Cool anti-perspective polyester fabric and preparation method thereof

An anti-perspective and fabric technology, applied in the directions of melt spinning, weaving, fabrics, etc., can solve the problems of affecting wearing comfort, limited adjustment, and air permeability, so as to facilitate industrialization, reduce transmission, and reduce dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

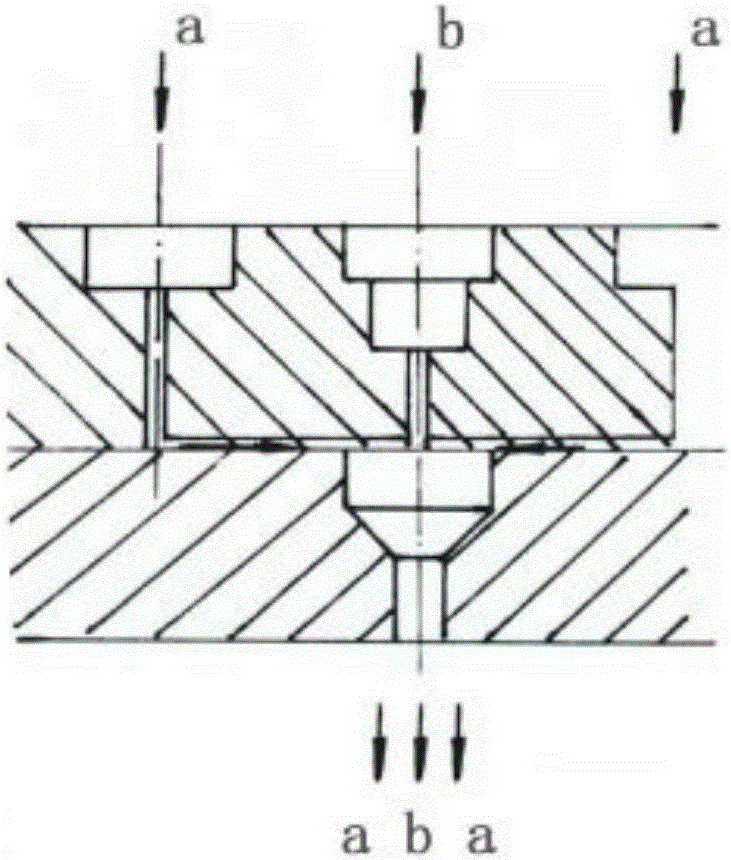

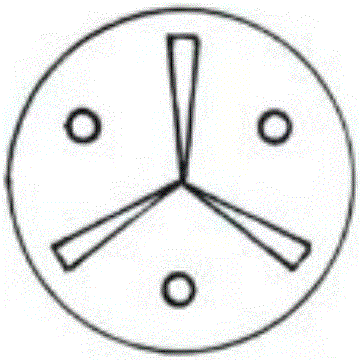

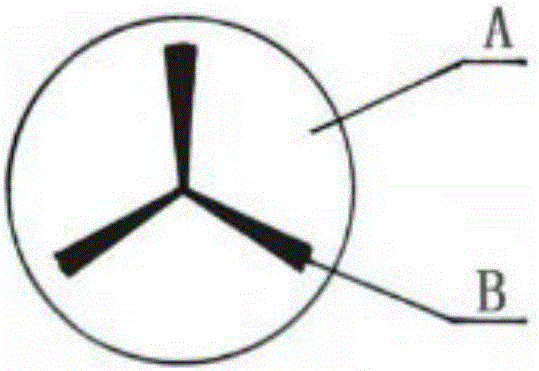

Embodiment 1

[0043] A method for preparing a cool anti-perspective polyester fabric, the component PET and the component contain 5wt% TiO 2 PET and 0.1wt% slip agent are used for melting orange petal composite spinning. The process conditions for melting orange petal composite spinning are: spinning temperature component PET is 284℃, component contains 5wt% TiO 2 The PET is 287℃; the side blowing wind speed is 0.450m / s, and the side blowing temperature is 2℃; GR 1 Speed 1047m / min, GR 1 Temperature 85℃; GR 2 Speed 4257m / min, GR 2 The temperature is 129℃; the winding head speed is 4197m / min; when starting to spin, the component is opened and contains 5wt% TiO 2 PET metering pump, the component contains 5wt% TiO 2 After the discharging of the PET is normal, turn on the metering pump of the component PET, the melt pressure of the component PET is 6.0MPa, and the component contains 5wt% TiO 2 The melt pressure of the PET is 1.0 MPa higher than the melt pressure of the component PET, and the aspe...

Embodiment 2

[0045] A preparation method of cool anti-perspective polyester fabric, the component PBT, component contains 16wt% TiO 2 PBT and 0.8wt% slip agent are used for melting orange petal composite spinning. The process conditions of melting orange petal composite spinning are: the spinning temperature component PBT is 286℃, and the component contains 16wt% TiO 2 The PBT is 289℃; the side blowing wind speed is 0.55m / s, and the side blowing temperature is 44℃; GR 1 Speed 1053m / min, GR 1 Temperature 87℃; GR 2 Speed 4257m / min, GR 2 Temperature 131℃; Winding head speed 4203m / min; When spinning starts, first open the component and contain 16wt% TiO 2 PBT metering pump, the component to be contained contains 16wt% TiO 2 After the PBT discharge is normal, turn on the PBT metering pump. The melt pressure of the component PBT is 7.0MPa, and the component contains 16wt% TiO 2 The melt pressure of the PBT is 2.0 MPa higher than the melt pressure of the component PBT, and the aspect ratio of the ...

Embodiment 3

[0047] A preparation method of cool anti-perspective polyester fabric, the component PTT and component contain 10wt% TiO 2 PTT and 0.2wt% slip agent are used for melting orange petal composite spinning. The process conditions of melting orange petal composite spinning are: the spinning temperature component PTT is 285℃, and the component contains 10wt% TiO 2 The PTT is 288℃; the side blowing wind speed is 0.50m / s, and the side blowing temperature is 23℃; GR 1 Speed 1050m / min, GR 1 Temperature 86℃; GR 2 Speed 4260m / min, GR 2 Temperature 130℃; winding head speed 4200m / min; when starting spinning, first open the component and contain 10wt% TiO 2 PTT metering pump, the component contains 10wt% TiO 2 After the PTT discharge is normal, turn on the metering pump of the component PTT, the melt pressure of the component PTT is 6.5MPa, and the component contains 10wt% TiO 2 The melt pressure of the PTT is 1.5 MPa higher than the melt pressure of the component PTT, and the aspect ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com