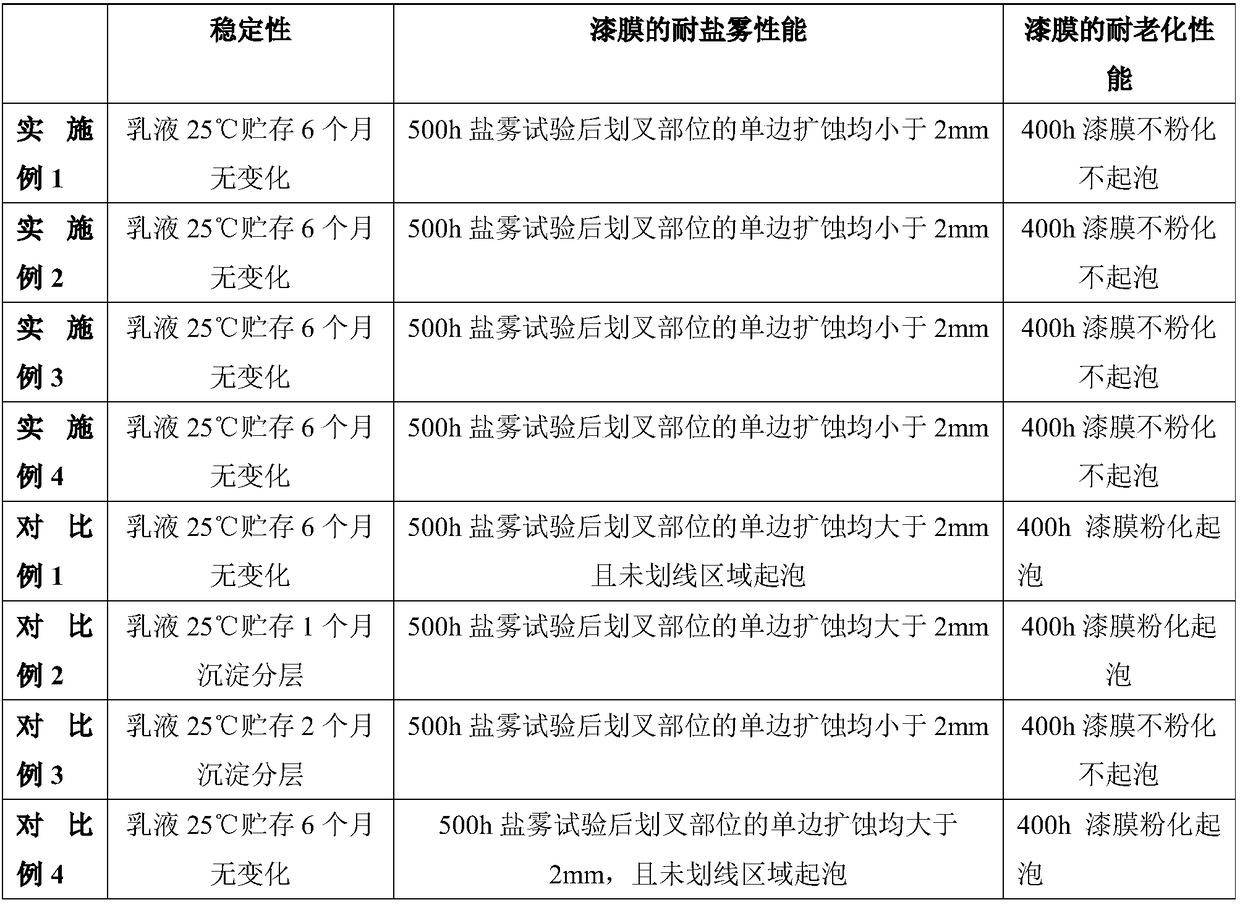

Preparation method of emulsion type adhesion promoter for polyolefin plastics

The invention discloses a preparation method of emulsion type adhesion promoter for polyolefin plastics. The emulsion type adhesion promoter for polyolefin plastics is obtained through dispersing and emulsifying chlorinated polyolefin, organic solvent, emulsifying agent and water under a proper condition. A small quantity of organic solvent facilitates dispersing chlorinated polyolefin resin in the emulsion preparation process; and the swelling role of organic solvent to polyolefine also ensures good adhesive attraction of a coating layer to a substrate when the emulsion is formed into a film. Compared with a similar solvent based product, the emulsion type polyolefine adhesion promoter lowers the use amount of the organic solvent and has the adhesion property which can be compared with the similar solvent based product. The emulsion type adhesion promoter for polyolefin plastics has simple preparation process, low price, favorable construction property, small environment pressure and wide market prospect.

