Patents

Literature

30results about How to "Easy to promote in industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

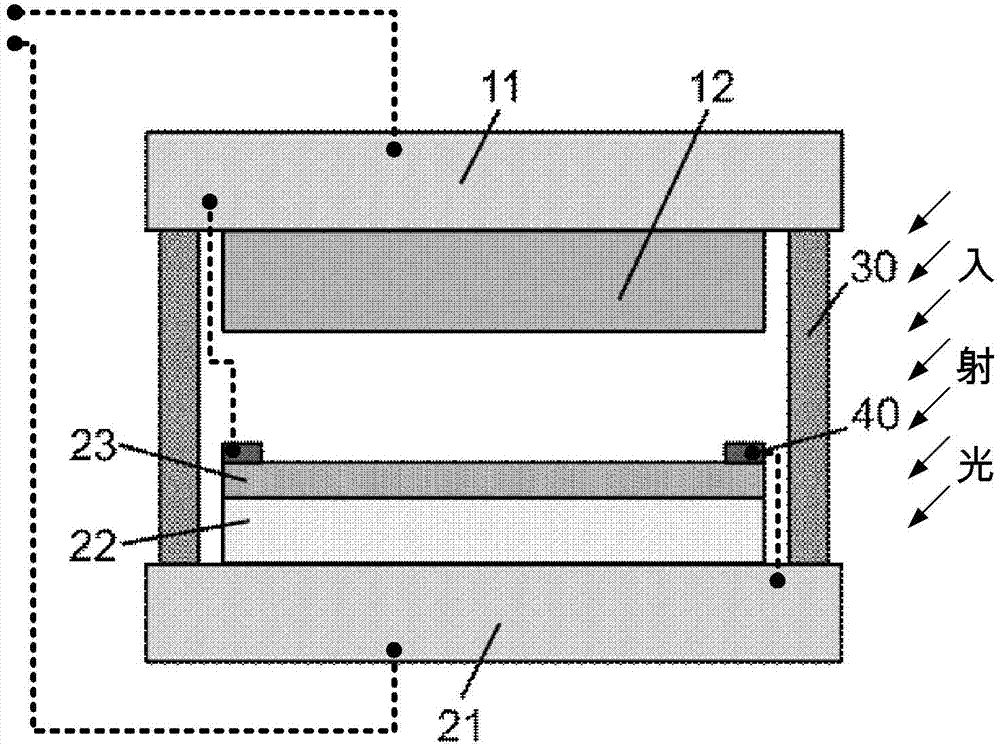

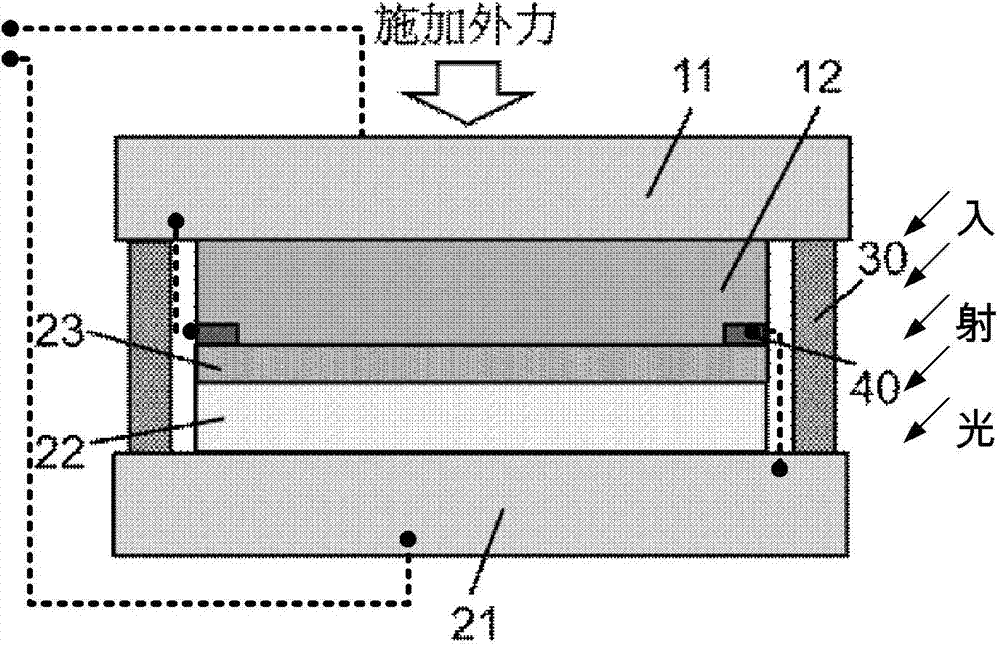

Self-driving photoelectric sensor and preparation method thereof

ActiveCN103780134ADiscriminant strengthImprove output performanceFriction generatorsEngineeringSelf driven

The invention provides a self-driving photoelectric sensor and a preparation method thereof. The self-driving photoelectric sensor integrates a photoelectric sensor into the structure of a friction nano generator, and the photoelectric sensor is driven by using output signals of the friction nano generator.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

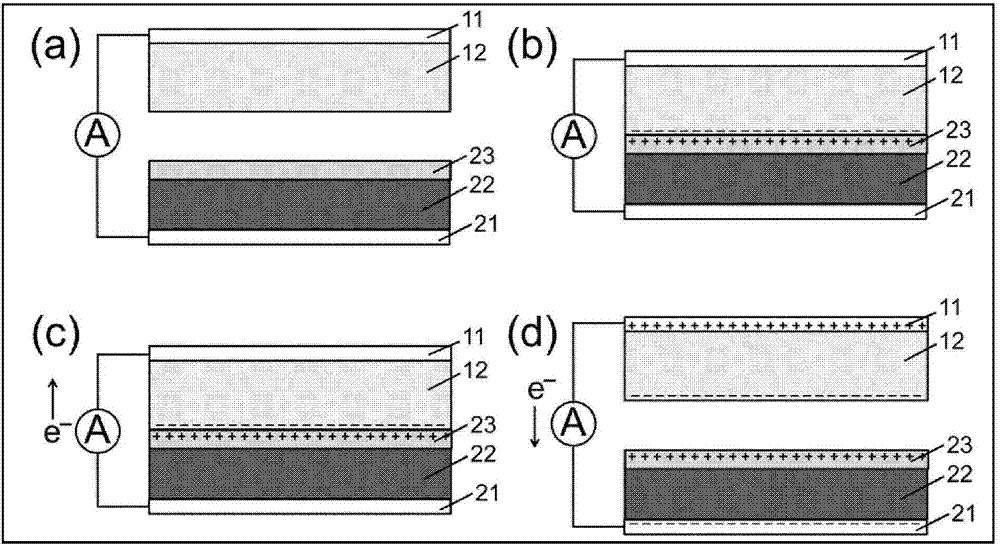

Ethanol content detecting reagent in saliva

InactiveCN101419172AStrong specificityHigh sensitivityMaterial analysis by observing effect on chemical indicatorBiological testingEthanol dehydrogenaseSolid phases

The invention relates to the technical field of clinical detection, in particular to a detection reagent for the content of alcohol in saliva. The invention discloses the detection reagent for the content of the alcohol in the saliva, which is characterized in that 1.25 to 0.5U of alcohol dehydrogenase, 0.05 to 0.2mg of coenzyme NAD and 0.025 to 0.2mg of tetrazolium salt are loaded and contained in a solid phase or semi-solid phase carrier with the area of 5.0*5.0mm<2>. The detection reagent for the content of the alcohol in the saliva has high specificity, high sensitivity, and quick reaction, does not contain poisonous substances, can detect orally, is safe and reliable, shows a result without a composite sensor host, can directly contrast readings with a colorimetric card, has better thermal stability, and can be preserved for 2 years at room temperature. The reagent has the advantages of good repetitiveness of determination results, convenient carrying, simple preparation technology, low cost, easy industry promotion and convenient field detection, and can be used for the detection of drunk drivers and taken as a simple tool for postmortem examination of judicial doctors.

