Method for multicolor spray coating and component after spray coating thereof

One component, the same technology, applied in the field of spraying production process of plastic parts, can solve the problems of complex process, low product yield and high production cost, and achieve the effect of simplifying the spraying process and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail below.

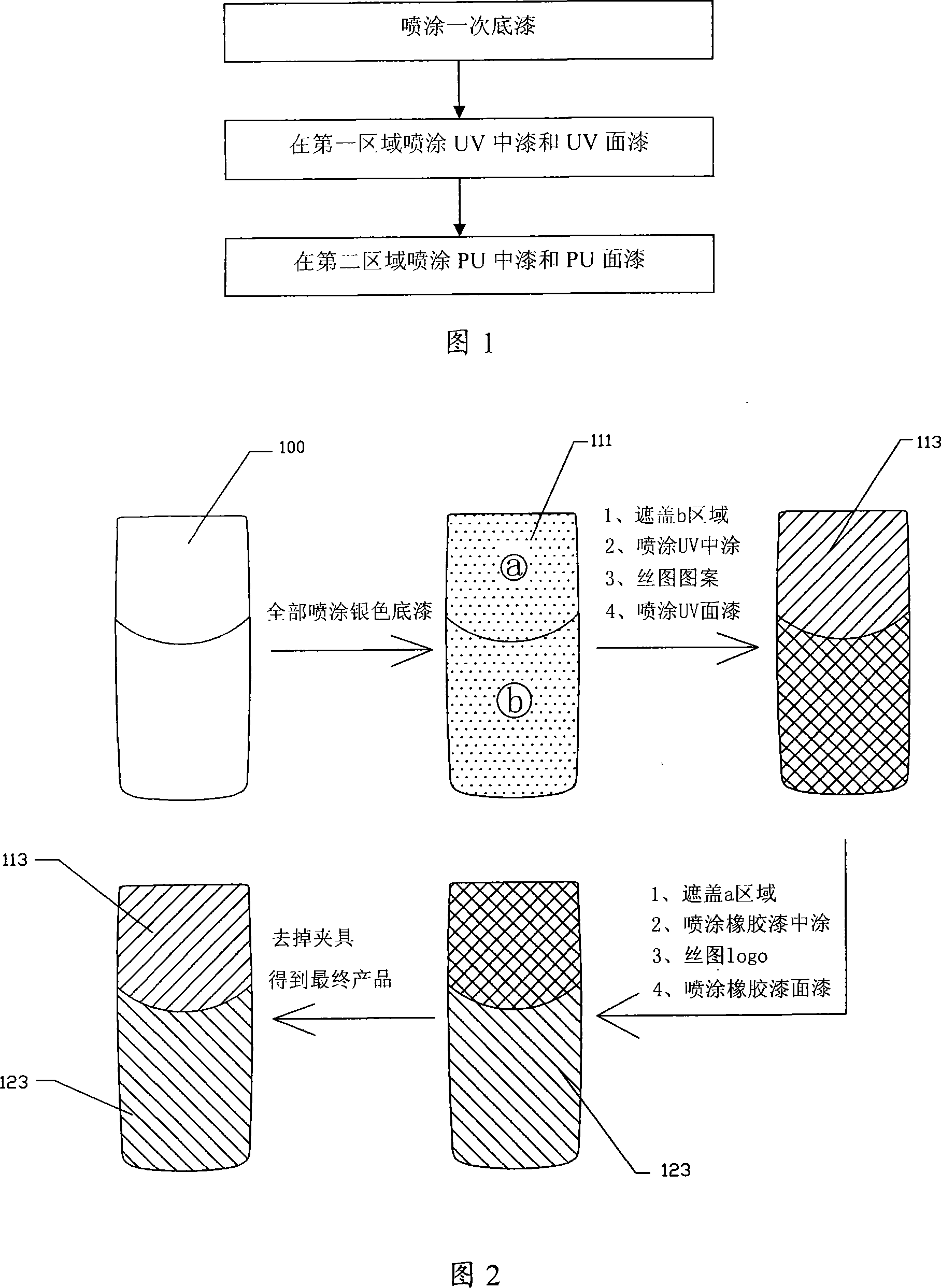

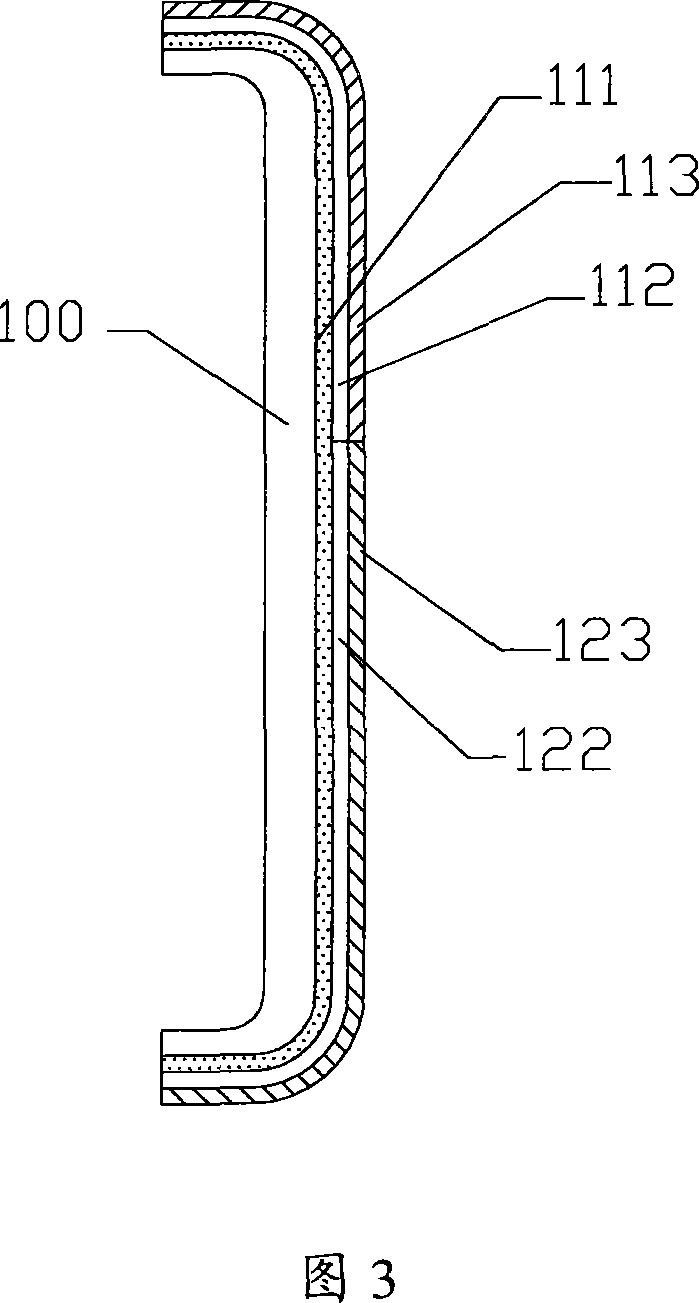

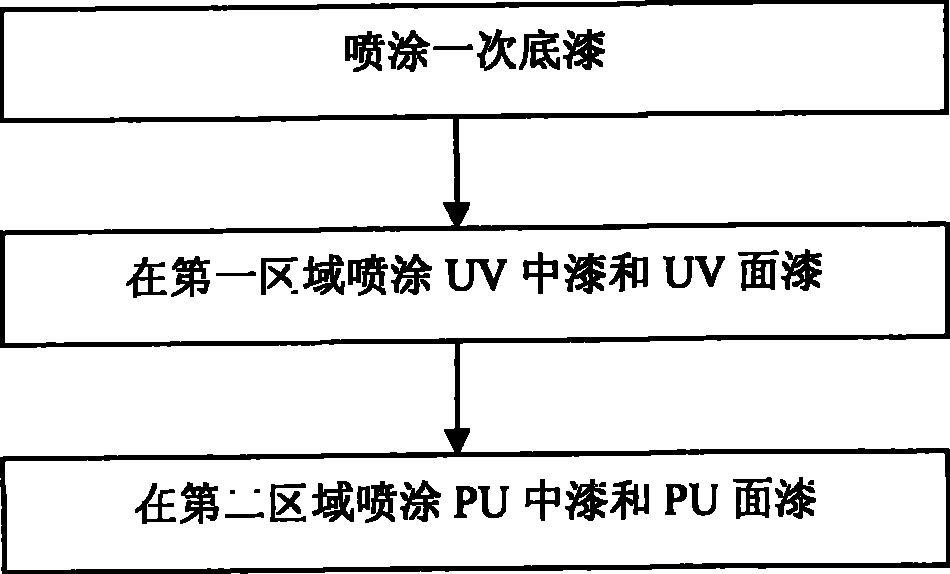

[0022] The method for multi-color spraying of the present invention and the parts after spraying thereof, as shown in Figure 1, has adopted a kind of method of common primer, and has simplified the step of two-color spraying, also solved simultaneously the interface of two kinds of colors cannot Problems to deal with. In two-color spraying, since high-gloss UV and bright color effects are to be achieved, it is necessary to have a good-quality primer for storage. The method of the present invention adopts a process of primer, so that the interface is treated once, and then in the subsequent process , using the high hardness characteristics of high-gloss UV to support the completion of the production process of PU paint, which improves the product quality and can be mass-produced. The present invention can be widely used in two-color and multi-color spraying on plastics, metals and other mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com