Owner:XI AN JIAOTONG UNIV +1

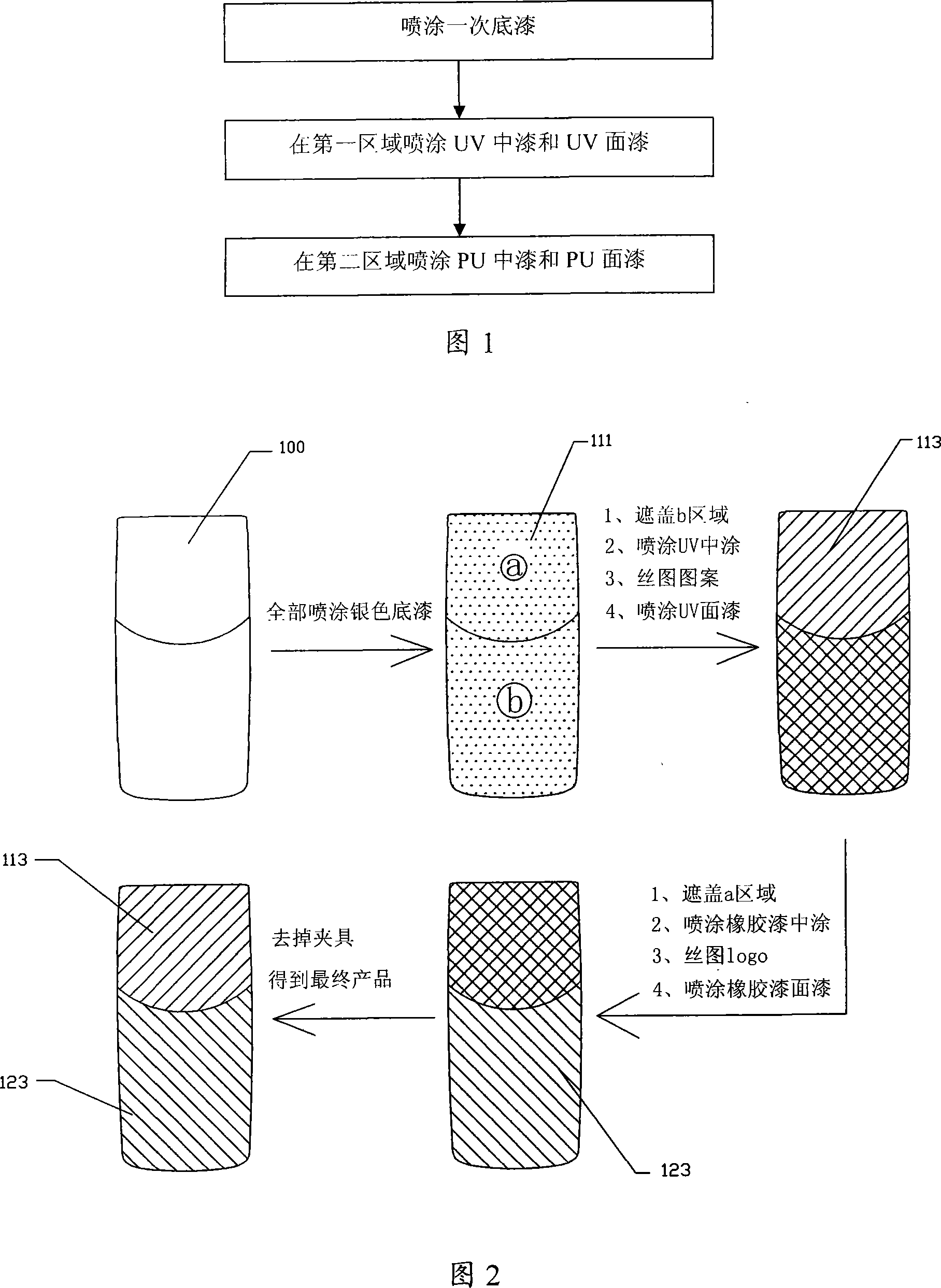

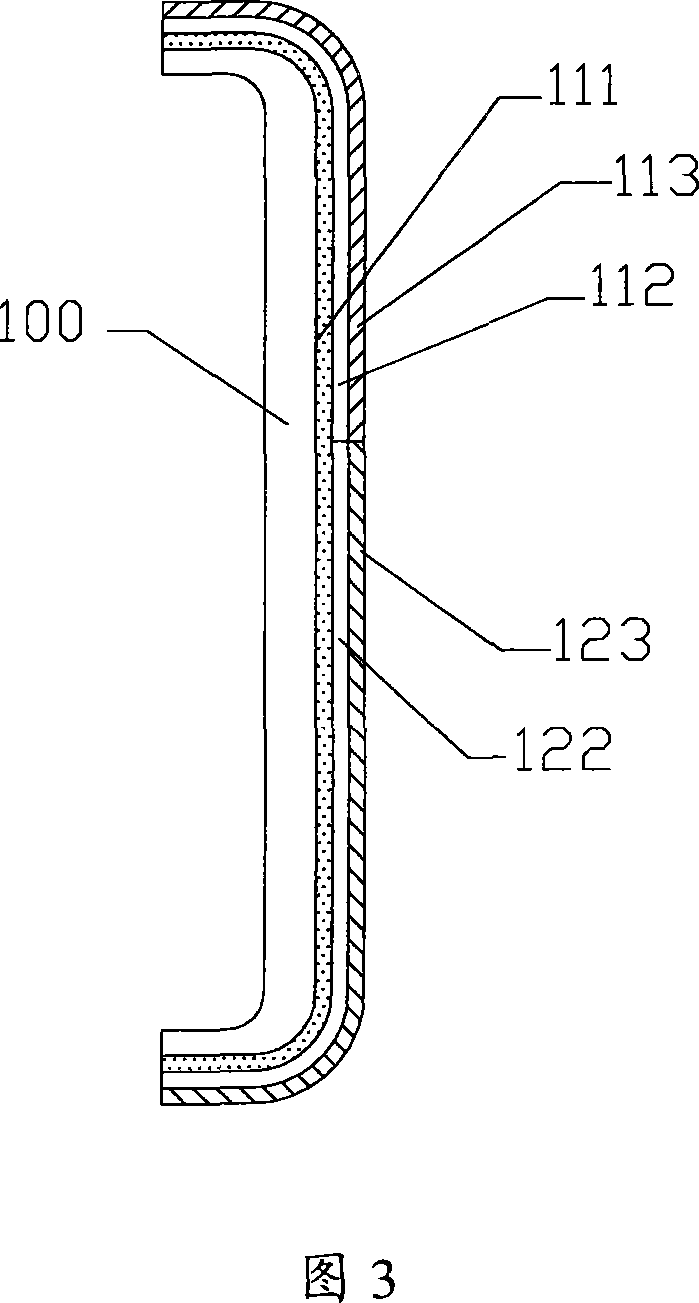

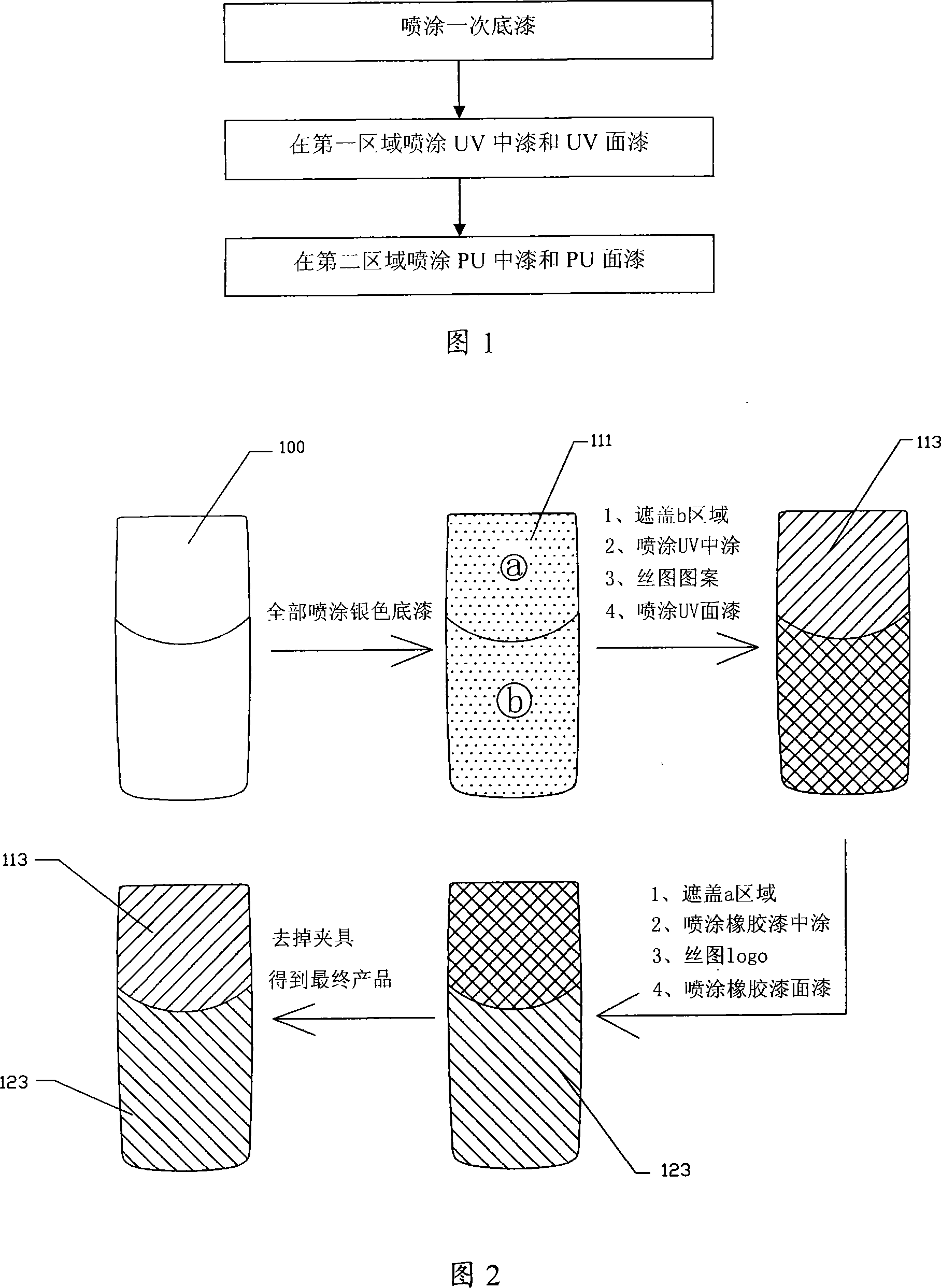

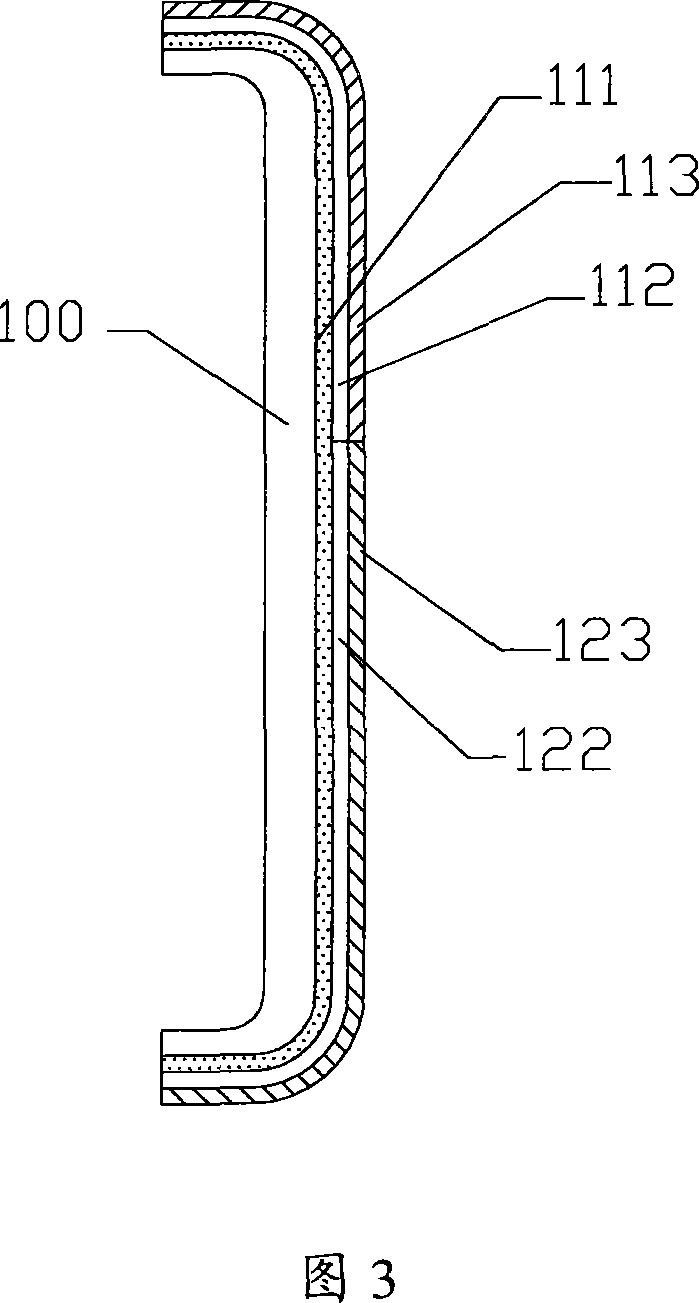

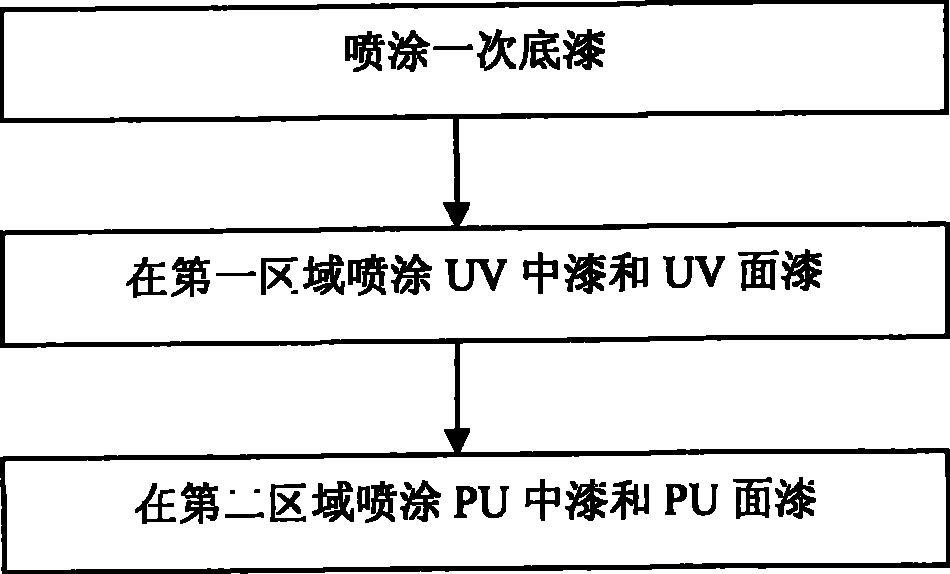

Method for multicolor spray coating and component after spray coating thereof

ActiveCN101176869ASimplify the painting processImprove yieldSpecial surfacesCoatingsLacquerSpray coating

The invention discloses a multi-color coating method and a coated part; wherein, the method comprises at least the following steps: a layer of priming paint is coated on the whole face plate; a first middle paint is coated on a first area of the face plate; a first top finish is coated on the first middle paint; a second middle paint is coated on a second area of the face plate, and a second top finish is coated on the second middle paint. Since the method of using the same priming paint when coating two colors, the invention has the advantages of simplified paint coating process and improved yield rate.

Owner:山东中盈铝业有限公司

Waterborne nano coil coating and preparation method thereof

The invention belongs to a waterborne nano coil coating and a preparation method thereof. Firstly, an inorganic material with no toxic property, foreign smell and combustion characteristic is used as a basic powder material of a coil coating, a waterborne acrylic emulsion, waterborne epoxy resin, water-soluble functional auxiliaries and other film forming matters are compounded, updated and modified by using a nanotechnology and nano materials, and gaps of large micro materials in a coating structure are filled by using various nano powder materials after the hydration of the coil coating is effectively finished, so that the coating generates a coating function enhancing effect under the synergistic action of multi-effect combination of the nano materials and micro materials, the defect that the performance of the waterborne coil coating prepared by a micrometer technology is lowered is overcome effectively, and the technical performance of the waterborne coil coating is remarkably enhanced. By using the waterborne nano coil coating and the preparation method thereof, the production efficiency is increased, the fire risks and industrial pollution of the traditional solvent type coil coating are eliminated, and meanwhile, the aim of safe, environment-friendly, low-consumption and efficient production is achieved.

Owner:北京中科捷达纳米应用科技有限公司

Epoxy acrylic cathode electrophoretic coating resin emulsion and preparation method thereof

ActiveCN109294314AGood storage stabilityAnti-corrosionAnti-corrosive paintsPaints for electrolytic applicationsEpoxyOrganic acid

The invention relates to the technical field of electrophoretic coating, and particularly relates to epoxy acrylic cathode electrophoretic coating resin emulsion and a preparation method thereof. Thepreparation method mainly comprises the following steps: firstly, synthesizing acrylic resin containing a reactive functional group; then, performing chain extension on epoxy resin until the epoxide equivalent is 400-900 with chain extender, and sequentially reacting the epoxy group in the chain-extended epoxy resin sequentially with organic secondary amine and the acrylic resin containing a reactive functional group to prepare epoxy acrylic resin; and mixing the epoxy acrylic resin with full-closed polyisocyanate, neutralizing the mixture with organic acid, and dispersing the mixture with deionized water to prepare the epoxy acrylic cathode electrophoretic coating resin emulsion. The resin emulsion is stable, has low solvent content and can be used as a film forming component of cathode electrophoretic coating; and the film has corrosion resistance, aging resistance and decorating performance, functions of priming coat and finishing coat can achieved by once electrophoretic coating, the coating process can be simplified, and the coating cost can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Water-based paint for steel tube external protection and preparation method of water-based paint

InactiveCN104559660ALess material consumptionStrong adhesionPaints with biocidesAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses a water-based paint for steel tube external protection. The water-based paint is prepared from the following raw material constituents in percentage by weight: 20.0-35.0% of an waterborne epoxy emulsion, 15.0-25.0% of water-based acrylic resin I, 15.0-25.0% of water-based acrylic resin II, 0.5-2.0% of propylene glycol, 2.0-5.0% of butyl cellosolve, 0.1-1.0% of a flash-rust inhibitor, 0.5-1.0% of a corrosion inhibitor, 0.5-2.0% of a salt spray resistant additive, 0.1-0.5% of a bactericide, 0.1-0.5% of a wetting agent, 0.05-0.5% of a defoaming agent, 0.1-1.0% of a thickening agent, and 21.3-27.5% of deionized water; the water-based paint is prepared from the following steps: (1) preparing the raw materials; (2) burdening and dispersing; (3) filtering and packaging. The water-based paint disclosed by the invention belongs to the varnish system; the dry film thickness of the paint is only 20-30 microns; the water-based paint is good in adhesive force, corrosion resistance and water penetration resistance; the surface gloss of the coating can be up to 90 degrees, the salt spray resistance property can be up to 300 hours above, and the outdoor weather resistance can be more than 1 year.

Owner:SHANGHAI HILONG PETROCHEM RES INST +3

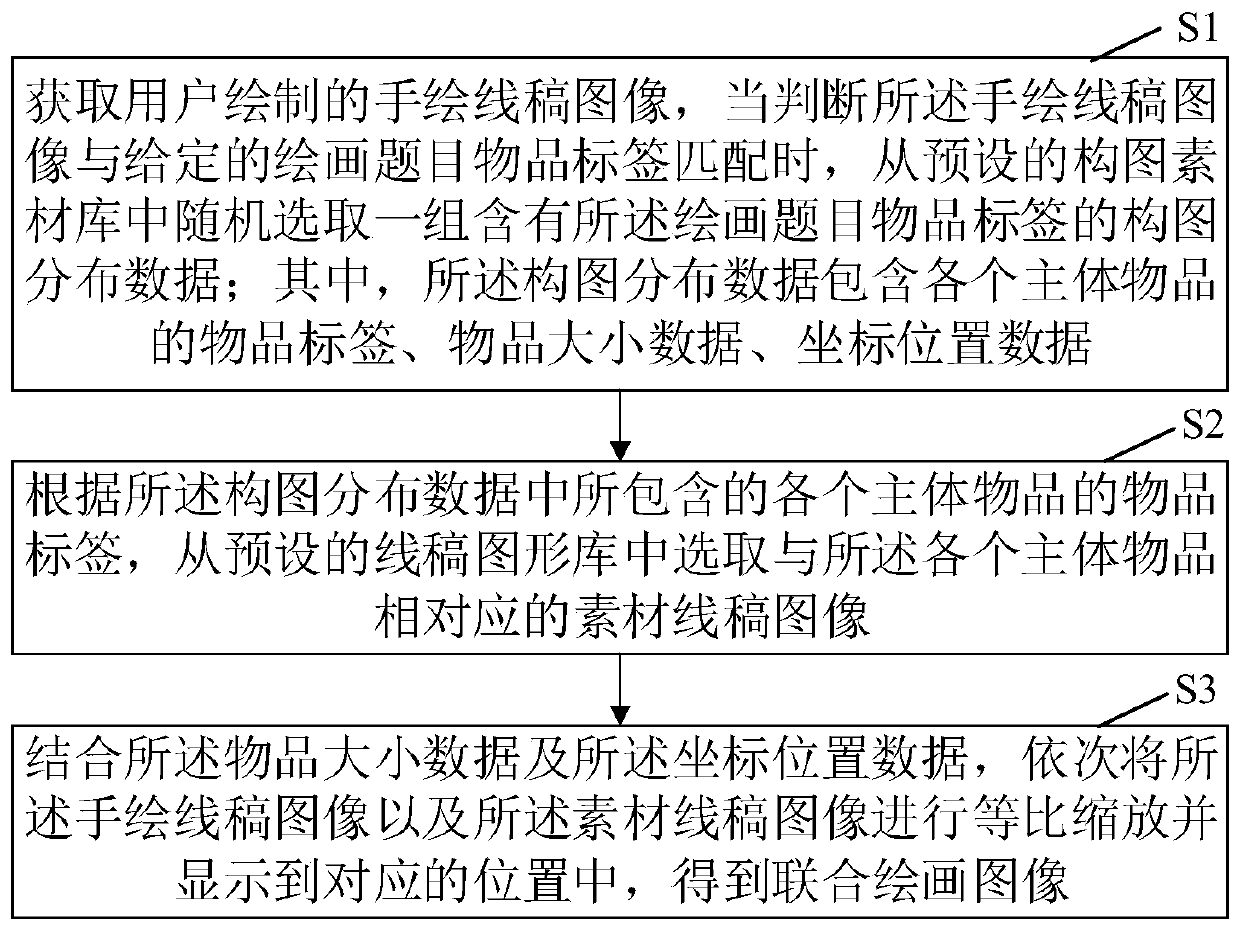

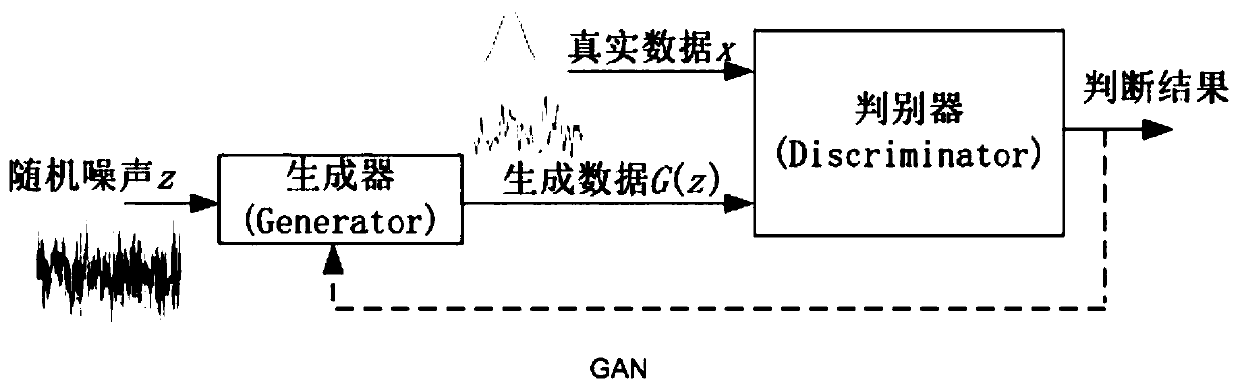

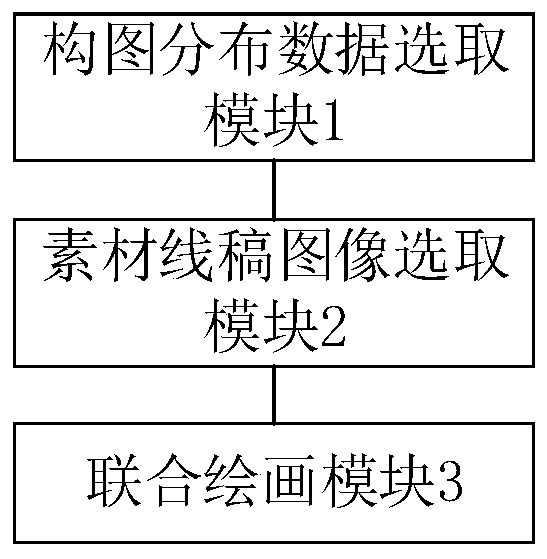

Joint drawing method and device, terminal equipment and readable storage medium

PendingCN110097616AAdd funSimplify the painting processEditing/combining figures or textManufacturing computing systemsGraphicsTerminal equipment

The invention discloses a joint drawing method and device, terminal equipment and a readable storage medium, and the method comprises the steps: obtaining a hand-drawn line draft image drawn by a user, and selecting a group of composition distribution data containing an article label from a preset composition material library when the hand-drawn line draft image is judged to be matched with a given drawing topic article label; selecting a material line draft image corresponding to each main body article from a preset line draft graphic library according to the article label of each main body article contained in the composition distribution data; and in combination with the object size data and the coordinate position data of each main body object, sequentially performing equal-ratio zooming on the hand-drawn line draft image and the material line draft image, and displaying the hand-drawn line draft image and the material line draft image in corresponding positions to obtain a combined drawing image. According to the invention, the single article element image drawn by the user can be drawn, supplemented and perfected through the material library, so that people without professional drawing skills can create the drawing works with full composition and rich elements.