Owner:SHANGHAI JINLONG BIOLOGICAL TECH

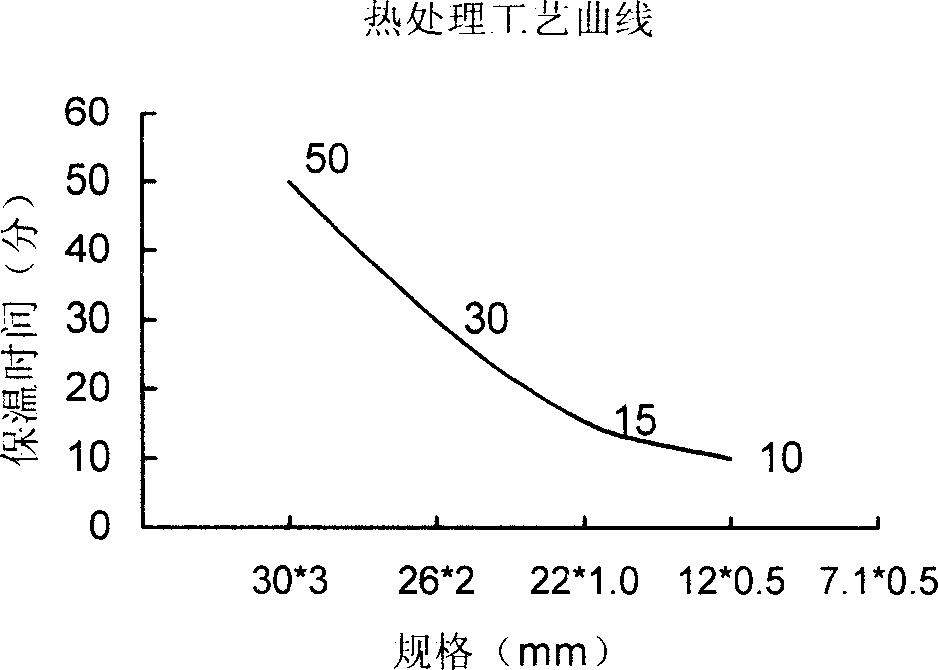

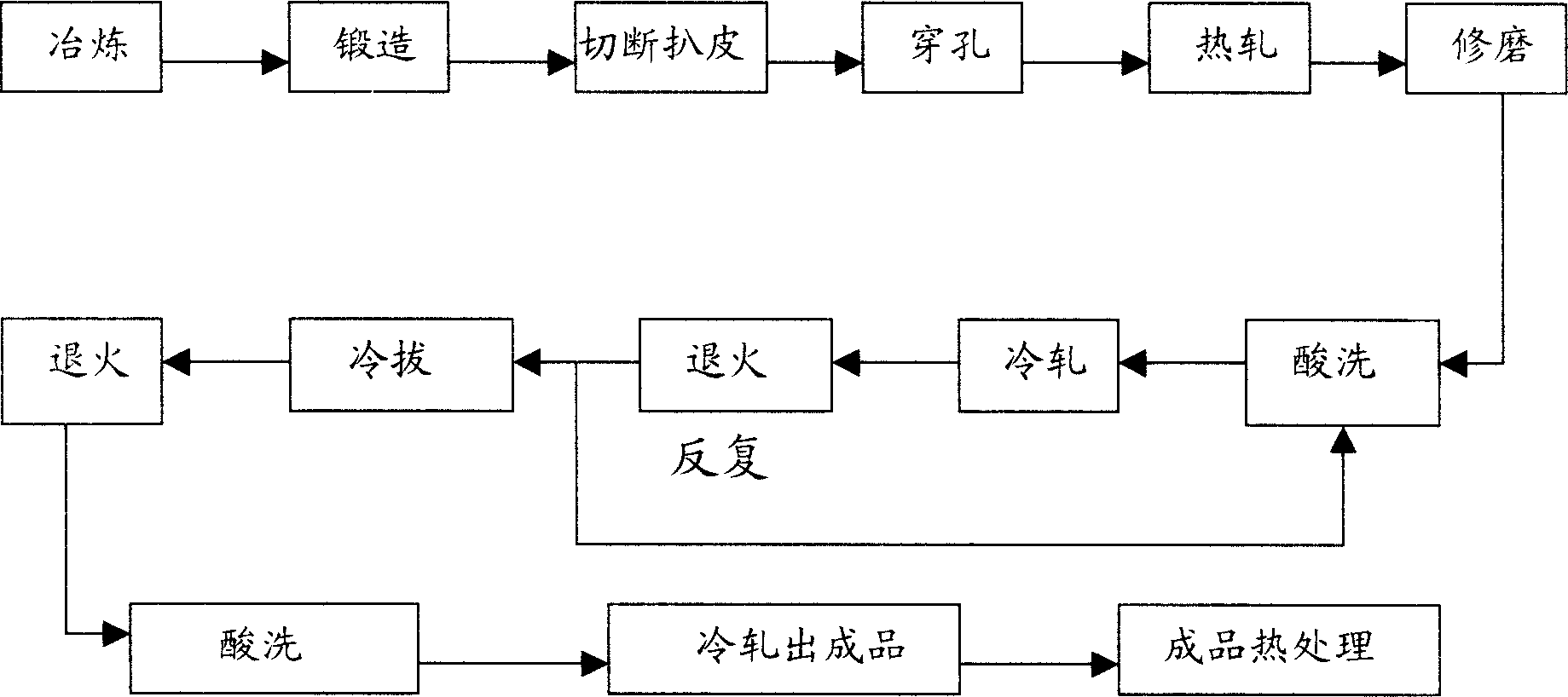

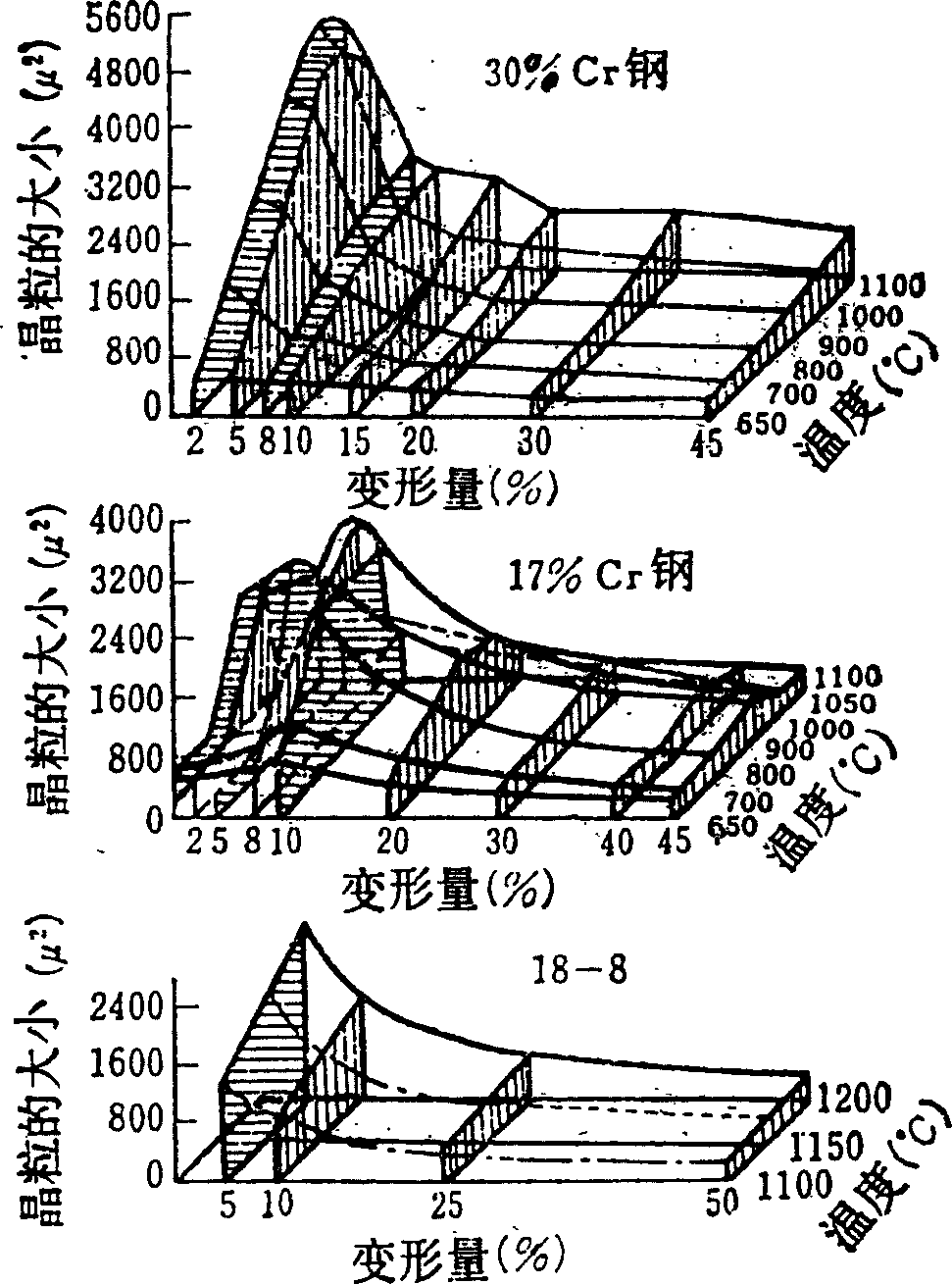

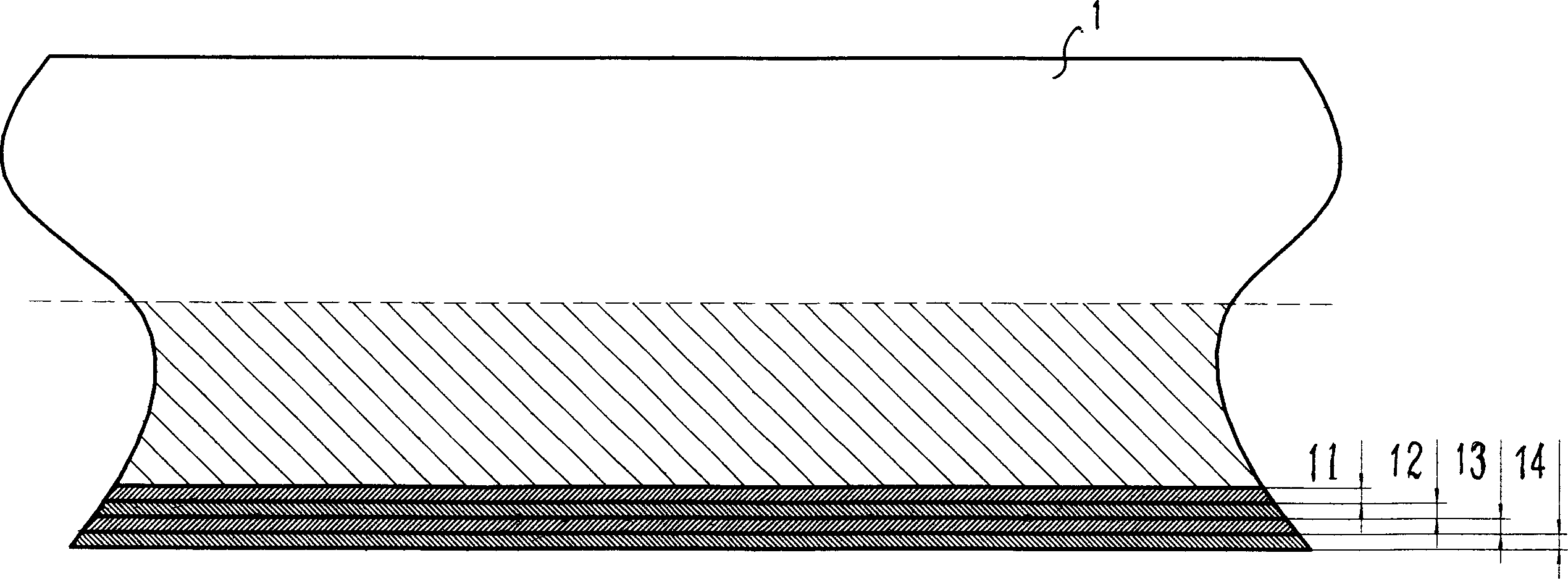

Manufacturing method of ferritic stainless steel seamless pipe with small diameter

InactiveCN1721753ASignificant advantagesSignificant beneficial effectRigid pipesMetal rolling arrangementsIngotProcess conditions

This invention relates to a process method to make stainless steel tube without gap, which comprises the following steps: providing the required steel ingot; forging; heating tube blank; drilling and rolling; processing the rolling, empty sinking, cold-drawing; again empty sinking, final product annealing and final product making.

Owner:天津冶金集团天材科技发展有限公司

Preparation method of test paper for detecting alcohol content in saliva and test paper prepared thereby

InactiveCN1837821ASignificant advantagesSignificant beneficial effectMaterial analysis by observing effect on chemical indicatorBiological testingSolid-state chemistryPhosphate

This invention relates to a preparation method of test paper for detecting alcohol content in saliva and test paper prepared thereby. Wherein, using pure cotton pulp filter paper as the bottom carrier of test paper; with solid chemistry technique, adding in turn the tetramethyl benzidine, phosphate buffer, HRP, alcohol oxidase and BSA on the paper, and multiple-step vacuum drying. This invention is safe and reliable for test, can read result directly with color-matching card, and has well repeatability for wide application.

