Top edge beam structure of fuel cell hydrogen energy automobile

A fuel cell and top side beam technology, which is applied to the superstructure, the superstructure sub-assembly, and the connection between the superstructure sub-assemblies, etc., can solve the problem that the battery life of new energy vehicles is particularly affected, and the welding and painting processes are complicated. , unfavorable to the lightweight of the whole vehicle, to achieve the effect of simple and reliable connection, simplified welding and coating process, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0015] An embodiment of the present invention provides a roof side beam structure of a fuel cell hydrogen energy vehicle.

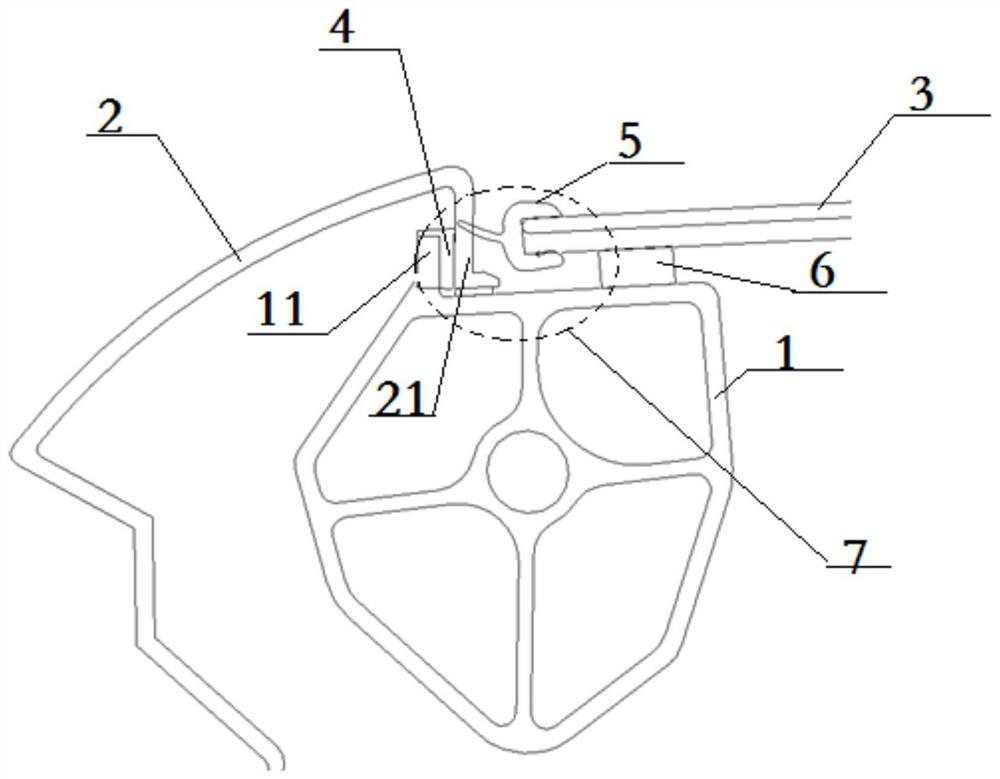

[0016] see figure 1 , figure 1 It is a schematic diagram of the roof rail structure of a fuel cell hydrogen energy vehicle in an embodiment of the present invention; it includes a roof rail 1, a roof rail guard plate 2 and a top cover 3;

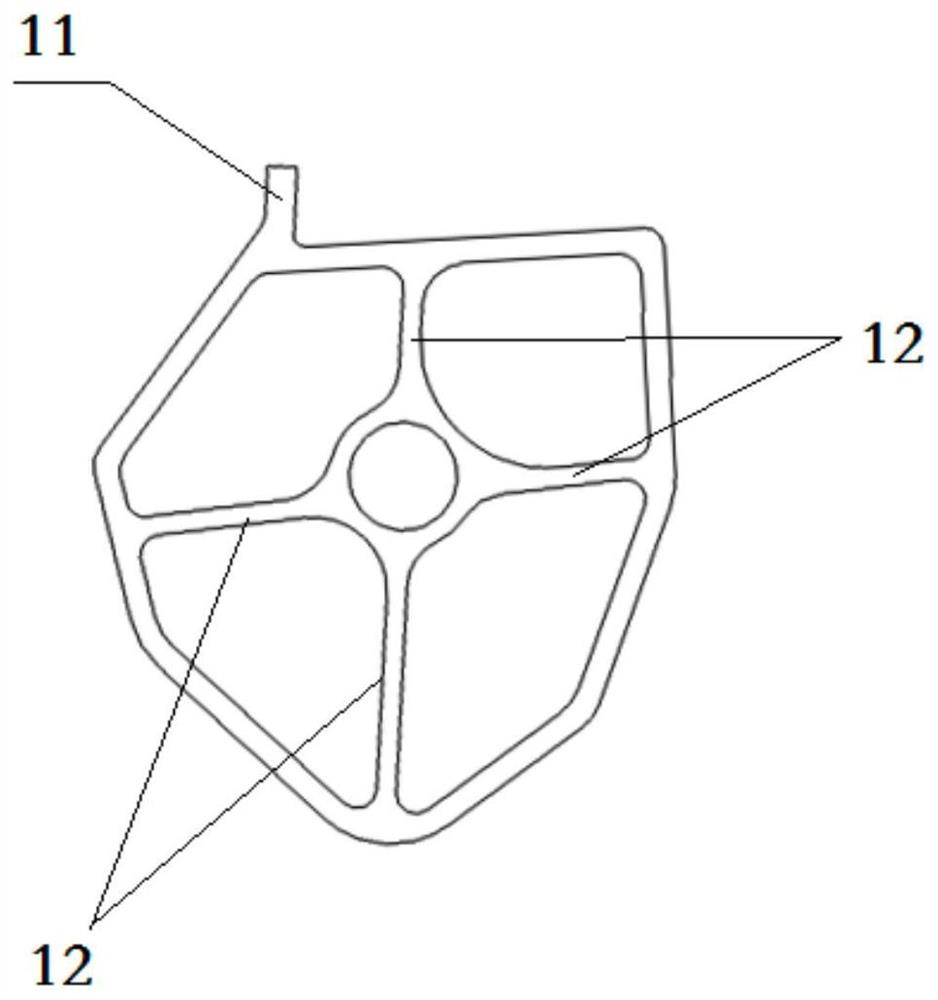

[0017] Wherein, the upper part of the top edge beam 1 is provided with a notch portion 11; the notch portion 11 is vertically arranged along the z-axis direction, and is used to prevent water accumulated on both sides of the top cover 3 from penetrating into the side wall and Both sides of the cover 3 form a U-shaped drainage groove structure 7 from front to ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com