Owner:GUANGDONG INTELL VISION TECH CO LTD

Preparation method for water-based epoxy primer and application of water-based epoxy primer to carbon fibre bicycle

InactiveCN107201135ALow VOC contentReduce pollutionPretreated surfacesEpoxy resin coatingsEnvironmental resistanceEpoxy

The invention relates to the technical field of carbon fibre bicycle coating, in particular to a preparation method for water-based epoxy primer and application of the water-based epoxy primer to a carbon fibre bicycle. The preparation method comprises the following steps: mixing water-based epoxy resin and a water-based epoxy curing agent in a proportion, and then regulating the viscosity to obtain the water-based epoxy primer. The water-based epoxy primer is non-toxic and environment-friendly, and is applicable to the primer of a carbon fibre bicycle frame and accessories; the pollution to the environment caused by the water-based epoxy primer is greatly reduced; the damage to the body of an operator can be reduced; the preparation method is simple; a coating process can be simplified; the production efficiency can be improved; the water-based epoxy primer can be applied to various parts of the carbon fibre bicycle.

Owner:TAISHAN SPORTS IND GRP +1

Anhydrous phosphating agent

InactiveCN106399987ASimplify the painting processReduce processing timeMetallic material coating processesPolyvinyl butyralOrganic solvent

The invention discloses an anhydrous phosphating agent. The anhydrous phosphating agent is prepared from, by weight, 20 parts to 40 parts of phosphoric acid, 3 parts to 15 parts of polyvinyl butyral, 3 parts to 12 parts of silicone oil, 5 parts to 10 parts of sodium borate, 8 parts to 18 parts of resin, 3 parts to 14 parts of citric acid and 30 parts to 60 parts of organic solvents. A preparation method of the anhydrous phosphating agent includes the following steps that a, mixed liquid of polyvinyl butyral resin and the organic solvents is prepared; b, phosphoric acid and citric acid organic solvent mixed liquid is prepared; and c, mixing is performed, wherein the solutions obtained in the steps of a and b, silicone oil and sodium borate are mixed according to the formula, and the phosphating agent is prepared in a stirring manner. The phosphating agent is good in phosphating effect, small in sewage discharge amount, free of corrosivity, simple in preparation process and low in cost.

Owner:广州市汇盛金丰科技企业孵化器有限公司

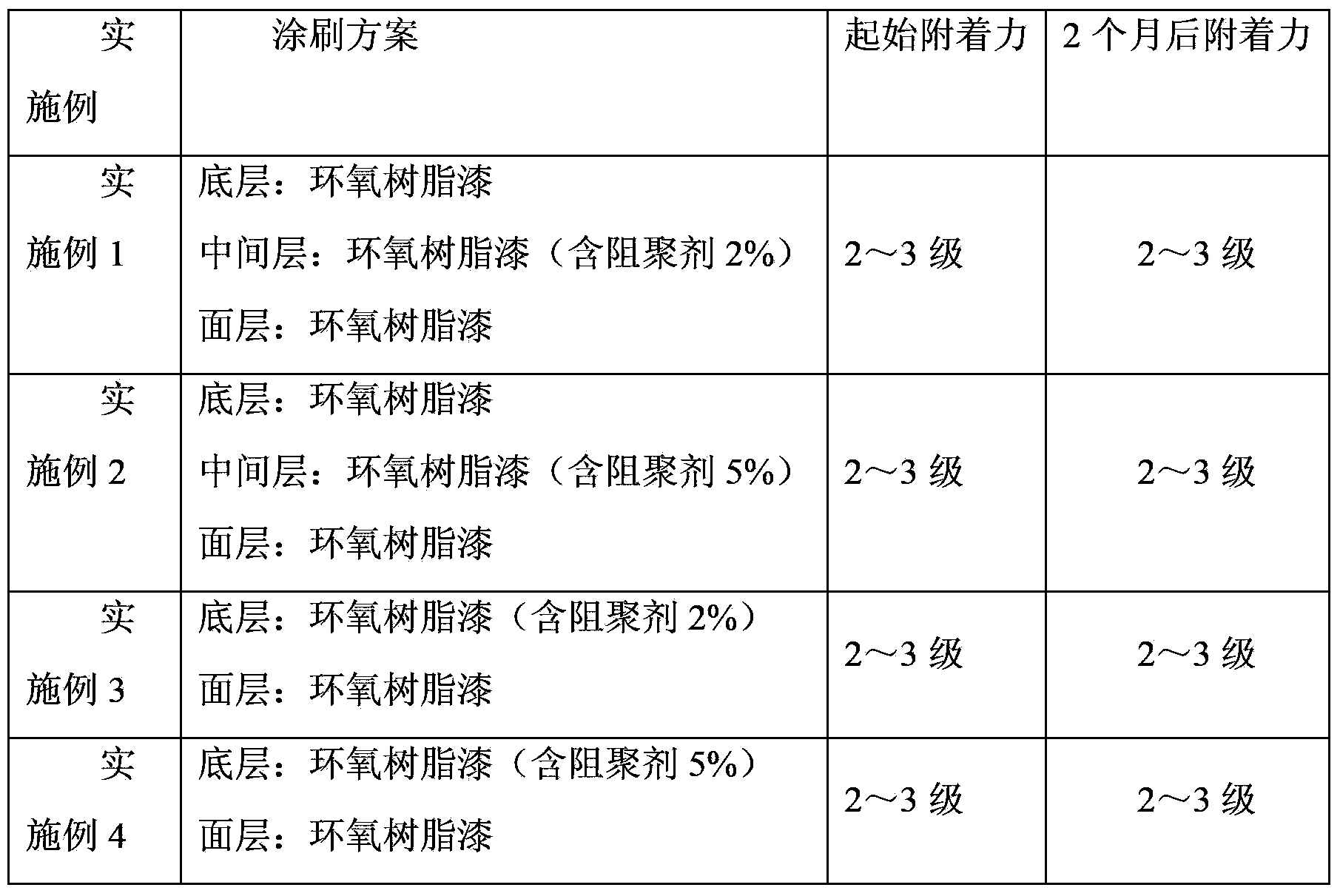

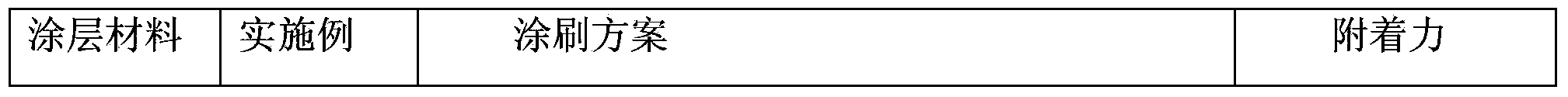

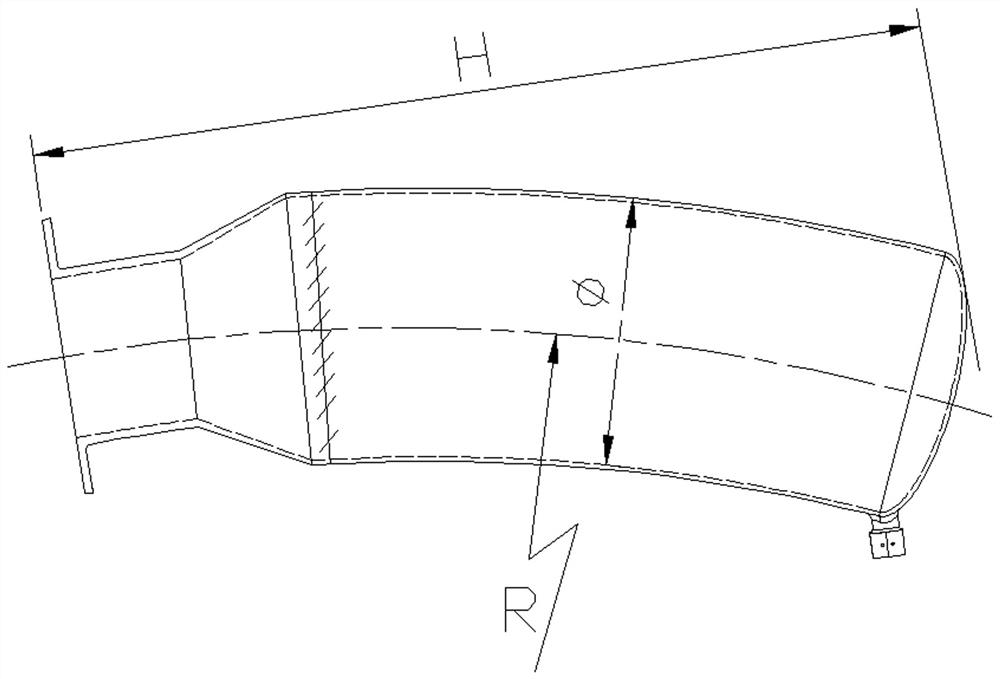

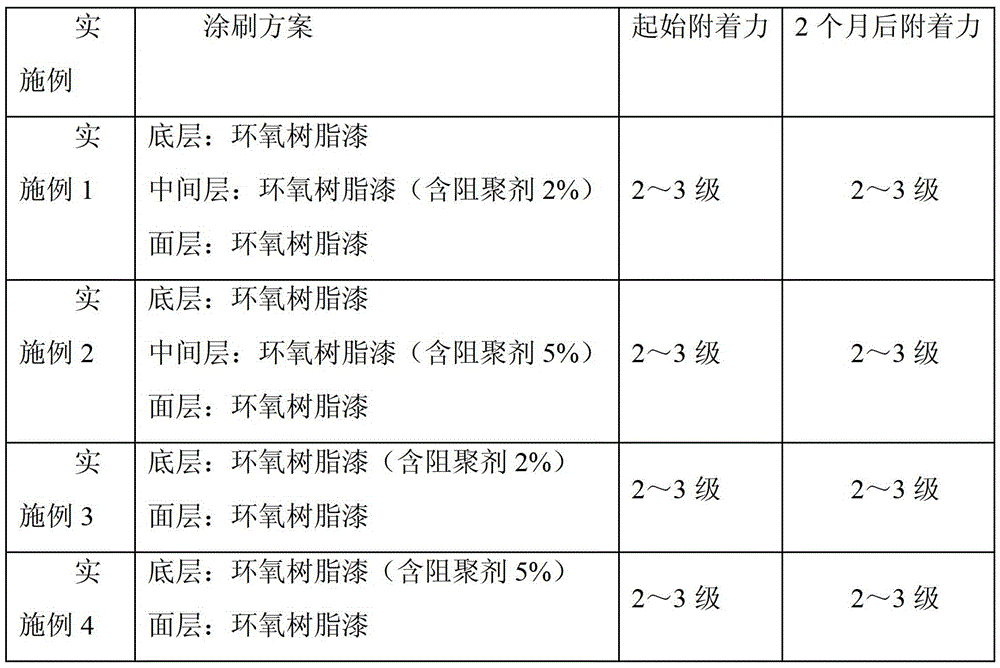

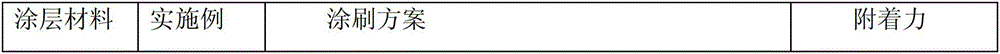

Storage method for aromatic alkene monomer

ActiveCN104250202AGood compatibilityEvenly distributedHydrocarbon purification/separationHydrocarbonsChemistryEnforcement

The invention relates to a storage method for a monomer, and especially relates to a storage method for an aromatic alkene monomer in a storage tank. The storage method for the aromatic alkene monomer in the storage tank means that the inner wall of the storage tank of the aromatic alkene monomer is coated with a coating containing a polymerization inhibitor, the coating is composed of a bottom layer and a surface, the bottom layer is a coating containing the polymerization inhibitor, and the surface layer is a coating not containing polymerization inhibitors. Compared with protective coating technologies in the prior art, the storage method for the aromatic alkene monomer has different effect, during enforcement, the polymerization inhibitor is grinded, screened and added into coating materials, a heating mixing manner is employed, the polymerization inhibitor has good compatibleness with the coating materials and the addition quantity of the polymerization inhibitor is large, so that the coating adhesive force and the polymerization-inhibiting time are effectively improved, and thus the long-term polymerization inhibiting effect is reached and the polymerization inhibiting period can reach 6 years or more.