Owner:丁国兴

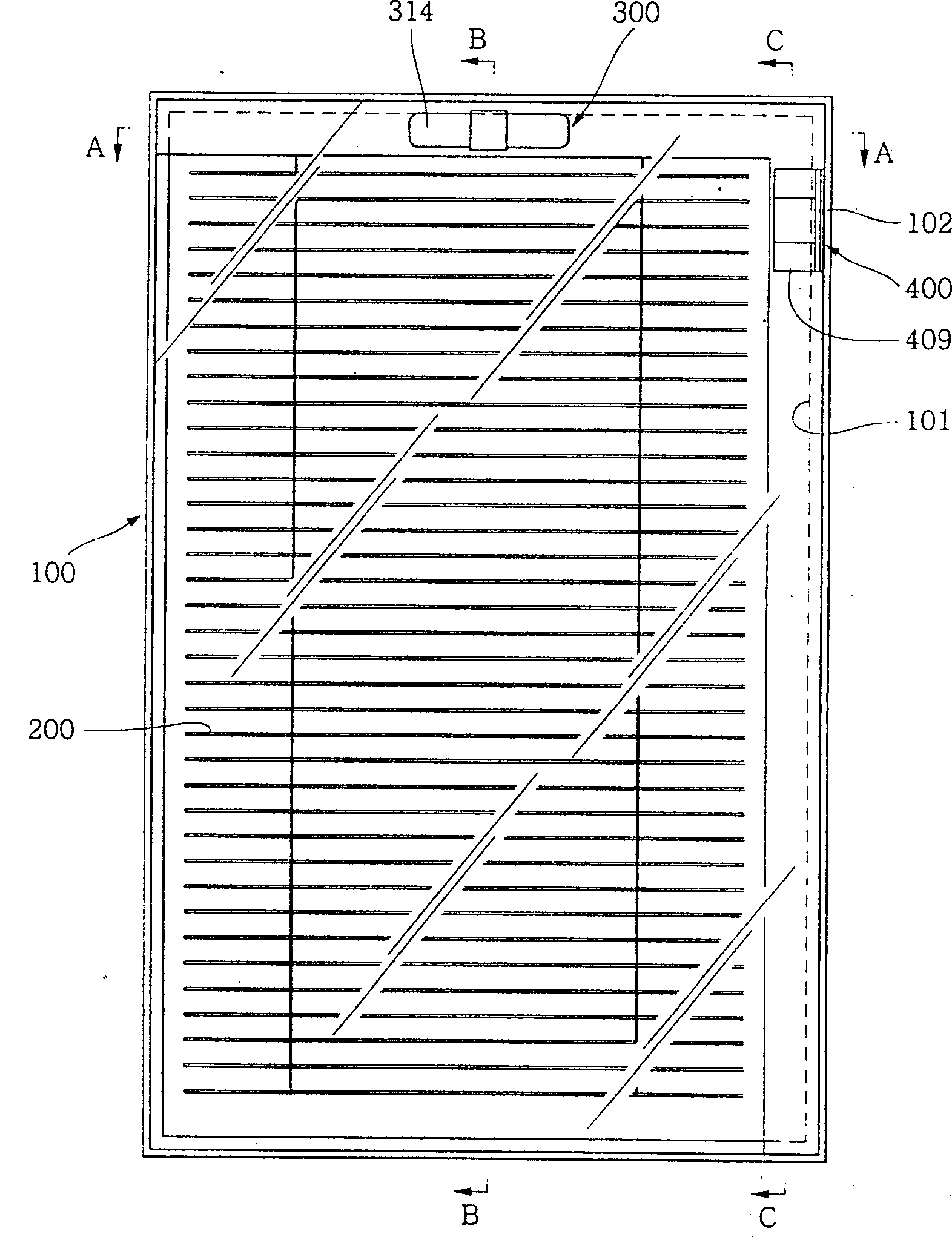

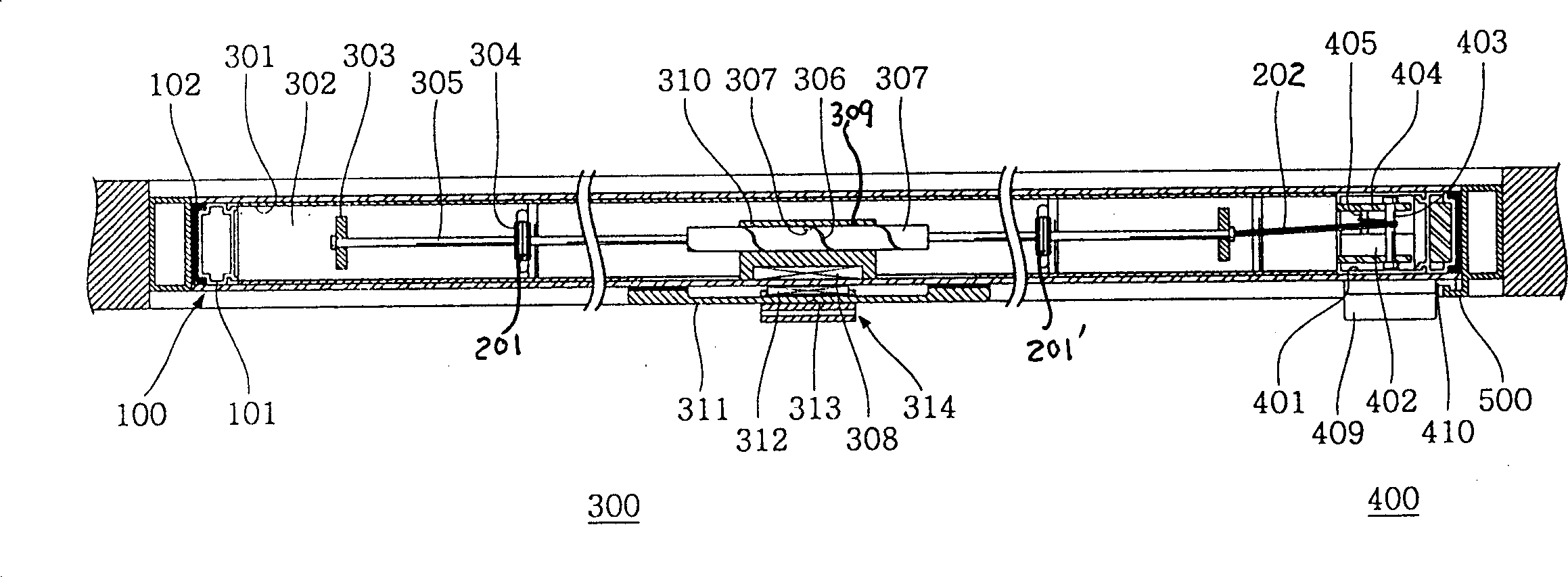

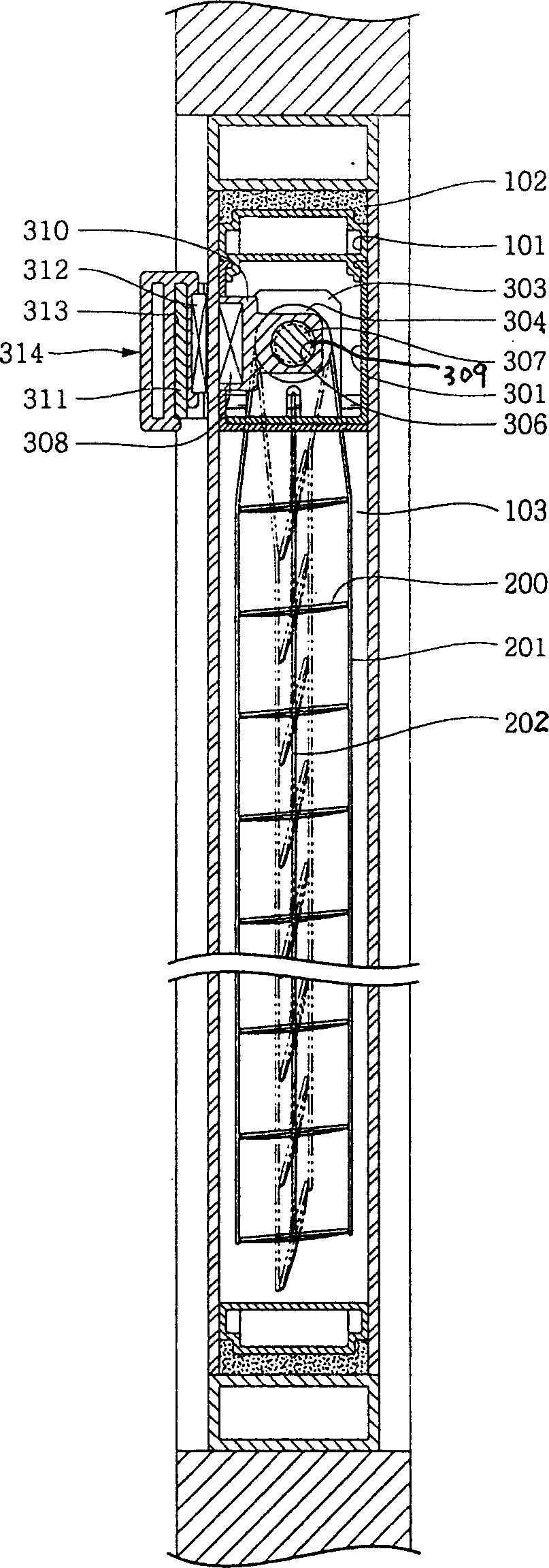

Improved dual-layer glass window with louver sandwich

InactiveCN1379164ASignificant advantagesSignificant beneficial effectLight protection screensUnits with parallel planesWindow shutterFixed frame

An improved dual-glass window with louver window between two glasses features that the fixing frame of the said dual-glass window has a transverse frame unit in it, the said transverse frame has two axles able to be turned and a magnetic angled regulator for regulating its angle, and a vertical frame of the said louver window has a magnetic open-close regulator for regulating the open (or close) state of louvers. Its advantages are simple structure, and high safety and reliability.

