Patents

Literature

138results about How to "Guaranteed spinnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

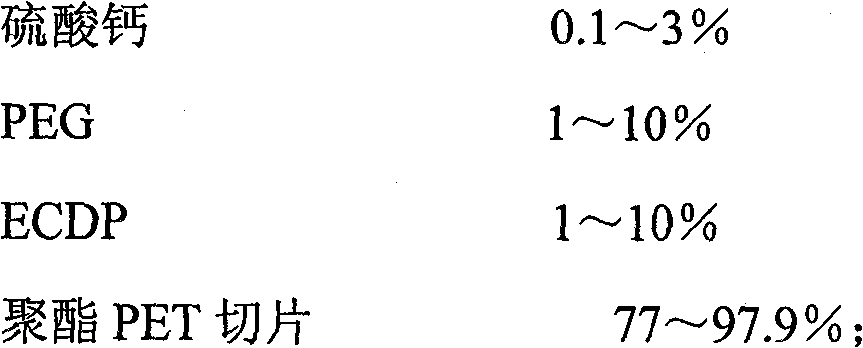

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Sheath-core bicomponent fiber and functions thereof

InactiveCN102108565AMoisture absorption and quick dryingGuaranteed spinnabilityConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a sheath-core bicomponent fiber and functions thereof. The composition of the fiber is a polymer, and the composition of a sheath is the mixture of polymer and alkali soluble polyester, the compound ratio of a sheath core is 10 / 90-30 / 70, and alkali-soluble pet in the sheath composition accounts for 5-25wt% of the total weight of the fiber. After being made into textures, the sheath-core bicomponent fiber is subjected to weight reduction treatment and endowed with the performances of moisture absorption and fast drying, so that textiles with the performances of moisture absorption and fast drying can be produced; and the wicking height of the fiber is as high as 75-125mm, and the evaporation rate of water is 75-95%.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

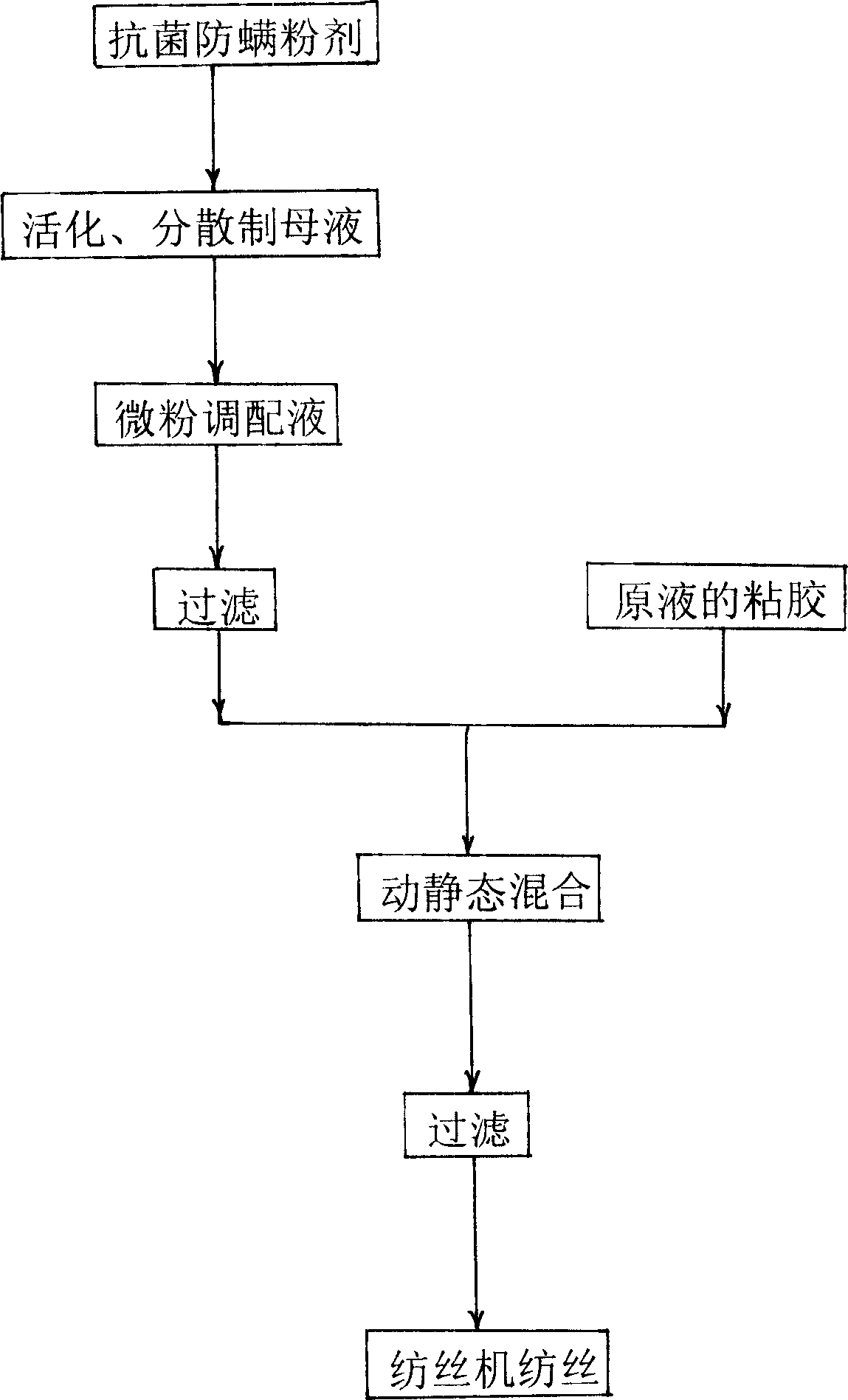

Antibacterial mite-resistant cellulose viscose and its making method

InactiveCN1995498AIncrease functional valueChange a single functionFilament/thread formingArtificial filaments from viscoseCelluloseHuman health

The invention discloses an antibacterial anti-mite viscose fiber and the manufacturing method. The fiber is characterized in that after antibacterial anti-mite solution is mixed with the viscose solution with the proportion of 0.1-2%, the spinning is run; and antibacterial anti-mite viscose fiber product with 30 of the number of monofilament, 0% of the deviation of the number of monofilament, 6. 3mg / 100g of residue, 0.4% of oil percentage, 3. 5 grade of dyeing evenness, and 99. 6% of anti-mite ratio is obtained. The manufacturing method comprises preparing antibacterial anti-mite mother solution, preparing antibacterial anti-mite matching solution, rubbing and filtering the antibacterial anti-mite matching solution, mixing with the viscose, and filtering. The invention is benefit for human health and can improve the performance and added value of viscose fiber effectively. It is favor of environmental protection.