Owner:CHINA PETROLEUM & CHEM CORP

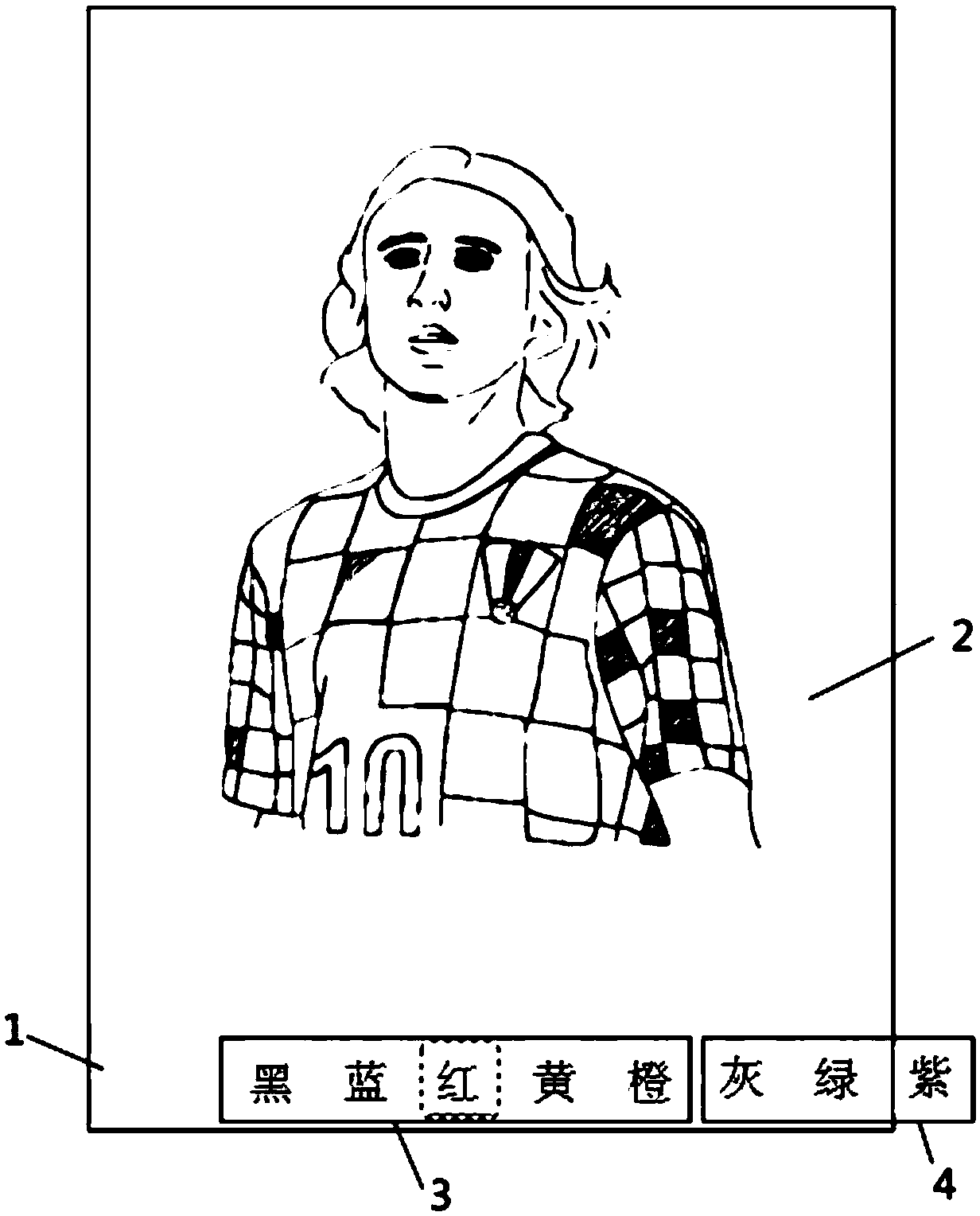

A painting system and method based on a touch screen and a robot arm

PendingCN109445623AOmit manual operationIntelligent painting processTexturing/coloringOther artistic work equipmentsComputer graphics (images)Color changes

The invention discloses a drawing system and a drawing method based on a touch screen and a robot arm. The system comprises a touch screen providing a drawing operation interface, comprising a color picking area and a drawing area, wherein the color picking area comprises a color picking block corresponding to a color value; a drawing module comprising a robot arm and a stylus; a control module obtaining the image information to be drawn and outputting the drawing control instruction to the manipulator. The invention uses the robot arm to clamp a touch pen to draw on a touch screen, and provides a robot drawing mode for artistic creation by using a new technology, and solves the problems of inconvenience in color toning, color taking and color changing when drawing on a drawing paper.

Owner:GUANGDONG INTELL VISION TECH CO LTD

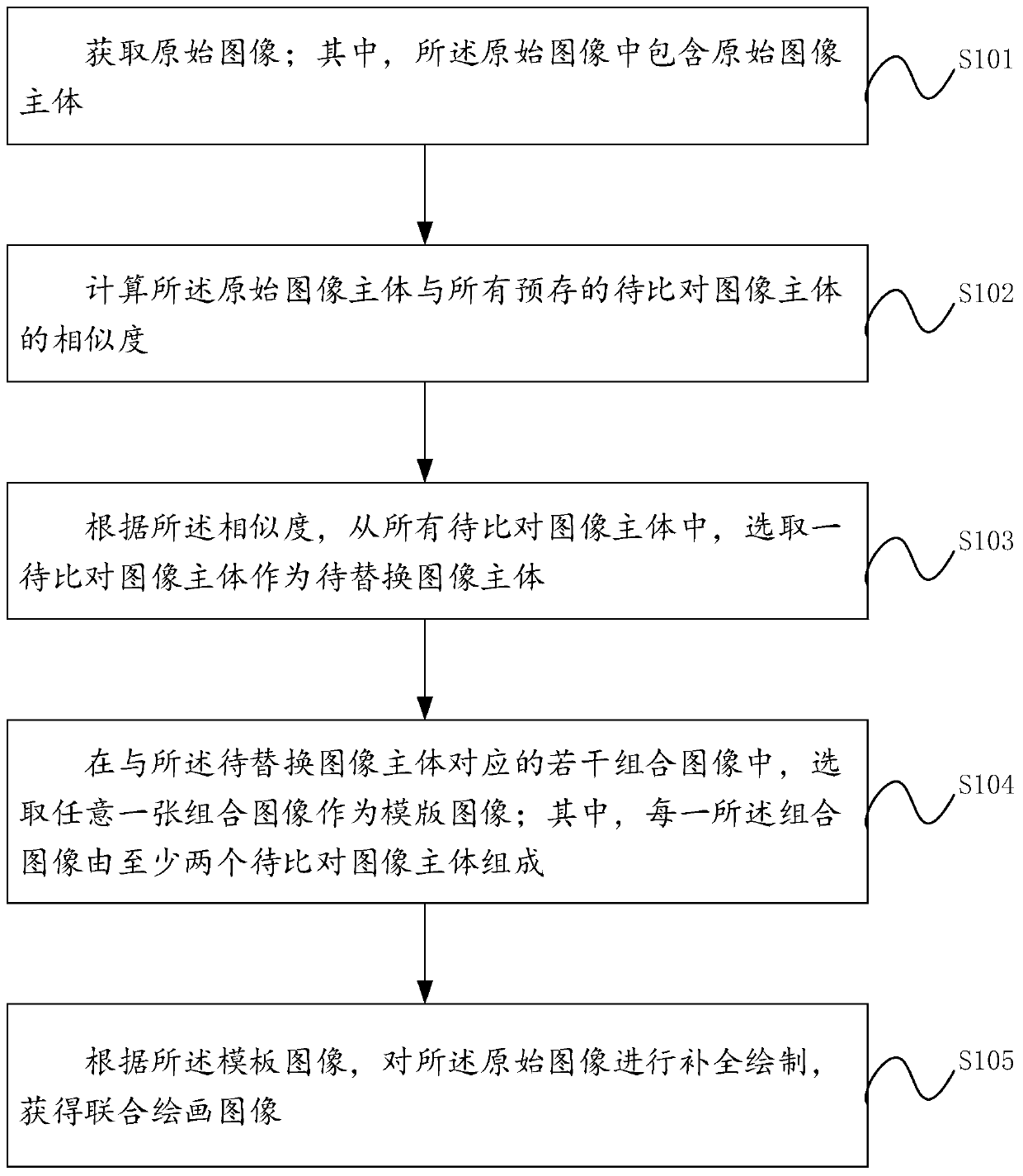

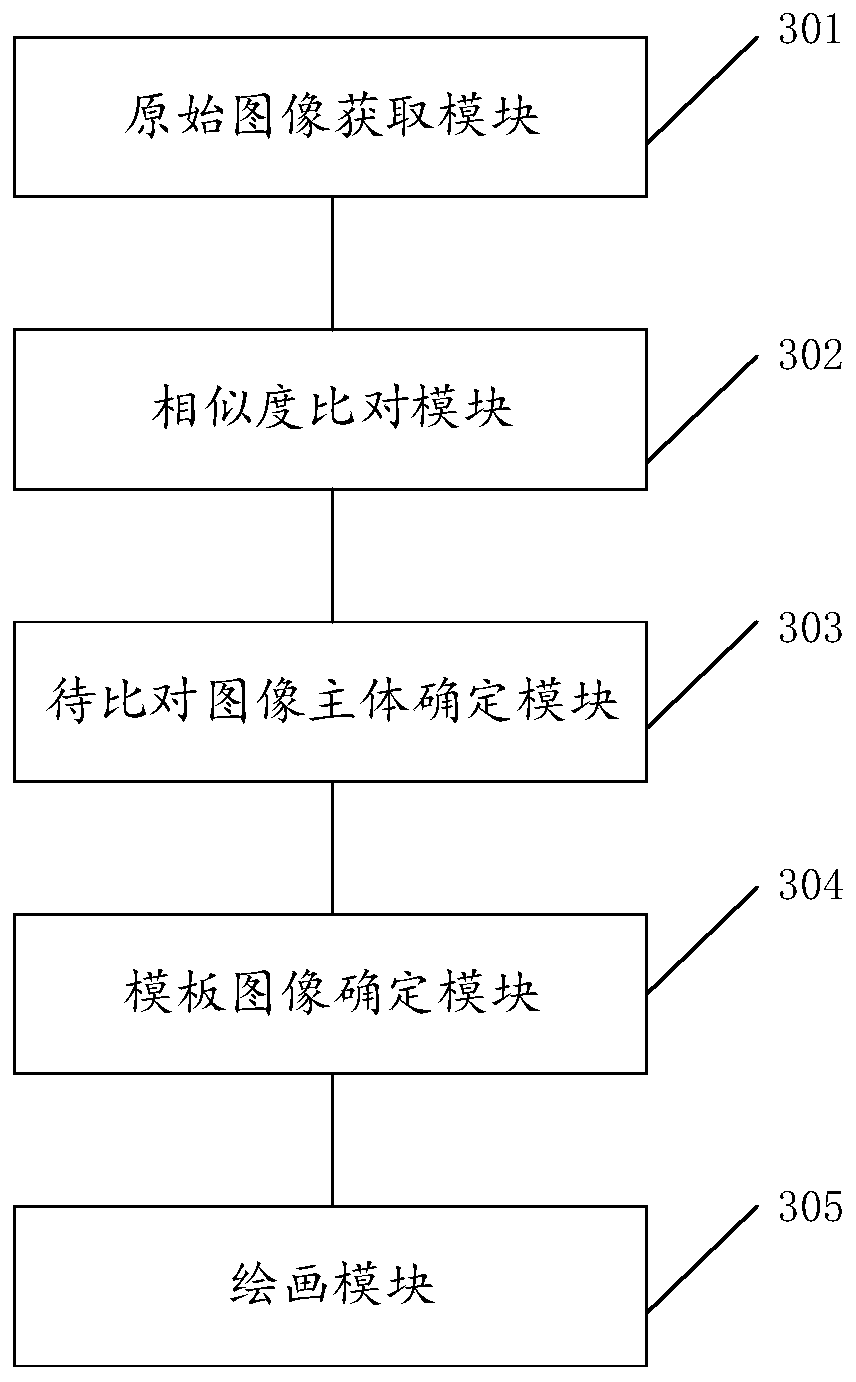

Joint drawing method and device, terminal setting and computer readable storage medium

ActiveCN109993816AAdd funFull compositionEditing/combining figures or textComputer graphics (images)Terminal equipment

The invention discloses a joint drawing method and device, terminal equipment and a computer readable storage medium. The method comprises the steps that an original image is acquired; wherein the original image comprises an original image main body; calculating the similarity between the original image main body and all pre-stored to-be-compared image main bodies; according to the similarity, selecting a to-be-compared image main body from all to-be-compared image main bodies as a to-be-replaced image main body; selecting any one combined image from the plurality of combined images corresponding to the image main body to be replaced as a template image; wherein each combined image is composed of at least two image main bodies to be compared; and according to the to-be-compared image mainbody except the to-be-replaced image main body in the template image, carrying out completion drawing on the original image to obtain a joint drawing image. According to the embodiment of the invention, the original image can be complementarily drawn through the template image, so that the composition of the original image is plump, and the image main body is richer.

