Pearl regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and fiber, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of poor spinnability, low content of pearl particles in fibers, etc. Guaranteed spinnability and effective content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

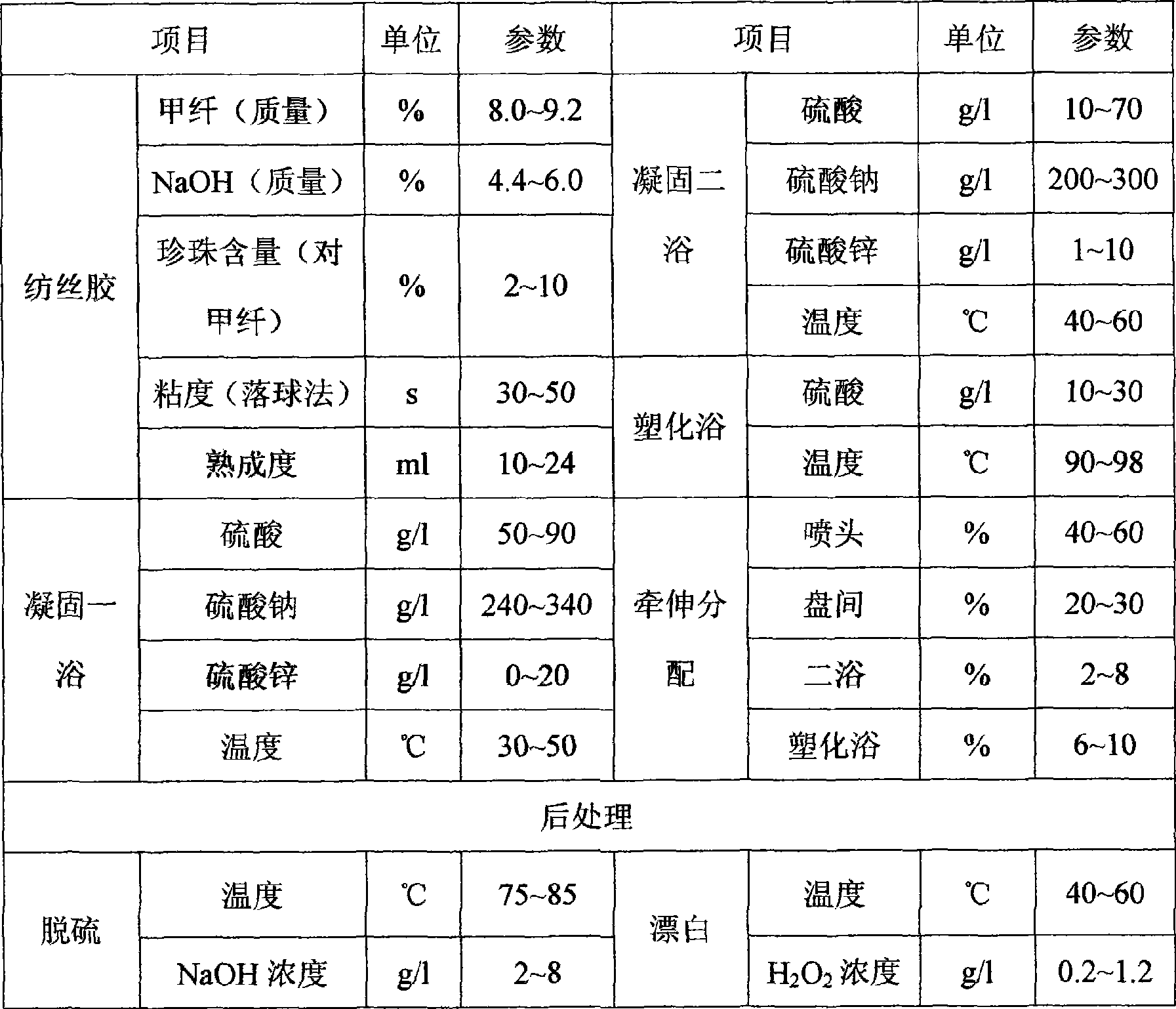

[0022] Embodiment one: produce 1.67dtex*38mm cotton type pearl viscose staple fiber (the content of pearl micropowder in the fiber is 3% relative to the first fiber)

