Patents

Literature

37results about How to "Adhesion does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

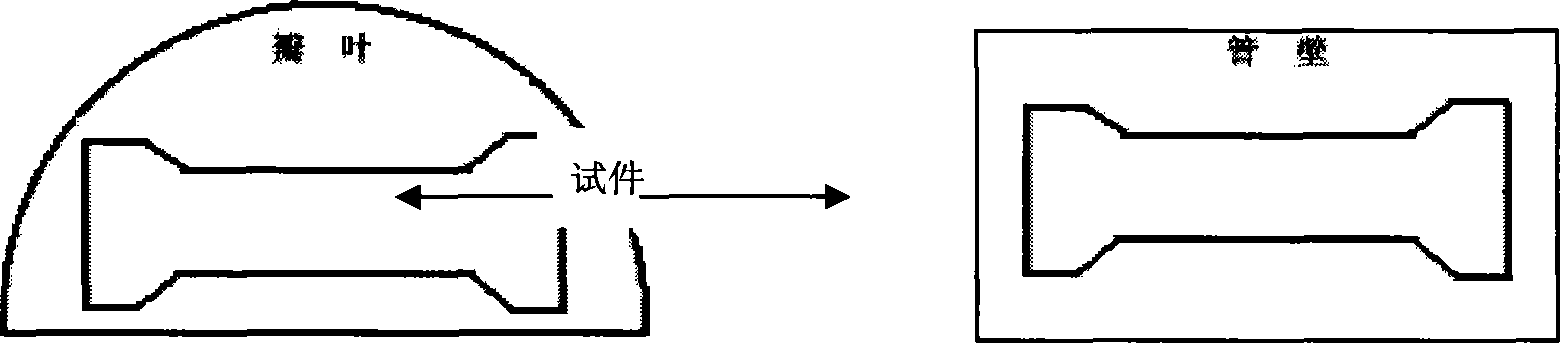

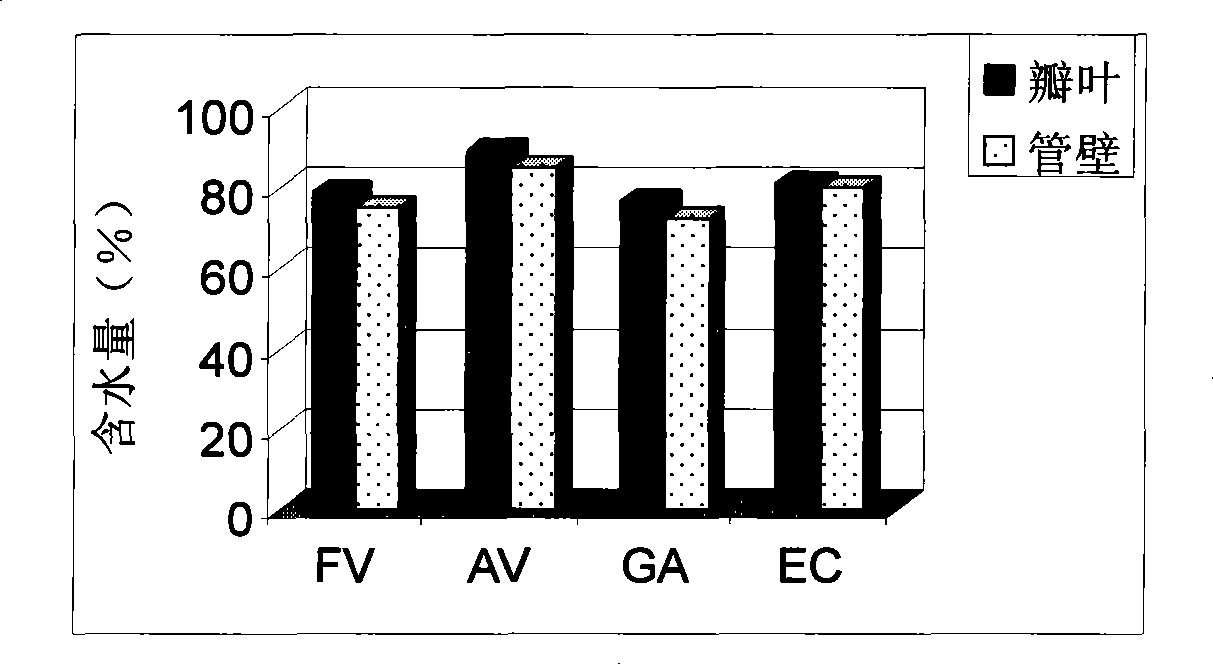

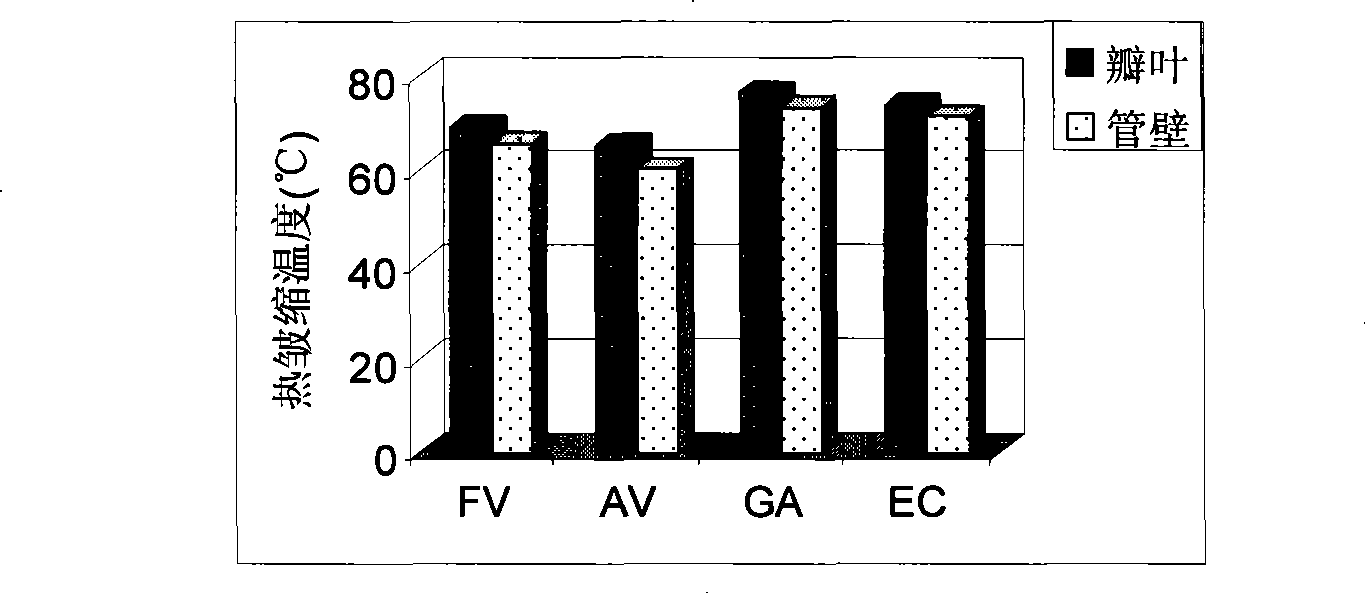

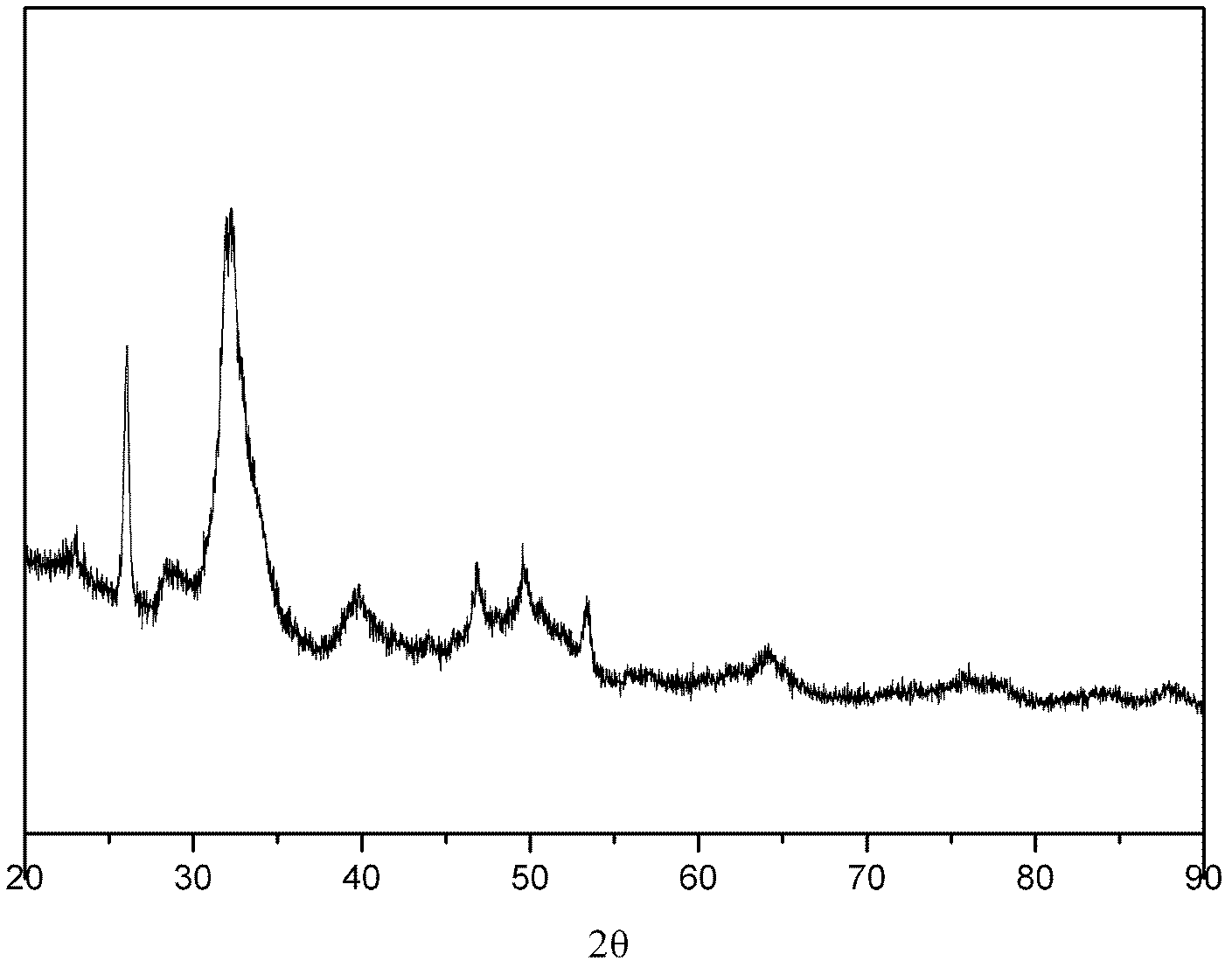

Method for improving de-cellular system engineering valve/blood vessel stent

The invention discloses a method for linking a RGD improved acellular tissue engineering valve / intravascular stent with epoxy chloropropane. The method, by using epoxy groups of the epoxy chloropropane, cross links and fixes the functional domain RGD (YGRGDSP) polypeptide of cell adhesion and recognition receptors on an acellular tissue engineering valve / intravascular stent material; meanwhile, the chemical crosslinking function of the epoxy chloropropane can fully cross link the collagen protein which is the main component of the acellular stent material so as to achieve the purposes of anti-calcification and reducing the zymolysis speed inside the stent material, and finally proving the improved acellular tissue engineering valve / intravascular stent with better biological and mechanical properties, higher adhesion rate toward seed cell, and better property of delaying enzyme digestion and anti-calcification, therefore, the acellular tissue engineering valve / intravascular stent can actually meet the requirements of tissue engineering valves.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Preparation method for anti-infectious nano collagen/ calcium phosphate bone repair material