Owner:GUANGDONG INTELL VISION TECH CO LTD

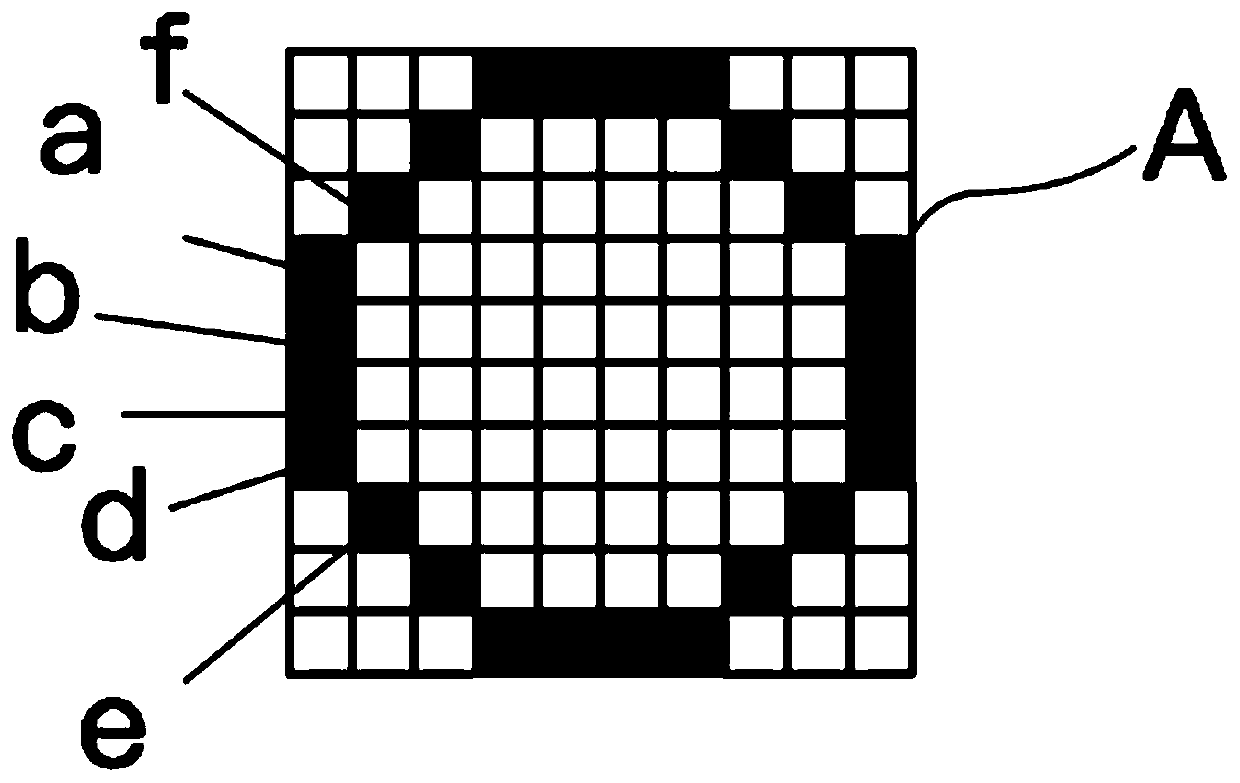

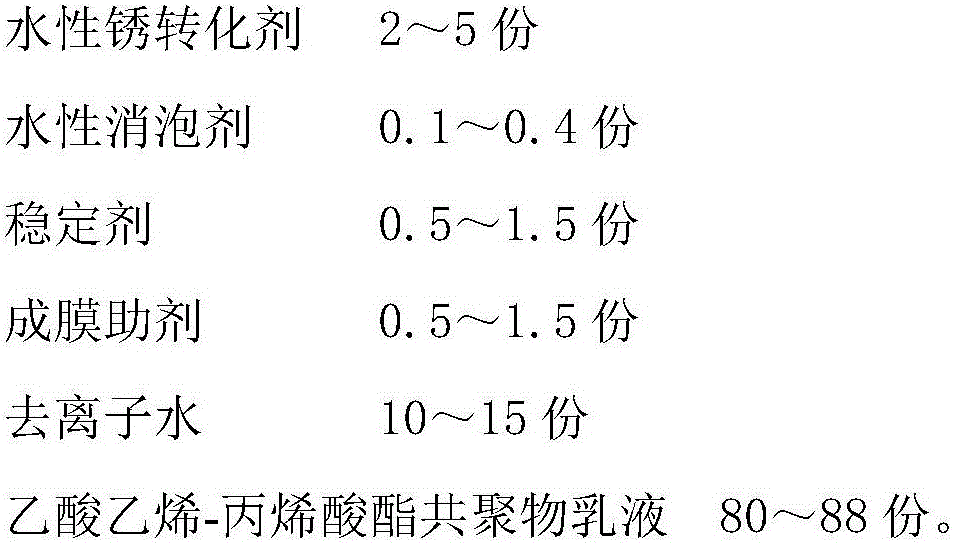

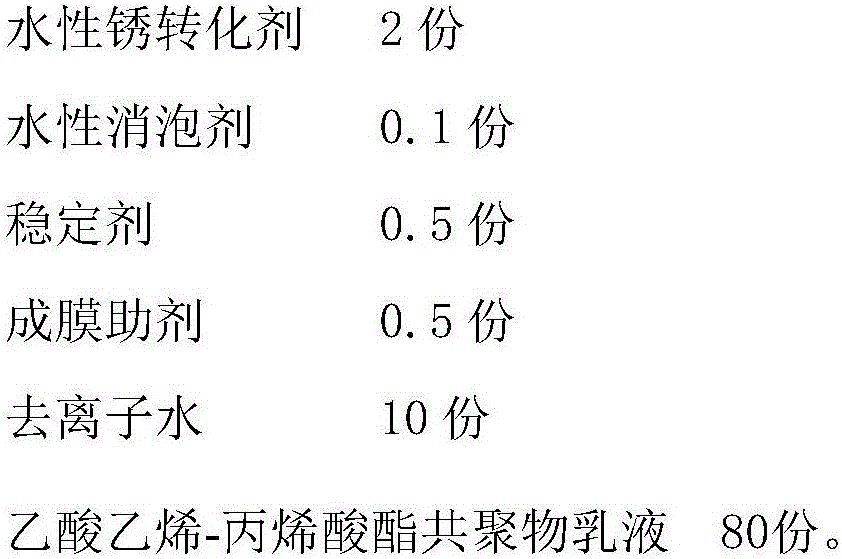

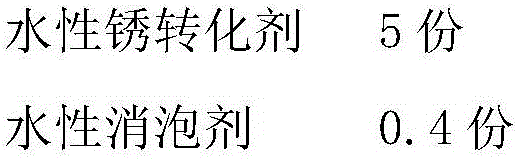

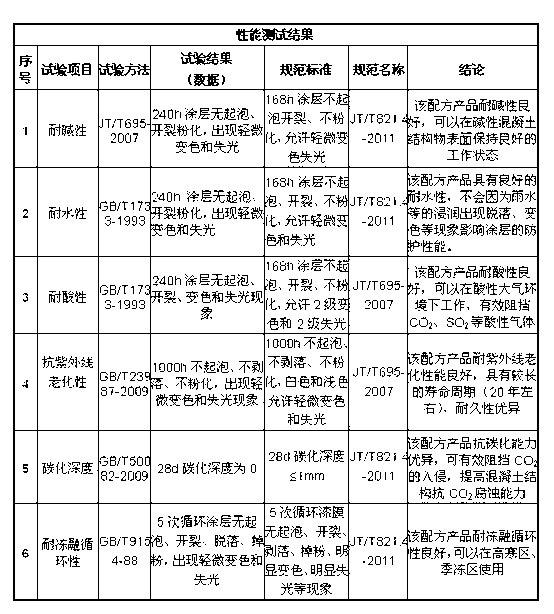

Water-based rust converting primer and preparation method thereof

InactiveCN105885568ADefoaming stabilityFast defoamingAnti-corrosive paintsWater basedOrganic solvent

The invention provides water-based rust converting primer and a preparation method thereof. The water-based rust converting primer is prepared from the following components in parts by weight: 2-5 parts of a water-based rust converting agent, 0.1-0.4 part of a water-based defoamer, 0.5-1.5 parts of a stabilizer, 0.5-1.5 parts of a film forming aid, 10-15 parts of deionized water, and 80-88 parts of vinyl acetate-acrylate copolymer emulsion. The water-based rust converting primer prepared by the invention coats or is sprayed on the rusting surface of a ship, a rusting layer is directly converted into an inert and hard protecting film, so that the surface is protected against being rusted for a long time, and double effects of removing rust and preventing rust are achieved; and moreover, the deionized water is used as a cosolvent, an organic solvent is not required to be added, the environment is protected, and the water-based rust converting primer is harmless to human bodies.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

Coating process applied to surfaces of plywood

InactiveCN102513282ANothing producedSimplify the painting processPretreated surfacesSpecial surfacesChemistryInfrared lamp

The invention discloses a coating process applied to the surfaces of plywood, which is that in a powder coating device where the layout and power of an infrared lamp tube meet the requirement that each surface of the plywood can be directly and effectively radiated, first the plywood is heated by infrared rays, heating temperature ranges from 90 DEG C to 140 DEG C, and heating time ranges from 1 minutes to 10 minutes; then low temperature curing powder paint is evenly sprayed on the surfaces of the plywood; and further the coating on the surfaces of the plywood is heated, fused and cured by the infrared rays, the heating temperature ranges from 110 DEG C to 140 DEG C, and the heating time ranges from (1) minutes to 10 minutes. The coating process applied to the surfaces of the plywood and the used powder paint have the advantages that 1 a coating procedure is simple, and forming can be finished at one step; (2) the coating is environment-friendly, no solvent and toxic volatility mater are produced and the like, thereby according with national industrial policies; (3) the powder paint can be recovered and recycled; and (4) surface coating with different lines, colors and gloss can be obtained through formula adjustment, and the decoration effect is good.

Owner:CHINA NAT ELECTRIC APP RES INST +1

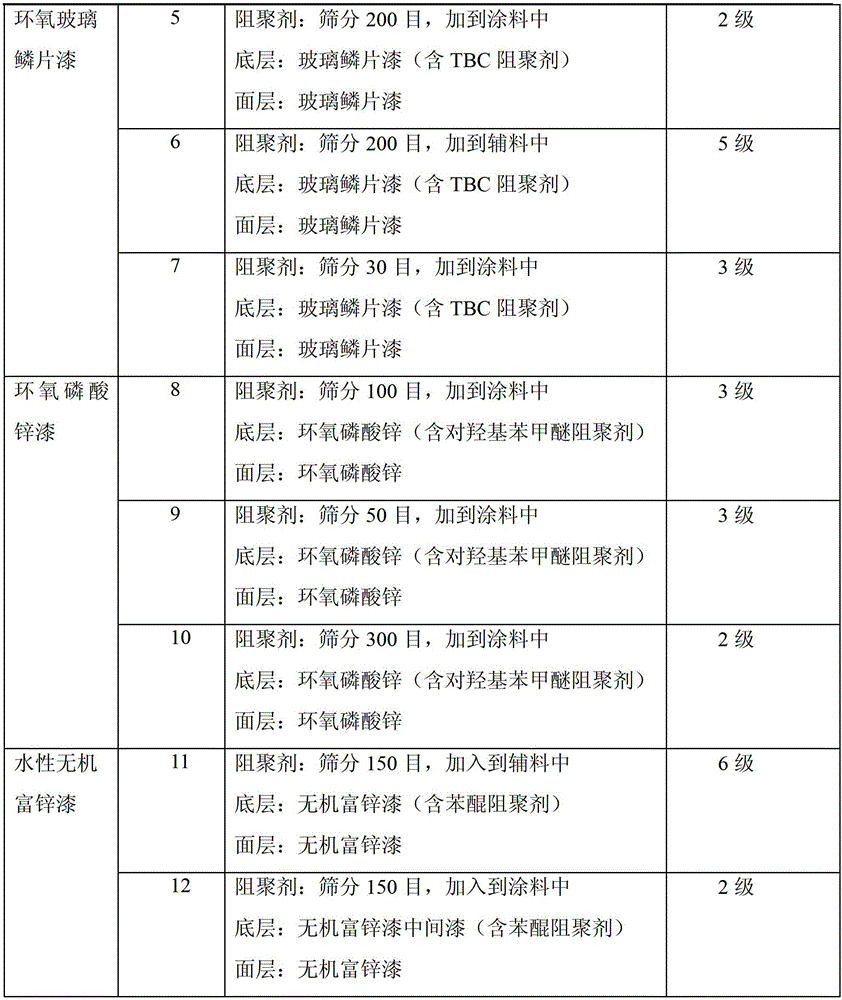

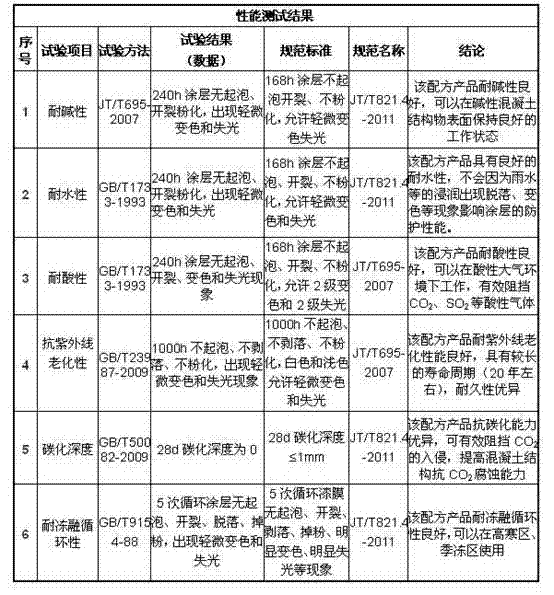

Polyvinyl chloride-polyvinylidene emulsion based concrete bridge structure surface protective coating material and preparation method thereof

InactiveCN103013240AReduce carbonizationImprove the protective effectCoatingsPolymer scienceEmulsion

The invention relates to a polyvinyl chloride-polyvinylidene emulsion based concrete bridge structure surface protective coating material and a preparation method thereof. Most of existing concrete surface protective coatings are poor in carbonization resistance and ageing resistance and complex in painting process. The coating material is composed of 80-90 parts of polyvinyl chloride-polyvinylidene emulsion, 1-3 parts of bentonite, 0.3-1 part of aqueous antiager, 1-5 parts of titanium dioxide, 1-5 parts of sericite, 2-10 parts of functional assistant system and 2-9 parts of adjustment assistant system, wherein the adjustment assistant system is composed of antifoaming agent, dispersing agent and leveling thickener according to the mass ratio of 2:1:4. The coating material enables concrete to have excellent protective effects under accelerated carbonizing conditions, carbonization of the concrete is decelerated, the coating material is excellent in ageing resistance, the coating painting process is simple, all procedures from production to construction are safe and environment-friendly, and environment pollution is avoided.

Owner:CCCC CIVIL ENG SCI & TECH +1

Preparation method of emulsion type adhesion promoter for polyolefin plastics

The invention discloses a preparation method of emulsion type adhesion promoter for polyolefin plastics. The emulsion type adhesion promoter for polyolefin plastics is obtained through dispersing and emulsifying chlorinated polyolefin, organic solvent, emulsifying agent and water under a proper condition. A small quantity of organic solvent facilitates dispersing chlorinated polyolefin resin in the emulsion preparation process; and the swelling role of organic solvent to polyolefine also ensures good adhesive attraction of a coating layer to a substrate when the emulsion is formed into a film. Compared with a similar solvent based product, the emulsion type polyolefine adhesion promoter lowers the use amount of the organic solvent and has the adhesion property which can be compared with the similar solvent based product. The emulsion type adhesion promoter for polyolefin plastics has simple preparation process, low price, favorable construction property, small environment pressure andwide market prospect.

