Heave duty anticorrosion sealing wrapping maintenance method for surface of steel component

A steel component and heavy-duty anti-corrosion technology, which is applied in the field of heavy-duty anti-corrosion sealing and wrapping protection on the surface of steel components, and in the field of steel structure surface corrosion protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0068] Processing and preparation of quick-drying zinc-rich silane-modified polymer sealant, the raw material composition and weight parts of the quick-dry zinc-rich silane-modified polymer sealant in Example 1-2 are shown in Table 1, wherein SAX510 is Japanese Kanka Sanjia Oxygen-terminated silane-modified polymer resins, STP and SPUR trimethoxy-terminated silane-modified polymer resins are alkaline resins with a pH value, and the amount of basic additives can be reduced accordingly.

[0069] Table 1 Example 1-Example 2 The composition of each raw material and parts by weight Unit: parts by weight

[0070]

[0071] Weigh each raw material according to the weight part of the material in Table 1, first use the connection N 2 The pipeline of the storage device is slowly and continuously filled with clean and dry N into the clean and dry double planetary mixer tank 2 , then first put the non-alcoholic plasticizer into it, then add highly active silane-modified polymer resin, ...

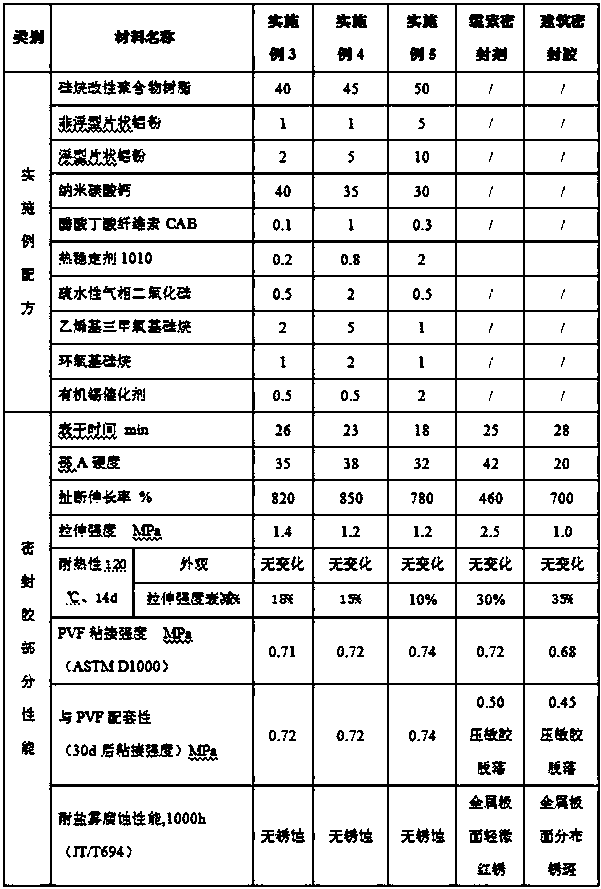

Embodiment 3-5

[0077] Preparation of vulcanized aluminum-rich silane-modified polymer sealant. See Table 3 for the raw material composition and parts by weight of the vulcanized aluminum-rich silane-modified polymer sealant in Examples 3-5.

[0078] Table 3 The composition and parts by weight of each material in Embodiment 3-5 Unit: parts by weight

[0079]

[0080] Weigh each material according to the weight of vulcanized aluminum-rich silane-modified polymer sealant materials in Table 3, first put the silane-modified polymer resin into a clean and dry double planetary mixer, and then add hydrophobic fumed silica, Nano-calcium carbonate, cellulose acetate butyrate, heat stabilizer 1010, 50-70% by weight of vinyltrimethoxysilane, vacuumize and stir and disperse at a speed of 50-100rpm for 10-30min; then gradually heat to 50- 70°C, stir at a high speed of 1000-1500rpm for 30-90min, until the sealant paste is fine and uniform, then cool it down to below 40°C; then add non-leafing flake alum...

