OLED device containing light extraction film adhesion promotion layer

A technology of adhesion promotion layer and light extraction film, which is applied in the field of OLED devices, can solve problems such as difficulty in finding a balance between hardness and adhesion, deterioration of light extraction film hardness, and influence of light extraction efficiency, etc., to achieve mass production, The effect of low cost and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of OLED device without adhesion promotion layer of light extraction film

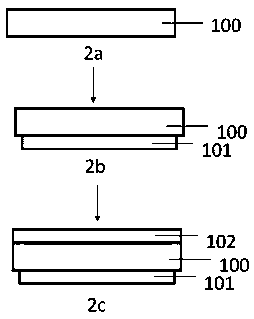

[0038] The preparation method of the OLED device without the adhesion promotion layer of the light extraction film includes the following steps: (see figure 2 )

[0039] Step 1. The cleaning machine cleans the 370mmX470mm alkali-free glass substrate 100, removes the surface oil and particle impurities, and removes water, see figure 2 a;

[0040] Step 2. Prepare bottom-emitting OLED device 101 by evaporation method, and the emitted light is emitted from the surface of the substrate (light-emitting surface) without OLED device, see figure 2 b;

[0041] Step 3: Spin-coating a spin-coating solution containing zirconia, titanium oxide scattering particles and high molecular polymer on the light-emitting surface of the glass substrate 100, and spraying a spraying solution containing acrylate and epoxy resin after UV curing, and then UV curing again Obtain the light extraction film 102,...

Embodiment 2

[0043] Example 2 Preparation of OLED device containing light extraction film adhesion promotion layer

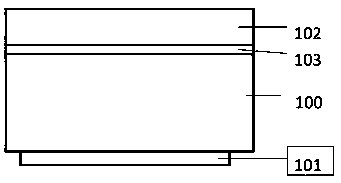

[0044] The OLED device of the present invention containing a light extraction film adhesion promoting layer, such as figure 1 As shown, contains:

[0045] a) Glass substrate (100);

[0046] b) An OLED device (101) made on a glass substrate, which is a bottom-emitting device, and the light emitted is injected into the air through the glass substrate;

[0047] c) The light extraction film (102) provided on the side of the glass substrate without the OLED device;

[0048] d) An adhesion promoting layer (103) provided between the light extraction film (102) and the glass substrate (100).

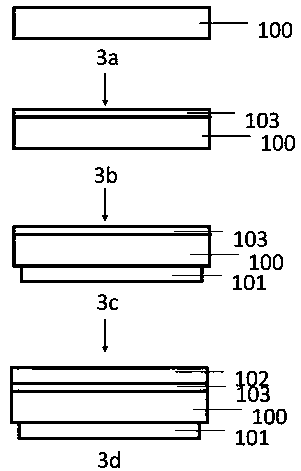

[0049] The preparation method of the OLED device of the present invention includes the following steps (see image 3 ):

[0050] Step 1. The cleaning machine cleans the 370mmX470mm alkali-free glass substrate 100, removes the surface oil and particle impurities, and removes water, see image 3 a;

[0051...

Embodiment 3

[0055] Example 3 Preparation of OLED device containing light extraction film adhesion promotion layer

[0056] The OLED device of the present invention containing a light extraction film adhesion promoting layer, such as figure 1 As shown, contains:

[0057] a) Glass substrate (100);

[0058] b) An OLED device (101) made on a glass substrate, which is a bottom-emitting device, and the light emitted is injected into the air through the glass substrate;

[0059] c) The light extraction film (102) provided on the side of the glass substrate without the OLED device;

[0060] d) An adhesion promoting layer (103) provided between the light extraction film (102) and the glass substrate (100).

[0061] The preparation method of the OLED device of the present invention includes the following steps (see image 3 ):

[0062] Step 1. The cleaning machine cleans the 370mmX470mm alkali-free glass substrate 100, removes the oil stains and particulate impurities on the surface, and removes water, see i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com