Owner:XI AN JIAOTONG UNIV +1

Protective coating material for concrete bridge structure surface based on pure acrylic emulsion and preparation method thereof

The invention relates to a concrete bridge structure surface protective coating material based on pure acrylic emulsion and a preparation method thereof. Most of the conventional concrete surface protective coatings are poor in carbonization resistance and ageing resistance and complex in brushing process steps. The concrete bridge structure surface protective coating material is prepared by mixing the following components together in parts by weight: 75 to 85 parts of pure acrylic emulsion, 1 to 3 parts of pure acrylic emulsion, 0.3 to 0.5 part of a water-based anti-aging agent, 1 to 3 parts of titanium pigment, 1 to 3 parts of sericite, 3 to 7 parts of a functional auxiliary agent system, 1.5 to 3.5 parts of a regulating auxiliary agent system, 0.5 to 2 parts of a leveling-type thickening agent and 5 to 10 parts of water, wherein the functional auxiliary agent system consists of a hydrophobing agent, a stain-resistant agent and an adhesive force accelerant in a mass ratio of 3:1:2; and the regulating auxiliary agent system consists of an antifoaming agent and a dispersant in a mass ratio of 1:6. By adopting the concrete bridge structure surface protective coating material, concrete achieves an excellent protection effect under an accelerated carbonization condition, the carbonization of the concrete is delayed, the ageing resistance of the concrete is excellent, the coating brushing process steps are simple, and all links from production to construction are safe and environment-friendly without environmental pollution.

Owner:CCCC CIVIL ENG SCI & TECH

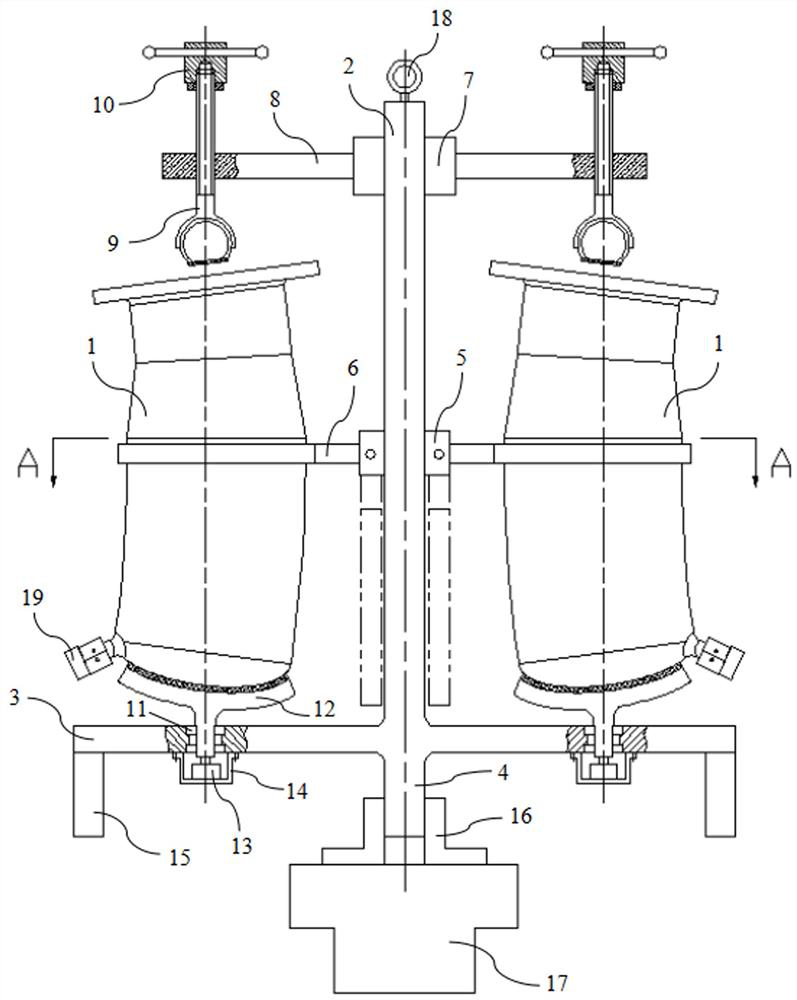

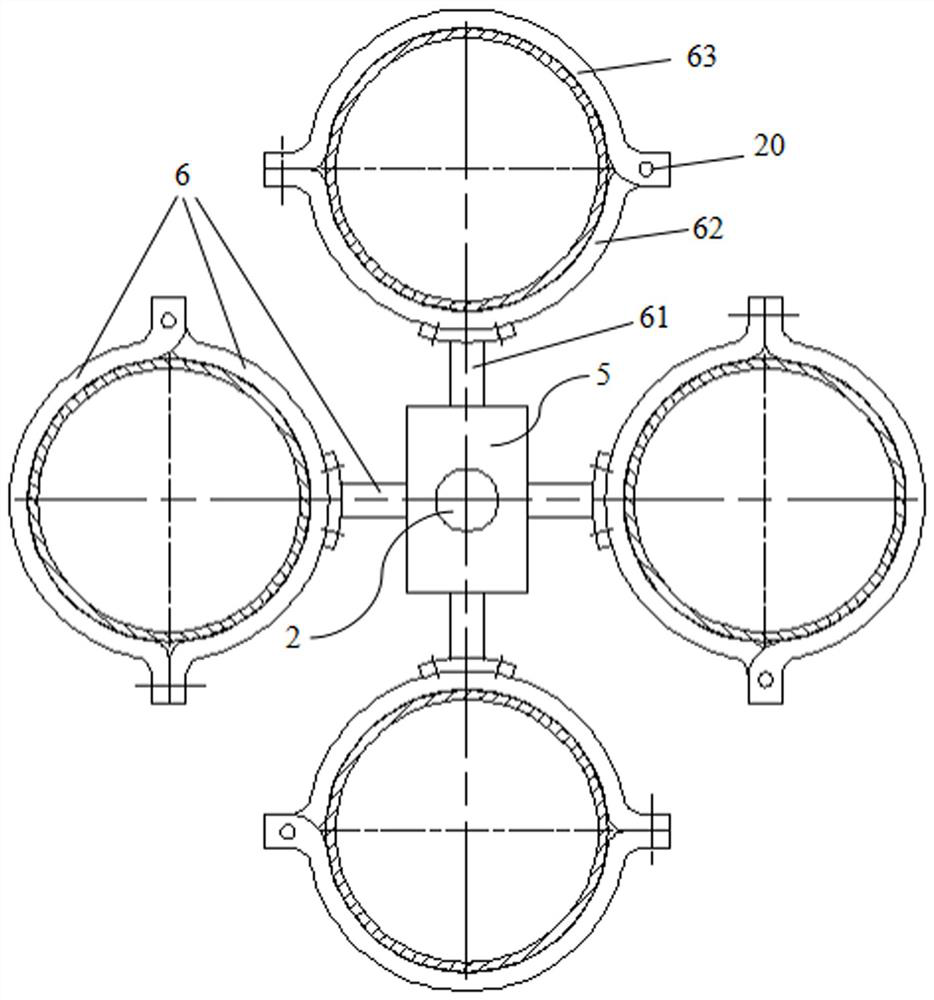

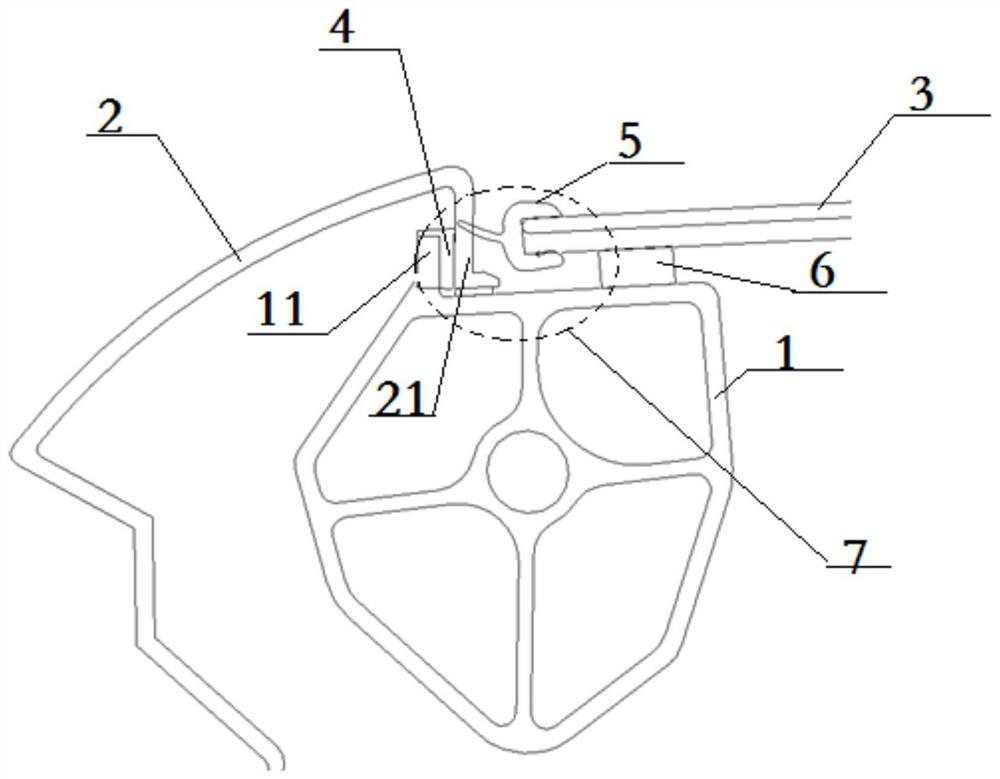

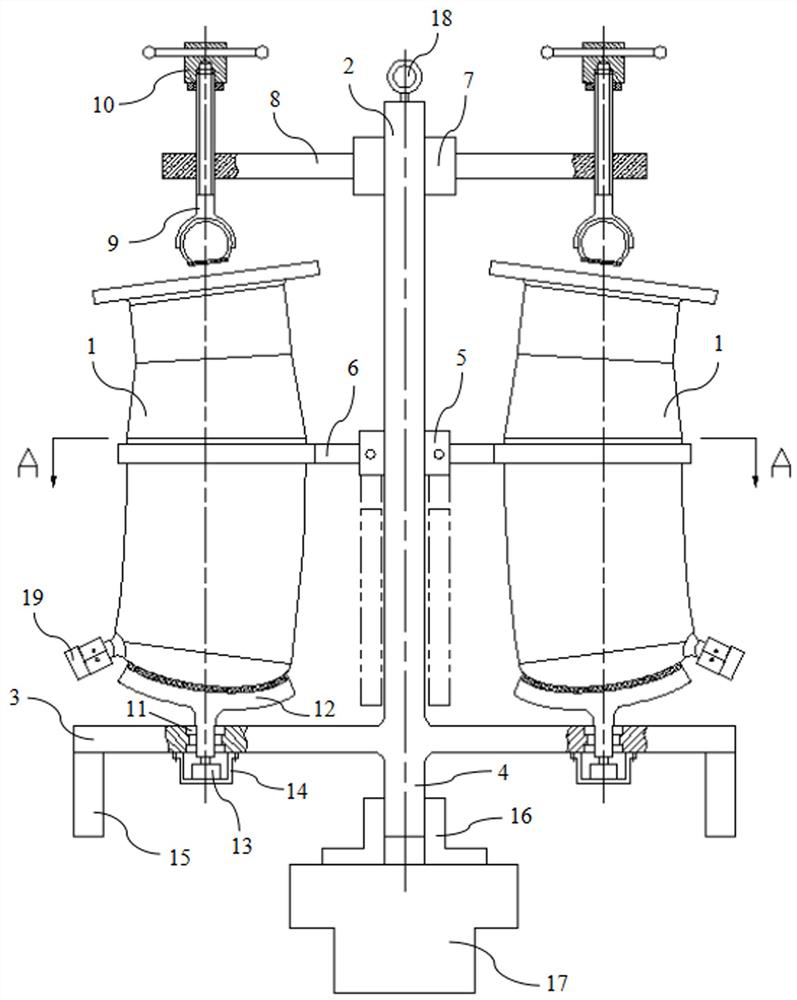

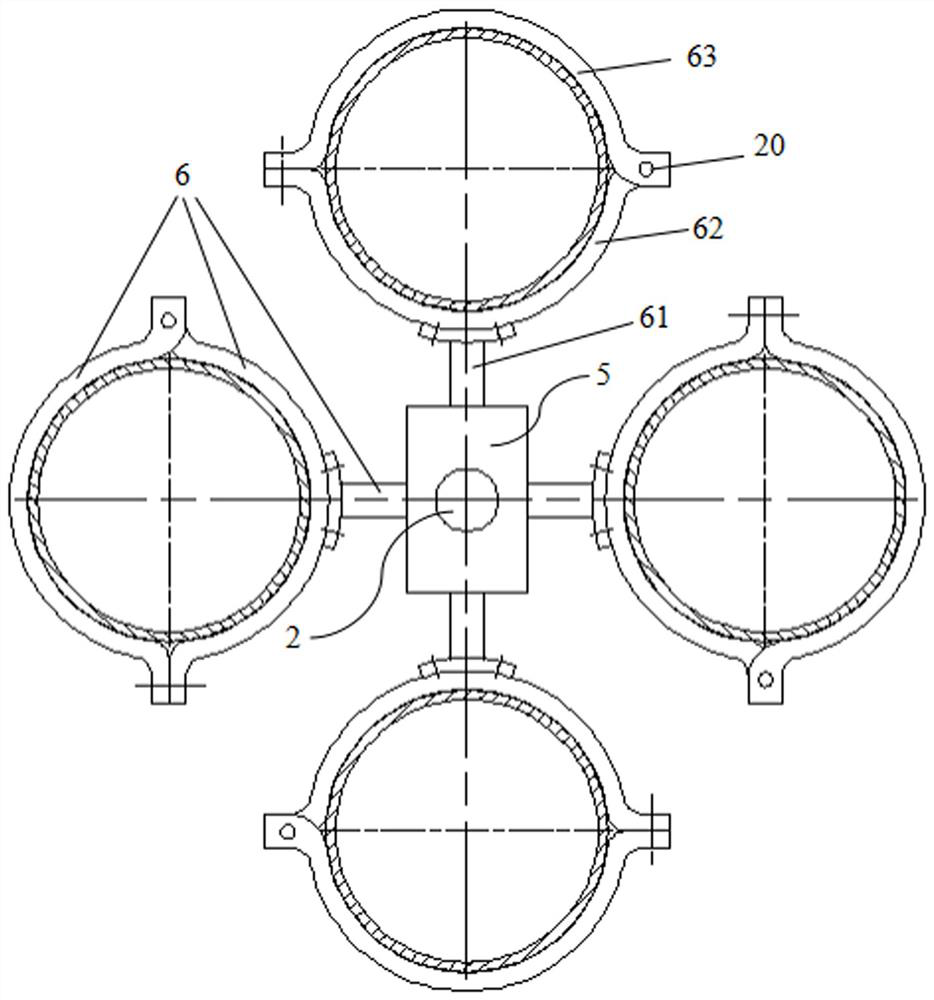

Interior painting device, interior painting method and painting method for slide rail sleeve