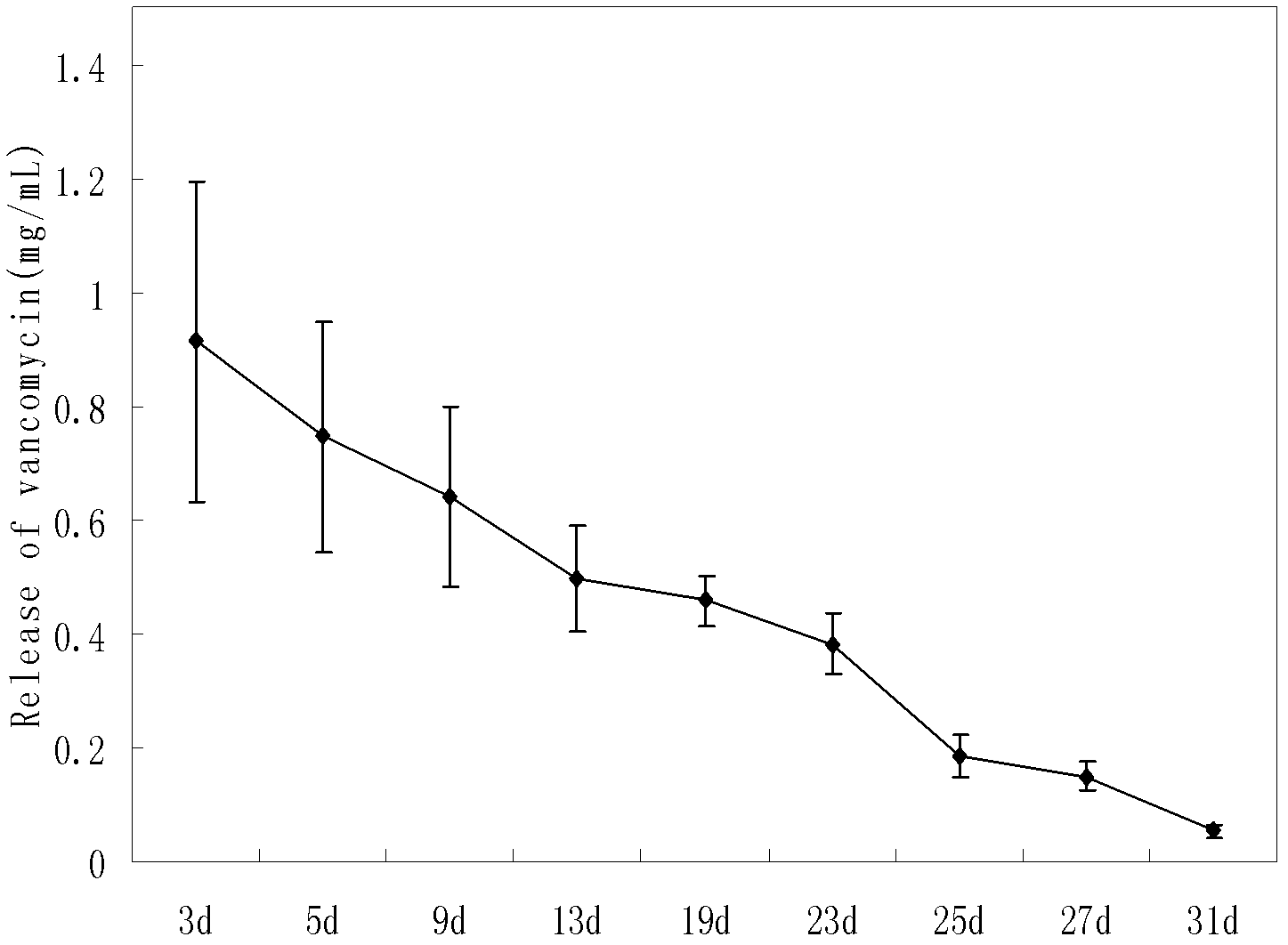

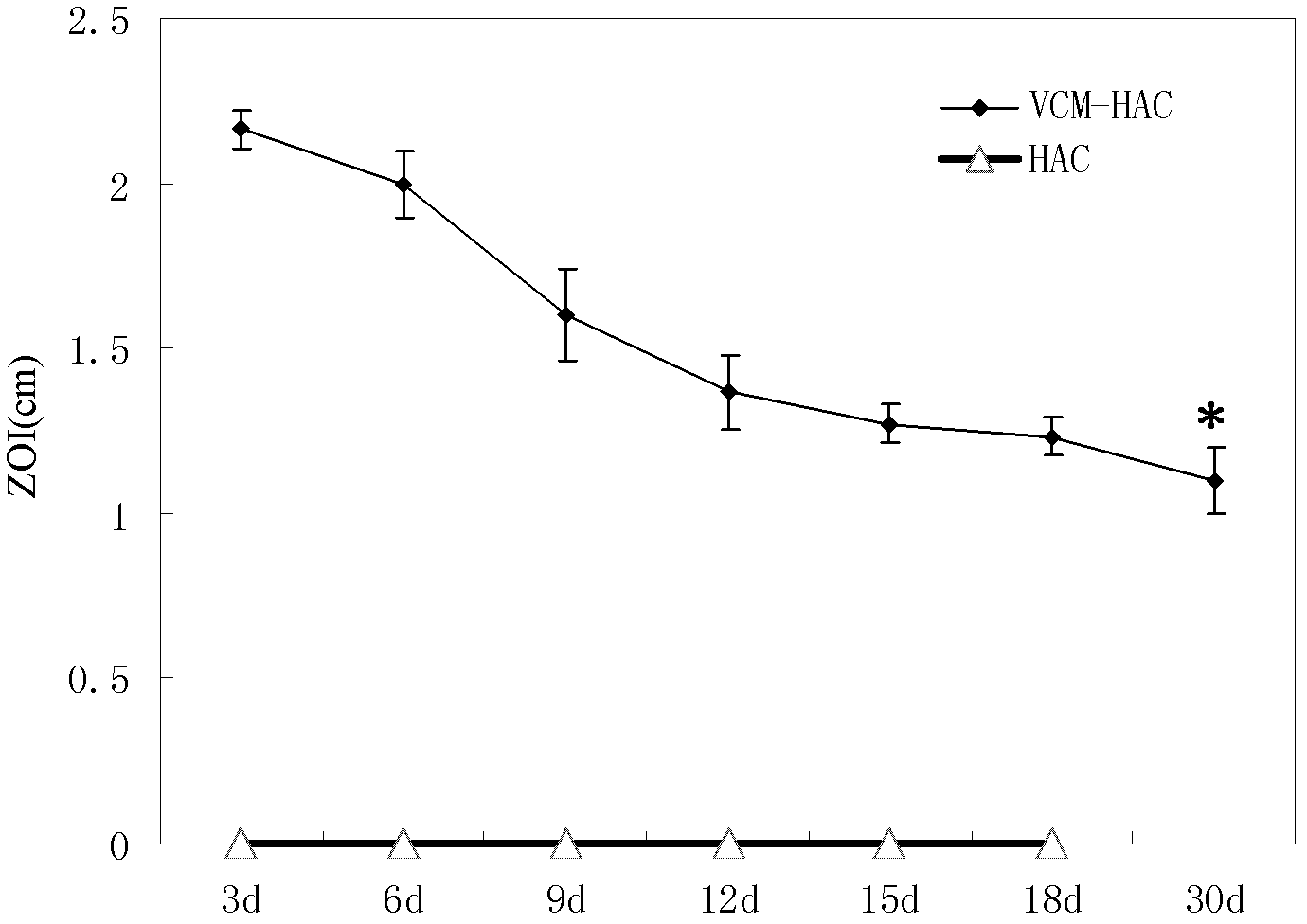

The invention discloses a preparation method for an anti-infectious nano collagen / calcium phosphate bone repair material, and belongs to the field of biomedical materials. The method comprises the following steps of: slowly dripping solution containing calcium ions and aqueous solution containing phosphate radical ions into acid-soluble collagen solution, dripping NaOH solution to regulate the pH value, performing freeze drying, grinding to obtain dry powder for later use, dissolving poly-L-lactic acid in 1,4-dioxane, stirring for a certain time, mixing the solution and the dry powder uniformly, finally adding vancomycin, stirring uniformly, removing the solvent by adopting a freeze drying method, and preparing the anti-infectious nano collagen / calcium phosphate bone repair material. The prepared bone repair material has excellent biocompatibility, infection resistance and a micro-structure similar to human body.