Owner:YIBIN GRACE

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

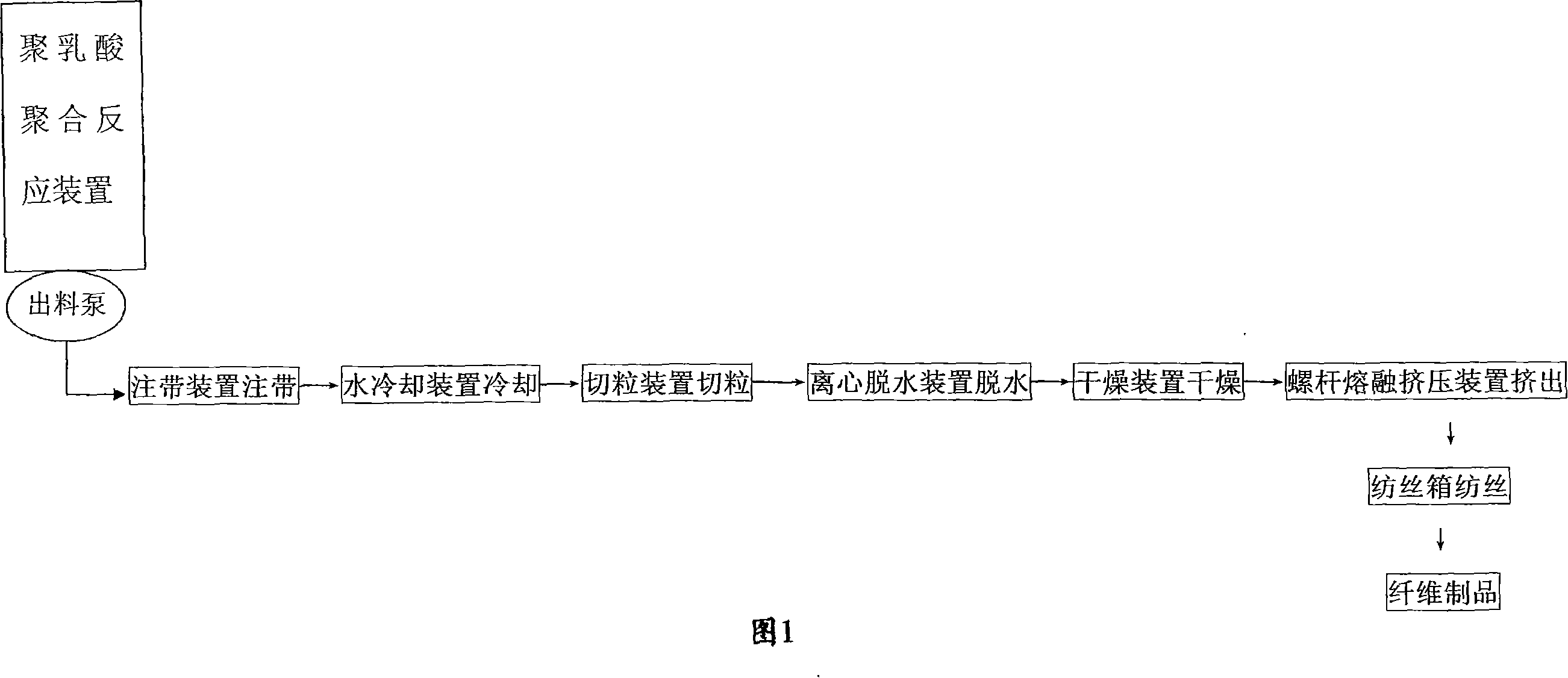

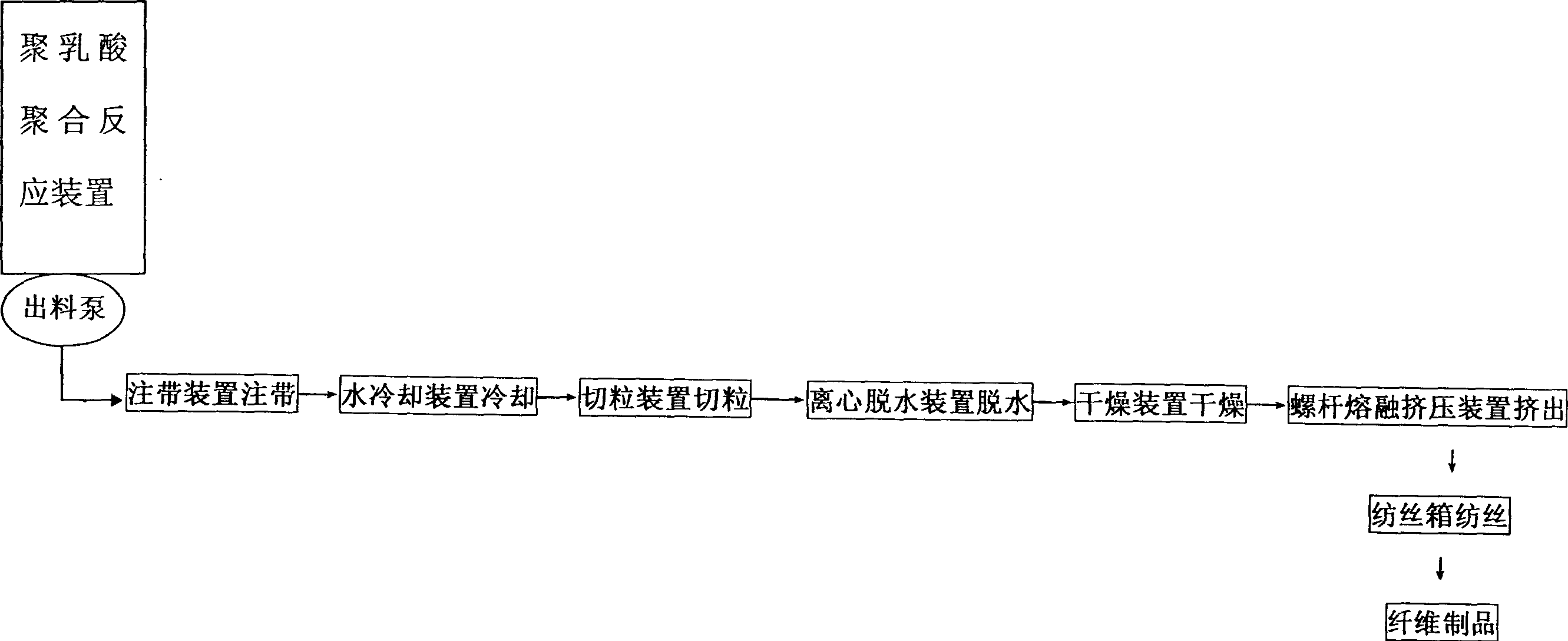

Method for direct preparation of fiber product from polylactic acid polymerized melt

ActiveCN101086089AGuaranteed qualityLow costMelt spinning methodsNon-woven fabricsFiberPositive pressure

A directive preparing method of fiber products through polylactic acid polymeric welding flux belongs to high polymer materials application technology. It heats the polylactic acid polymeric welding flux which is prepared through the polymerization reaction in the polylactic acid polymerization reaction device by means of a welding flux conveyer which is connected between the discharge port of termination device discharge pump of polylactic acid polymerization reaction device and the feeding inlet of spinning runk, and guides the polylactic acid polymeric welding flux into spinning runk in positive pressure and thermal insulation state, then the spinning runk spins the guided polylactic acid polymeric welding flux and prepares fabric products. The advantages are: it avoids the impact of spinning performance caused by dry, it ensures spinning performance and also ensures the quality of fiber products; the polylactic acid polymeric welding flux is guided into spinning runk to spin from discharge pump and through welding flux conveyer, so the technology process is very simple and easy, the equipment investment is less; due to no granulating, dewatering, drying, screw bolt squeezing and melting, energy consumption can be saved more than one third, it is useful for reducing the cost of fiber products.

Owner:李振华

Preparation method of polyacrylonitrile-based precursor

ActiveCN105671668AGuaranteed filtering effectNot easy to blockMonocomponent synthetic polymer artificial filamentWet spinning methodsSolventItaconic acid

The present invention relates to a preparation method of a polyacrylonitrile-based precursor, and mainly solves the problems that in the prior art bubbles in a material sprayed out by a filter cannot be completely eliminated, spinnability is poor, wire broken rate is high, and a carbon fiber precursor obtained by spinning is low in strength and unstable in performance. The preparation method well solves the problems, and the preparation method includes the following steps: 1) solvent dimethyl sulfoxide, first monomer acrylonitrile, a second monomer itaconic acid and initiator azodiisobutyronitrile are polymerized to obtain a spinning stock solution, and a high performance polyacrylonitrile copolymer spinning stock solution is obtained by filtering after demonomerisation and defoaming of the spinning stock solution; nascent fiber is obtained by jet extrusion and consolidation forming; and a high-performance polyacrylonitrile carbon fiber precursor is obtained by drawing, water washing, oiling, compacting by drying, steam stretching, heat-setting and collection of the nascent fiber; and the method can be used for the industrial production of the carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Photochromic viscose fiber and preparation method thereof

ActiveCN104357936AProtect strong baseProtect from strong acidsArtificial filaments from viscoseEmulsionColor changes

The invention relates to a photochromic viscose fiber and a preparation method thereof, belonging to the technical field of textile. The photochromic viscose fiber is prepared from an adhesive, photochromic microcapsules and a fiber reinforced agent, wherein the content of the photochromic microcapsules is 1-20wt%, and the content of the fiber reinforced agent is 0.1-10wt%. The preparation method of the photochromic viscose fiber comprises the following steps: (1) dissolving the photochromic microcapsules and the fiber reinforced agent into water to form dispersed viscose emulsion; (2) feeding the dispersed viscose emulsion into viscose to be spun, and mixing; (3) molding by spinning in an acid bath to obtain a photochromic viscose fiber product. The photochromic viscose fiber is simple and reasonable in components and simple in preparation method; the obtained fiber is uniform in whole color change; the strength of the photochromic viscose fiber reaches or exceeds that of the conventional viscose fiber, so that the demand of fabric manufacture can be met.

Owner:XINXIANG CHEM FIBER

Polyvinylidene fluoride piezoelectric non-woven fabric, and preparing method and application thereof

InactiveCN103469485AGuaranteed spinnabilityGet rid of time constraintsNon-woven fabricsSpinning solutions preparationElectrospinningOperability

The invention discloses a polyvinylidene fluoride piezoelectric non-woven fabric, and a preparing method and application thereof. The method includes 1, dissolving polyvinylidene fluoride in common electrospinning solvent, and obtaining polyvinylidene fluoride solvent; 2, allowing the polyvinylidene fluoride solvent to stand to form gel solid, performing special heating processing on the gel solid, and cooling to obtain polyvinylidene fluoride electrospinning solvent; 3, optimizing process parameters of electrospinning, utilizing the polyvinylidene fluoride electrospinning solvent prepared in step 2 to electrospin through an electrospinning machine, soaking the obtained product into deionized water, and then taking out and drying to obtain nano piezoelectric non-woven fabric with fine piezoelectric property. The preparing method is simple in operation, maintaining time of the polyvinylidene fluoride electrospinning solvent is prolonged, operability of the polyvinylidene fluoride electrospinning is improved, development of researching polyvinylidene fluoride electrospinning can be promoted, and the new method is provided for preparing the piezoelectric non-woven fabric.

Owner:SOUTH CHINA UNIV OF TECH

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

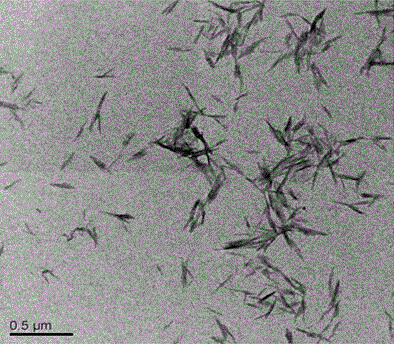

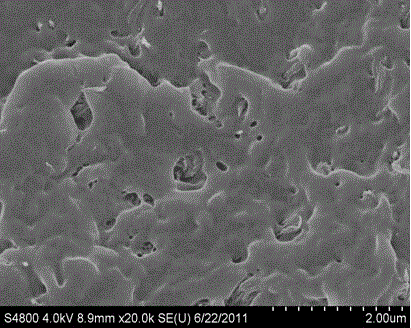

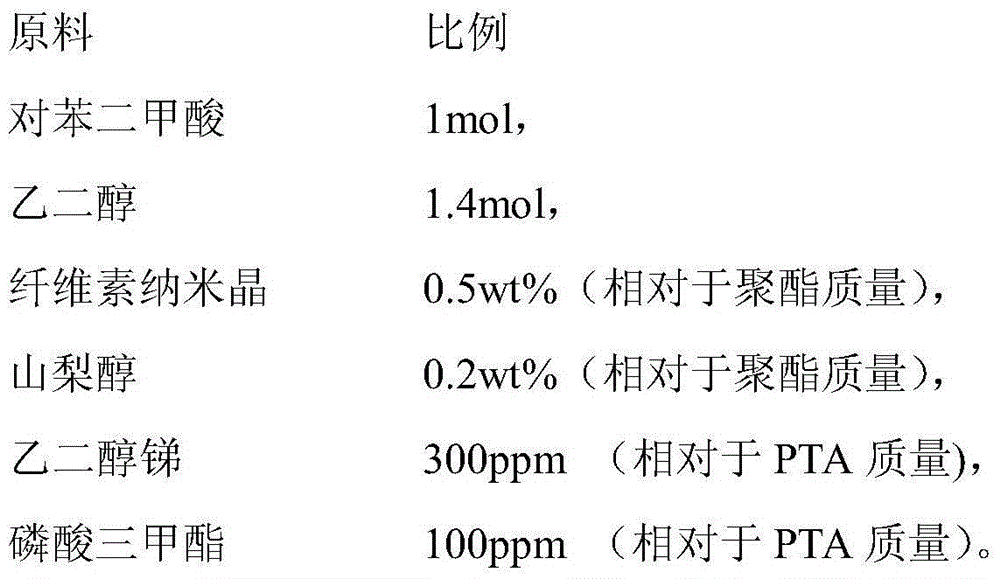

Hydrophilic polyester fiber modified by cellulose nanocrystal and preparation method thereof