ActiveCN112774943BImprove consistencyEven paint jobLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention relates to an inner cavity painting device, an inner cavity painting method and a painting method for slide rail sleeves. The inner cavity painting device for the slide rail sleeve, including: bearing column, base, clamping beam, swivel seat assembly, clamping assembly and faucet plug; the base is connected to the lower end of the bearing column ; the swivel seat assembly is arranged on the base, and is used to lift the tail end of the slide rail sleeve and drive the slide rail sleeve to rotate around its lengthwise axis; the clamping assembly includes a cone A shell-shaped sealing disc and a joint bearing, the conical shell-shaped sealing disc abuts against and seals the opening at one end of the slide rail sleeve. The invention can automatically, efficiently and evenly finish the painting of the inner cavity, improves the consistency of the quality of the pouring primer, significantly shortens the time interval between painting and anodizing the surface of the slide rail sleeve, and further improves the quality of the slide rail sleeve. Anti-corrosion effect on the surface of the cylinder.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Storage method of aromatic olefin monomer

ActiveCN104250202BIncrease the amount of participationEffectively control the release rateHydrocarbon purification/separationHalogenated hydrocarbon separation/purificationArylPolymer science

The invention relates to a storage method for monomers, in particular to a storage method for aromatic olefin monomers in storage tanks. The method for storing aromatic olefin monomers in the storage tank according to the present invention is to paint the inner wall of the aromatic olefin monomer storage tank with a coating containing a polymerization inhibitor. The coating is composed of a bottom layer and a surface layer, and the bottom layer is The coating contains a polymerization inhibitor, and the surface layer is a coating without a polymerization inhibitor. The storage method of the aromatic olefin monomer described in the present invention is different from the protective coating process effect described in the prior art. In the implementation process, the polymerization inhibitor is added to the coating material after being ground and screened, and heating The mixing method has good compatibility with the coating material, and a large amount of polymerization inhibitor is added, which effectively improves the adhesion of the coating and the duration of polymerization inhibition, so as to achieve the effect of long-term polymerization inhibition, and the polymerization inhibition period can reach more than 6 years.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly nanoscale bottom infiltrated layer material used for protecting concrete surface and preparation method of environment-friendly nanoscale bottom infiltrated layer material

The invention relates to an environment-friendly nanoscale bottom infiltrated layer material used for protecting a concrete surface and a preparation method of the environment-friendly nanoscale bottom infiltrated layer material. A conventional infiltrated layer material used for protecting the concrete surface is extremely poor in permeability, can not guarantee the firm bonding with a concrete base, and is easy to fall off from the concrete surface under the action of external erosion conditions. The invention provides the nanoscale bottom infiltrated layer material which is prepared from an inorganic nano silicon dioxide solution, styrene-acrylic emulsion, pure acrylic emulsion, gamma-aminopropyl triethoxy silane, isobutyl triethoxy silane, sodium metaphosphate, tributyl phosphate and one of tetrabutyl orthosilicate, butyl acetate, sodium methyl silicate, acrylate and ethyl acetate. The environment-friendly nanoscale bottom infiltrated layer material can quickly infiltrate into concrete by certain depth and react with a concrete base material to seal pores inside the concrete, is good in bonding performance with a surface protective layer material, and can ensure the firm bonding between a concrete protective system and the concrete surface under the action of an outside environment and delay the occurrence of concrete diseases.

Owner:CCCC CIVIL ENG SCI & TECH

Rapid anhydrous phosphorization liquid having chemical impregnation action

InactiveCN1213168CStrong adhesionPhosphating time is shortMetallic material coating processesChemical treatmentPolyvinyl butyral

There is a kind of quick non-water bonderizing liquid, it belongs to chemistry treatment field of metal surface. The techonlogy is providing a kind of quick, normal temperature and short time bonderizing liquid. The technology scheme is, the proportion is: 5-15 poly vinyl alcohol butyric aldehyde, 60-100 alcohol, 4-10 orthophosphoric acid, 0.1-1 tannin, 12-30 pimelin ketone, 10-20 resin. The manufacturing method is: poly vinyl alcohol butyric aldehyde is added into alcohol and immersed for 24 hours, then adds in resin and pimeline ketone, heated and blended; the tannin is added into orthophosphoric acid and immersed for one hours, and adds in pimelin ketone and blended, then blended the two mixed liquid and gets the bonderizing liquid.

Owner:陈二孝

Coating process of plasterboard exterior laminated layer

PendingCN106140581ASave puttying processSimplify the painting processSpecial surfacesCoatingsSquare meterViscosity

The present invention provides a coating process for the external laminate layer of gypsum board, which includes setting the conditions for coating the external laminate layer of the gypsum board. The coating environmental conditions are that the temperature is above 5°C and the humidity is between 0 and 75%; Set the viscosity of the coating material to 1000 to 8000mpa.s, the coating speed to 0.2 to 1m / s, and the coating tool to be a soft brush or spray gun; times; simplify the coating process, shorten the construction period, reduce the cost by 10 to 12 yuan per square meter, and improve the coating quality and use effect.

