Preparation method of polyaniline modified graphene oxide/hydroxylated boron nitride composite epoxy coating

A kind of oxide stone, polyaniline technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor solubility and processability, and achieve improved corrosion resistance, excellent anti-corrosion performance, and good anti-corrosion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

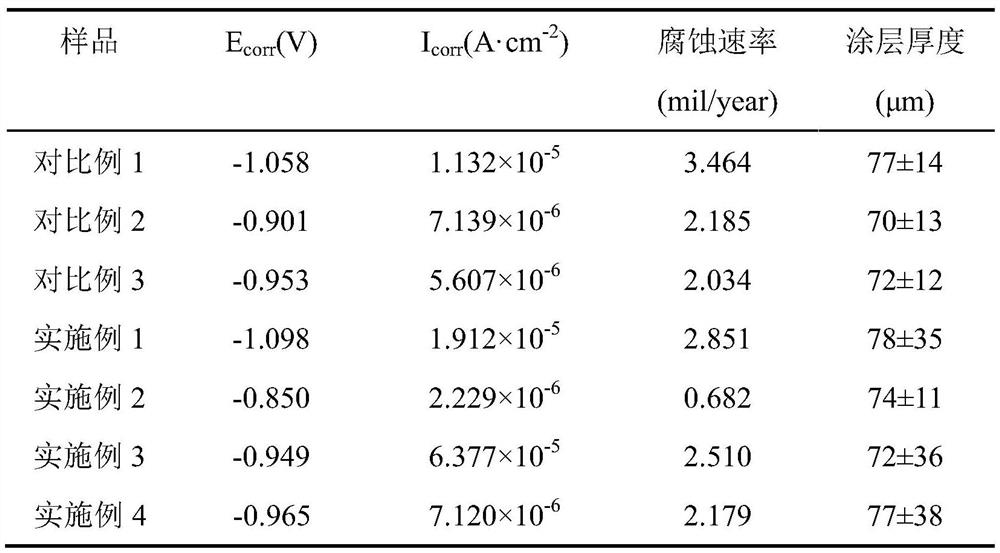

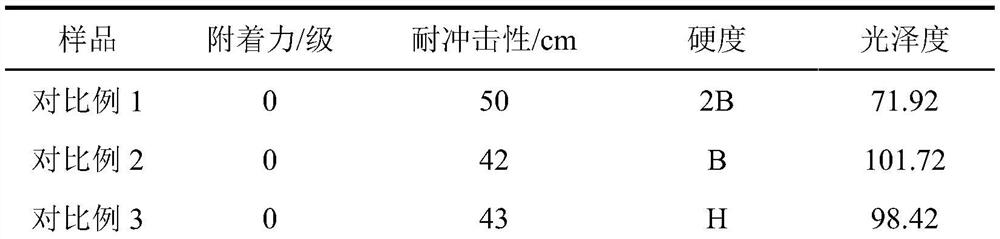

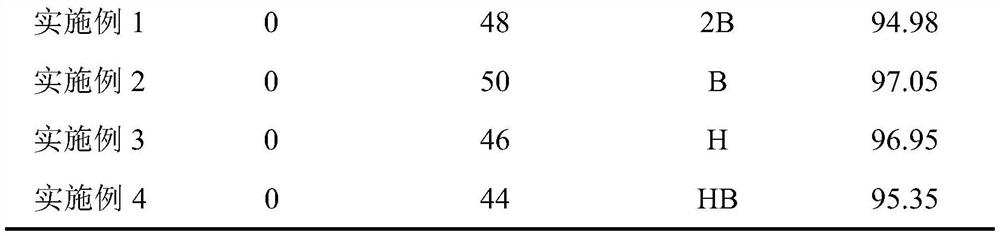

Examples

Embodiment 1

[0025] (1) 100 g of thionyl chloride and 2.5 g of graphene oxide were weighed and placed in a three-necked flask, and the mixed solution was ultrasonically treated to prepare a uniform dispersion. After refluxing for 24 hours under the protection of nitrogen, add an appropriate amount of toluene and distill under reduced pressure for 3 times to obtain graphene acid chloride. Dissolve the obtained solid acyl chloride graphene in an appropriate amount of toluene and disperse evenly, add 4g of p-phenylenediamine, reflux for 12 hours under nitrogen protection, add an appropriate amount of organic solvent and distill under reduced pressure for 3 times, centrifuge and freeze-dry to obtain amino-modified graphite oxide ene (rGO-NH 2 )powder.

[0026] (2) Weigh 2.5g rGO-NH 2 The powder and 2g of aniline were added to the hydrochloric acid solution, the ultrasonic power was set to 700W, and the ultrasonic time was 60min, and the solution was ultrasonically dispersed to a uniform disp...

Embodiment 2

[0033] (1) 120 g of thionyl chloride and 1.25 g of graphene oxide were weighed and placed in a three-necked flask, and the mixed solution was ultrasonically treated to prepare a uniform dispersion. After refluxing for 24 hours under the protection of nitrogen, add an appropriate amount of toluene and distill under reduced pressure for 3 times to obtain graphene acid chloride. Dissolve the obtained solid acyl chloride graphene in an appropriate amount of toluene and disperse evenly, add 5g of p-phenylenediamine, reflux for 12 hours under the protection of nitrogen, add an appropriate amount of organic solvent and distill under reduced pressure for 3 times, centrifuge and freeze-dry to obtain amino-modified graphite oxide ene (rGO-NH 2 )powder.

[0034] (2) Weigh 1.25g rGO-NH 2 The powder and 1g of aniline were added to the hydrochloric acid solution, the ultrasonic power was set to 800W, and the ultrasonic time was 50min, and the solution was ultrasonically dispersed to a uni...

Embodiment 3

[0041] (1) 80 g of thionyl chloride and 0.5 g of graphene oxide were weighed and placed in a three-necked flask, and the mixed solution was ultrasonically treated to prepare a uniform dispersion. After refluxing for 24 hours under the protection of nitrogen, add an appropriate amount of toluene and distill under reduced pressure for 3 times to obtain graphene acid chloride. Dissolve the obtained solid acyl chloride graphene in an appropriate amount of toluene and disperse evenly, add 2g of p-phenylenediamine, reflux for 12 hours under nitrogen protection, add an appropriate amount of organic solvent and distill under reduced pressure for 3 times, centrifuge and freeze-dry to obtain amino-modified graphite oxide ene (rGO-NH 2 )powder.

[0042] (2) Weigh 0.5rGO-NH 2 The powder and 2.5g of aniline were added to the hydrochloric acid solution, the ultrasonic power was set to 600W, and the ultrasonic time was 30min, and the solution was ultrasonically dispersed until it was unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com