Owner:TSINGHUA UNIV +1

Amlexanox double layer oral patches and its preparing method

InactiveCN1615857AAdhesion does not affectAvoid influenceOrganic active ingredientsDigestive systemWater insolubleIrritation

The double layer Amlexanox oral patch includes two layers, one adhered Amlexanox layer with Amlexanox in 0.1-10 mg and the other water insoluble protecting layer. The double-layer design reduces the dissolving of medicine to the side opposite to the oral cavity mucous membrane and reduces the bi-directional adhesion between gum and oral cavity mucous membrane, makes most of the medicine penetrate to the ulcer surface and decreases the upset in the oral cavity. The double layer Amlexanox oral patch is located to the ulcer focus, has no irritation to the ulcer surface and acting period as long as 3-4 hr.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

Preparation method of emulsion type adhesion promoter for polyolefin plastics

The invention discloses a preparation method of emulsion type adhesion promoter for polyolefin plastics. The emulsion type adhesion promoter for polyolefin plastics is obtained through dispersing and emulsifying chlorinated polyolefin, organic solvent, emulsifying agent and water under a proper condition. A small quantity of organic solvent facilitates dispersing chlorinated polyolefin resin in the emulsion preparation process; and the swelling role of organic solvent to polyolefine also ensures good adhesive attraction of a coating layer to a substrate when the emulsion is formed into a film. Compared with a similar solvent based product, the emulsion type polyolefine adhesion promoter lowers the use amount of the organic solvent and has the adhesion property which can be compared with the similar solvent based product. The emulsion type adhesion promoter for polyolefin plastics has simple preparation process, low price, favorable construction property, small environment pressure and wide market prospect.

Owner:XI AN JIAOTONG UNIV +1

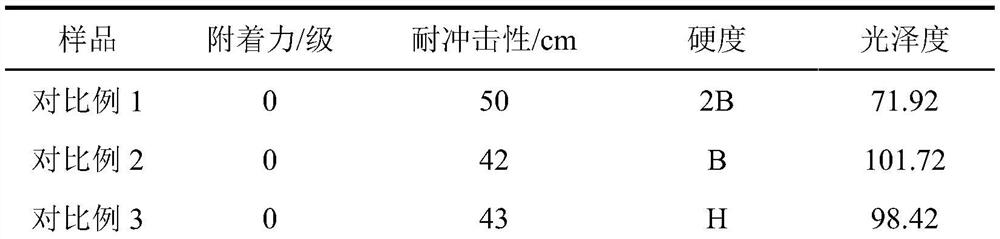

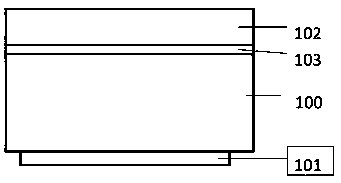

Household appliance printing panel producing method and household appliance printing panel produced thereby

InactiveCN102248824AImprove slipImprove scratch resistanceCasings/cabinets/drawers detailsOther printing apparatusTextile printerPolyester

The invention discloses a household appliance printing panel producing method and a household appliance printing panel produced thereby. The method sequentially comprises the following steps of: (1) pretreating a substrate, namely taking a galvanized steel plate or an aluminum-zinc plated silicon steel plate as the substrate, coating a chromate passivating film on the surface of the substrate, forming a base coating layer on the surface by using a coating which does not contain slip agents, and drying; (2) printing a pattern, namely printing the pattern on a blocky substrate subjected to basecoating treatment by using screen printing equipment or offset printing equipment, and drying; and (3) performing varnish finishing, namely coating a transparent polyester coating or an ultraviolet light curing transparent coating on the surface of the pattern, and curing to form a varnish finishing layer of which the dry film thickness is 10 to 100 micrometers. The panel produced by the method has a distinct pattern, a product has a high machining property, and the production method meets the requirement of machining of the household appliance printing panel.

Owner:达州市拓普节能建材有限公司

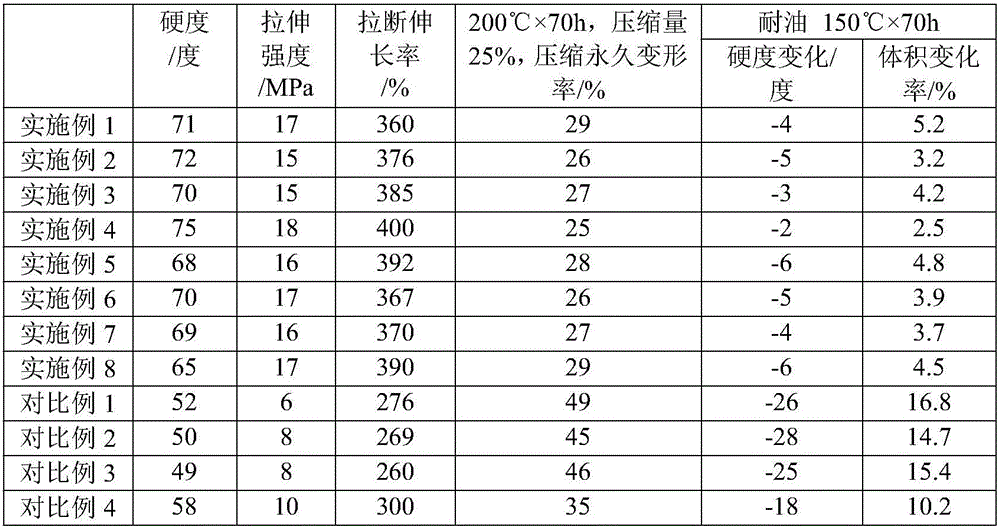

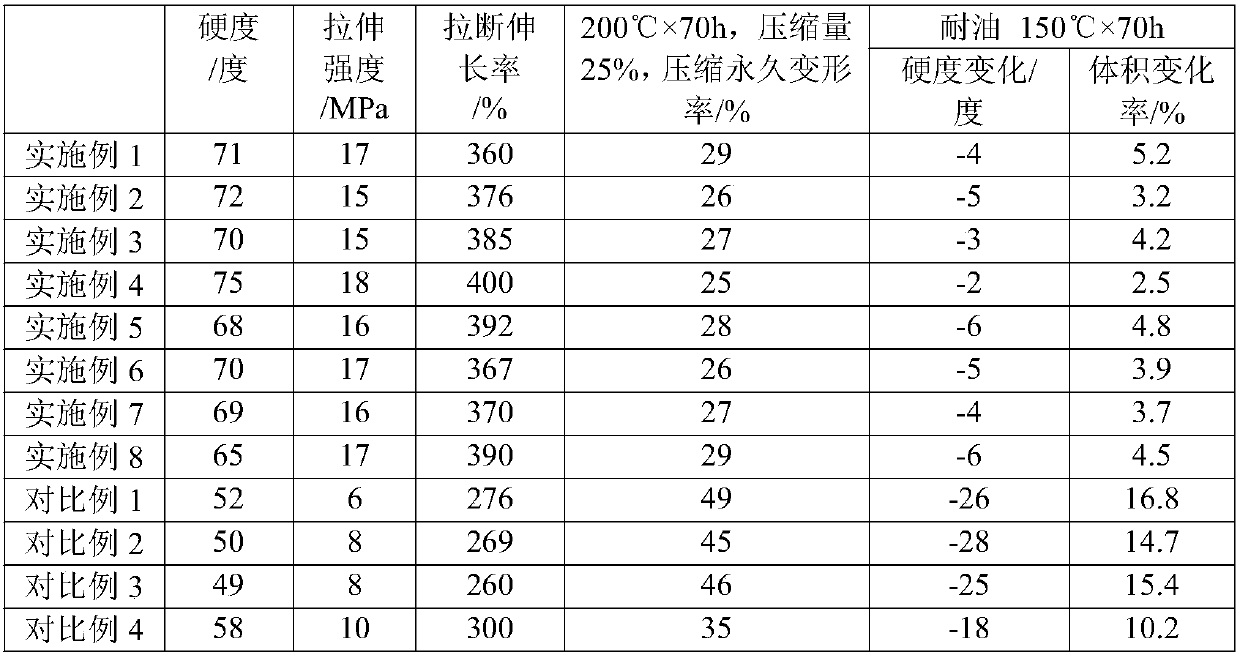

Seal ring for special fluororubber motor for nuclear power and preparation method of seal ring

ActiveCN106589709AGood oil resistance at high temperatureImprove performanceNuclear powerEngineering

The invention discloses a seal ring for a special fluororubber motor for nuclear power and a preparation method of the seal ring. The seal ring for the special fluororubber motor for the nuclear power is prepared from the following raw materials in parts by weight: 85 to 90 parts of fluororubber, 5 to 8 parts of acid-acceptor, 2 to 5 parts of compound vulcanizing agent, 8 to 10 parts of reinforcing agent and 1 to 2 parts of additive. The fluororubber motor seal ring is high in mechanical strength, excellent in oil resistance under high temperature, and suitable for a motor of a nuclear-powered ship.

Owner:南阳天一密封股份有限公司

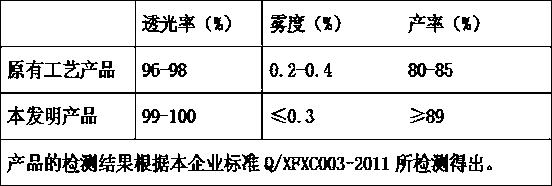

Emulsifying defoaming system and PVB (Polyvinyl Butyral) resin production method employing the same

ActiveCN103007587AGood emulsifying effectGood repeatabilityFilm/foil adhesivesFoam dispersion/preventionPlasticizerReaction system

The invention provides an emulsifying defoaming system and a PVB (Polyvinyl Butyral) resin production method employing the same and relates to an additive and application thereof in a resin production process, wherein the emulsifying defoaming system is composed of an emulsifier and a defoamer; the weight percentage of the emulsifier is 50-99.9%; and the emulsifier is the mixture of sodium hexadecyl sulfosuccinate or octyl phenyl polyoxyethylene ether and sodium alkyl sulfosuccinate. The emulsifying defoaming system is applied so that bubbles generated by stirring while the excellent emulsification effect of the reaction system is achieved; so that therefore, the generation of massive wastes can be reduced and the quality and yield of the product can be improved. Simultaneously, the defoamer applied in the emulsifying defoaming system provided by the invention is also advantages for improving the compatibility of a plasticizer with the resins. The formation of bubbles in the subsequent extrusion curtain coating processing procedure of the resins also can be eliminated in the presence of the defoamer; and the obtained membrane is free of defect apparently.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

Chinese medicinal double-layer patch for treating oral ulcer and preparation method thereof