Owner:重庆圣石牛建材有限公司

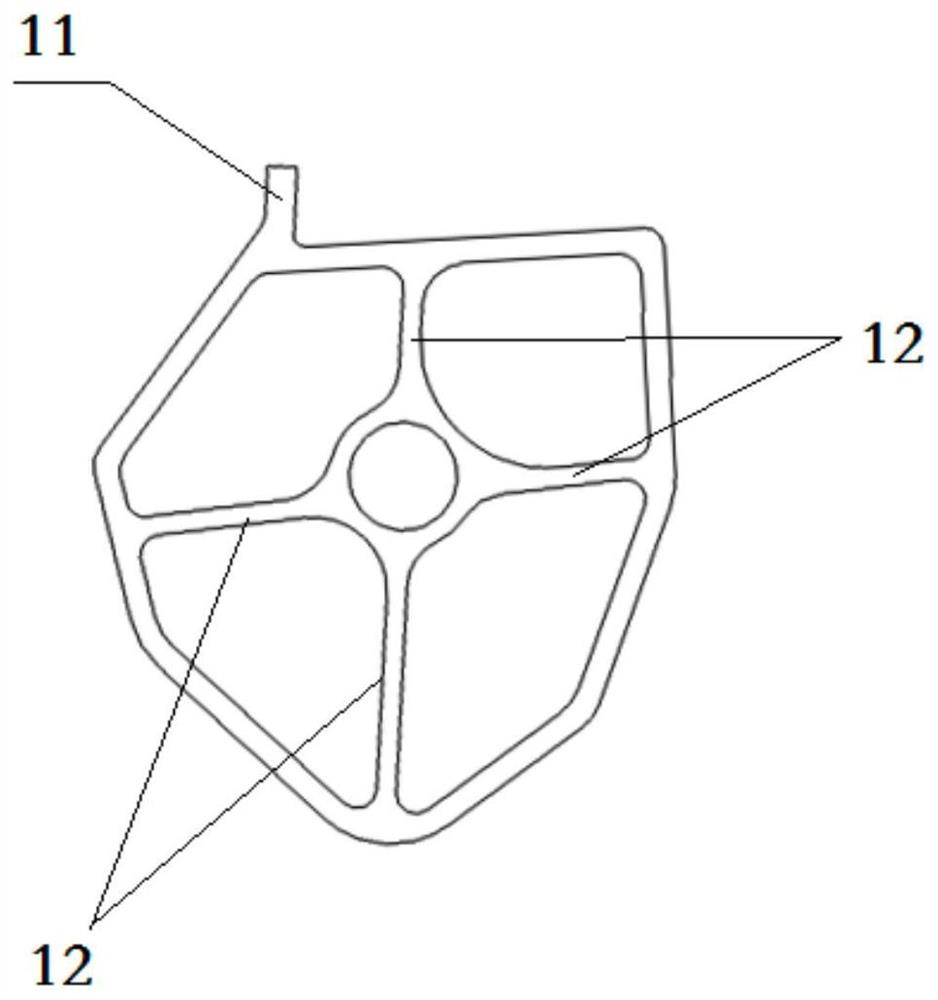

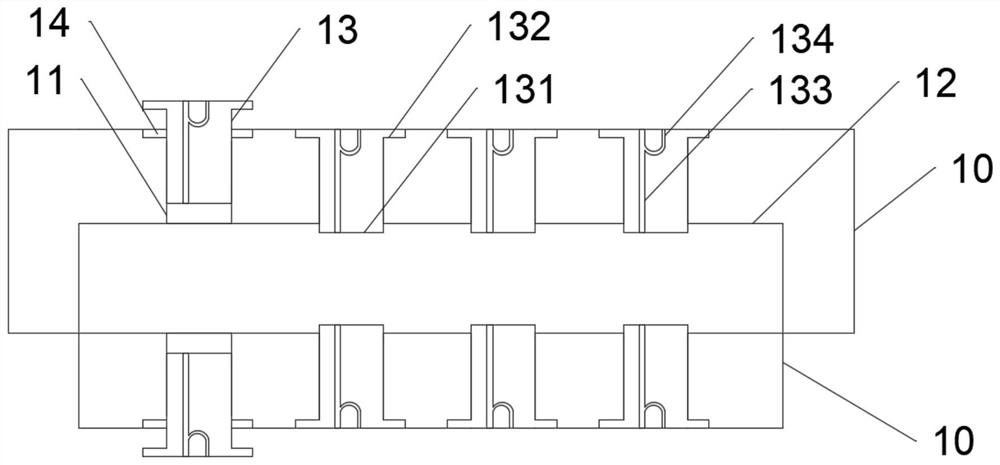

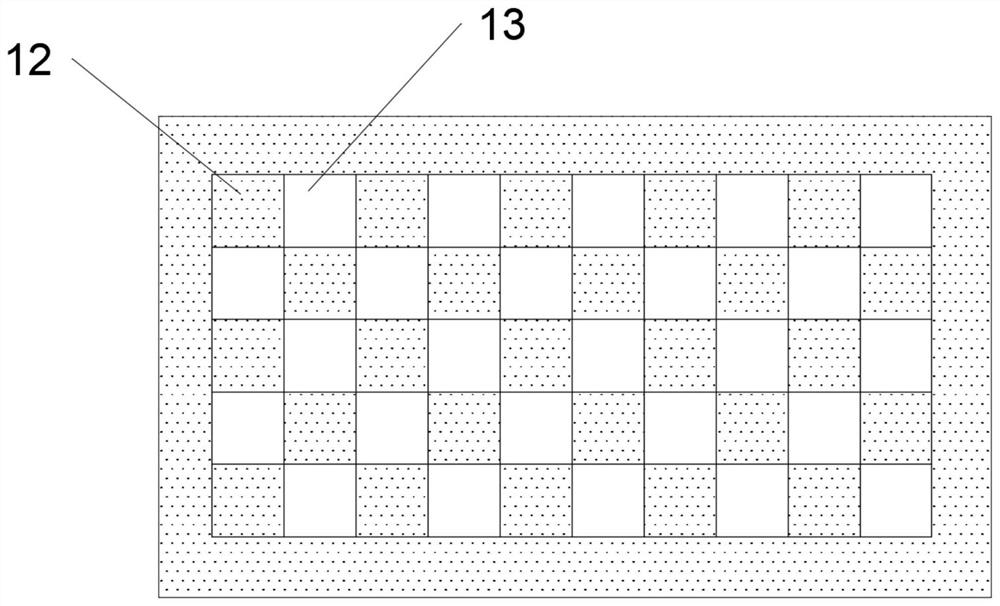

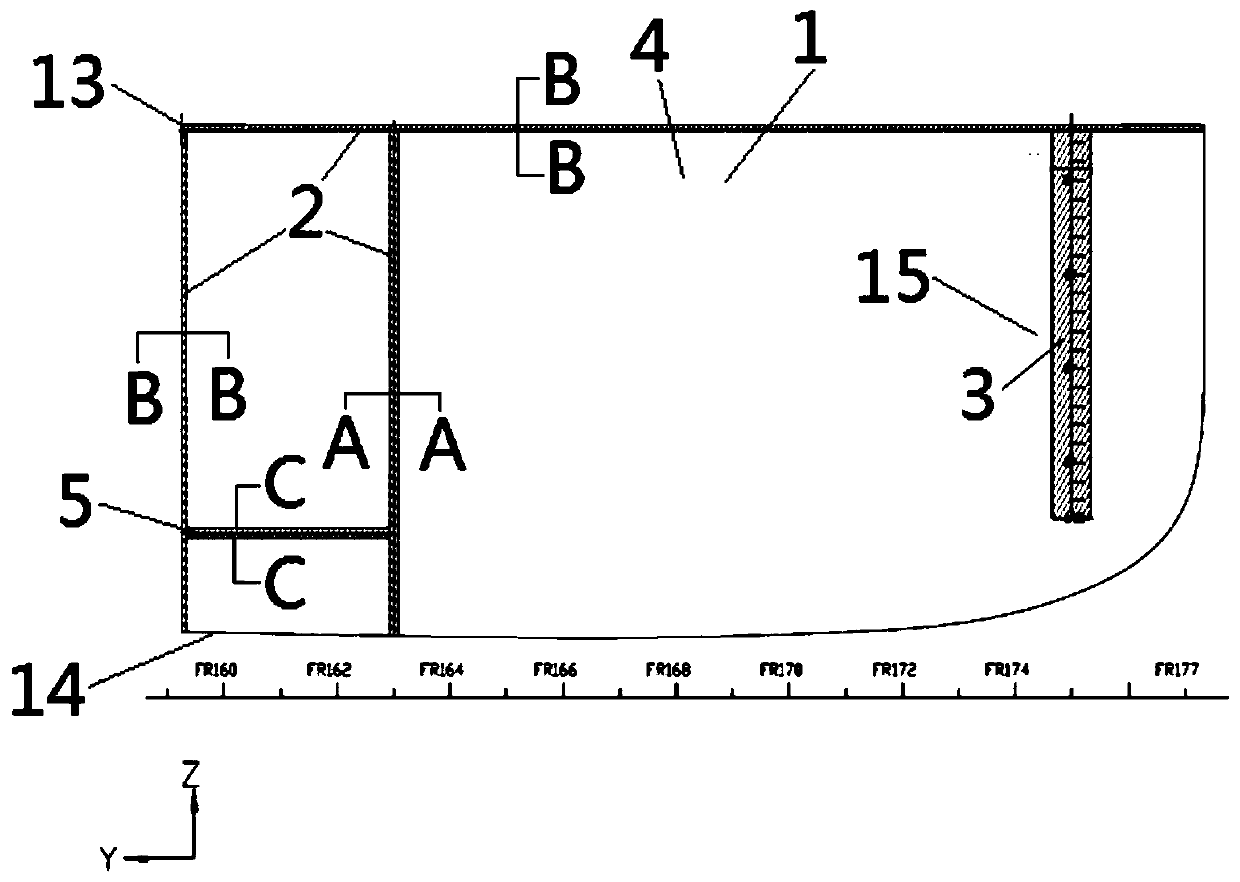

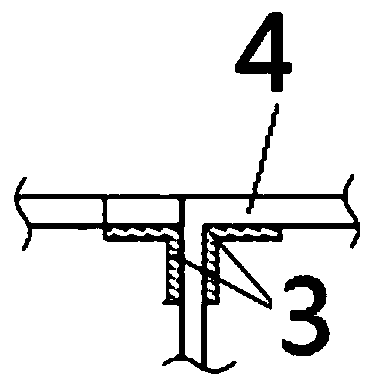

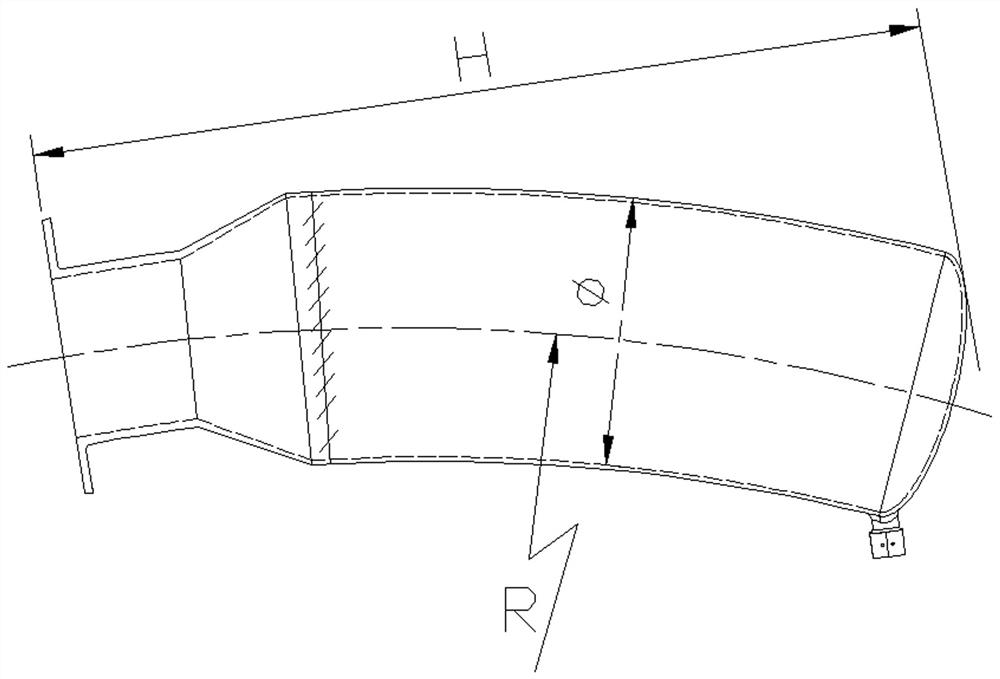

Top edge beam structure of fuel cell hydrogen energy automobile

PendingCN112193330AReduce in quantityReduce painting costSuperstructure subunitsSuperstructure connectionsFuel cellsStructural engineering

The invention provides a top edge beam structure of a fuel cell hydrogen energy automobile. The top edge beam structure comprises a top edge beam, a top edge beam protection plate and a top cover; a seam allowance part is arranged at the upper part of the top edge beam; a bending part matched with the seam allowance part in shape is arranged at one end, connected with the top cover, of the top edge beam protection plate; the end face of the inner side of the bending part and the seam allowance part are bonded in a sealed mode through a sealing rubber strip, and the waterproof effect is achieved; a sealing strip is arranged between the outer side end surface of the bending part and the top cover, so that a waterproof effect is achieved; the interior of the top edge beam is hollow, a plurality of reinforcing ribs are arranged in a hollow cavity of the top edge beam, and the purpose of improving the bending and torsional rigidity of a vehicle body is achieved. The invention has the beneficial effects that the torsion and bending rigidity of a whole vehicle is effectively improved while the weight of the vehicle body is greatly reduced and the cost is reduced.

Owner:黄冈格罗夫氢能汽车有限公司

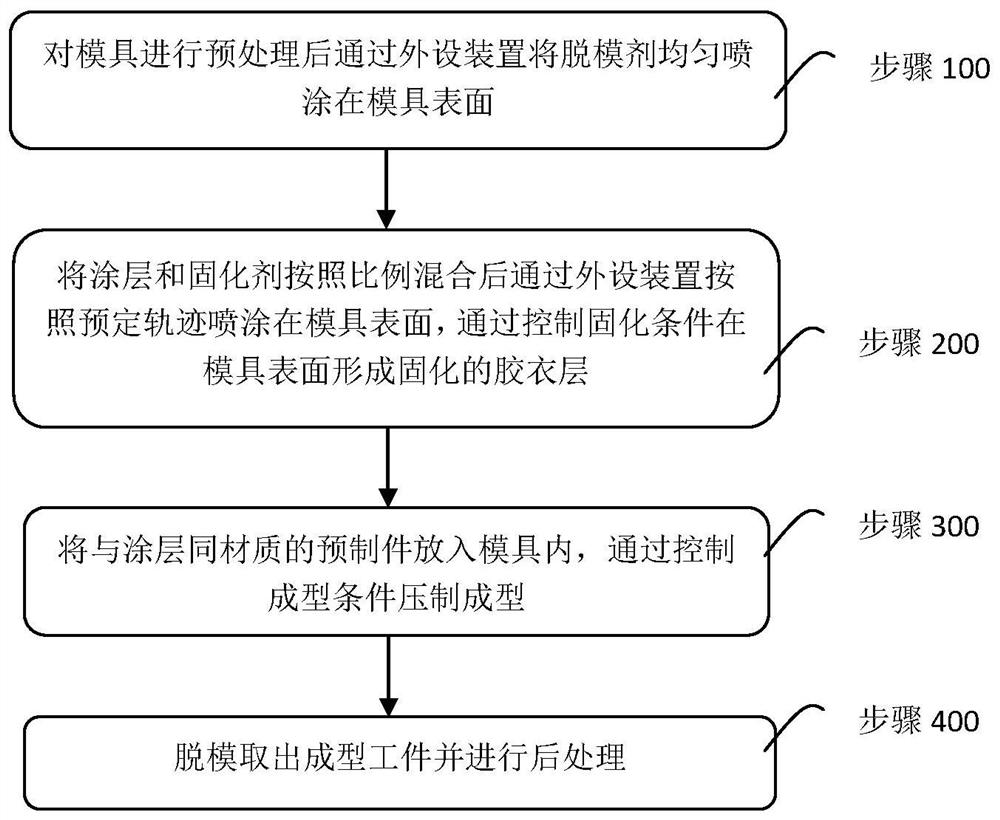

Composite material in-mold coating process

The invention discloses a composite material in-mold coating process. The composite material in-mold coating process comprises the following steps that step 100, after a mold is pretreated, a release agent is evenly sprayed to the surface of the mold through an external device; step 200, a coating and a curing agent are mixed according to a proportion, the coating and the curing agent are sprayed on the surface of the mold through the external device according to a preset track, and a cured gel coat layer is formed on the surface of the mold by controlling curing conditions; step 300, a prefabricated part which is made of the same material as the coating is put into a mold, and compression molding is carried out by controlling molding conditions; and step 400, demolding is carried out, and a formed workpiece is taken out and is subjected to post-treatment. The composite material in-mold coating process is adopted, the gel coat is evenly sprayed on the surface of the mold, after the coating is cured, raw materials are put into the mold to be cured and formed, then a product can be taken out to obtain a colored product, the surface of the workpiece is covered with the gel coat coating while the workpiece is formed, the formed workpiece covered with the gel coat layer is obtained at a time, the original paint spraying procedure is simplified, and the pressing difficulty is reduced.

Owner:中机精密成形产业技术研究院(安徽)股份有限公司

Waterborne nano coil coating and preparation method thereof

InactiveCN103232771BAppropriately adjust performance technical indicatorsEasy to useEpoxy resin coatingsEpoxyFire risk

The invention belongs to a waterborne nano coil coating and a preparation method thereof. Firstly, an inorganic material with no toxic property, foreign smell and combustion characteristic is used as a basic powder material of a coil coating, a waterborne acrylic emulsion, waterborne epoxy resin, water-soluble functional auxiliaries and other film forming matters are compounded, updated and modified by using a nanotechnology and nano materials, and gaps of large micro materials in a coating structure are filled by using various nano powder materials after the hydration of the coil coating is effectively finished, so that the coating generates a coating function enhancing effect under the synergistic action of multi-effect combination of the nano materials and micro materials, the defect that the performance of the waterborne coil coating prepared by a micrometer technology is lowered is overcome effectively, and the technical performance of the waterborne coil coating is remarkably enhanced. By using the waterborne nano coil coating and the preparation method thereof, the production efficiency is increased, the fire risks and industrial pollution of the traditional solvent type coil coating are eliminated, and meanwhile, the aim of safe, environment-friendly, low-consumption and efficient production is achieved.

Owner:北京中科捷达纳米应用科技有限公司

Polyvinyl chloride-polyvinylidene emulsion based concrete bridge structure surface protective coating material and preparation method thereof

InactiveCN103013240BReduce carbonizationImprove the protective effectCoatingsPolymer scienceEmulsion

Owner:CCCC CIVIL ENG SCI & TECH +1

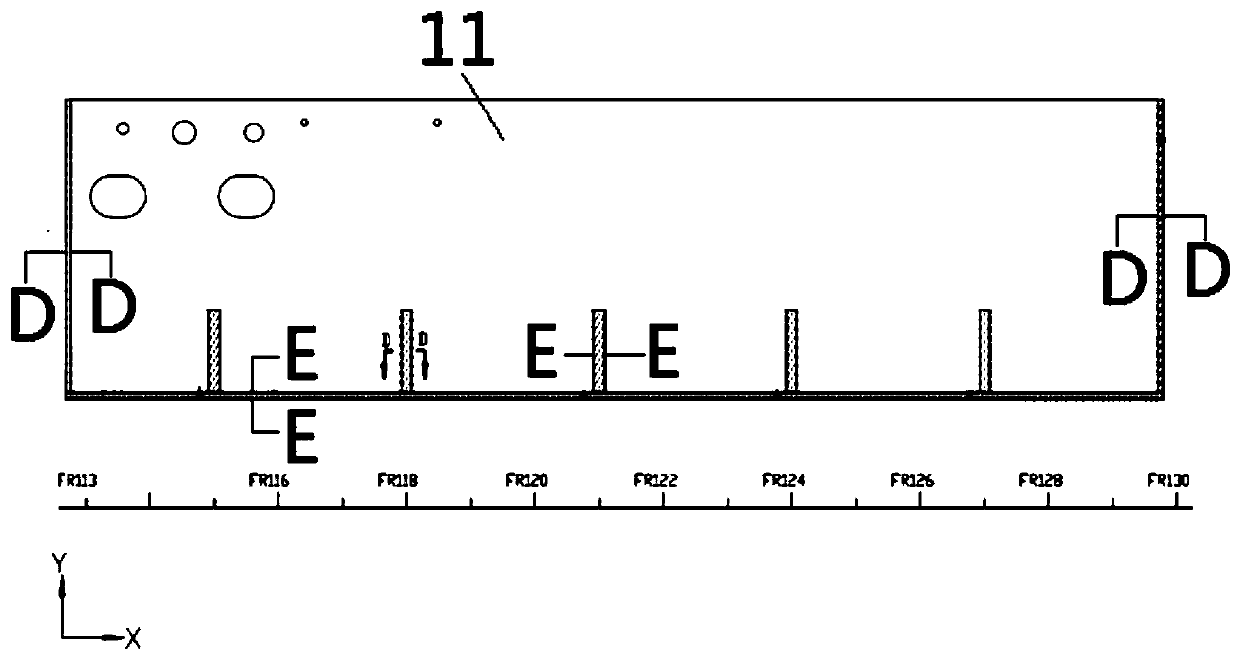

Ship segmented coating process method

InactiveCN111252209AReduce wasteReduce labor intensityWaterborne vesselsMarine engineeringPaper tape

The invention provides a ship segmented coating process method applied to the technical field of ship production and manufacturing. The ship segmented coating process method comprises the following process steps of: 1) marking a coating reserved part (2) at a welding seam position with a sealing test requirement of a ship segment (1) when a ship is designed; 2) before the ship segment (1) is coated, adhering an adhesive paper tape (3) to the coating reserved part (2) for shielding; 3) spraying the ship segment (1); 4) after spraying of the ship segment (1) is completed, removing the adhesive paper tape (3), and folding and connecting the ship segment (1), thus realizing welding of coating reserved parts. According to the ship segmented coating process method provided by the invention, thesteps are simple, and in the ship manufacturing process, the ship segmented coating process is improved, so that the problem of repeated construction in the construction process is effectively avoided, the labor cost and waste of spraying paint are reduced, the coating process is simplified, and the labor intensity of workers is reduced.

Owner:WUHU SHIPYARD CO LTD

Inner cavity painting device, inner cavity painting method and painting method for sliding rail sleeve

ActiveCN112774943AImprove consistencyEven paint jobLiquid surface applicatorsCoatingsMechanical engineeringAnodic oxidation

The invention relates to an inner cavity painting device, an inner cavity painting method and a painting method for a sliding rail sleeve. The inner cavity painting device for the sliding rail sleeve comprises a force bearing column, a base, a clamping beam, a rotating seat assembly, a clamping assembly and a water nozzle plug. The base is connected to the lower end of the force bearing column; and the rotating seat assembly is arranged on the base and used for lifting the tail end of the sliding rail sleeve and driving the sliding rail sleeve to rotate around the axis in the length direction of the sliding rail sleeve. The clamping assembly comprises a conical-shell-shaped sealing disc and a knuckle bearing, and the conical-shell-shaped sealing disc abuts against and seals an opening at one end of the sliding rail sleeve. According to the device, painting work of an inner cavity can be automatically, efficiently and uniformly completed, the consistency of priming paint filling and coating quality is improved, the time interval between surface painting and anodic oxidation of the sliding rail sleeve is remarkably shortened, and the anti-corrosion effect of the surface of the sliding rail sleeve is further improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com