Owner:天津青亚玻璃制品有限公司

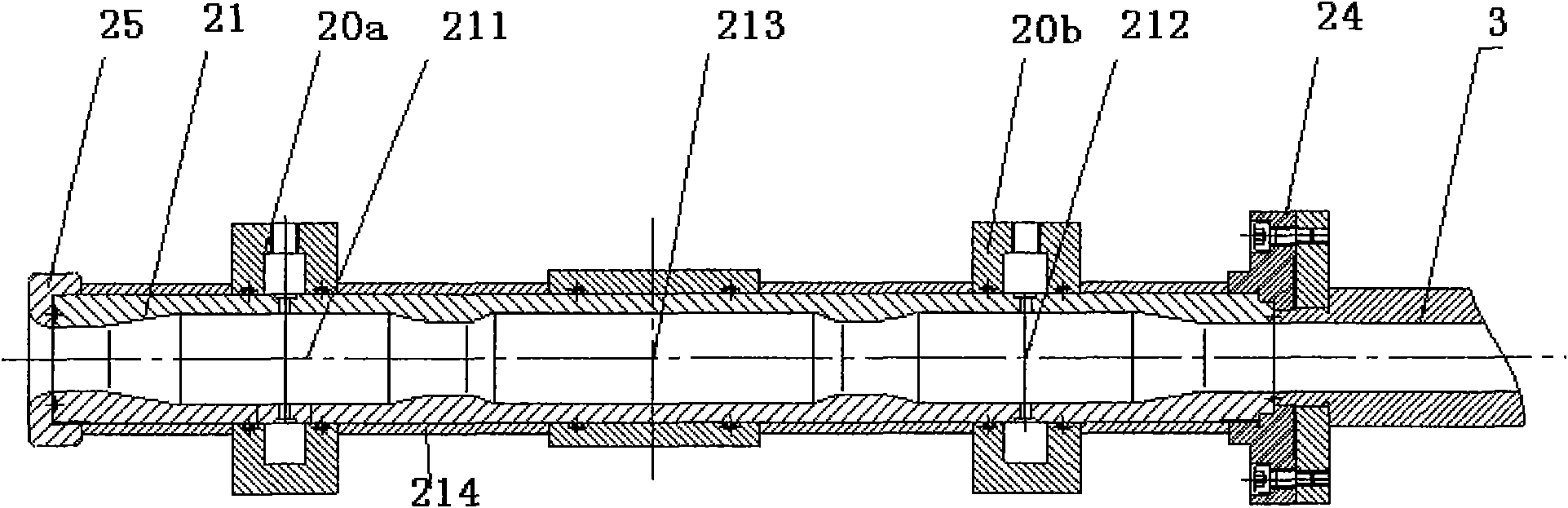

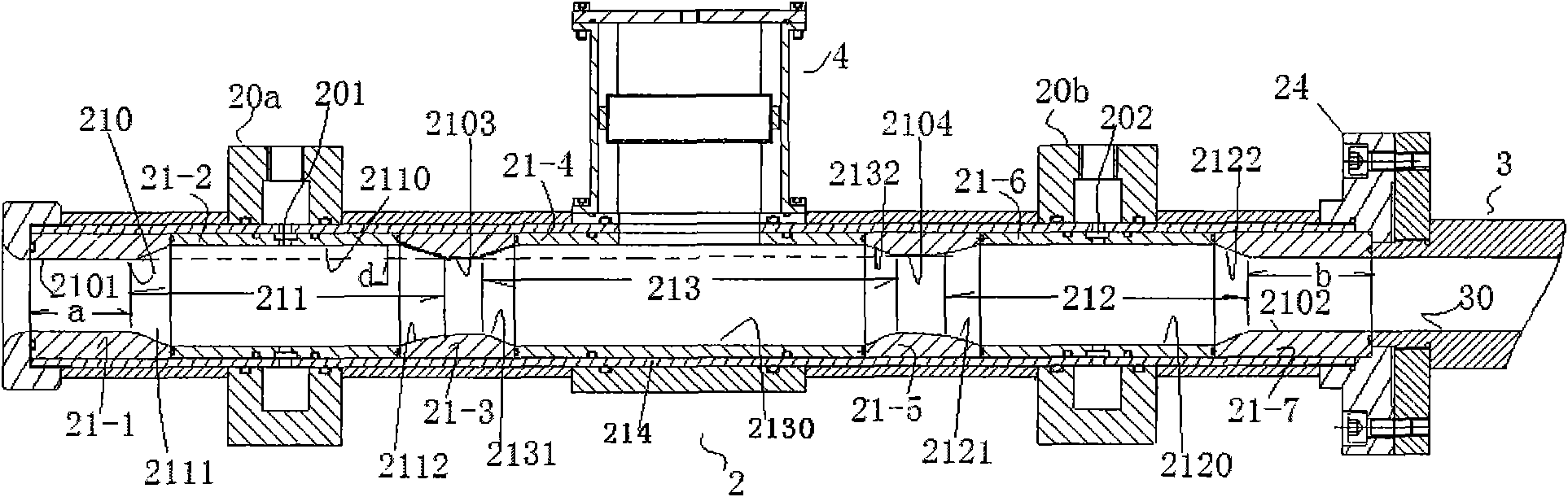

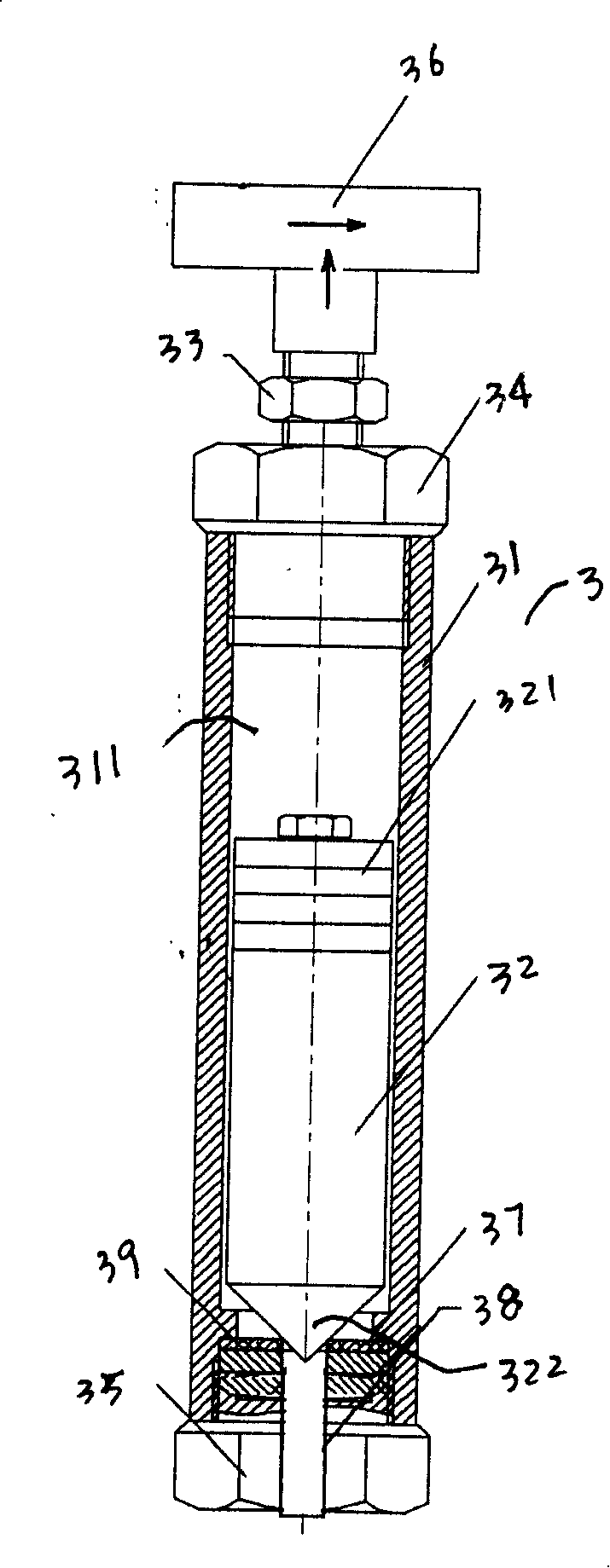

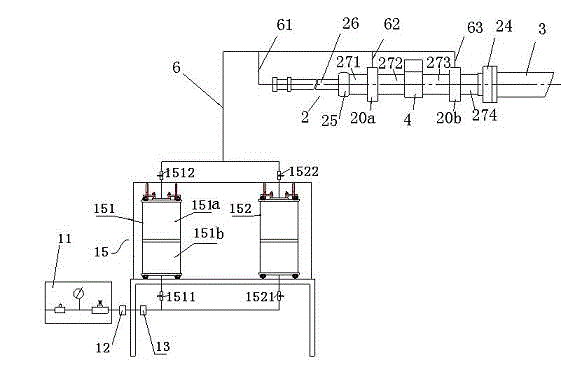

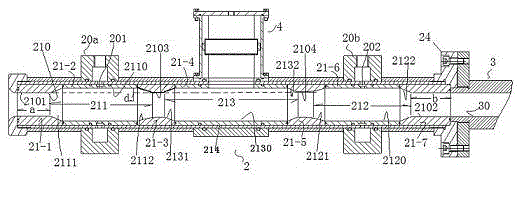

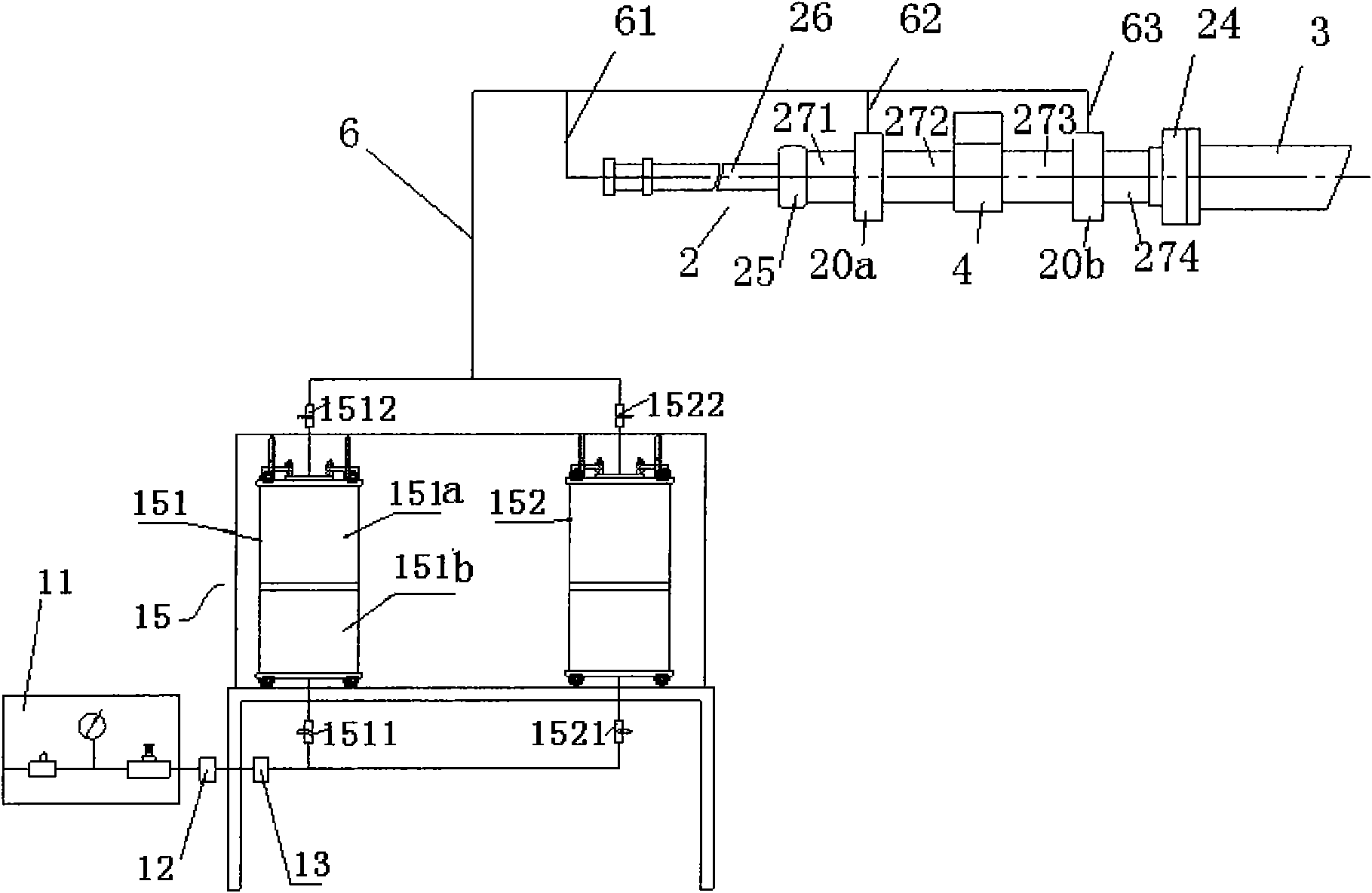

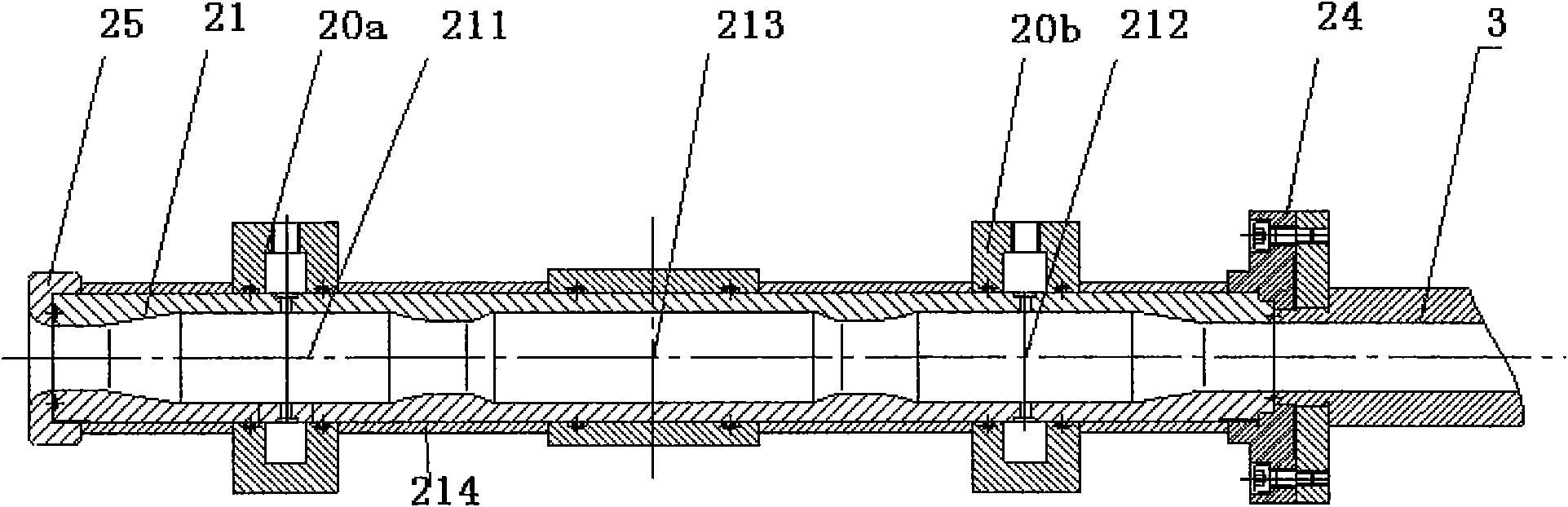

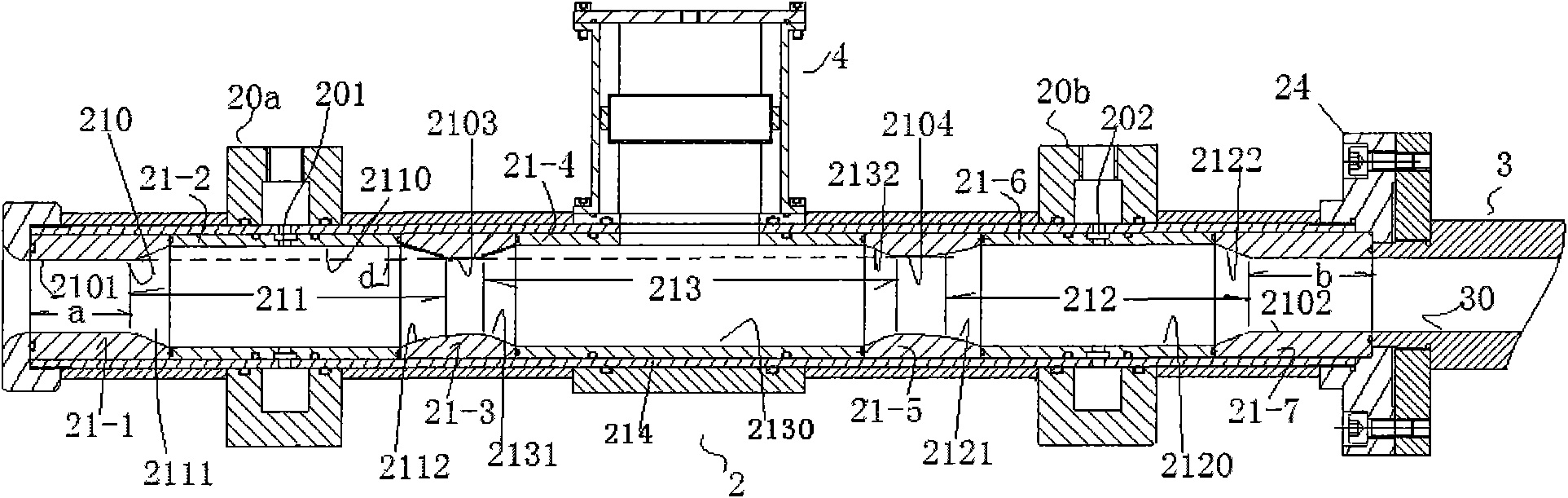

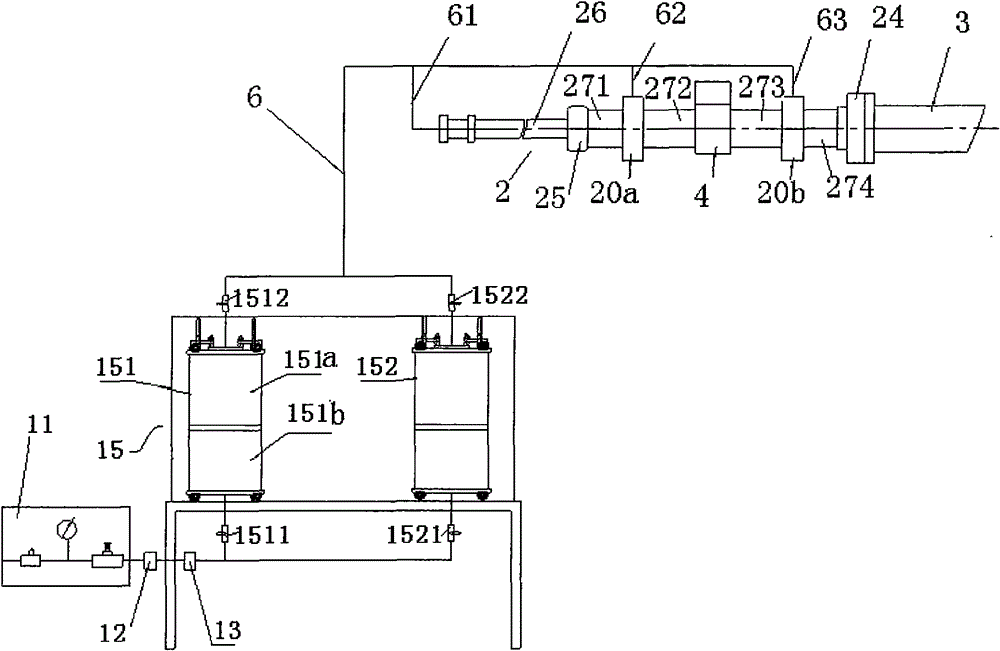

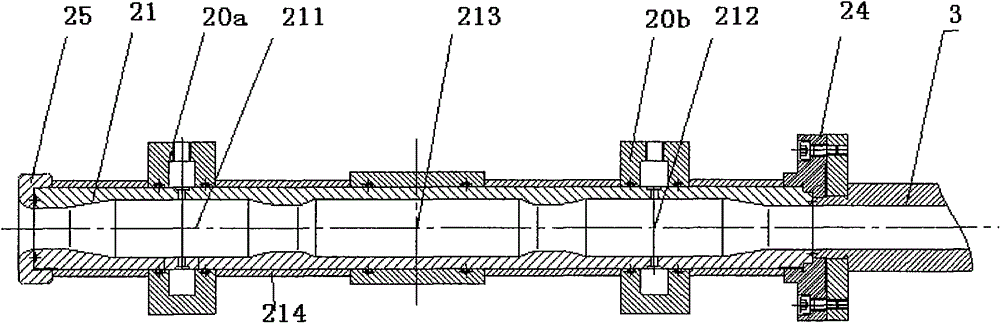

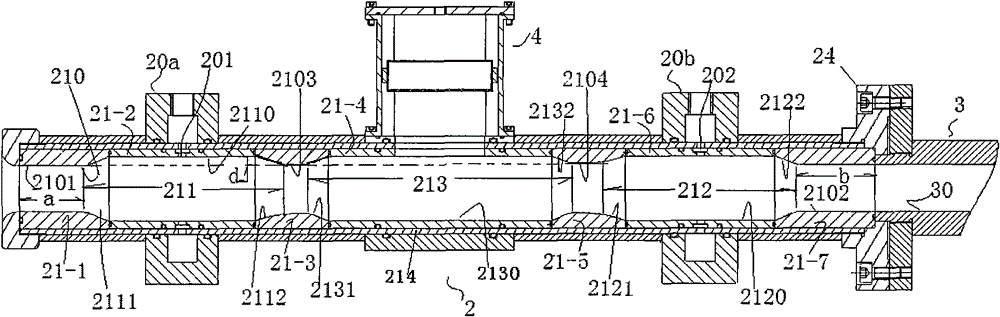

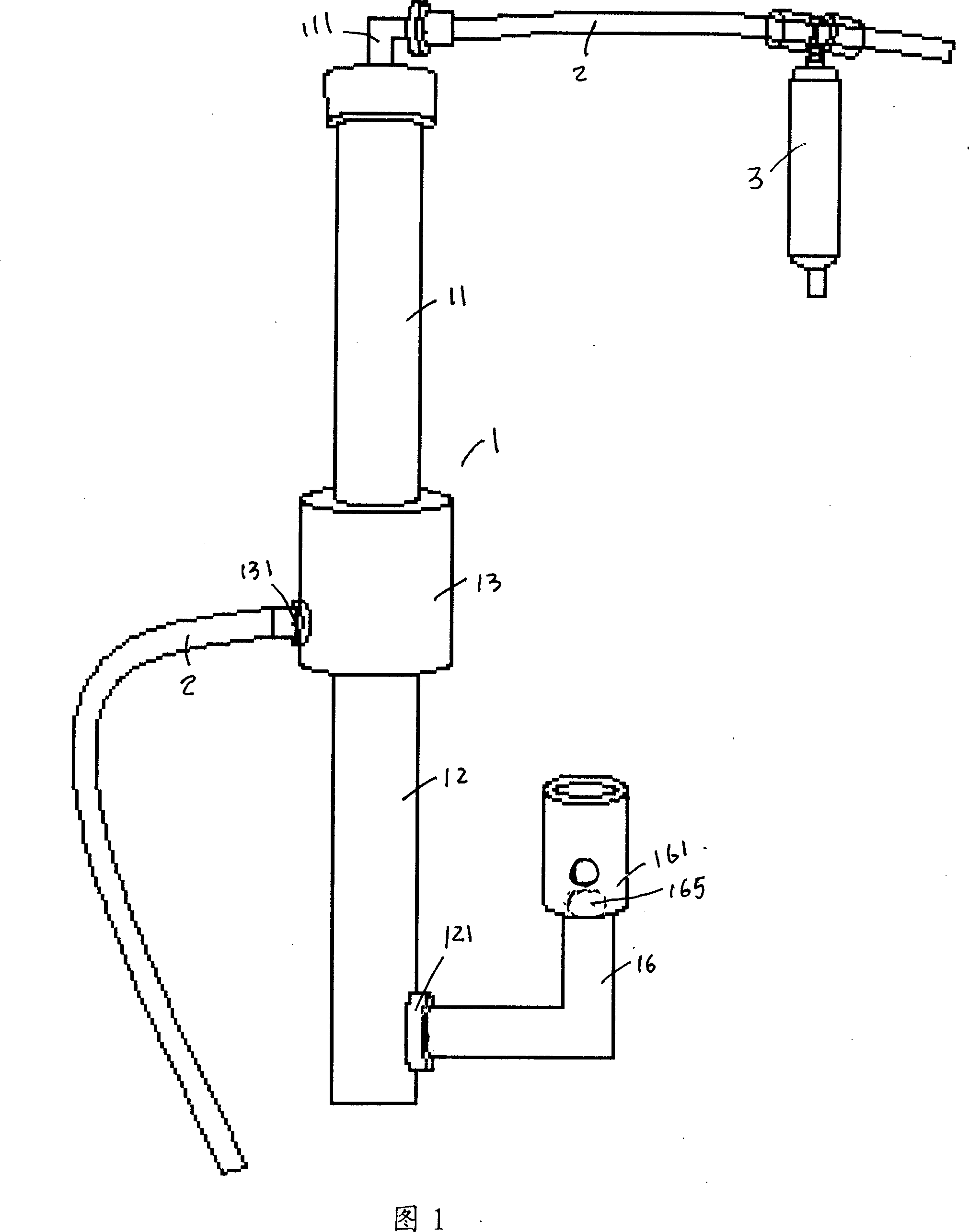

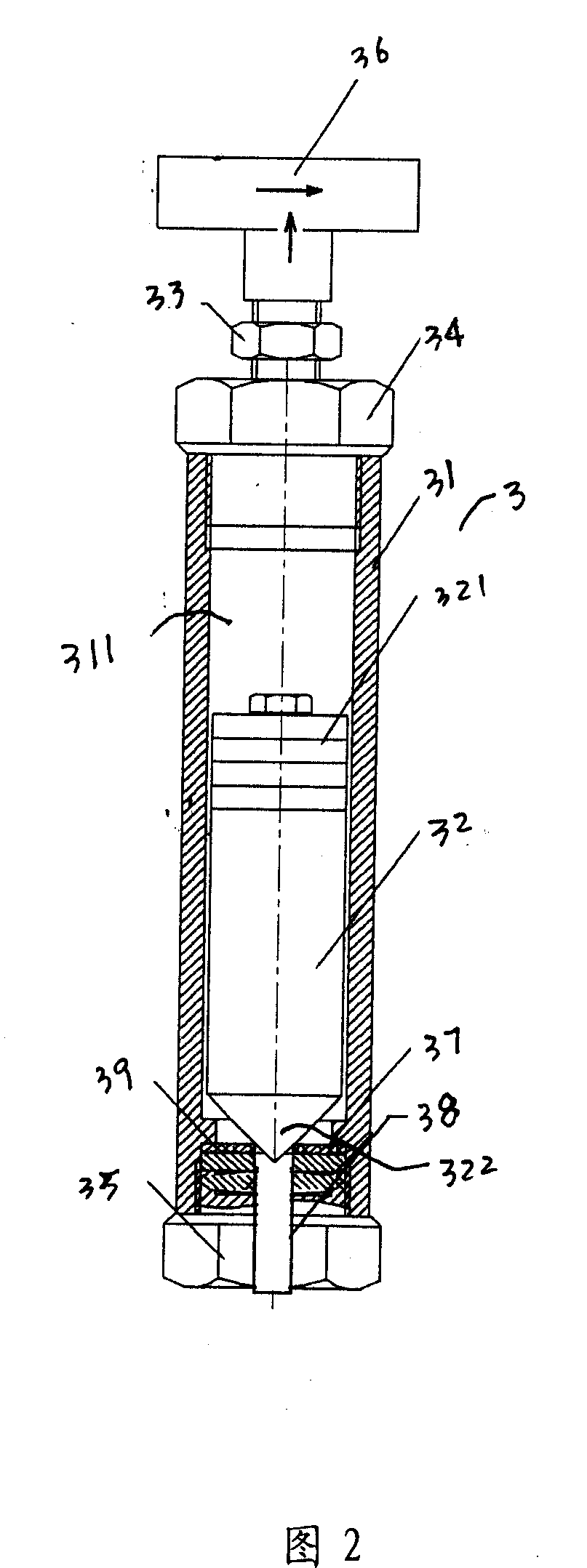

Glass fiber reinforced plastic tubular product pultrusion glue-injection device and glue-injection unit

A glass fiber reinforced plastic tubular product pultrusion glue-injection device and a glue-injection unit relate to a device that dips glue solution in pultrusion equipment and leads glass yarn and felt to be compounded and thermoset so as to form continuous sectional materials, wherein a glue solution supply unit and the glue-injection unit are connected through a glue solution conveying pipe in a manner of being capable of injecting the glue solution to the glue-injection unit which is configured in a manner of being capable of connecting with a pultrusion mold. The proposal can realize the work of dipping the glass yarn and felt by injecting the glue solution in a closed mold device and effectively avoid the free volatilization of the glue solution and ensure the stability of viscosity of the glue solution in the whole pultrusion process. The proposal can control the glue solution supply, and the glue-injection mold has strong adaptability and is easier for industrial promotion.