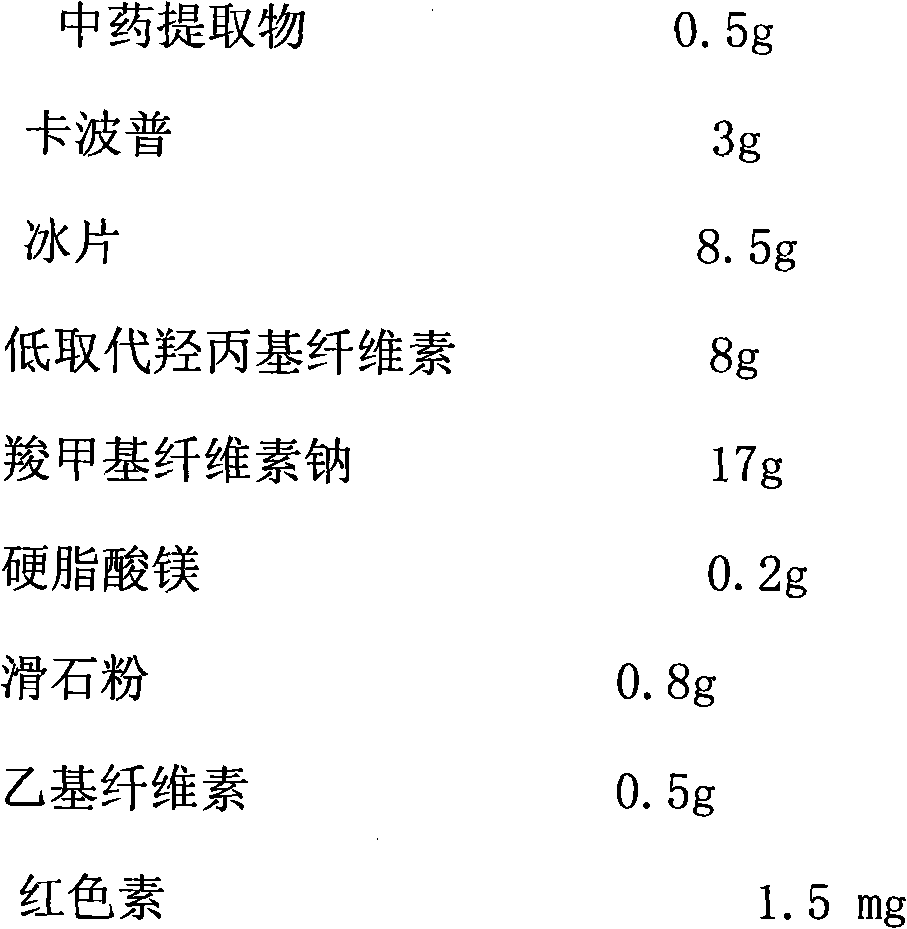

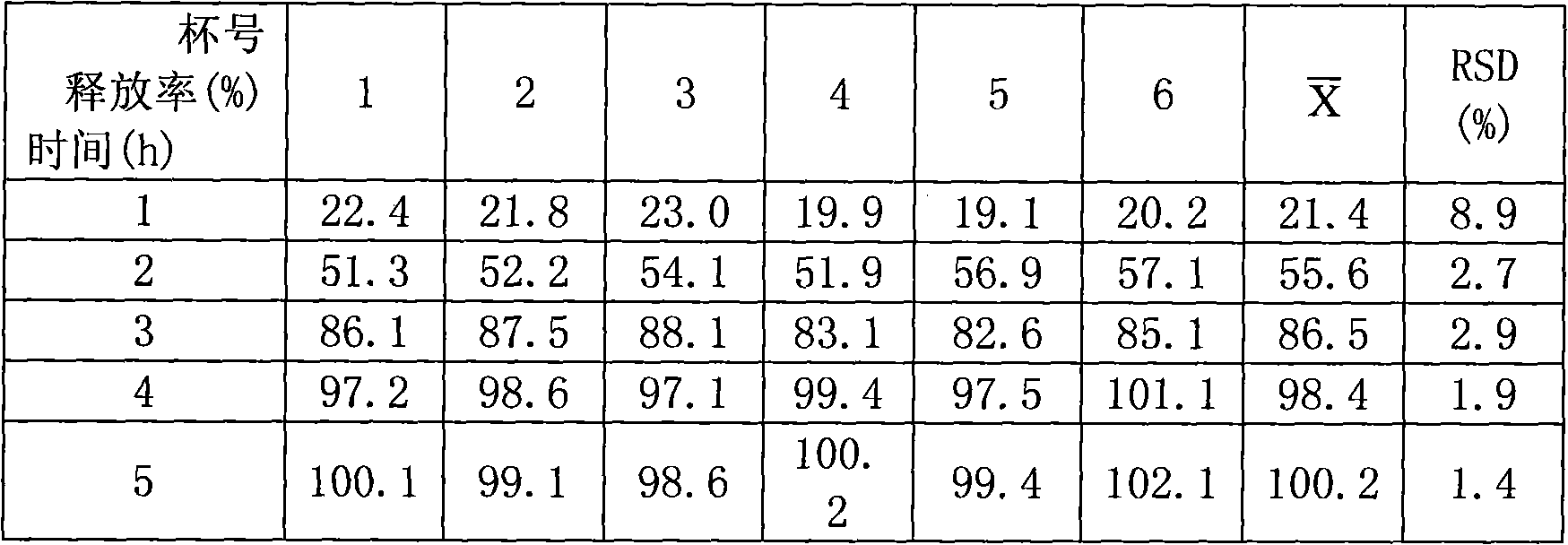

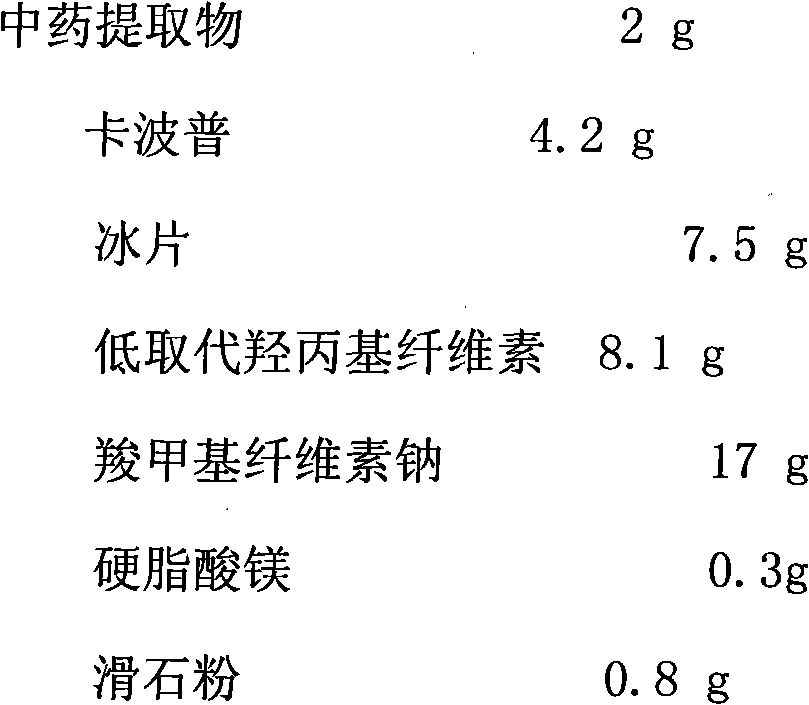

InactiveCN102048816AAdhesion does not affectAvoid influenceAnthropod material medical ingredientsDigestive systemSodium carboxymethylcelluloseUlcer care

The invention relates to a Chinese medicinal double-layer patch for treating oral ulcer. The patch consists of a medicine-containing adhesion layer and a water-insoluble protective layer, wherein the medicine-containing adhesion layer comprises 0.1 to 15mg of Chinese medicinal extract, carbopol, borneol, low-substituted hydroxypropyl cellulose and sodium carboxymethyl cellulose; the water-insoluble protective layer consists of ethyl cellulose and edible pigment; and the Chinese medicinal extract consists of 8 to 12g of mint, 15 to 20g of honeysuckle flower, 5 to 10g of liquoric root and 10 to 15g of Chinese gall. The double-layer patch medicine can fully improve local ulcer tissues and repair and cure the ulcer soon to fulfill the aim of treatment; the Chinese patent medicine is nontoxic and harmless to human bodies, is not required to be decocted and is convenient to administrate; the patch treats both symptoms and root causes and has obvious clinical curative effects; and the effective rate reaches 96 percent.

Owner:TIANJIN PACIFIC PHARMA

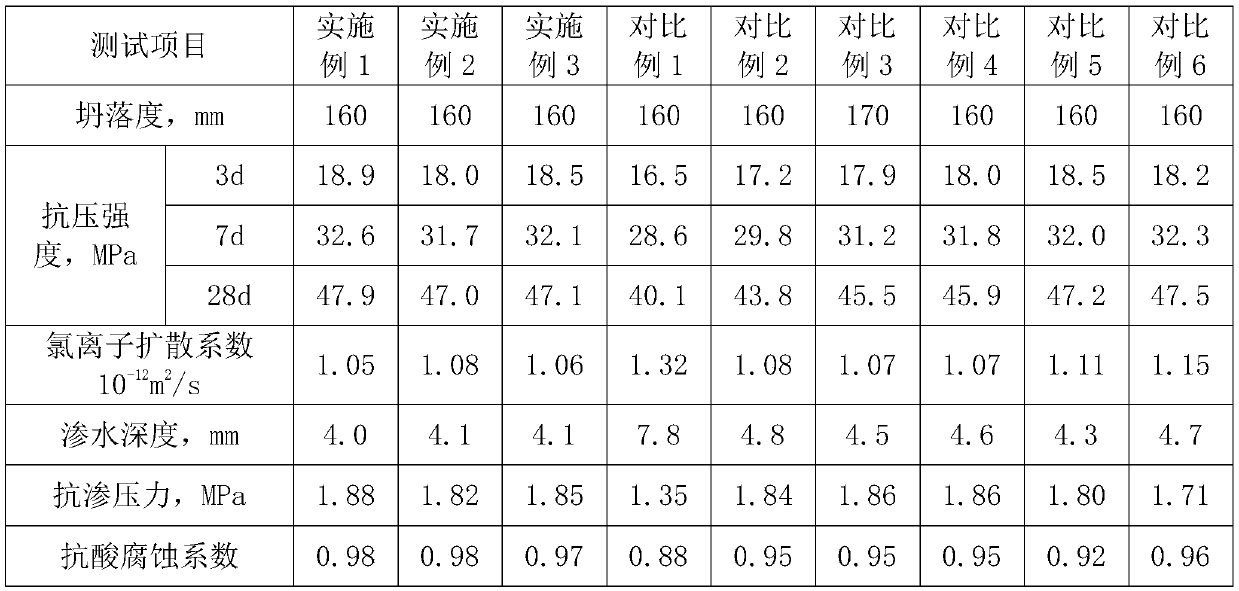

Waterproof concrete and preparation method thereof

The invention discloses waterproof concrete and a preparation method thereof, wherein the waterproof concrete is prepared from the following components in parts by weight: 300 to 350 parts of cement,600 to 700 parts of fine aggregate, 900 to 1000 parts of coarse aggregate, 100 to 120 parts of an admixture, 8 to 10 parts of an additive, 25 to 30 parts of a waterproof agent and 130 to 150 parts ofwater, wherein the preparation method of the waterproof agent comprises: taking 40-60 parts by weight of modified basalt fiber and 5-7 parts by weight of disproportionated potassium rosinate, uniformly stirring, adding 30-40 parts by weight of a UEA expanding agent, 3-5 parts by weight of sodium dodecyl sulfate and 3-5 parts by weight of ferrous sulfate, and uniformly stirring to obtain the waterproof agent. The waterproof concrete provided by the invention has excellent water resistance, excellent permeability resistance and excellent acid corrosion resistance.