ActiveCN104404647AImprove accessibilityGood dispersionMonocomponent polyesters artificial filamentArtifical filament manufactureCelluloseAlcohol

The invention relates to a hydrophilic polyester fiber modified by cellulose nanocrystal and a preparation method thereof and aims to solve a problem of a poor hydrophilicity of conventional polyester. The preparation method includes following steps: (1) mixing a cellulose nanocrystal aqueous suspension liquid and 75-85% by weight of ethylene glycol and removing water from a mixed liquid to prepare an ethylene glycol suspension liquid of the cellulose nanocrystal; (2) preparing a mixed slurry liquid from the ethylene glycol suspension liquid of the cellulose nanocrystal and terephthalic acid; (3) preparing a catalyst liquid form the balanced ethylene glycol and a catalyst; (4) mixing the mixed slurry liquid, the catalyst liquid and a thermal stabilizing agent, and performing a first esterification reaction in a reaction kettle with stirring and heating; (5) performing a secondary esterification reaction with addition of a polyhydroxy-alcohol; (6) performing vacuumizing condensation polymerization to obtain a hydrophilic polyester melt, and cooling and pelleting the melt to obtain a hydrophilic polyester chip; and (7) performing melt spinning to the hydrophilic polyester chip to prepare the hydrophilic polyester fiber.

Owner:嘉兴逸鹏化纤有限公司

Preparation method of flame retardation spandex fibers

ActiveCN105420844AHigh fastnessImprove flame retardant performanceFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolymer solution

The invention relates to a preparation method of flame retardation spandex fibers. The method comprises the following steps: 1, reacting polyether glycol with diisocyanate in a DMAC (dimethyl acetamide) solution according to a molar ratio of polyether glycol to diisocyanate of 1:1.55-1:2.15 to prepare a prepolymer, and carrying out a chain extension reaction on the prepolymer and a mixed amine chain extender to prepare a polyurethane polymer solution with the viscosity meeting spinning requirements; and 2, adding a phenylphosphonate halogen-free phosphorus flame retardant, a nonmetal oxide synergistic flame retardant, a dyeing assistant and other assistants to the polyurethane polymer solution, mixing until uniformity, slaking the obtained solution, and spinning the slaked solution. Compared with fibers in the prior art, the fibers obtained in the invention have the advantages of environmental protection, good spinnability, no influences of the halogen-free phosphorus flame retardant on the performances of spandex, no introduction of other metal ions by the synergistic flame retardant, and meeting of Oeko-Tex100 standards.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

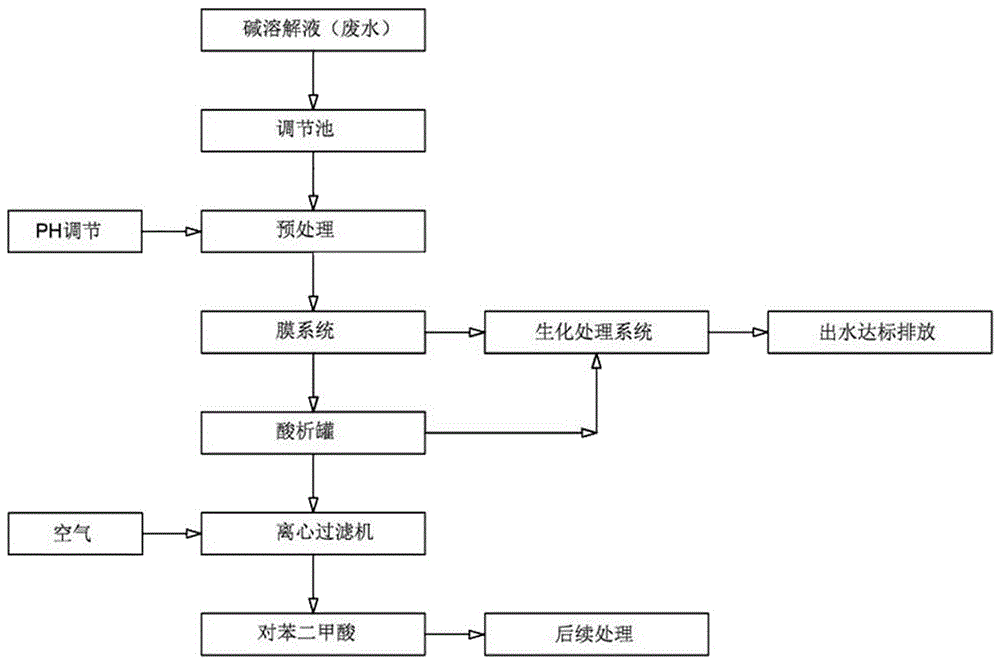

Soluble textile recovery, regeneration and recycle technology

InactiveCN106065085AGuaranteed spinnabilityGuaranteed rendering effectProductsReagentsSolubilityTextile fiber

The invention discloses a soluble textile recovery, regeneration and recycle technology. According to the technology, polyester-type solubility-controllable soluble fibers are woven through a conventional weaving method, the obtained fabric is dyed and finished and then is subjected to tailoring to obtain ready-made clothes or is subjected to injection molding processing to obtain a soluble cloth accessory, the ready-made clothes or the soluble cloth accessory is dissolved under a certain condition, the solution is filtered, the dissolved matters are recovered so that high purity terephthalic acid and glycol are obtained, the terephthalic acid and glycol are used for soluble polyester polymerization so that soluble polyester slices are obtained, the soluble polyester slices can be re-spun to form soluble fibers for recycle, a loose undissolved textile is disinfected, stripped or re-dyed to form a loose fiber polymer with good quality, the loose fiber polymer is dried and optionally, the dried fiber polymer is subjected to gentle carding so that high-quality textile fibers are obtained for recycle.

Owner:余燕平 +3

Anti-ultraviolet bamboo charcoalviscose fiber and preparation method thereof

ActiveCN103556252AGood antibacterial effectGood deodorizing functionArtificial thread manufacturing machinesArtificial filaments from viscoseBamboo charcoalViscose fiber

The invention provides an anti-ultraviolet bamboo charcoalviscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoalviscose fiber is poor in spinning property. The anti-ultraviolet bamboo charcoalviscose fiber is characterized by being obtained by mixing an anti-ultraviolet bamboo charcoal solution with mucilage glue through spinning before injection, and carrying out wet spinning and post-treatment, wherein the anti-ultraviolet bamboo charcoal solution is formed by mixing an anti-ultraviolet masterbatches and a bamboo charcoal solution; the anti-ultraviolet masterbatches contain an anti-ultraviolet agent. The fiber comprises the components by weight percent: 0.01-10 percent of the anti-ultraviolet agents and 0.1-10 percent of bamboo charcoal; the ultraviolet shielding rate is more than or equal to 95 percent, the ammonia absorption rate is more than or equal to 50 percent, and the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The anti-ultraviolet bamboo charcoalviscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the anti-ultraviolet effect of the anti-ultraviolet bamboo charcoalviscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

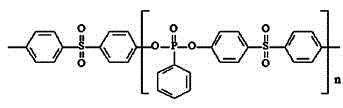

Preparation method of cationic dyeable polyester fiber

ActiveCN107604463AReduce pressure riseLess impuritiesFilament/thread formingMonocomponent polyesters artificial filamentPressure risePolymer science

The invention relates to a preparation method of cationic dyeable polyester fiber, first, dimethyl isophthalate-5-benzenesulfonate sodium, ethylene glycol and a catalyst are mixed for ester exchange reaction, after completion of the reaction, ethylene glycol, a complex ion regulator and sulfuric acid are added for adjusting, terephthalic acid, ethylene glycol, a catalyst and a flatting agent are mixed for esterification reaction, a product obtained by adjusting after the ester exchange reaction is added into the reaction system with esterification reaction end point is reached for polycondensation to obtain spinning melt, and finally the cationic dyeable polyester fiber is obtained by metering, extrusion, cooling, oiling, stretching, heat setting and winding of the spinning melt. The method reduces the production of impurities in the fiber production process, thereby reducing the pressure rise of a spinning assembly and a filter, prolonging the service life, reducing the production cost and ensuring the continuity and safety of the whole production process, and the method has good economic value and popularization value.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