Owner:天津市金锚科技发展有限公司

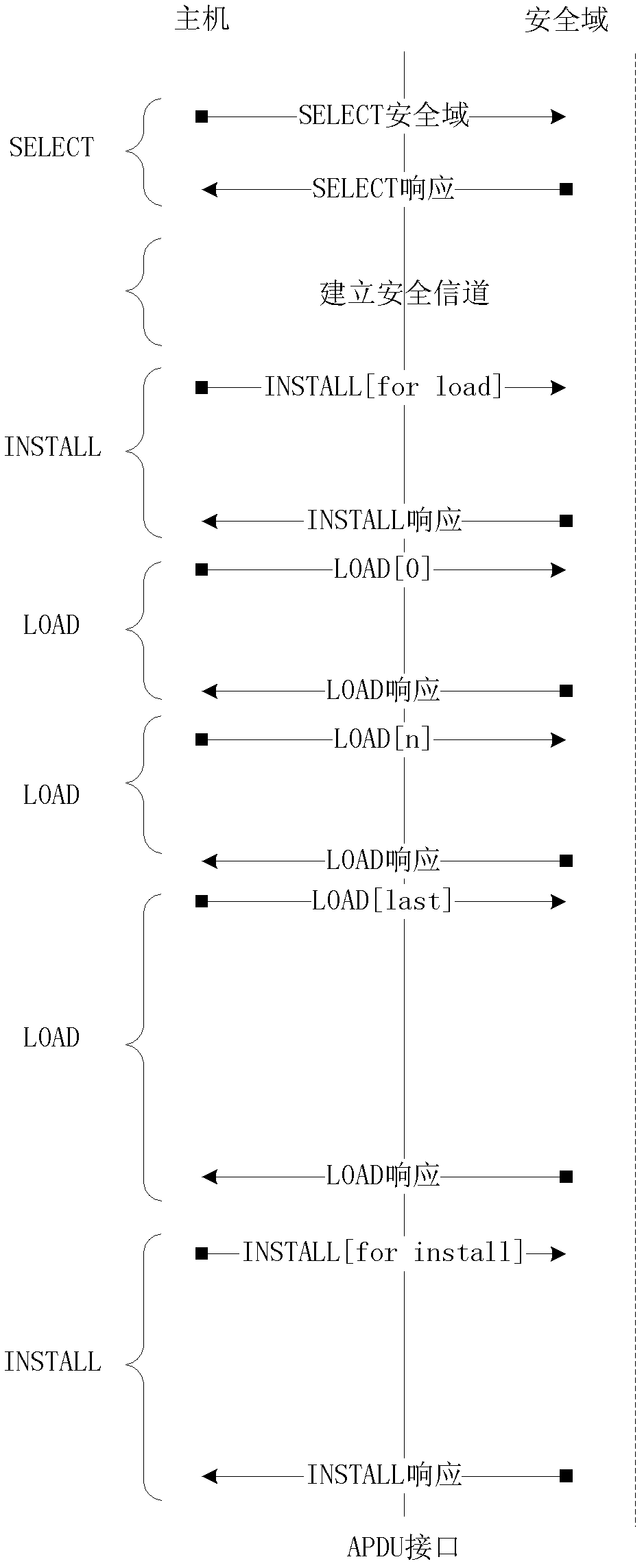

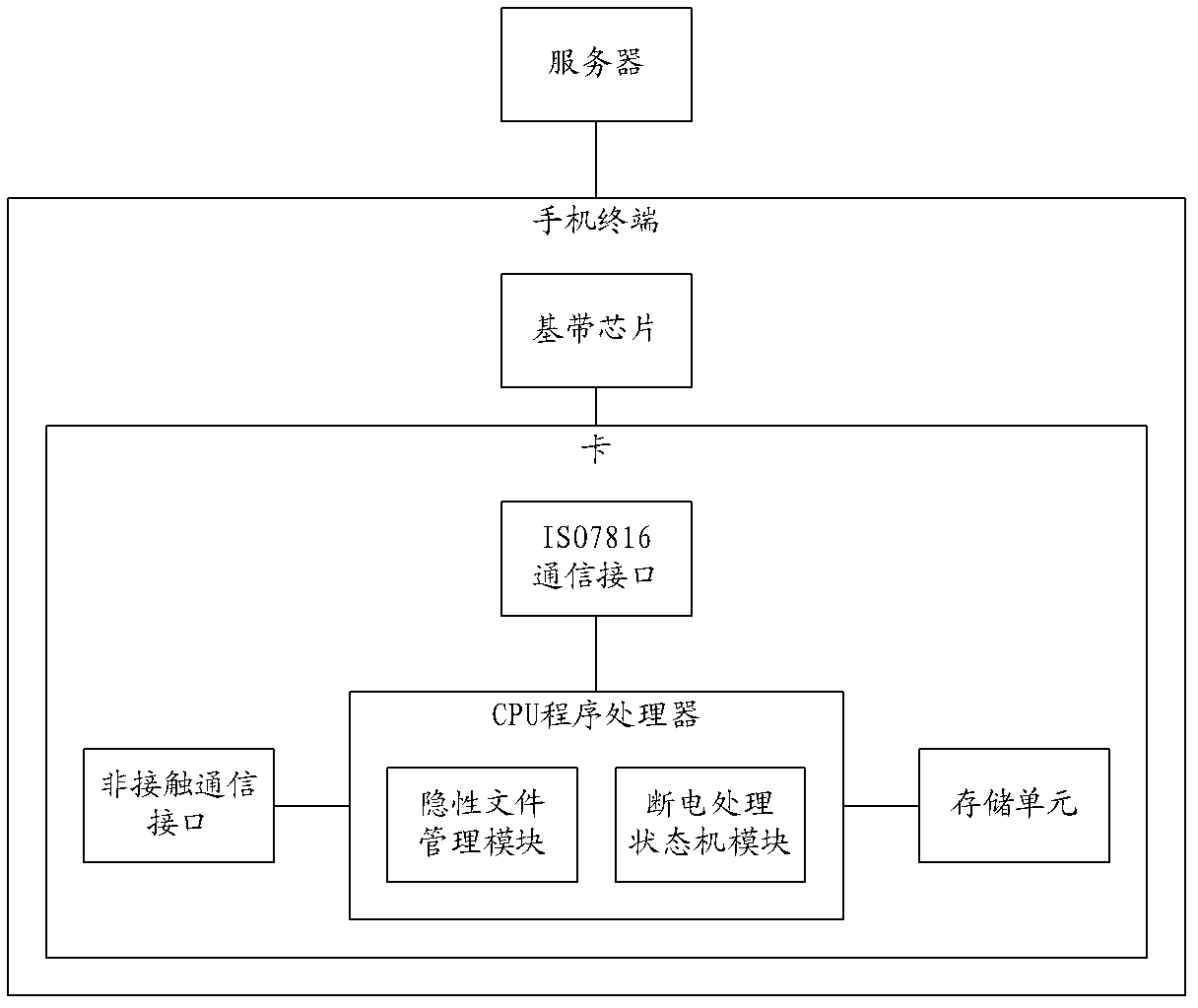

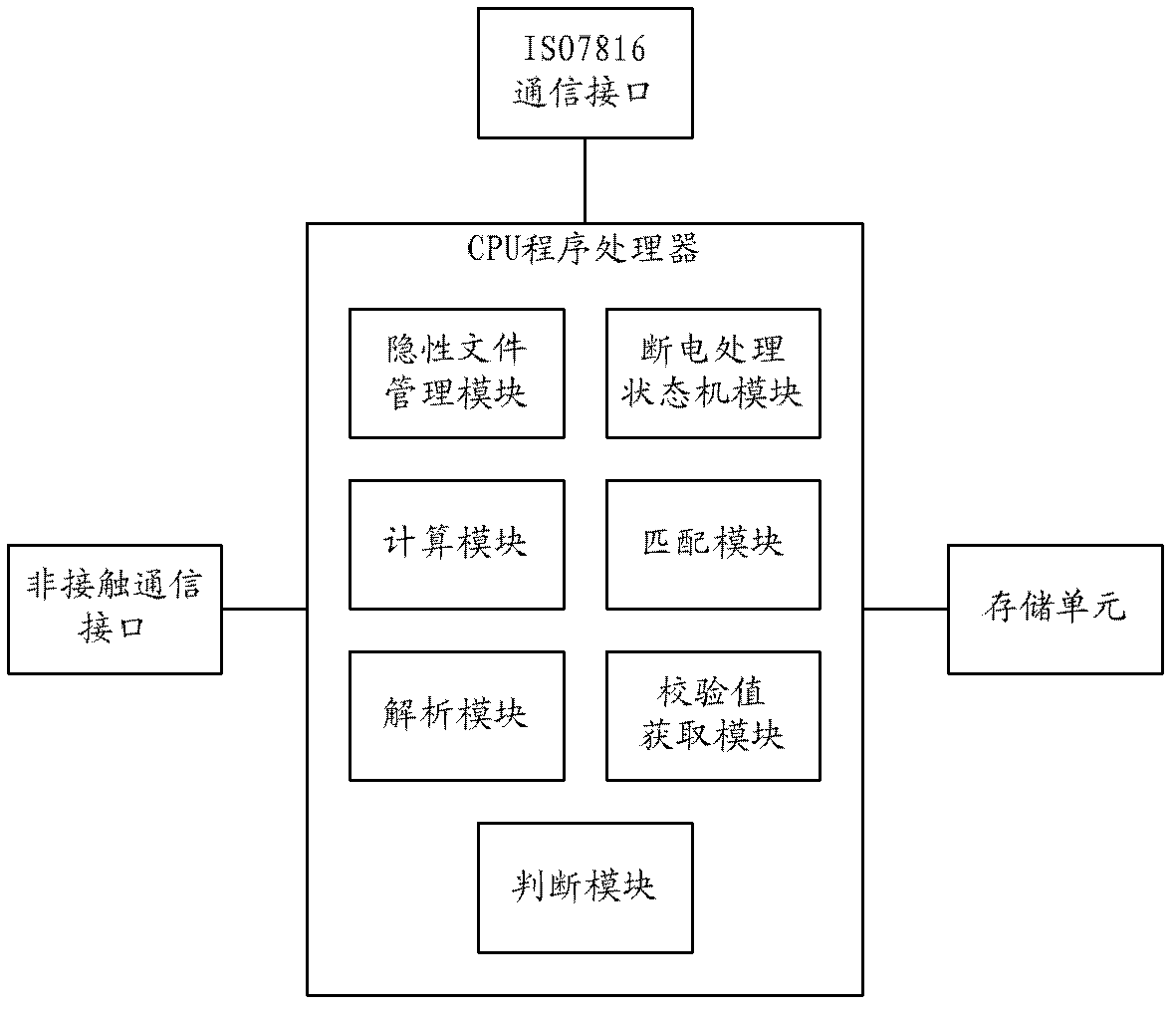

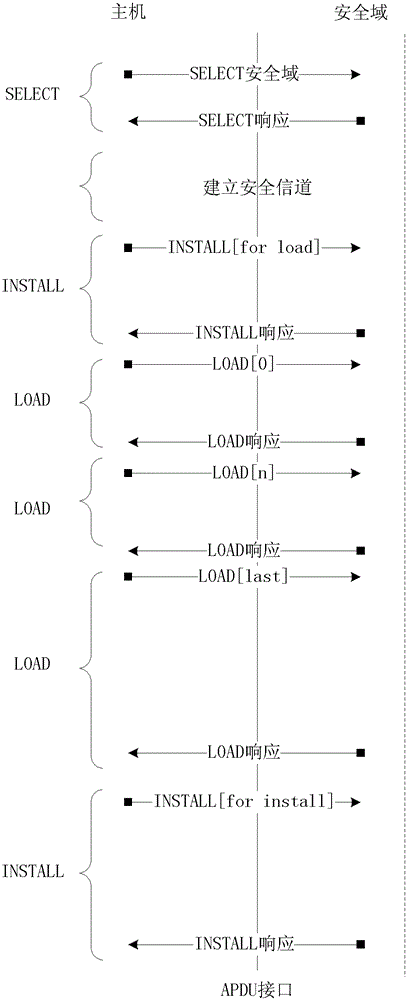

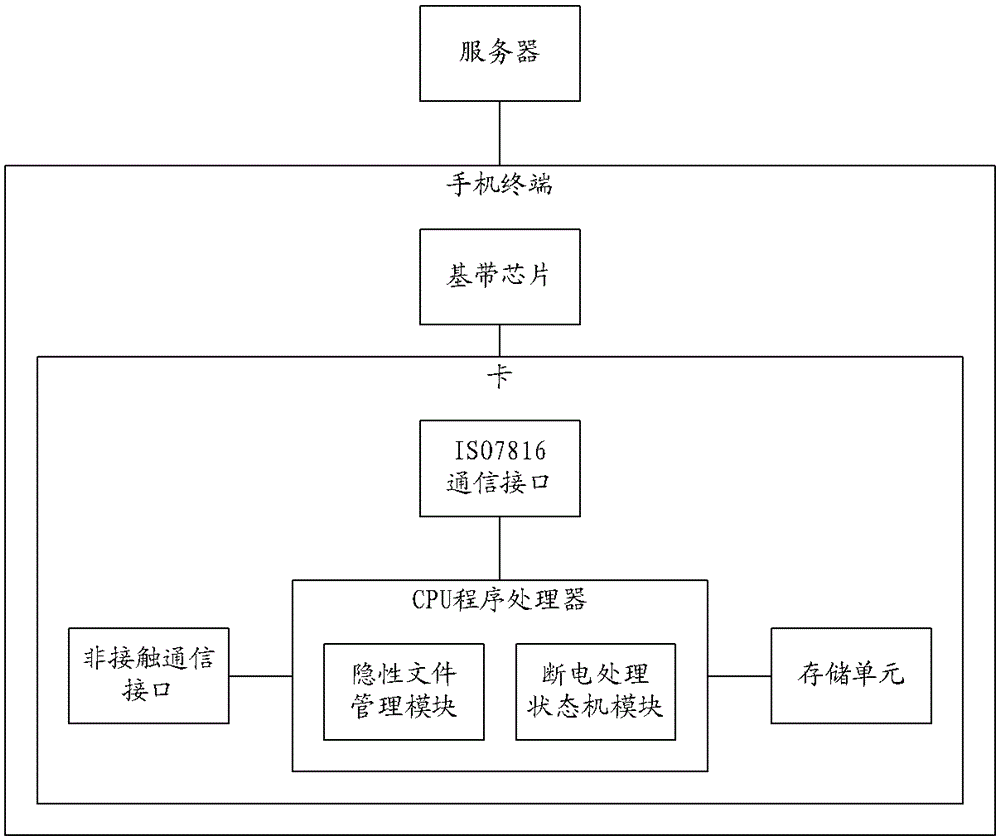

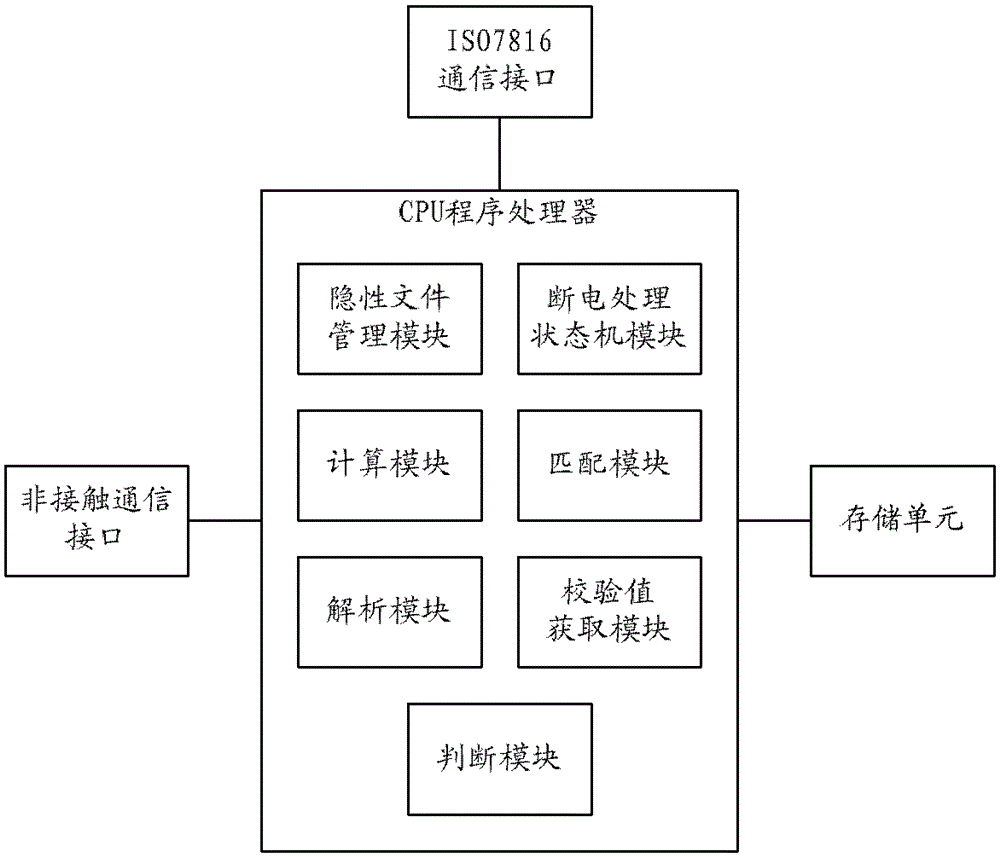

Card application downloading method, system and device

ActiveCN103309758ASolve wasteSolve space problemsDigitally marking record carriersFault responseComputer hardwareUtilization rate

The invention discloses a card application downloading method, a card application downloading system and a card application downloading device. The method comprises the following steps of setting an application hidden file and an application example hidden file in a card, wherein the application hidden file is used for storing application data received in a card application downloading process, and the application example hidden file is used for storing downloaded application example data; setting not less than 2 states in the card application downloading process; and judging whether power is cut off or not between the states, and if the power is cut off, clearing the application hidden file or the application example hidden file. According to the technical scheme, influence on the use of the card after the power is cut off in card application downloading and installation processes can be avoided, the utilization rate of a space in the card can be increased, and the card application downloading and installation performance can be improved.