Owner:成都新豪鼎盛建材有限公司

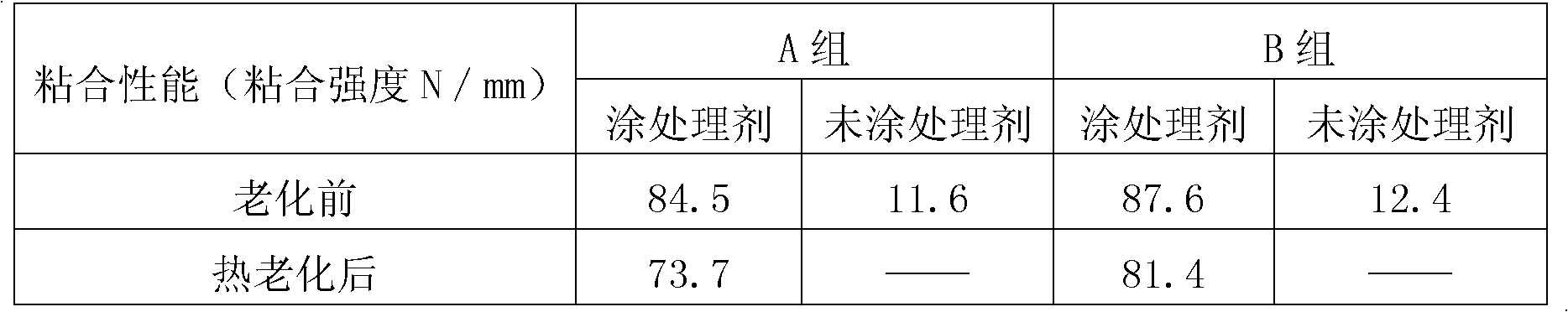

Belt steel wire surface treating agent for retreading steel wire radial tire and preparation method thereof

InactiveCN101974761APrevent re-oxidation and rustEasy to operatePotassium ferrocyanidePhosphoric acid

The invention discloses a belt steel wire surface treating agent for retreading a steel wire radial tire and a preparation method thereof. The treating agent comprises an oxide layer removing agent, a corrosion inhibitor, an oxidation inhibitor, a dispersing and tackifying agent and water, wherein the oxide layer removing agent comprises phosphoric acid, oxalic acid, industrial salicylic acid and potassium ferrocyanide. The invention has the advantages of removing an oxide layer on the polished surface of a belt steel wire, preventing the metal surface after the oxide layer is removed from reoxidation and corrosion, effectively ensuring the normal conduction of a high strength cohesion reaction between new tread rubber and the polished belt steel wire and not influencing the cohesion of the new tread rubber with the original tire rubber on the original belt steel wire. The treating agent can be coated for use so that the operation is convenient.

Owner:镇江泛华新材料科技发展有限公司

Metronidazole stomatocace double-layer paster and preparation method thereof

InactiveCN101450053AStrong adhesionAdhesion does not affectOrganic active ingredientsDigestive systemDissolutionDentistry

The invention relates to a metronidazole stomatocace patch and preparing method thereof, the oral cavity adhere patch is divided into two layers, one layer is an adhere layer containing amlexanox 0. 1-10 mg; the other layer is a protecting layer which is insoluble. According to the double-layer design, the dissolution of the medicament towards the opposite side of the oral mucosa and the bidirectional adhesion between the gingiva and oral mucosa of the patch can be reduced, the medicament can be infiltrated into ulcer surface and the uncomfortableness of the medicament in the oral cavity can be reduced. The double-layer oral cavity adhere patch is positioned on the focus position, has no simulation for the ulcer surface, has slow-release action for exerting medicament effect as long as 3-4 hours, can alleviate the pain caused by the ulcer for long time.

Owner:TIANJIN PACIFIC PHARMA

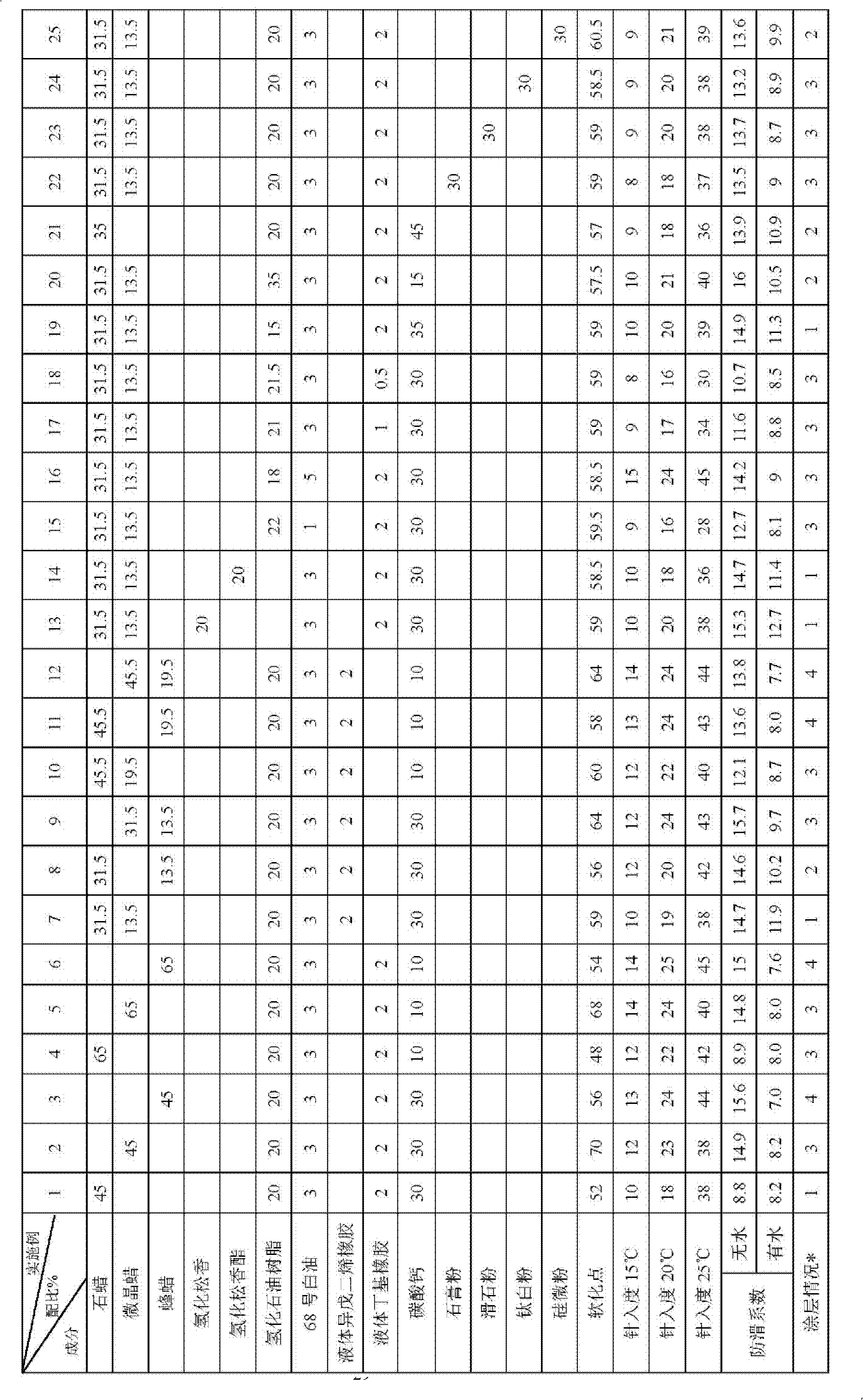

Antiskid wax for surfboards and its preparation method

The invention aims to provide an antiskid wax for surfboards and its preparation method. The antiskid wax for surfboards has strong viscosity and toughness, has good adhesion when applied on the surfboards, and can form a discontinuous coating. Especially when the antiskid wax is exposed to water, the adhesion force is not affected, and the wax layer has the advantages of strong toughness, hard shedding, and no fear of scratching. Besides, the wax layer does not skid by itself, and does not lose the antiskid performance in use due to softening caused by heat generated by friction. The antiskid wax is not only suitable for surfboards, but also suitable for skid resistance of ice hockey sticks, sailboards, ship decks, footboards, golf clubs or other sports equipment and similar smooth surfaces. The antiskid wax is convenient to use, can achieve good effects, and is not influenced by the environment after use. There is no need to worry the problem that the antiskid performance declines in water. With the advantages of safety, no toxicity, and low price, the antiskid wax is very popular with domestic and foreign customers, so that the purpose of the invention is realized.