Embodiment 6

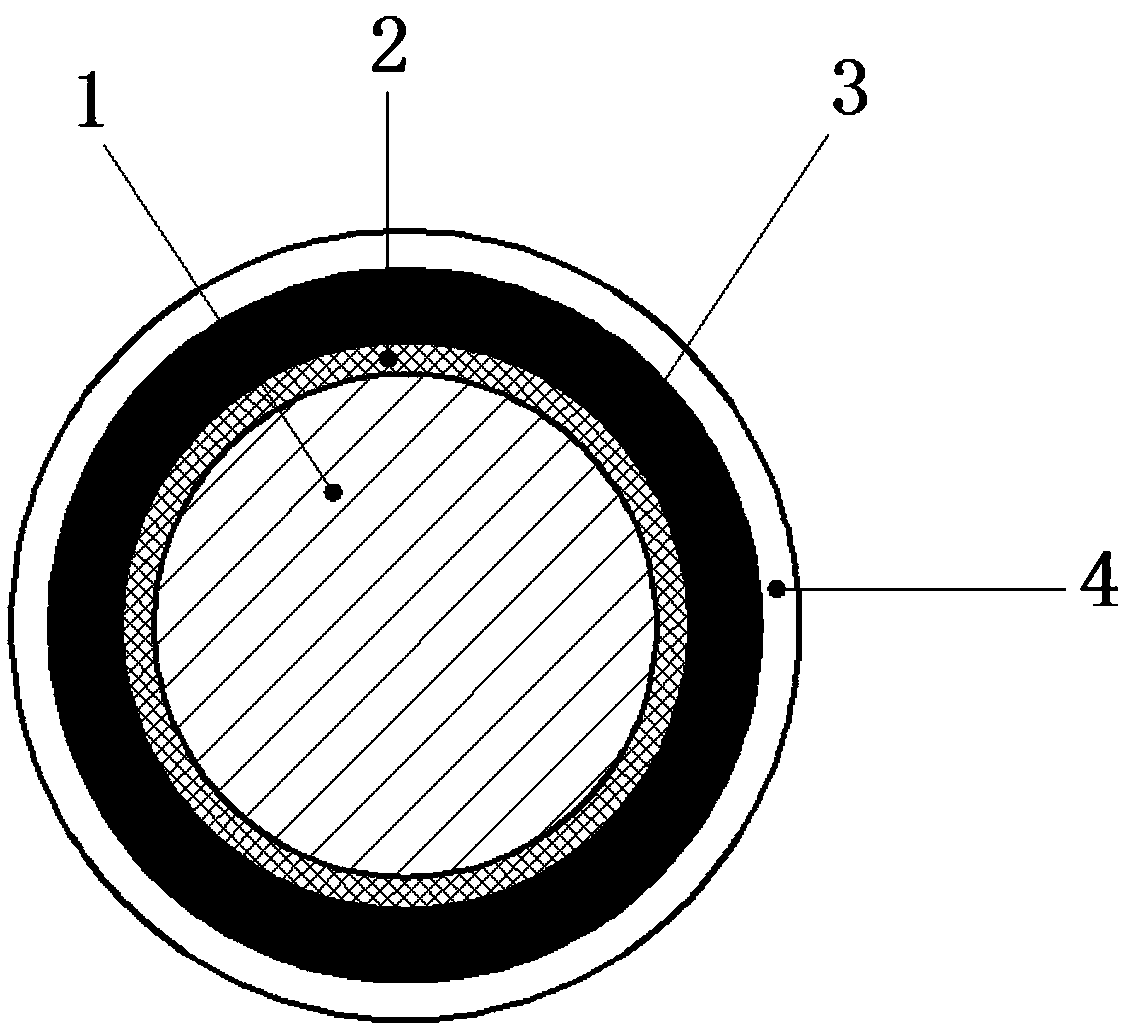

[0083] Such as figure 1 As shown, the surface heavy-duty anti-corrosion seal wrapping maintenance method of steel components in a petrochemical plant, the specific steps are as follows:

[0084] The first step substrate treatment

[0085] Firstly, remove the heavy-duty anti-corrosion coating of the steel component base 1 that has failed, peeled off, etc., and manually polish and clean the rust and other pollutants on the surface, so that the surface cleanliness reaches St3 level.

[0086] The second step is to prepare the inner sealing protective layer

[0087] After the surface of the substrate is cleaned and dried, immediately apply a layer of fast-drying zinc-rich silane modified polymer sealant in Example 1, and fill and scrape the corrosion pits, defects, and rough surfaces on the surface of the steel component substrate 1 caused by corrosion to form The inner sealing protective layer 2 has an average thickness of about 0.1-0.5 mm.

[0088] The third step is to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com