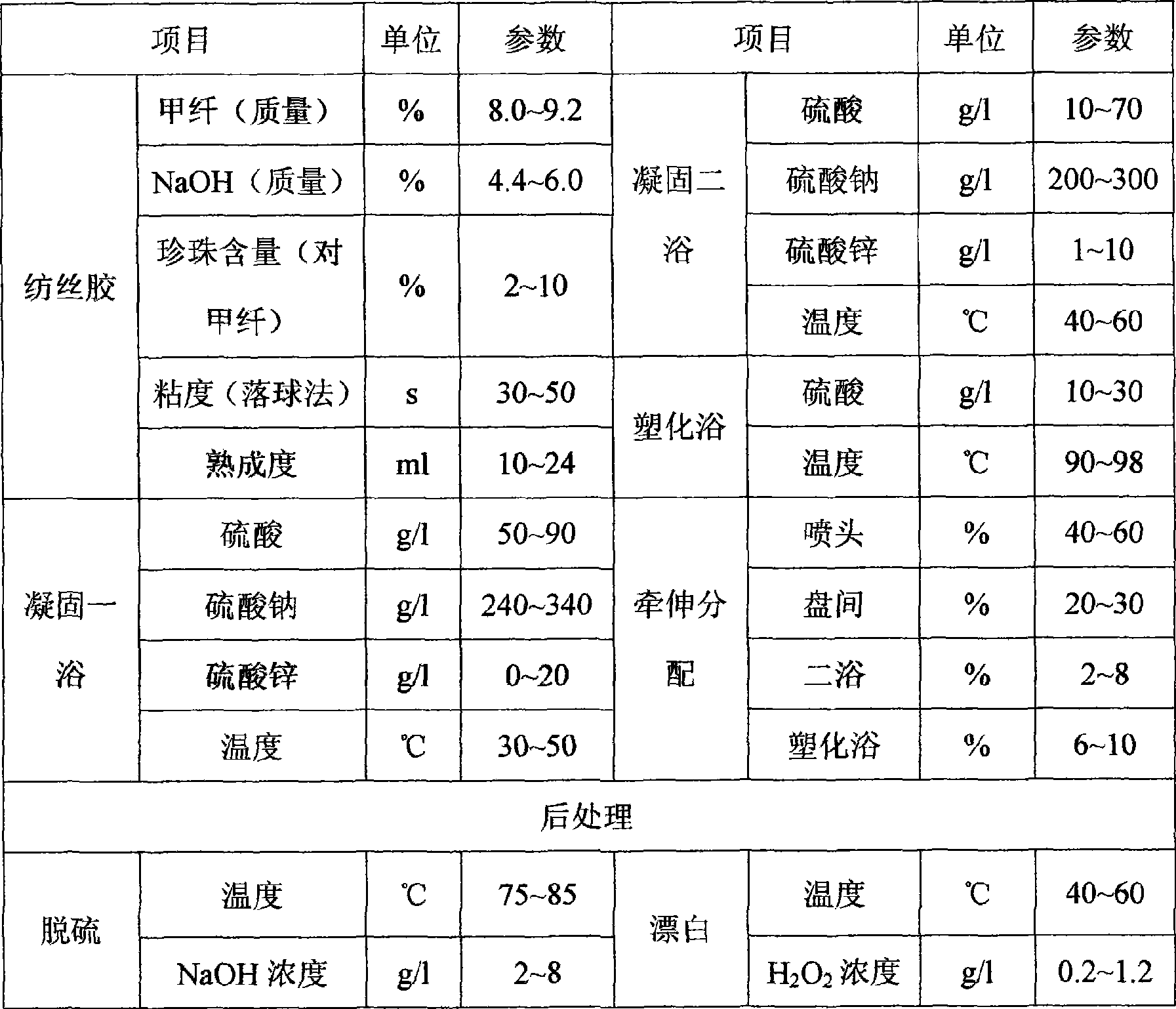

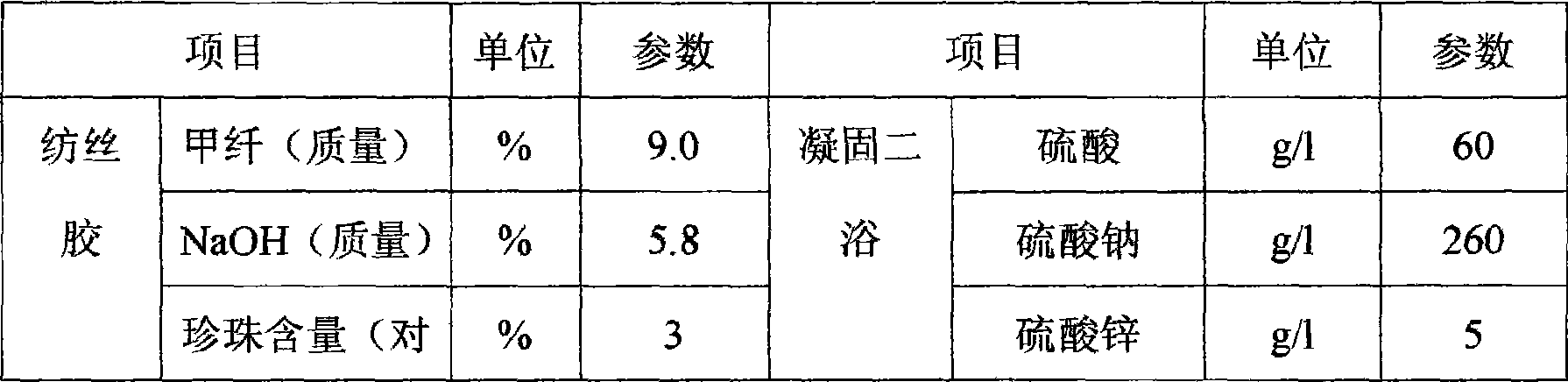

Pearl regenerated cellulose fiber and preparation method thereof

InactiveCN101532184AGuaranteed spinnabilityReduce churnMonocomponent cellulose artificial filamentArtifical filament manufactureEmulsionRegenerated cellulose

The invention discloses pearl regenerated cellulose fiber and a preparation method thereof. The pearl regenerated cellulose fiber is prepared by adding a pearl emulsion containing pearl micropowder into soluble glue during the preparation of spinning glue, evenly mixing the mixture, and then performing filtration, defoaming and spinning working procedures, wherein two-bath spinning, plasticizing bath drawing molding and multi-stage drawing molding processes are adopted during the spinning, the pearl content in the fiber is 2 to 10 percent of the mass of alphacellulose, the total mass content of amino acid in the fiber is more than or equal to 0.02 percent, and the fiber contains more than or equal to 12 kinds of trace elements. The production method ensures the even distribution of the pearl micropowder in the spinning glue, can also remove a trace amount of pearl micropowder with large particle size through the filtration, and ensures the spinnability of the prepared fiber; and the mild two-bath spinning, plasticizing bath molding and multi-stage drawing molding processes reduce the loss of the pearl micropowder and ensure the effective content of the pearl micropowder in the fiber.

Owner:CHTC HELON

Preparing method for ordinary-pressure positive-ion dyeable polyester fiber

ActiveCN107541803ALess impuritiesReduce pressure riseMonocomponent polyetheresters artificial filamentMelt spinning methodsPressure risePolyethylene glycol

The invention relates to a preparing method for an ordinary-pressure positive-ion dyeable polyester fiber. The preparing method includes the steps that dimethyl isophthalate-5-sodium benzenesulfonate,ethylene glycol, a catalyst and an anti-ether agent are mixed to be subjected to an ester exchange reaction, the reaction is end, then ethylene glycol and sodium ethylene glycol are added, modulationis carried out, then terephthalic acid, ethylene glycol and a catalyst are mixed, and the mixture is subjected to an esterification reaction; the modulated product after the ester exchange reaction is end and polyethylene glycol are added into an esterification reaction system reaching the end point of the esterification reaction, condensation polymerization is carried out, and spinning melt is obtained; the spinning melt is measured, extruded, cooled, subjected to oil applying, stretched, subjected to heat setting and wound, and the ordinary-pressure positive-ion dyeable polyester fiber is prepared. According to preparing method, generation of impurities in the polyester-fiber production process is reduced, pressure rising of a spinning assembly and a filter is reduced accordingly, the service cycle of the polyester fiber is prolonged, the continuity and the safety of the whole production process are guaranteed, and the preparing method has the good economic value and popularizationvalue.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Preparation method of heat-sensitive copolyester fiber

ActiveCN108660537AReduce consumptionReduce self-condensation side reactionsMonocomponent polyetheresters artificial filamentMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to a preparation method of a heat-sensitive copolyester fiber. The preparation method comprises the following steps: mixing terephthalic acid, aliphatic diol I, a guide and a titanium-silicon-cobalt composite catalyst uniformly, then subjecting the mixture to an esterification reaction, a pre-polycondensation reaction and a final polycondensation in sequence to obtain heat-sensitive copolyester, and then preparing the heat-sensitive copolyester fiber by melt direct spinning; the aliphatic diol I is propylene glycol or butylene glycol; the guide is an ester compound generated by a reaction between dibasic acid and aliphatic diol II; the molar ratio of the terephthalic acid to the aliphatic diol I is 1:(1.05-1.10); the titanium-silicon-cobalt composite catalyst is formed by compounding a titanium-silicon composite catalyst and a cobalt catalyst; the titanium-silicon composite catalyst is obtained by loading a titanium-based catalyst with a silicon-based catalyst; and polysiloxane and a copolymerization component are added during the final polycondensation reaction. The preparation method provide by the invention is few in side reactions and high in reaction rate; an obtained product is concentrated in molecular weight distribution and good in quality; and the fiber is prepared with the melt direct spinning.