[0023] Preparation of pearl emulsion: use 1±0.2 micron pearl powder, polyethylene glycol (PEG-400), sodium hexametaphosphate and water to mix and disperse and emulsify through a high-pressure homogenizer for later use. The components of pearl emulsion are shown in Table 1-1

[0024] Table 1-1 Composition of Pearl Emulsion

[0025] ingredients Pearl powder Hexametaphosphate PEG-400 water Content % (mass) 18 5 20 57

[0026] Production of pearl regenerated cellulose fiber: add pearl emulsion to the dissolving glue according to 3% of the mass of the pearl relative to the first fiber, mix evenly, filter and defoam to obtain the spinning glue, spin the spinning glue in two baths, and then desulfurize it , washing, oiling, bleaching and drying processes, the pearl fiber with a pearl cont...

Embodiment 2

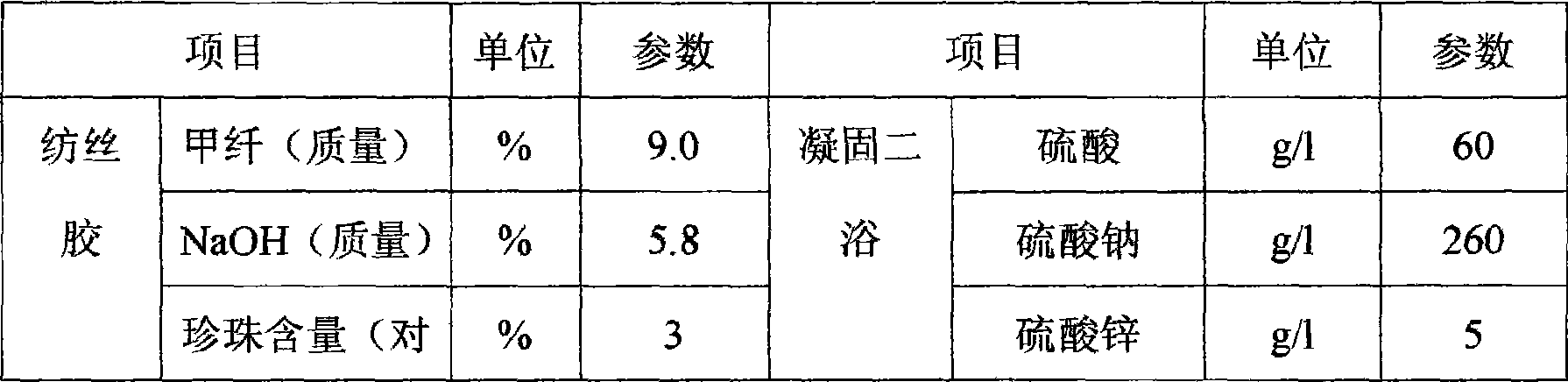

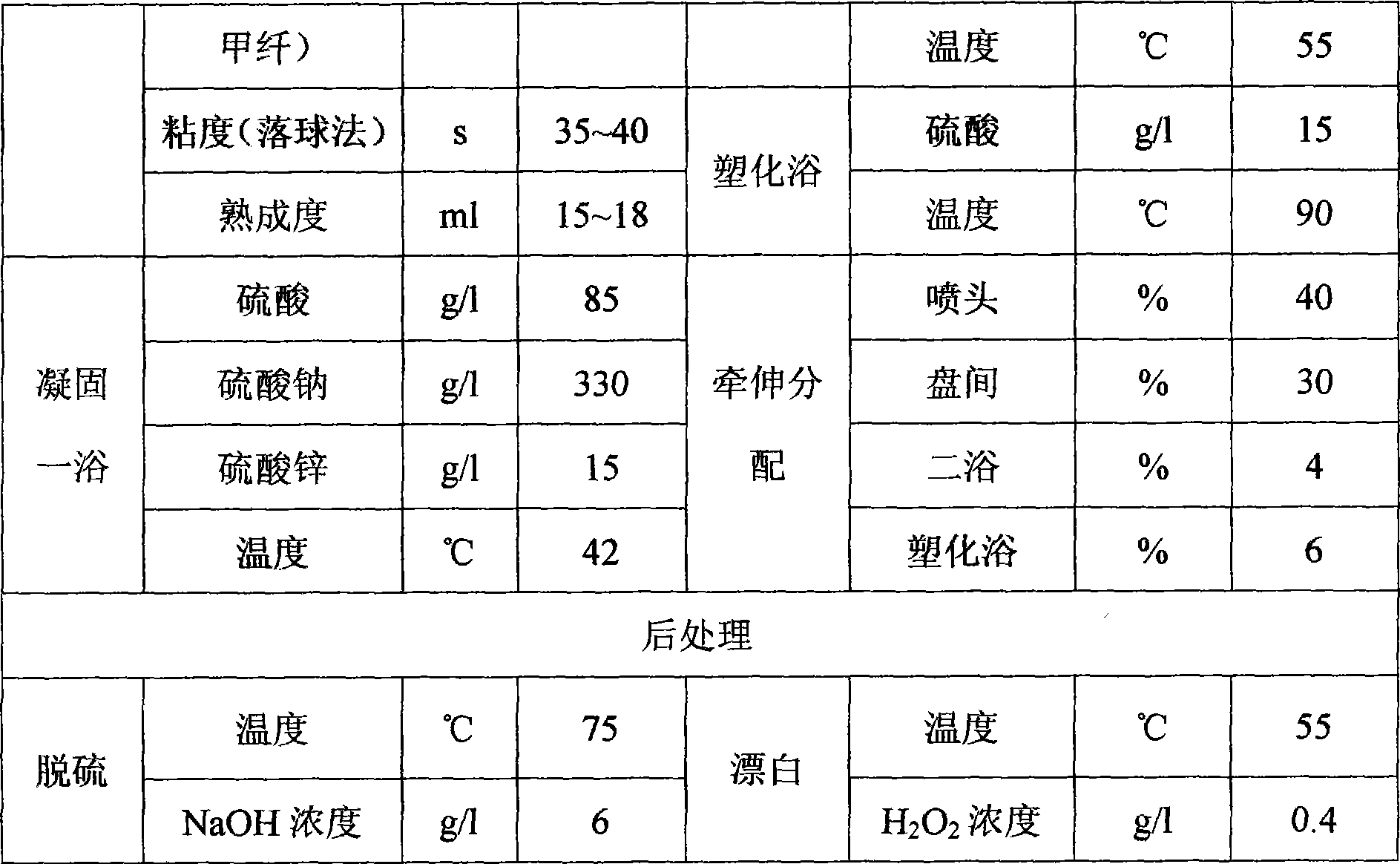

[0039] Embodiment two: 2.22dtex mid-length pearl viscose staple fiber production (pearl content in the fiber is 7% relative to the first fiber quality)

[0040] Preparation of pearl emulsion: use 1±0.4 micron pearl powder, sodium tripolyphosphate, Span-80, PEG-1500 and water to mix and then disperse and emulsify through a high-pressure homogenizer for later use. The components of pearl emulsion are shown in Table 2-1

[0041] Table 2-1 Composition of Pearl Emulsion

[0042] ingredients Pearl powder sodium tripolyphosphate Span-80 PEG-1500 water Content % (mass) 24 3 16 12 45

[0043] Production of pearl regenerated cellulose fiber: further grind and disperse the pearl emulsion with a star ball mill, add 7% of the pearl relative to the quality of the first fiber into the dissolving glue and mix evenly, filter and defoam to obtain the spinning glue, and make the spinning glue After two-bath spinning and forming, desulfurization, water washing, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com