Paper making material, preparation method and paper making method of environment-friendly synthetic paper

A synthetic paper, environmental protection technology, applied in the direction of papermaking, textiles and papermaking, synthetic cellulose fibers, etc., can solve problems such as hindering production and application promotion, affecting printability, recycling difficulties, etc., to achieve industrial production and promotion, improve Compatibility and dispersibility, the effect of solving limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

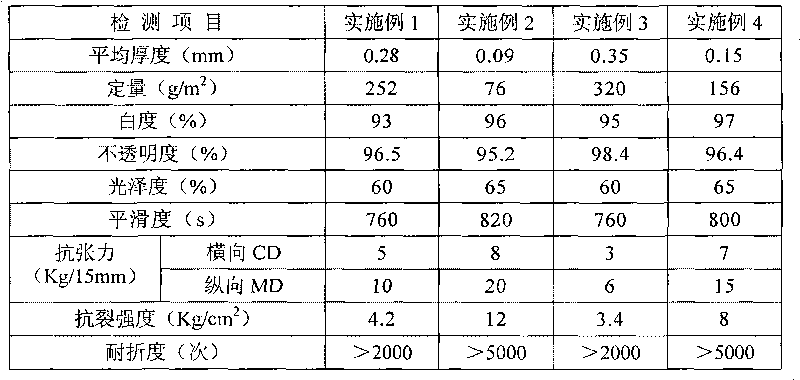

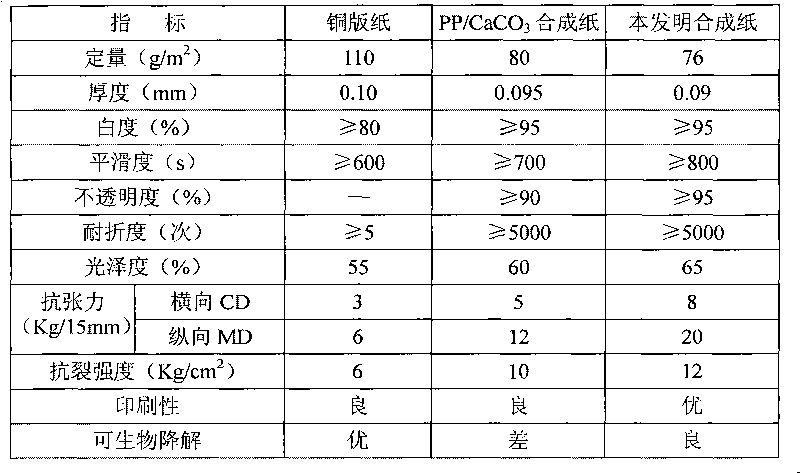

Examples

Embodiment 1

[0036] Raw materials (by total weight, the same below): modified wollastonite fiber 70%, thermoplastic cornstarch 10%, nitrocellulose 5%, polypropylene-maleic anhydride graft copolymer 10%, ethylene / vinyl acetate Copolymer 2%, white oil 3%. Among them, the modified wollastonite fiber is obtained by processing according to the method reported by Li Zhen et al. ; Thermoplastic starch is obtained by processing according to the aforementioned CN1778833A method (hereinafter all the same).

[0037] Put the modified wollastonite fiber into the SHR-300A high-mixer, and stir at 120°C and 900 rpm for 20 minutes to preheat and dehydrate. After the moisture content is ≤10%, add thermoplastic cornstarch and keep stirring for 20 minutes. Minutes, add nitrocellulose and stir for 20 minutes, add white oil and stir for 10 minutes, finally add the mixture of ethylene / vinyl acetate copolymer and polypropylene-maleic anhydride graft copolymer, stir for 8 minutes and discharge.

[0038] The abov...

Embodiment 2

[0041] Raw materials: modified sepiolite fiber 40%, thermoplastic tapioca starch 30%, cellulose acetate 5%, polyethylene-maleic anhydride graft copolymer 20%, mineral oil 3%, titanium dioxide 2%. The modified sepiolite fiber wherein can be by the mode of above-mentioned embodiment 1 or according to Shen Shangyue et al. "Wollastonite surface modification and effect evaluation" ("Mineral Protection and Utilization" 2000, (6): 24-28) It is obtained by processing in the manner reported.

[0042] Stir the modified sepiolite fiber in a high-mixer at 110°C and 600 rpm for 15 minutes to preheat and dehydrate until the water content is ≤10%, then add thermoplastic tapioca starch, keep stirring for 15 minutes, and then add cellulose acetate Stir for 15 minutes, add mineral oil and stir for 10 minutes, finally add polyethylene-maleic anhydride graft copolymer and titanium dioxide, stir for 5 minutes and discharge.

[0043] The above mixture is extruded and granulated by a two-stage scre...

Embodiment 3

[0046] Raw materials: modified gypsum whiskers 50%, thermoplastic corn starch 20%, ethyl cellulose 10%, polypropylene-maleic anhydride graft copolymer 15%, ethylene / vinyl acetate copolymer 3%, oxidized polyethylene wax 2 %. Among them, the modified gypsum whiskers are according to Shi Yubei et al. "The Mineralogical Characteristics of Yunnan Wollastonite and the Application of Mineral Resin Fillers in the Wood-based Panel Industry" ("Forest Industry" 2004, 31(4): 7-10) It is obtained by processing in the manner reported.

[0047] Put the modified gypsum whiskers in a high-speed mixer at 100°C and 300 rpm for 10 minutes to preheat and dehydrate until the water content is ≤10%, add thermoplastic wheat starch, keep stirring for 10 minutes, add ethyl cellulose Stir for 10 minutes, add oxidized polyethylene wax and stir for 5 minutes, finally add the mixture of ethylene / vinyl acetate copolymer and polypropylene-maleic anhydride graft copolymer, stir for 5 minutes and discharge.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com