Owner:江苏泰尔新材料股份有限公司

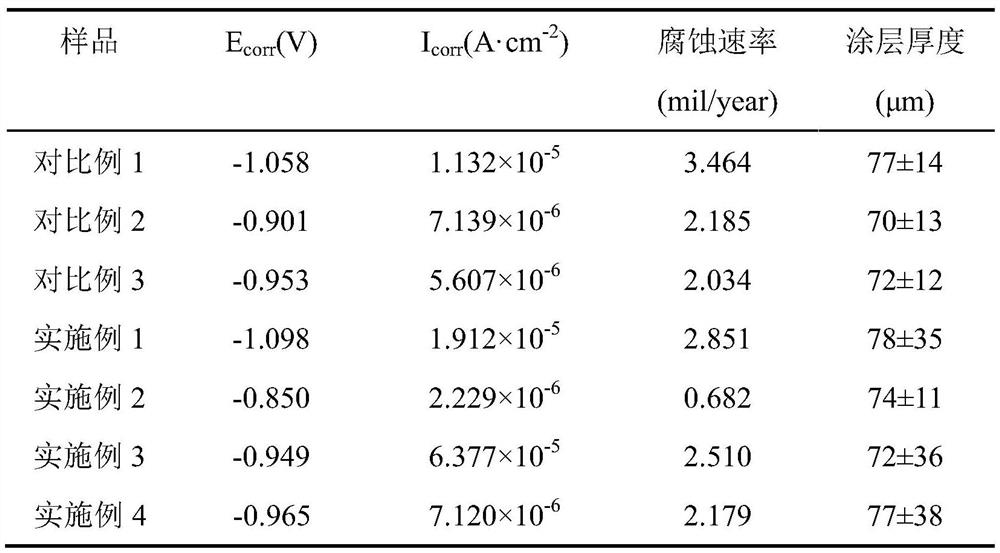

Preparation method of polyaniline modified graphene oxide/hydroxylated boron nitride composite epoxy coating

ActiveCN112724787AImprove anti-corrosion performanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsOrganosolvFirming agent

The invention discloses a preparation method of a polyaniline modified graphene oxide / hydroxylated boron nitride composite epoxy coating, which comprises the following steps of carrying out amino modification on graphene oxide by phenylenediamine to obtain amino modified graphene oxide, carrying out in-situ polymerization on the amino modified graphene oxide and an aniline hydrochloric acid solution to obtain PrGO, combining the PrGO with hydroxylated boron nitride, and carrying out mutual intercalation on the PrGO and BN(OH)x to obtain a BN(OH)x-PrGO mixture, and finally, combining the BN(OH)x-PrGO mixture with epoxy resin through a cardanol modified curing agent to prepare the BN(OH)x-PrGO composite epoxy coating. According to the preparation method, boron nitride and graphene oxide are respectively modified, so that the dispersity and material compatibility of PrGO and BN(OH)x in an organic solvent are effectively improved, and the corrosion resistance, glossiness and adhesive force of the epoxy composite coating are greatly improved due to the high shielding and synergistic effects of the two modified materials.

Owner:JIANGNAN UNIV

Water-based highly-filled glaze for carpentry, preparation method of water-based highly-filled glaze and construction process

The invention belongs to the field of coatings, and relates to water-based highly-filled glaze for carpentry, a preparation method of the water-based highly-filled glaze and a construction process. The water-based highly-filled glaze for the carpentry comprises, in weight percentage, 15%-25% of water-base resin, 0.5%-2% of bentonite, 40%-60% of powder materials, 1%-10% of water, 1%-10% of water-based color paste color powder and 10.6%-22.5% of other functional additives. The glaze has good filling functions without affecting coloring and is good in anti-settling effect, various water-based primers can effectively adhere, and delaminating is avoided.

Owner:AODA KOALA PAINT HUIZHOU

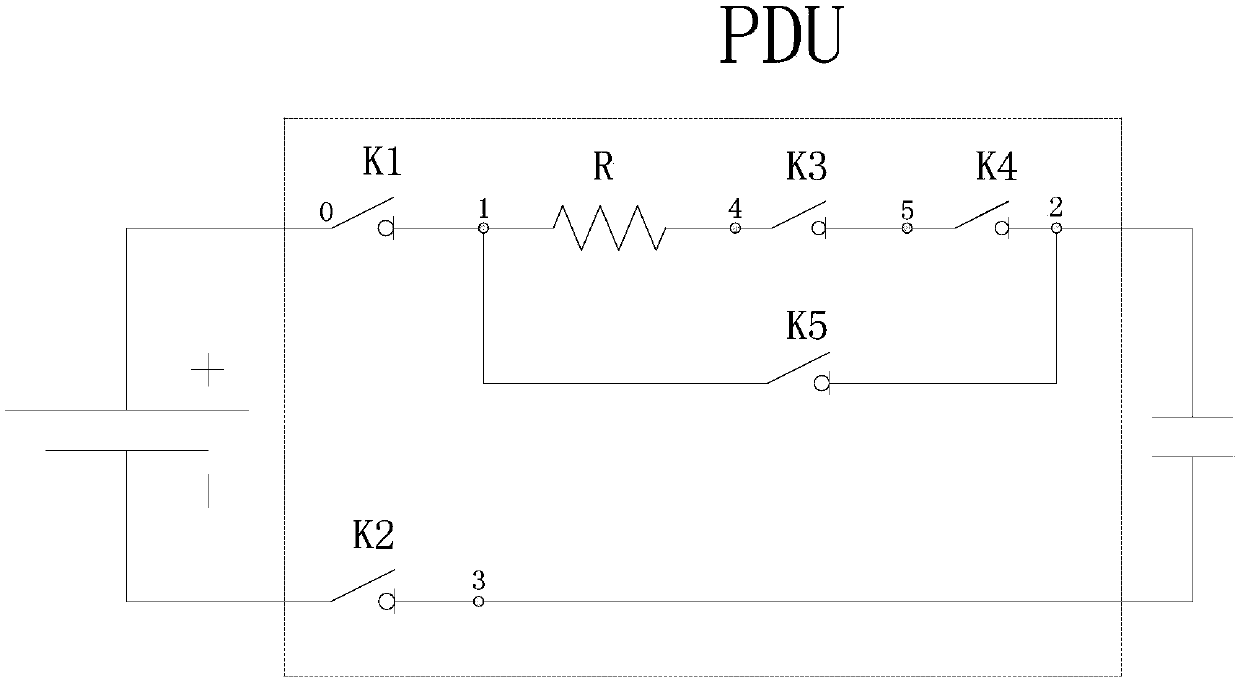

PDU relay adhesion detection circuit and method and automobile operation control method

PendingCN109581214AAdhesion does not affectReduce the likelihood of stickingElectric devicesCurrent/voltage measurementCapacitanceElectricity

The invention relates to a PDU relay adhesion detection circuit and method and an automobile operation control method. The PDU relay adhesion detection circuit includes a battery box, a main relay, acapacitor, a precharge resistor, a first precharge relay and a second precharge relay, one end of the main relay is electrically connected to the anode end of the battery box, and the other end of themain relay is electrically connected to one end of the capacitor; the other end of the capacitor is electrically connected to the cathode end of the battery box, one end of the precharge resistor iselectrically connected to the common end of the battery box and the main relay, and the other end of the precharge resistor is electrically connected to one end of the first precharge relay; and the other end of the first precharge relay is electrically connected to one end of the second precharge relay, and the other end of the second precharge relay is electrically connected to the common end ofthe main relay and the capacitor. According to the PDU relay adhesion detection circuit and method and the automobile operation control method, the two precharge relays are used for being prechargedin series, the probability of simultaneous adhesion of the two precharge relays is low, and the effect of protecting the battery box can be achieved.

Owner:ZHUHAI GUANGTONG AUTOMOBILE +1

Composite adhesion agent

InactiveCN103013397AImprove stabilityHigh transparencyMonocarboxylic acid ester polymer adhesivesPolyether adhesivesPolyvinyl butyralPolymer science

The invention discloses a composite adhesion agent which comprises the components in percentage by mass as follows: 13%-15% of poly vinyl acetate, 2%-5% of sodium silicate, 10%-13% of polyvinyl butyral, 1%-2% of polyethylene glycol-400, 5%-6% of dibutyl phthalate, 10%-14% of isopropyl alcohol, 6%-8% of sodium aluminate, 12%-16% of methyl vinyl silicone rubber and the balance of methylbenzene, and the sum of the mass percentage of the components is 100%. The composite adhesion agent has the advantages of good stability, high transparency and high viscosity, lower the cost and can be used for adhesion of woods, metals and plastics.

Owner:张亮

Degradable UV gravure embossed sand-feeling ink for gold and silver cardboard

The invention relates to the technical field of ink, and in particular, relates to a degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard material. The ink comprises the following components by the weight percentage: 15%-25% of epoxidized soybean oil acrylate, 10%-15% of acrylate, 15%-25% of 1,6-hexanediol diacrylate, 10%-20% of isobornyl acrylate, 2%-4% of a 184 photoinitiator, 3%-6% of a TPO photoinitiator, 8%-12% of an amine initiator, 3%-5% of sand finish powder, 5%-8% of wax powder, and 1%-3% of an auxiliary agent. The degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard has no solvent and no toxic gas emissions when in use, is environmentally friendly, and has no pollution; the ink after curing has the advantages of strong pattern three-dimensional sense, good adhesion force and good fluidity, can meet the requirements of decorative inks, can be biodegraded after being discarded, meets new concepts of environmental protection, reduces environment pollution, and achieves the purpose of sustainable development.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

A kind of emulsification defoaming system and the production method of PVB resin adopting this system

ActiveCN103007587BGood emulsifying effectGood repeatabilityFilm/foil adhesivesFoam dispersion/preventionPlasticizerReaction system

The invention provides an emulsifying defoaming system and a PVB (Polyvinyl Butyral) resin production method employing the same and relates to an additive and application thereof in a resin production process, wherein the emulsifying defoaming system is composed of an emulsifier and a defoamer; the weight percentage of the emulsifier is 50-99.9%; and the emulsifier is the mixture of sodium hexadecyl sulfosuccinate or octyl phenyl polyoxyethylene ether and sodium alkyl sulfosuccinate. The emulsifying defoaming system is applied so that bubbles generated by stirring while the excellent emulsification effect of the reaction system is achieved; so that therefore, the generation of massive wastes can be reduced and the quality and yield of the product can be improved. Simultaneously, the defoamer applied in the emulsifying defoaming system provided by the invention is also advantages for improving the compatibility of a plasticizer with the resins. The formation of bubbles in the subsequent extrusion curtain coating processing procedure of the resins also can be eliminated in the presence of the defoamer; and the obtained membrane is free of defect apparently.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

Specific unsaturated polyester resin for manufacturing metal polished particles and preparation method of specific unsaturated polyester resin

InactiveCN105542133ALow heat release temperatureAvoid crackingPolishing compositions with abrasivesCobaltAccelerant

The invention discloses specific unsaturated polyester resin for manufacturing metal polished particles and a preparation method of the unsaturated polyester resin. The preparation method of the unsaturated polyester resin comprises the following steps: adding phthalic anhydride, maleic anhydride and propylene glycol in a reaction kettle according to a mol ratio of (1.8 to 1.9): 1: (2.9 to 3.1), carrying out a melt phase polycondensation reaction at a temperature of 160 to 220 DEG C, and adding hydroquinone after the reaction is completed to obtain polycondensate; adding the polycondensate to styrene, and stirring to uniformly dilute at the temperature of 50 to 85 DEG C; reducing the temperature of the material to below 50 DEG C, sequentially adding benzoquinone, 2, 5-di-tert-butylhydroquinone, a cobalt-series accelerant and an amine-series accelerant, and uniformly stirring to obtain the finished product. The unsaturated polyester resin is low in viscosity, and short in gelation time; the metal polished particles prepared from the unsaturated polyester resin and filler have high Bacho hardness and good impact toughness.

