Environment-friendly nanoscale bottom infiltrated layer material used for protecting concrete surface and preparation method of environment-friendly nanoscale bottom infiltrated layer material

An environmentally friendly concrete, nano-level technology, applied in the field of concrete protection, can solve the problems of inability to bond the concrete base surface firmly, increase the process, and cannot protect the protective effect of the protective layer, etc., to achieve excellent resistance to chloride ion erosion, good penetration and anchoring effect. , the effect of excellent protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

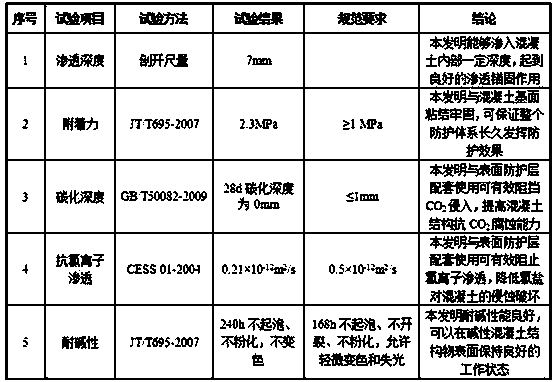

Examples

Embodiment 1

[0045] Step 1: Weigh 75 parts by weight of inorganic nano-silica solution, heat it to 55°C, and keep it warm;

[0046] Step 2: Mix 2 parts by weight of styrene-acrylic emulsion and 2 parts by weight of pure acrylic emulsion, stir until uniform, add to the solution in step 1, stir at a constant temperature for 30 minutes at a speed of 500r / min, and add 4 parts by weight while stirring The γ-aminopropyltriethoxysilane and the isobutyltriethoxysilane of 3 weight parts, the gained solution temperature is down to room temperature;

[0047] Step 3: Add 1 part of sodium metaphosphate and 1 part of tributyl phosphate into the solution obtained in step 2, and stir at a constant temperature for 15 minutes at a speed of 3000 r / min;

[0048] Step 4: Add 2 parts of butyl silicate to the solution obtained in Step 3, stir at a constant temperature at a speed of 500 r / min for 15 minutes, and let it stand for 10 minutes to obtain the bottom seepage layer material.

[0049] In step 1, the soli...

Embodiment 2

[0053]Step 1: Weigh 75 parts by weight of inorganic nano-silica solution, heat it to 55°C, and keep it warm;

[0054] Step 2: Mix 2 parts by weight of styrene-acrylic emulsion and 2 parts by weight of pure acrylic emulsion, stir until uniform, add to the solution in step 1, stir at a constant temperature for 30 minutes at a speed of 500r / min, and add 4 parts by weight while stirring The γ-aminopropyltriethoxysilane and the isobutyltriethoxysilane of 3 weight parts, the gained solution temperature is down to room temperature;

[0055] Step 3: Add 1 part of sodium metaphosphate and 1 part of tributyl phosphate into the solution obtained in step 2, and stir at a constant temperature for 15 minutes at a speed of 3000 r / min;

[0056] Step 4: Add 2 parts of butyl acetate into the solution obtained in Step 3, stir at a constant temperature at a speed of 500 r / min for 15 minutes, and let it stand for 10 minutes to obtain the material of the bottom seepage layer.

[0057] In step 1, t...

Embodiment 3

[0061] Step 1: Weigh 80 parts by weight of inorganic nano-silica solution, heat to 60°C, and keep warm;

[0062] Step 2: Mix 2 parts by weight of styrene-acrylic emulsion and 2 parts by weight of pure acrylic emulsion, stir until uniform, add to the solution in step 1, stir at a constant temperature for 30 minutes at a speed of 500r / min, and add 5 parts by weight while stirring The γ-aminopropyltriethoxysilane and the isobutyltriethoxysilane of 4 weight parts, the gained solution temperature is down to room temperature;

[0063] Step 3: Add 1 part of sodium metaphosphate and 1 part of tributyl phosphate into the solution obtained in step 2, and stir at a constant temperature for 15 minutes at a speed of 3000 r / min;

[0064] Step 4: Add 3 parts of sodium methyl silicate to the solution obtained in Step 3, stir at a constant temperature at a speed of 500 r / min for 15 minutes, and let stand for 10 minutes to obtain the bottom seepage layer material.

[0065] In step 1, the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com