Owner:DONGHUA UNIV

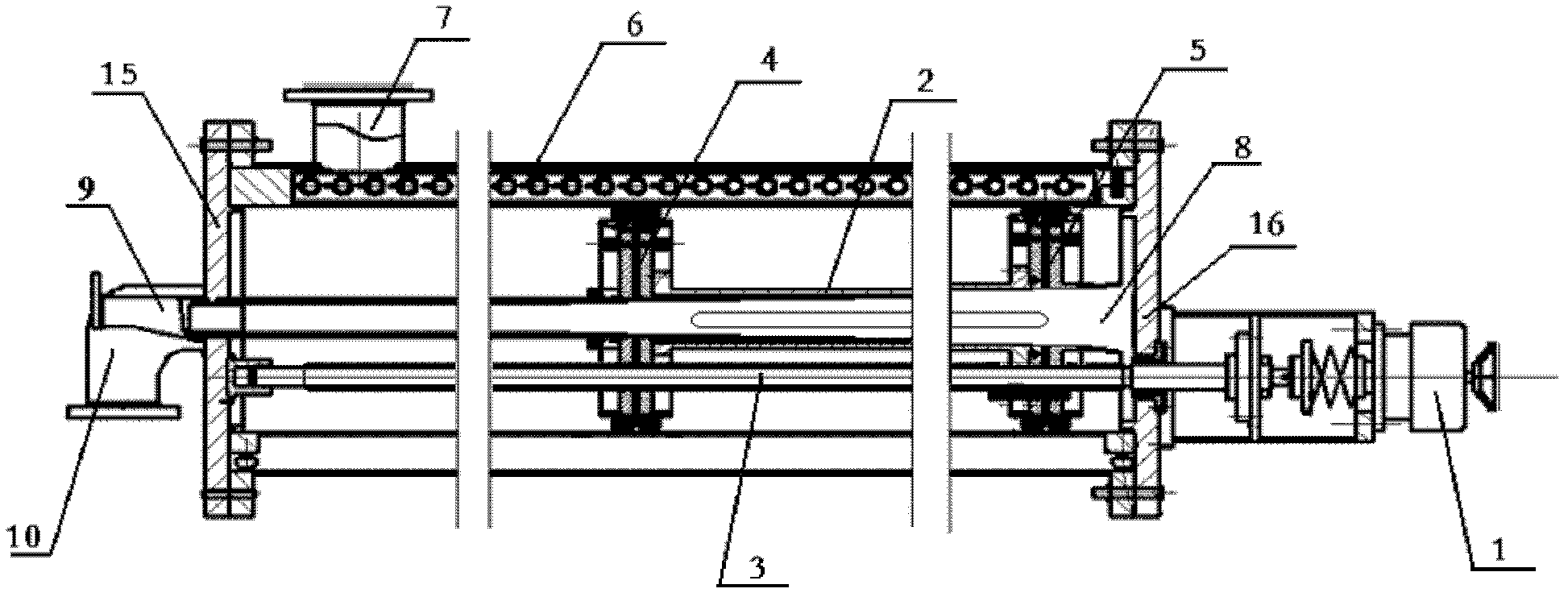

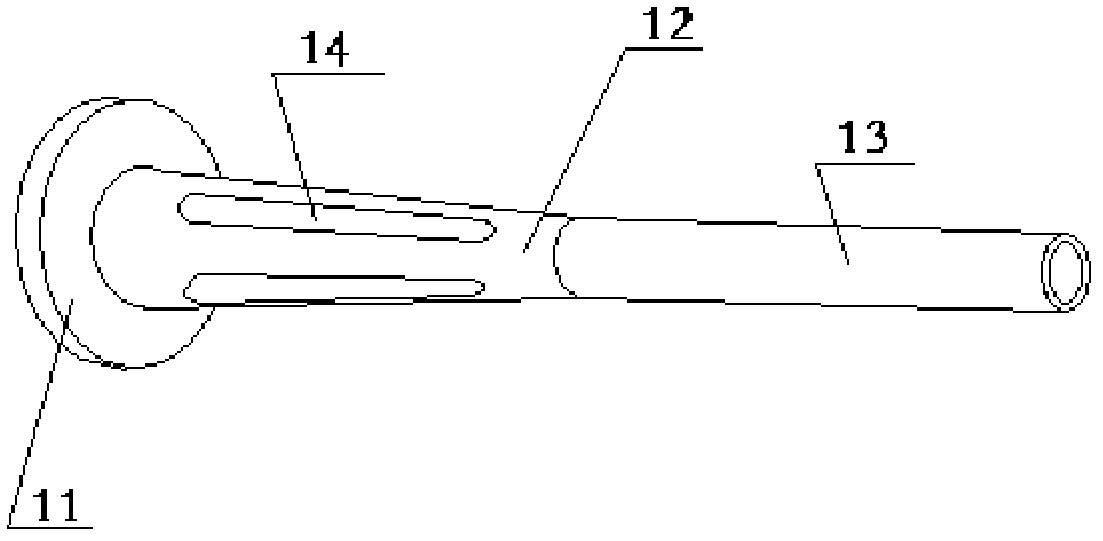

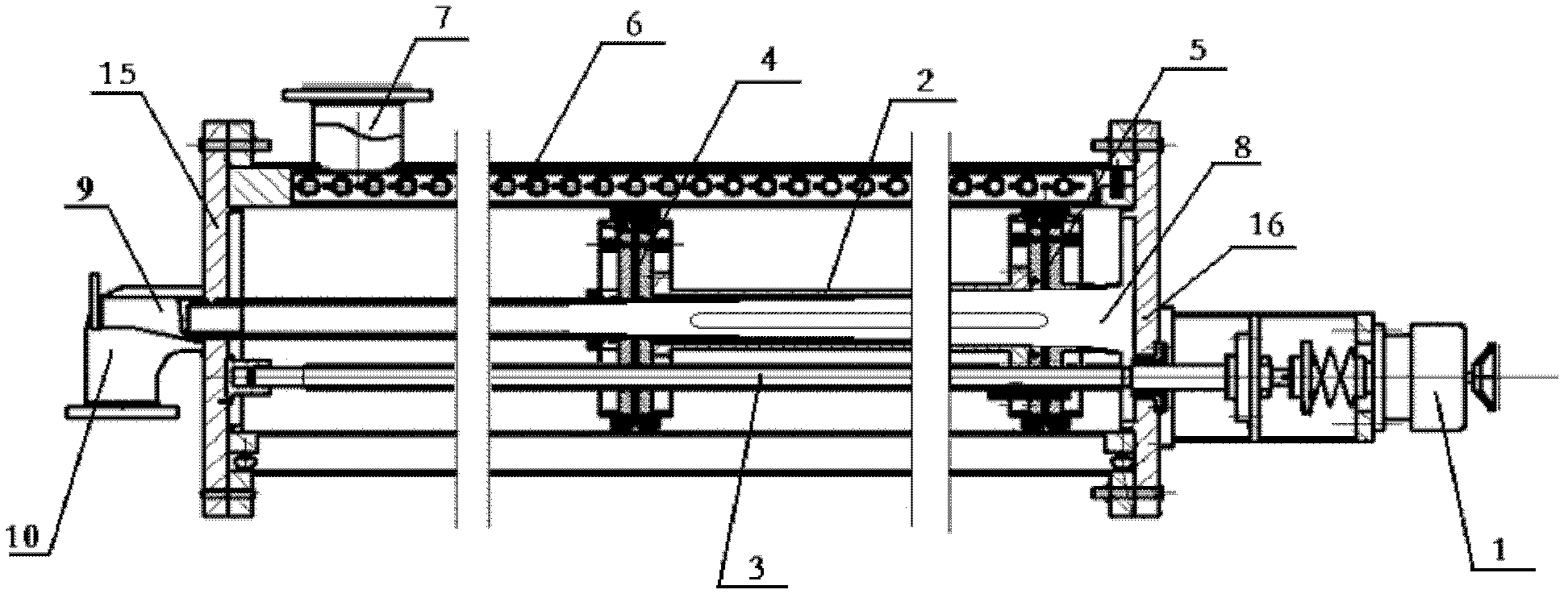

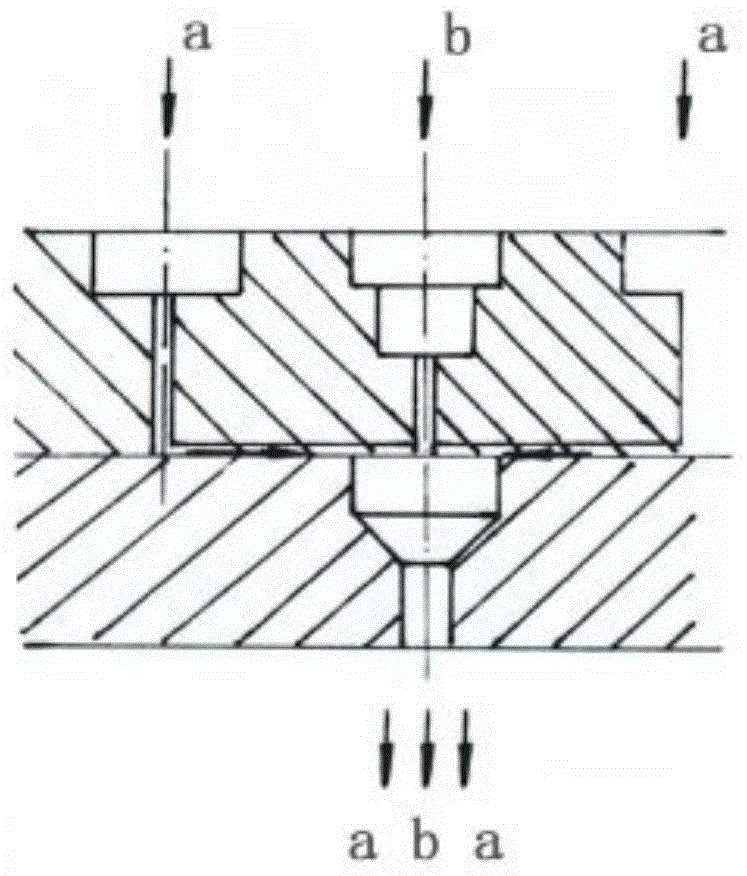

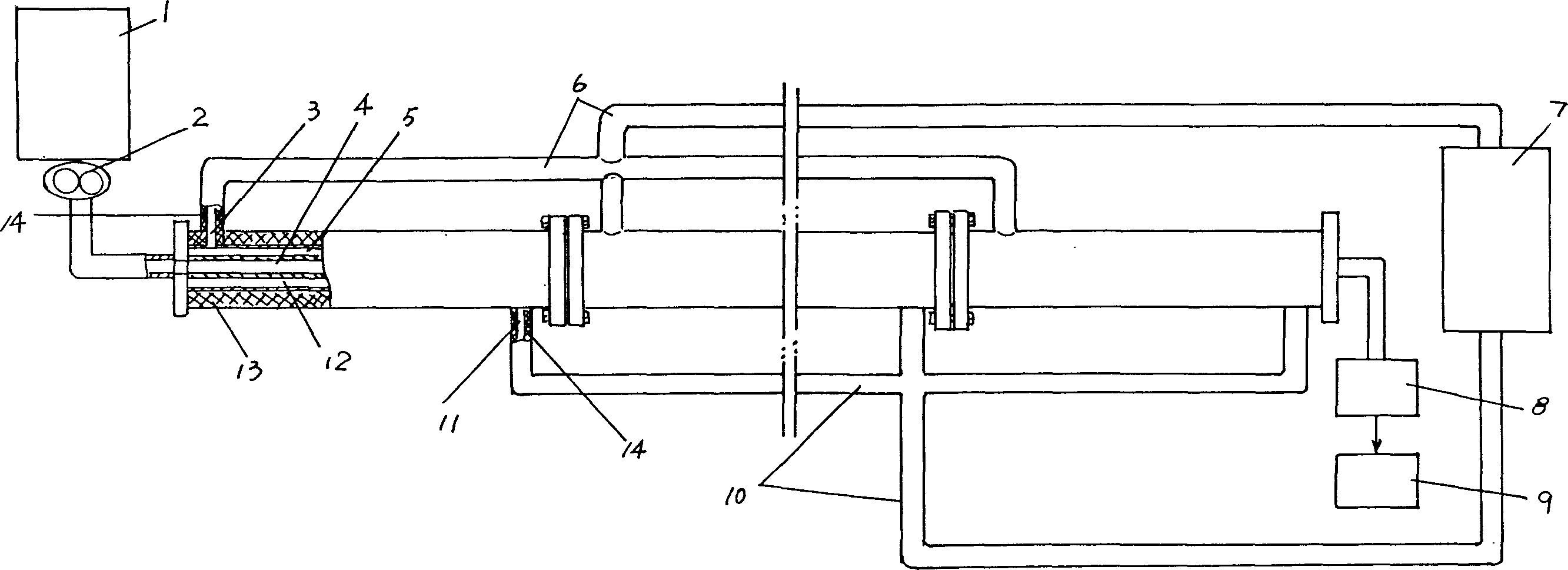

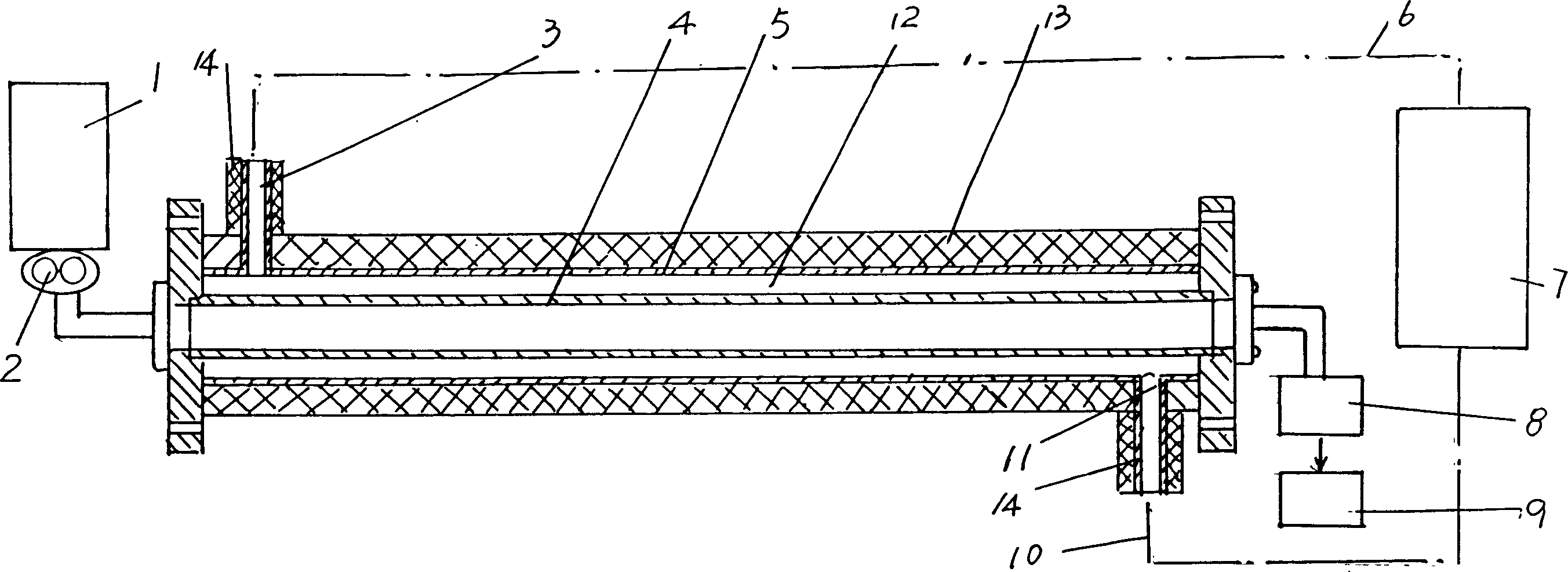

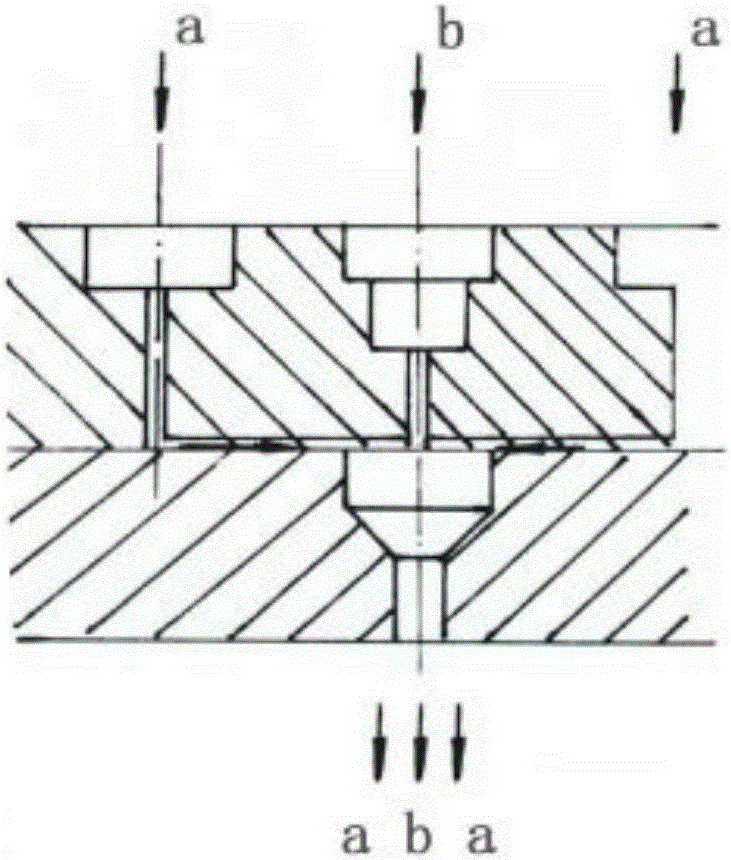

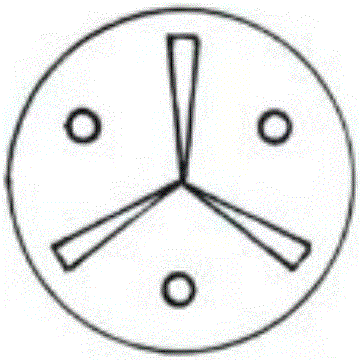

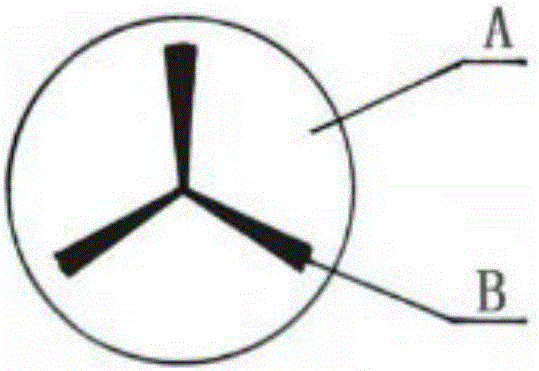

Back flushing filter

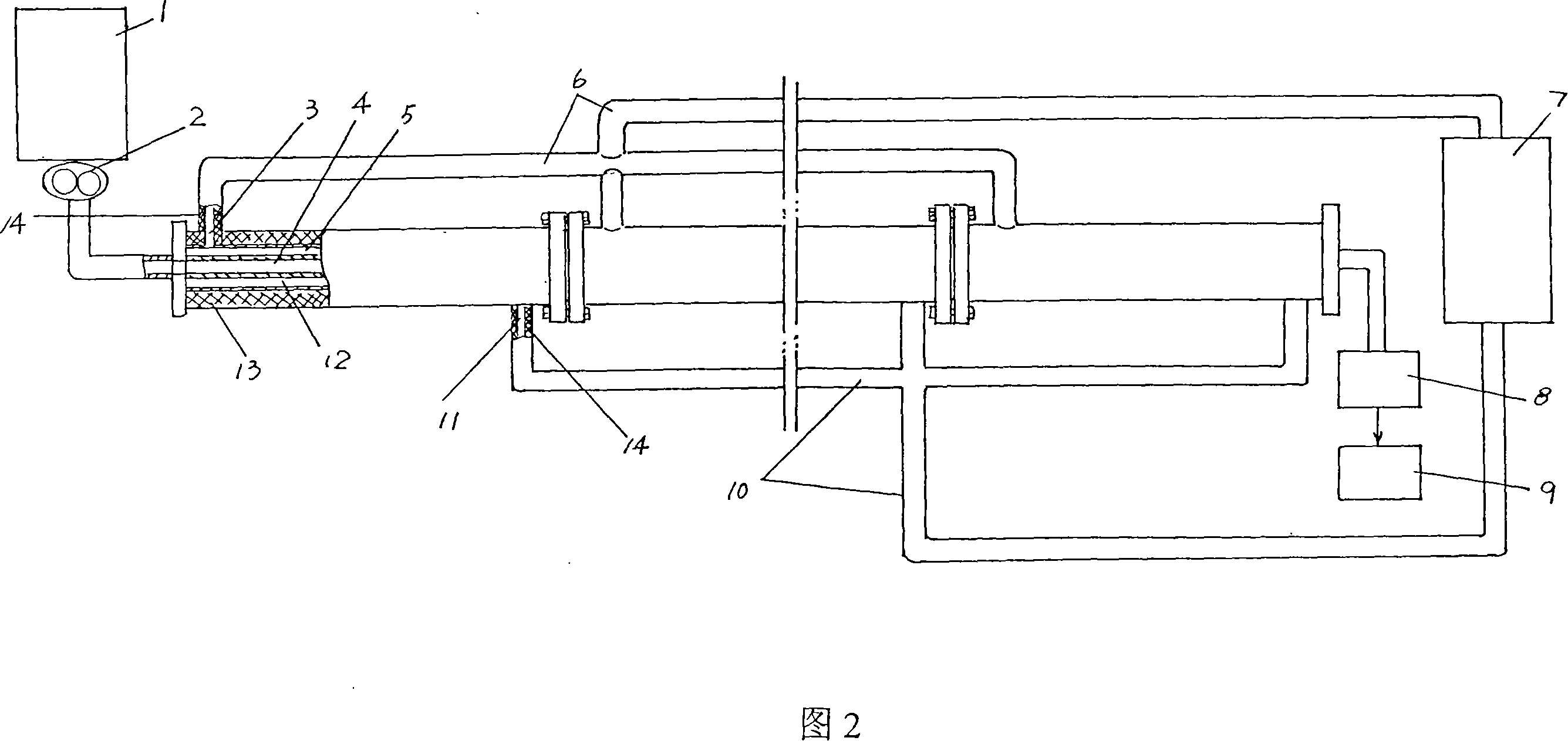

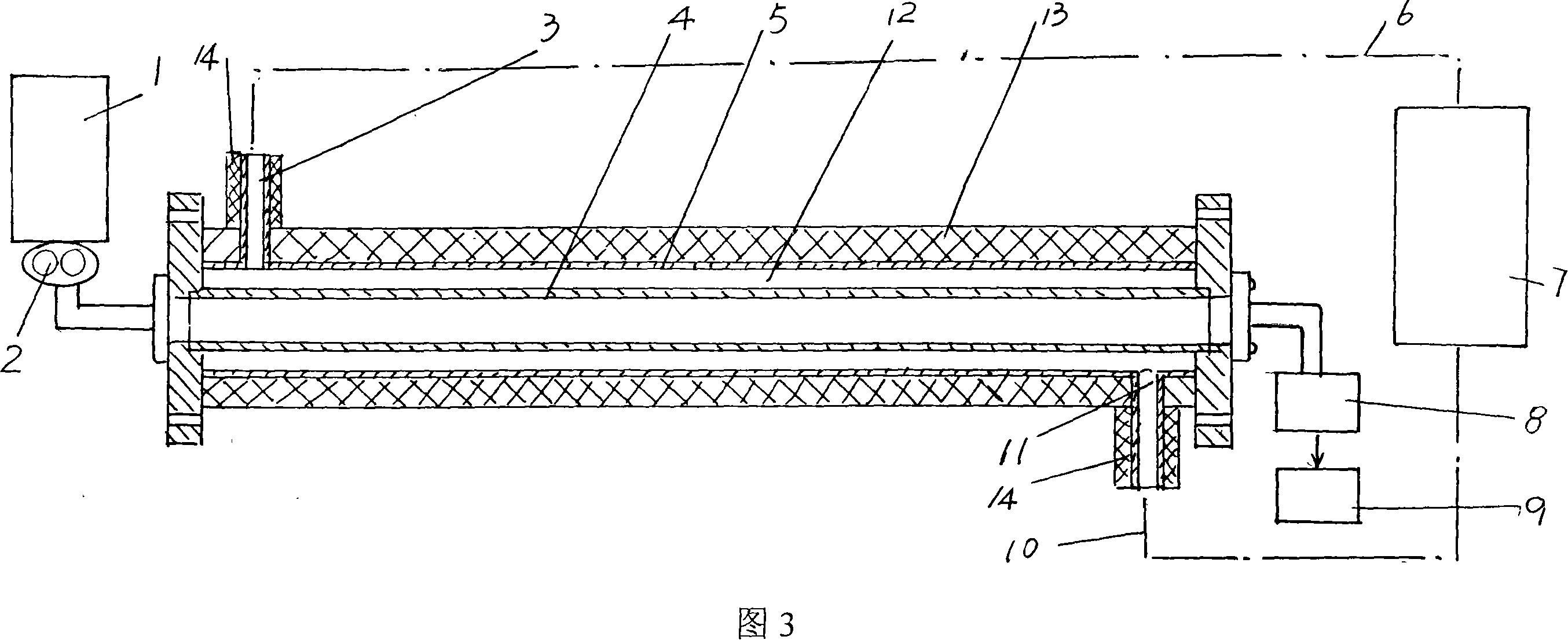

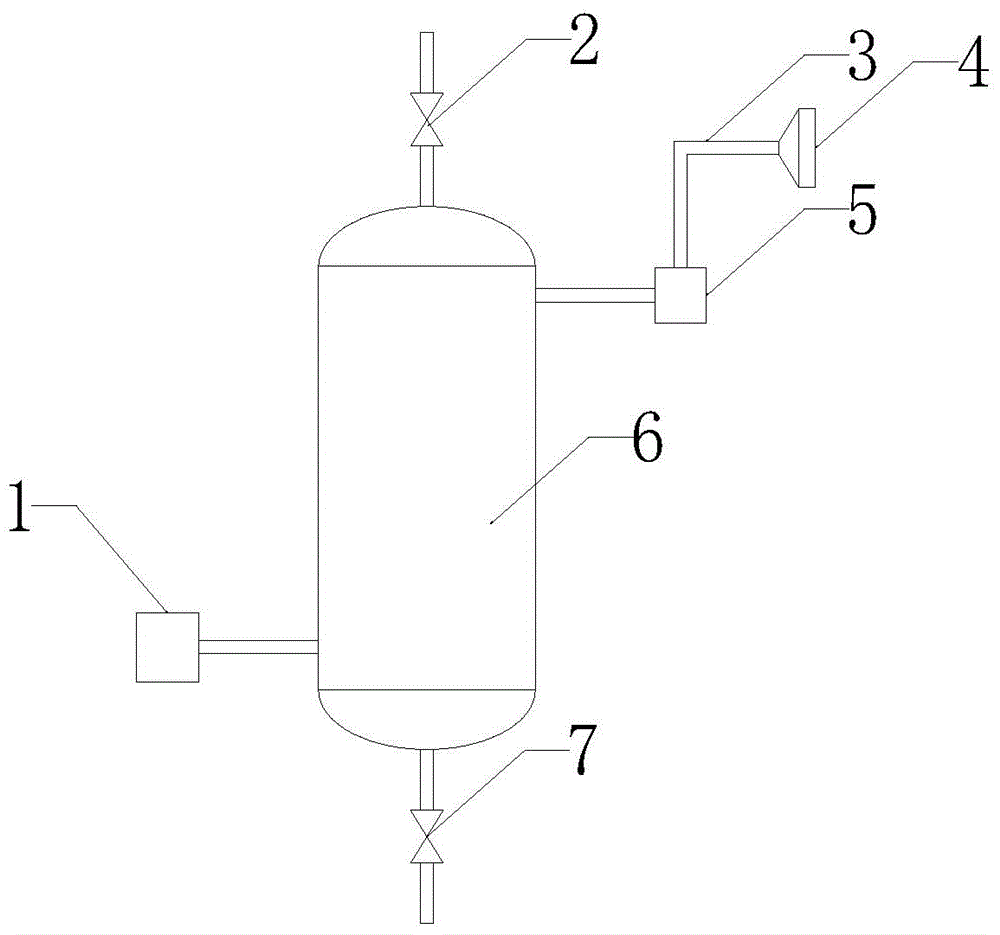

InactiveCN102626565AGuaranteed spinnabilityGuaranteed performanceFilament-forming treatmentStationary filtering element filtersEngineeringSmall footprint

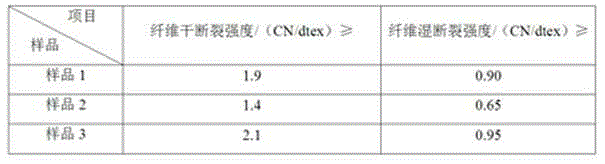

The invention relates to a back flushing filter. A back flushing drainage port between a connecting pipe and a central drainage pipe is opened and closed through displacement of front and back two pistons and the connecting pipe under the control of a screw rod, and a filtrate flows reversely on a filtering layer due to the pressure change occurring on a water outlet after the drainage port is opened, so that impurities clamped in the filtering layer are flushed out of the drainage port. The back flushing filter is an acrylic fiber spinning raw liquid automatic back flushing filter which has the advantages of continuous operation, high filtering efficiency, small floor area, capability of recovering waste liquid and the like, gel particles, insoluble mechanical impurities and the like existing in a spinning raw liquid can be effectively filtered, and the spinnability of the acrylic fiber spinning raw liquid and the performance of fiber are ensured.

Owner:DONGHUA UNIV

Antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278AImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

The invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof, which meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antibacterial bamboo charcoal viscose fiber is characterized by being obtained by mixing an antibacterial bamboo charcoal solution with viscose through injection before spinning, and carrying out wet spinning and post-treatment, wherein the antibacterial bamboo charcoal solution is formed by mixing an antibacterial solution and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-10 percent of an antibacterial agent and 0.1-10 percent of bamboo charcoal; the bacteriostasis rate is more than or equal to 90 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The antibacterial bamboo charcoal viscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the antibacterial bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