Owner:CHANGZHOU TIANMA GROUP CO LTD

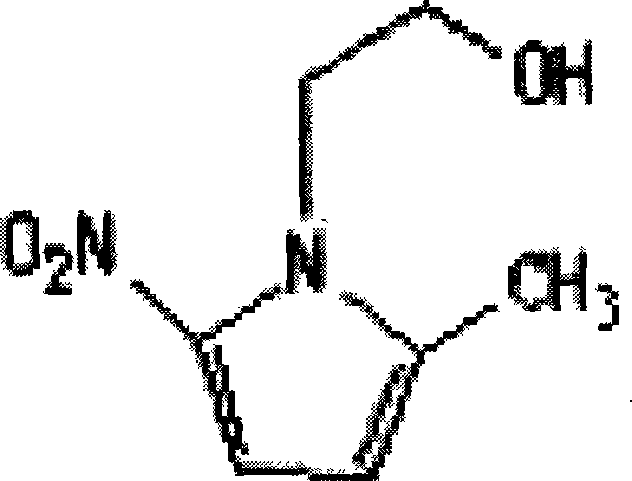

Ultraviolet curing magnetic roller coating with strong adhesive force and preparation method thereof

InactiveCN111286263AGood compatibilityLow tensile strengthPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention relates to coating, in particular to ultraviolet curing magnetic roller coating with high adhesive force and a preparation method thereof. The coating comprises, by weight, 15 to 35 parts of urethane acrylate, 0.01 to 10 parts of trimethylolpropane triacrylate, 1 to 8 parts of a photoinitiator, 10 to 20 parts of conductive carbon black, 8 to 18 parts of tin oxide, 0.4 to 1 part of polysiloxane, 0.2 to 1 part of a leveling agent, 0.1 to 1.5 parts of chitosan, 0.2 to 2.5 parts of glass beads, 0.5 to 5 parts of hydroxyethyl methacrylate phosphate, 0.01 to 0.4 part of modified polyurea N-methyl-2-pyrrolidone BYK-410 and 0.5 to 5 parts of an ethylene-vinyl acetate copolymer. The coating provided by the invention has the characteristics of strong adhesion to a magnetic roller substrate, good flexibility, conductivity, wear resistance and fast ultraviolet curing.

Owner:中山市锝力打印机设备有限公司

A kind of sealing ring for fluorine rubber motor special for nuclear power and preparation method thereof

ActiveCN106589709BGood oil resistance at high temperatureImprove performanceNuclear powerControl theory

The invention discloses a seal ring for a special fluororubber motor for nuclear power and a preparation method of the seal ring. The seal ring for the special fluororubber motor for the nuclear power is prepared from the following raw materials in parts by weight: 85 to 90 parts of fluororubber, 5 to 8 parts of acid-acceptor, 2 to 5 parts of compound vulcanizing agent, 8 to 10 parts of reinforcing agent and 1 to 2 parts of additive. The fluororubber motor seal ring is high in mechanical strength, excellent in oil resistance under high temperature, and suitable for a motor of a nuclear-powered ship.

Owner:南阳天一密封股份有限公司

Preparation method of emulsion type adhesion promoter for polyolefin plastics

The invention discloses a preparation method of emulsion type adhesion promoter for polyolefin plastics. The emulsion type adhesion promoter for polyolefin plastics is obtained through dispersing and emulsifying chlorinated polyolefin, organic solvent, emulsifying agent and water under a proper condition. A small quantity of organic solvent facilitates dispersing chlorinated polyolefin resin in the emulsion preparation process; and the swelling role of organic solvent to polyolefine also ensures good adhesive attraction of a coating layer to a substrate when the emulsion is formed into a film. Compared with a similar solvent based product, the emulsion type polyolefine adhesion promoter lowers the use amount of the organic solvent and has the adhesion property which can be compared with the similar solvent based product. The emulsion type adhesion promoter for polyolefin plastics has simple preparation process, low price, favorable construction property, small environment pressure andwide market prospect.

Owner:XI AN JIAOTONG UNIV +1

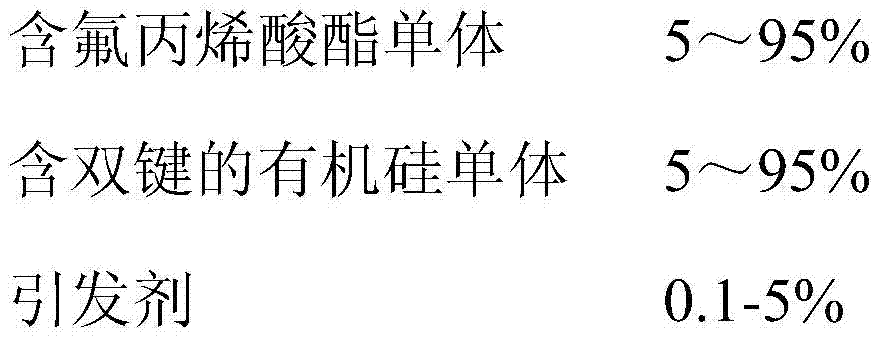

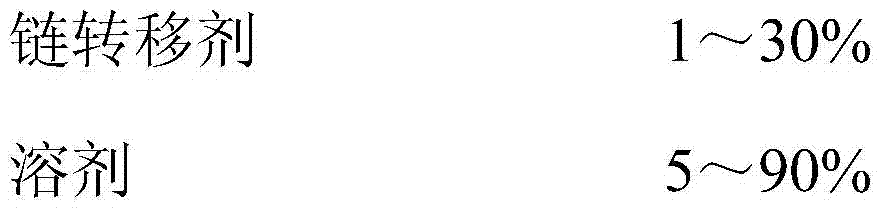

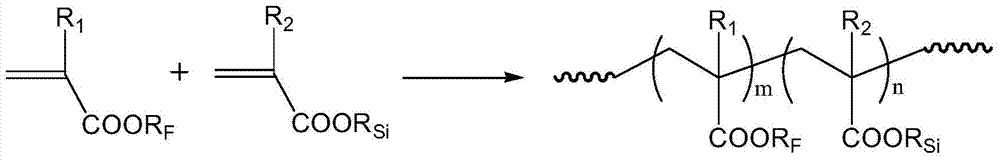

Auxiliary agent for reactive coating and printing ink and its synthesis method

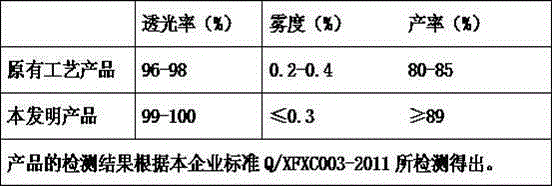

The invention discloses a reactive coating and ink auxiliary agent, which is mainly synthesized from a fluorine-containing acrylate monomer, a double bond-containing organic silicon monomer, an initiator, a chain transfer agent, and a solvent through a radical solution copolymerization process. The product of the present invention can not only effectively reduce the surface tension of the UV-curable coating and prevent the shrinkage cavity of the paint film, but also participate in the cross-linking reaction of the UV-curable coating to prevent it from migrating to the surface of the coating film, so as not to affect the vacuum aluminum plating of adhesion.

Owner:ANHUI XOANONS CHEM

Belt steel wire surface treating agent for retreading steel wire radial tire and preparation method thereof

InactiveCN101974761BPrevent re-oxidation and rustGuaranteed to proceed normallySalicylic acidPhosphoric acid

The invention discloses a belt steel wire surface treating agent for retreading a steel wire radial tire and a preparation method thereof. The treating agent comprises an oxide layer removing agent, a corrosion inhibitor, an oxidation inhibitor, a dispersing and tackifying agent and water, wherein the oxide layer removing agent comprises phosphoric acid, oxalic acid, industrial salicylic acid andpotassium ferrocyanide. The invention has the advantages of removing an oxide layer on the polished surface of a belt steel wire, preventing the metal surface after the oxide layer is removed from reoxidation and corrosion, effectively ensuring the normal conduction of a high strength cohesion reaction between new tread rubber and the polished belt steel wire and not influencing the cohesion of the new tread rubber with the original tire rubber on the original belt steel wire. The treating agent can be coated for use so that the operation is convenient.

