Water-based rust converting primer and preparation method thereof

A technology of rust conversion and rust conversion agent, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of rust residue, overall anti-corrosion decline, and difficulty in ensuring the quality of rust removal, etc., to achieve rapid defoaming, overall anti-corrosion performance improvement, Good effect of shear resistance and acid, alkali and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

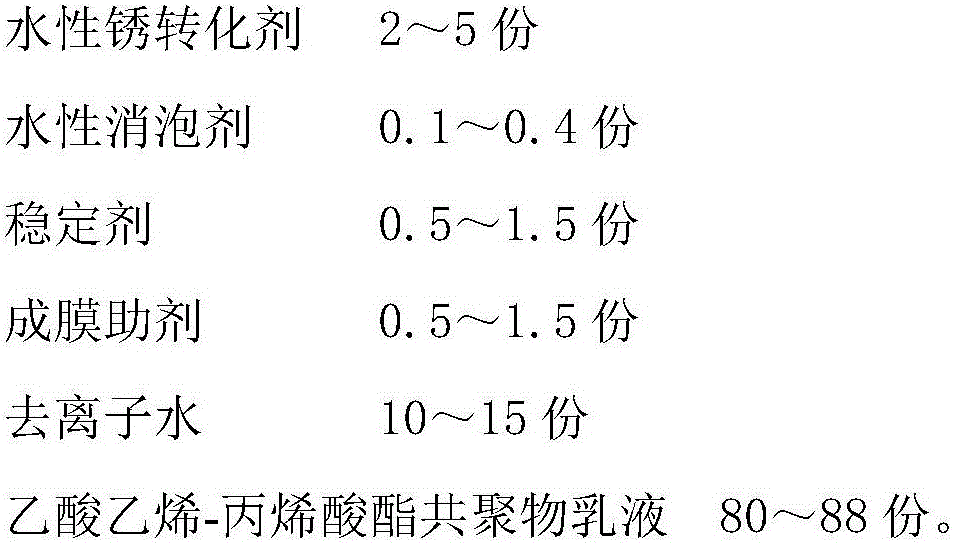

[0021] A water-based rust conversion primer, which is prepared from the following components in parts by weight:

[0022]

[0023] The preparation method is as follows: mix and stir deionized water, water-based rust conversion agent and film-forming aid according to the ratio; then add water-based defoamer and stabilizer for stirring; finally add vinyl acetate-acrylate copolymer emulsion and stir evenly That is, the water-based rust conversion primer is obtained.

Embodiment 2

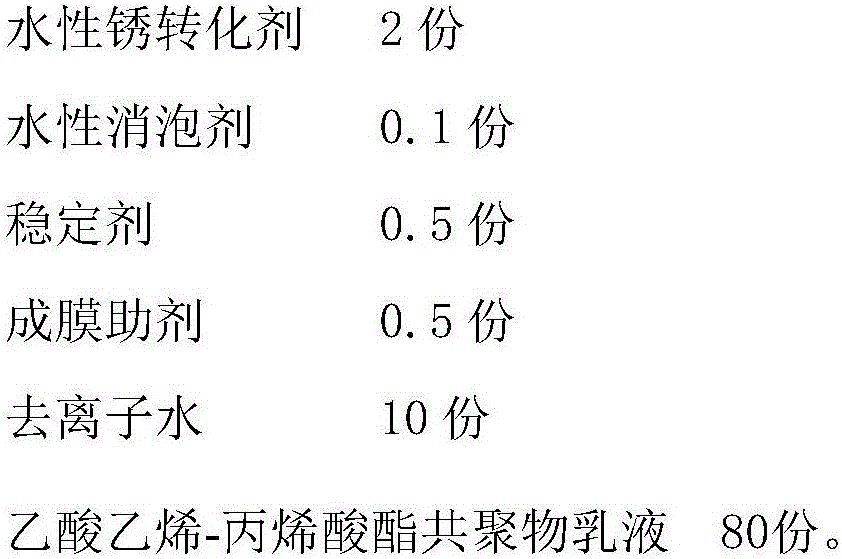

[0025] A water-based rust conversion primer, which is prepared from the following components in parts by weight:

[0026]

[0027]

[0028] Its preparation method is with embodiment 1.

Embodiment 3

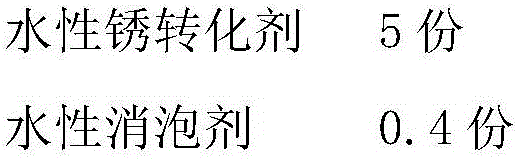

[0030] A water-based rust conversion primer, which is prepared from the following components in parts by weight:

[0031]

[0032] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com