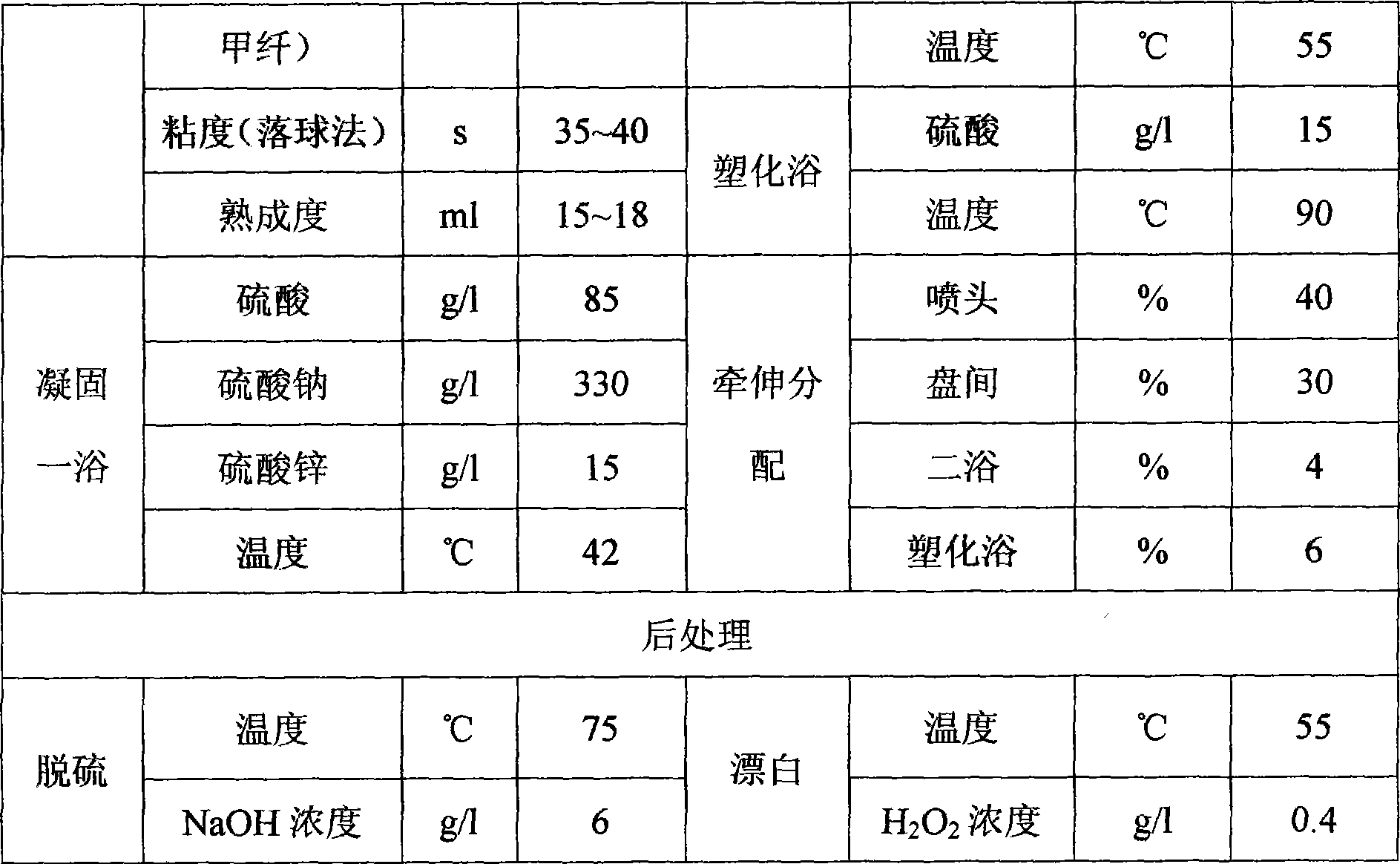

Production process of fine denier viscose staple fiber

InactiveCN103305939ARaise Strength IndexPromote rapid formationFilament manufactureStretch-spinning methodsCellulosePolymer science

The invention relates to a production process of fine denier viscose staple fiber, and belongs to the technical field of production of the viscose staple fiber. In the spinning step, a formed silk is guided and drafted by a silk guiding device and a drafting device; and in the silk guiding and drafting process, the total drafting rate is controlled at 130-160%, wherein the spinneret drafting rate is controlled at 60-80%, the air drafting rate is controlled at 25-40% and the plastic drafting rate is controlled at 5-12%. Through selection of the total drafting rate and various drafting rate allocations, in the spinning forming process and in the plastic state, neat arrangement of cellulose macromolecules of the fine denier staple viscose fiber is facilitated, rapid and high-quality formation of a crystalline area in the fiber is facilitated, and thus the fine denier viscose staple fiber is ensured to reach a higher strength index.

Owner:YIBIN GRACE +2

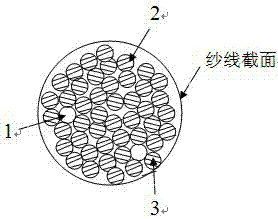

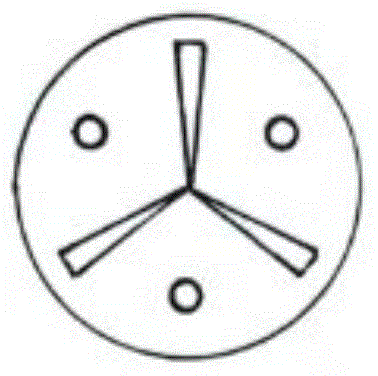

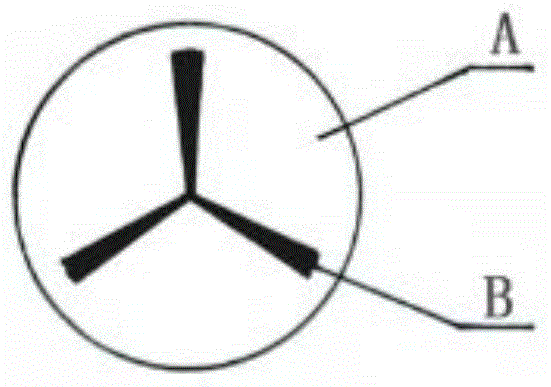

Antibiotic super see-through-prevention terylene fabric and manufacturing method thereof

The invention relates to an antibiotic super see-through-prevention terylene fabric and the manufacturing method thereof. The antibiotic super see-through-prevention terylene fabric is woven by interlacing of wefts and warps, and the wefts and warps are see-through-prevention DTY fibers which are non-ablative orange-slice-shaped two-component composite fibers containing 0.1-1wt% antiseptics, wherein non-ablative means the two-component is excellent in compatibility. The two-components are a polymer and the polymer containing 5-16wt% of TiO2, and 6-30wt % of the see-through-prevention DTY fibers are the polymer containing 5-16wt% of TiO2. The see-through-prevention DTY fibers are circular fibers, and distributed in a section with the polymer containing 5-16wt% of TiO2 as the center, the radius of the sector is 4 / 5-11 / 12 of the radius of the see-through-prevention DTY fibers, and the opacity of the see-through-prevention DTY fibers reaches 99-100%. The see-through-prevention DTY fibers are high in opacity, and the physical property indexes are similar to that of normal fibers. The fabric shading effect is excellent, transmission of visible lights can be greatly reduced, and the transmitted visible light is practically zero.

Owner:WUJIANG CITY HAICHENG TEXTILE

Method for directly preparing fiber product fron poly lactic acid polymerized smelting body

InactiveCN1900389AGuaranteed qualityLow costMelt spinning methodsMonocomponent polyesters artificial filamentFiberHeat conducting

A poly - lactic acid polymerization fusant directly preparing fiber method belongs to high molecular material applied technology field. It contains installing fusant pipe located in jacket between polyreaction device discharging pump material outlet and spinning box feed inlet, discharging pump directly feeding obtained poly - lactic acid polymerization fusant into spinning box through fusant pipe, leading-in heat-insulated heat conducting medium to jacket internal circulation, spinning box to make spinning to led poly - lactic acid polymerization fusant to obtain fiber products. Said invention has advantages of ensuring fiber quality and simple technological process.

Owner:恒天长江生物材料有限公司

Marine organism health care viscose fiber and production method thereof

InactiveCN101372767AGood health effectGuaranteed spinnabilityMonocomponent cellulose artificial filamentCelluloseBiocompatibility Testing

The invention discloses a halobios healthy viscose fiber and a production method thereof, the halobios healthy viscose fiber with 81.2 to 87.9 percent of cellulose, 3.0 to 6.0 percent of alga and 7 to 13 percent of water as well as 0.1 to 0.35 percent of oil agent is obtained by adding the halobios of alga in the viscose fiber production. The production method has simple technique and is convenient to implement; each index denier of the produced halobios healthy viscose fiber completely meets the variety requirements; besides, various healthy functions of special physicochemical property and excellent biocompatibility of the alga are combined together with the viscose fiber, thus greatly improving the healthy performance of the fiber and enlarging the application field of the fiber.

Owner:CHTC HELON

Cool anti-perspective polyester fabric and preparation method thereof

ActiveCN105155083AHigh opacityGood shading effectMelt spinning methodsWoven fabricsPolyesterWoven fabric

The invention relates to a cool anti-perspective polyester fabric and a preparation method thereof. The cool anti-perspective polyester fabric is formed in a way that warps and wefts are interweaved, the warps and wefts are anti-perspective DTY fibers, the anti-perspective DTY fibers are non-separating orange-type two-component composite fibers, and comprises 0.1-0.8wt% of a slip agent, non-separating means that the two components are good in compatibility; two components comprise a polymer and a polymer containing 5-16wt% of TiO2, and the polymer containing 5-16wt% of TiO2 accounts for 6-30wt% of the anti-perspective DTY fiber; in the anti-perspective DTY fibers, the polymer containing 5-16wt% of TiO2 takes the center of circle as the starting point and is distributed in a sector manner, the radius of the sector is 4 / 5-11 / 12 of the radius of the anti-perspective DTY fiber; and the opacity of the anti-perspective DTY fiber reaches 99%-100%. The anti-perspective DTY fiber is high in opacity, the physical index of the anti-perspective DTY fiber is very nearly the same as that of a conventional fiber; woven fabrics have an obvious shading effect, transmission of visible light is greatly reduced, and the transmission of visible light is almost zero.

Owner:WUJIANG CITY HAICHENG TEXTILE

Aromaticity bamboo charcoal fiber and preparation method thereof

ActiveCN103556264AImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

The invention provides an aromaticity bamboo charcoal fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The aromaticity bamboo charcoal fiber is characterized in that a finished product is obtained by taking cellulose fiber pulp as a raw material, mixing an aromaticity bamboo charcoal solution and viscose through injection before spinning and performing wet spinning and post-treatment, wherein the aromaticity bamboo charcoal solution is prepared by mixing fragrant masterbatches and a bamboo charcoal solution; the fragrant masterbatches contain perfumes; the fragrant perfume content of the fiber is 0.01-10 percent; the bamboo charcoal content is 0.1-10 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The aromaticity bamboo charcoal fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and hygroscopicity, can effectively and continuously scatter fragrance and has the effects of relieving pressure and enabling people to be invigorating.

Owner:YIBIN HIEST FIBER +1

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727BGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterPolyethylene glycol

Owner:XUZHOU SILK FIBER TECH

Method for preparing cationic modified PTT (polytrimethylene terephthalate) copolyester fiber

ActiveCN108624982AReduce contentReduce consumptionMonocomponent polyesters artificial filamentPolyethylene glycolSulfonate

The invention relates to a method for preparing cationic modified PTT (polytrimethylene terephalate) copolyester fiber. The method includes: evenly mixing terephthalic acid, 1,3-propylene glycol and aleading substance prior to performing sequentially esterification reaction, pre-polycondensation reaction and final polycondensation reaction to obtain cationic modified PTT copolyester which is subjected to polymer-melt directly spinning to obtain the cationic modified PTT copolyester fiber. The leading substance is compound ester generated from reaction of dimethyl isophthalate sulfonate sodiumsalt and dihydric alcohol, the molar ratio of phthalic acid to 1,3-propylene glycol is 1:1.05-1.10, time for pre-polycondensation reaction is 15-45 minutes, polysiloxane and polyethylene glycol are added in the final polycondensation reaction, and viscosity loss of the cationic modified PTT copolyester fiber is smaller than or equal to 0.001dL / g during polymer-melt directly spinning transportation.

Owner:浙江汇纤纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com