Owner:镇江泛华新材料科技发展有限公司

A kind of flexible ceramic coating and preparation method thereof

ActiveCN109796871BGood compatibilityAvoid crackingAntifouling/underwater paintsPaints with biocidesEmulsionCeramic coating

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Production method of biodegradable thermally bonded two-component composite filament fiber

ActiveCN102560709BGuaranteed spinnabilityAdhesion barrierMelt spinning methodsConjugated synthetic polymer artificial filamentsRoom temperatureViscose

Owner:TEXTILE INST JIANGSU PROVINCE

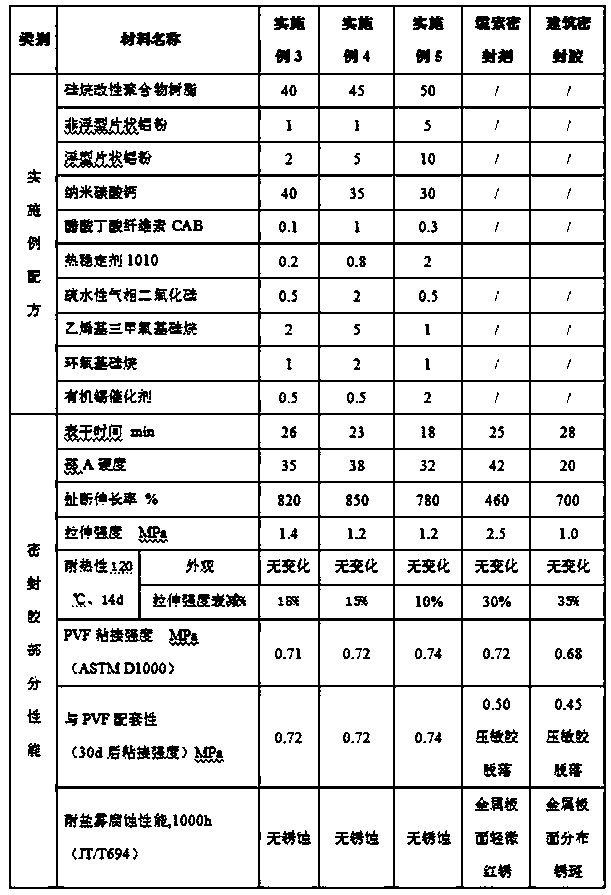

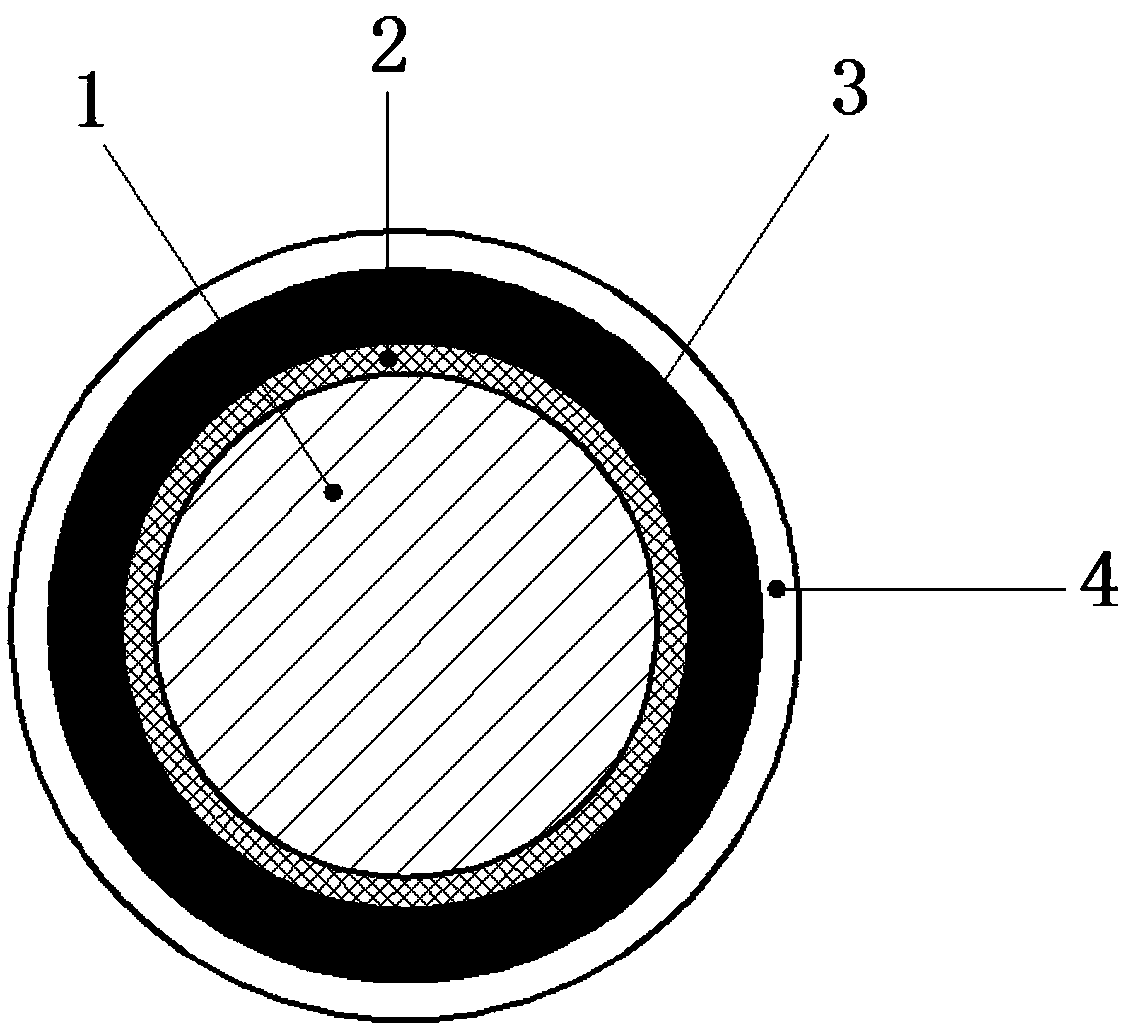

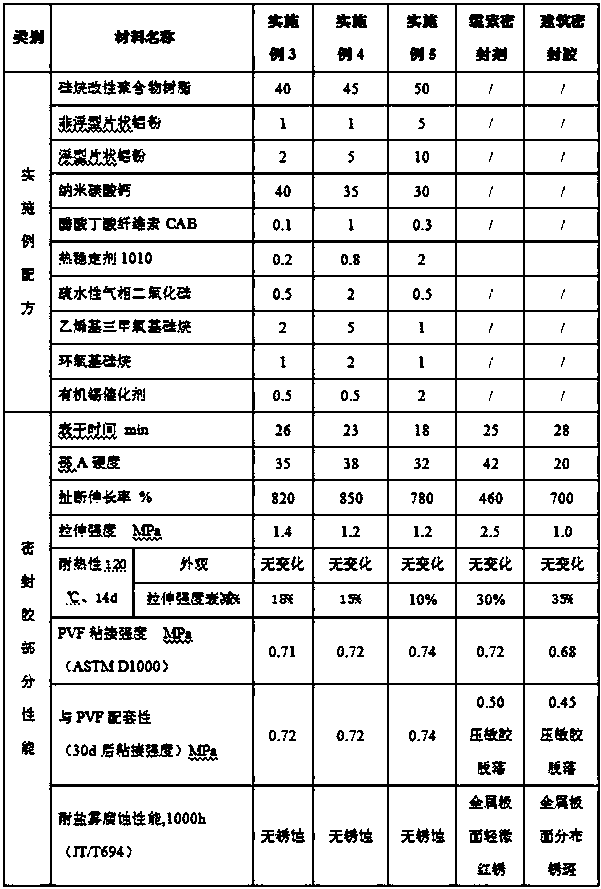

Maintenance method of heavy-duty anti-corrosion seal wrapping on the surface of steel components

The invention discloses a heave duty anticorrosion sealing wrapping maintenance method for the surface of a steel component. an originally invalided corrosion prevention material of a substrate is clear away firstly, the surface rust and other pollutants are cleaned, the surface cleanliness reaches an Sa2 level or the same degree, then a quick-drying type zinc-rich silane modified polymer sealantis brushed or scraped, brush coating or scrape coating of a vulcanized silicon-rich silane modified polymer sealant is carried out, and finally scrape coating of a PVF adhesive tape is carried out. The method has the advantages of low surface treatment, corrosion and corrosion resistance sealing, and has the comprehensive characteristics of heat resistance, weather resistance and pollution resistance, on-site operation is simple, fast, efficient, free of dead corners, good in sealing and wrapping appearance decoration performance, and capable of providing the protection life of 20 a or above of the steel component which the steel component is worked in a special harsh corrosion environment such as a heavy-pollution chemical environment, a marine tidal zone and the like, the economic loss caused by frequent maintenance in the fields of a chemical plant, marine engineering and the like is avoided, and the accident risk and abnormal shutdown loss caused by corrosion of equipment or the engineering are avoided.

Owner:上海岐海防腐工程技术有限公司

Non-woven fabric coating process with effect of effectively increasing adhesive force

The invention discloses a non-woven fabric coating process with an effect of effectively increasing adhesive force. The non-woven fabric coating process includes steps of 1), preparing adhesive powder, and to be more specific, selecting ethylene-vinyl acetate copolymer adhesive powder particles with the particle sizes of 290-320 nm and the weight proportions higher than 80%; 2), preparing resin solution, to be more specific, acquiring 20 parts of acrylic resin with the glass transition temperature Tg point lower than -35 Celsius degrees, sequentially adding 0.5 part of ammonia water and 79.5 part of water into the acrylic resin and uniformly mixing the ammonia water, the water and the acrylic resin with one another to obtain the resin solution; 3), acquiring non-woven fabrics, and uniformly attaching 14g / m<2> of resin solution on the non-woven fabrics; 4), uniformly sprinkling the adhesive powder particles on the surfaces with the attached resin solution. The non-woven fabric coating process has the advantage that the adhesive force of the non-woven fabrics of linings can be greatly increased, can reach 0.53 mgf, is greatly superior to adhesive force, which is 0.30 mgf, of generallinings, and can be enhanced by nearly 77%.

Owner:KUSN SHENGYU NON WOVEN FABRICS

Heave duty anticorrosion sealing wrapping maintenance method for surface of steel component

The invention discloses a heave duty anticorrosion sealing wrapping maintenance method for the surface of a steel component. an originally invalided corrosion prevention material of a substrate is clear away firstly, the surface rust and other pollutants are cleaned, the surface cleanliness reaches an Sa2 level or the same degree, then a quick-drying type zinc-rich silane modified polymer sealantis brushed or scraped, brush coating or scrape coating of a vulcanized silicon-rich silane modified polymer sealant is carried out, and finally scrape coating of a PVF adhesive tape is carried out. The method has the advantages of low surface treatment, corrosion and corrosion resistance sealing, and has the comprehensive characteristics of heat resistance, weather resistance and pollution resistance, on-site operation is simple, fast, efficient, free of dead corners, good in sealing and wrapping appearance decoration performance, and capable of providing the protection life of 20 a or above of the steel component which the steel component is worked in a special harsh corrosion environment such as a heavy-pollution chemical environment, a marine tidal zone and the like, the economic loss caused by frequent maintenance in the fields of a chemical plant, marine engineering and the like is avoided, and the accident risk and abnormal shutdown loss caused by corrosion of equipment or the engineering are avoided.

Owner:上海岐海防腐工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com