Owner:CHINA MOBILE COMM GRP CO LTD

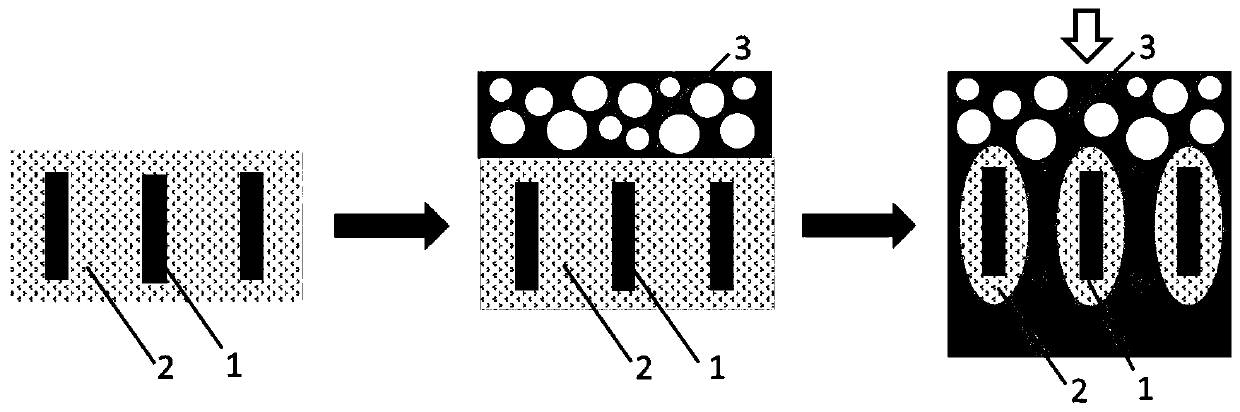

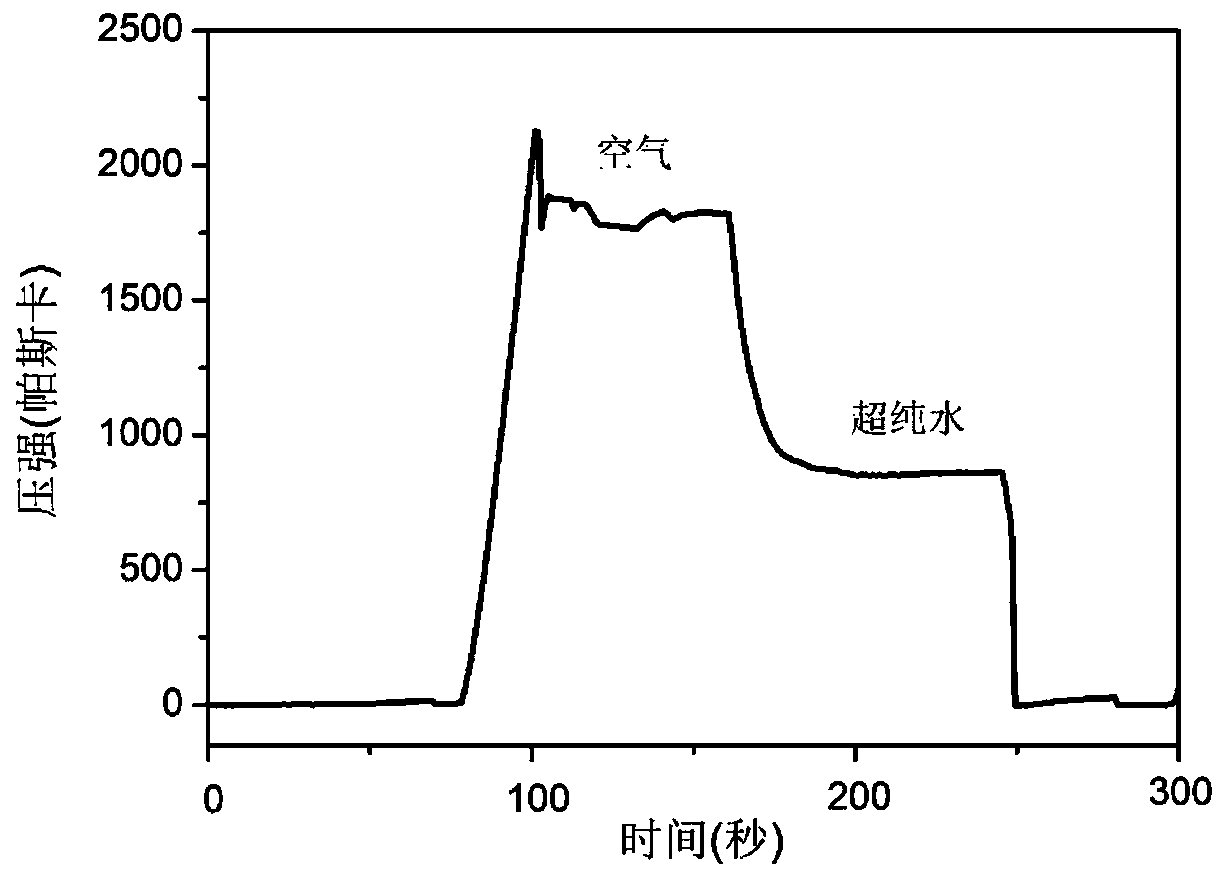

High efficiency liquid permeation and gas resistance fluid composite membrane system

ActiveCN110038448ALow investment costEasy to promote in industryMembranesSemi-permeable membranesPorous membraneProduct gas

The invention discloses a high-efficiency liquid permeation and gas resistance fluid composite membrane system which comprises a solid porous membrane and a functional fluid, wherein the functional fluid infiltrates the solid porous membrane to form a fluid gate control channel through which a transported fluid can pass; at the same flow rate, the transported fluid can more easily pass through thefluid gate control channel compared with a transported gas, the liquid permeation and gas resistance fluid composite membrane system with the separation efficiency as high as 100% can be obtained, and the liquid permeation and gas resistance fluid composite membrane system has wide application prospects in the fields of environment, energy, chemical reactors, medicines, aerospace and the like. The liquid permeation and gas resistance fluid composite membrane system effectively solves the problems that the traditional membrane separation method cannot realize liquid permeation and gas resistance function, is easy to pollute, has low service life, low separation efficiency, high investment cost and the like, and a technology using the high-efficiency liquid permeation and gas resistance fluid composite membrane system to carry out gas-liquid separation is a novel microporous membrane gas-liquid separation technology with low investment cost, high efficiency separation and easy industrialization popularization.

Owner:XIAMEN UNIV

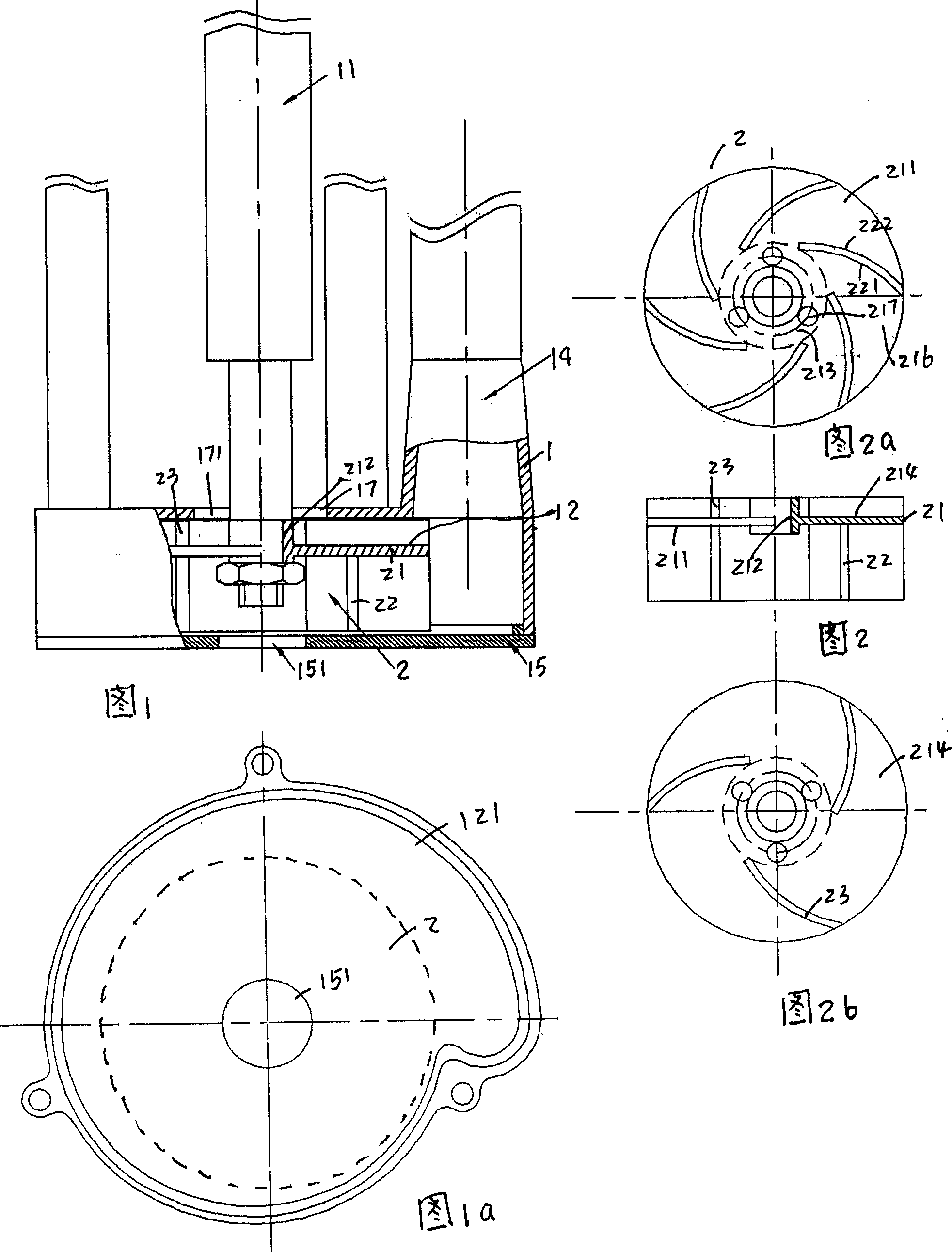

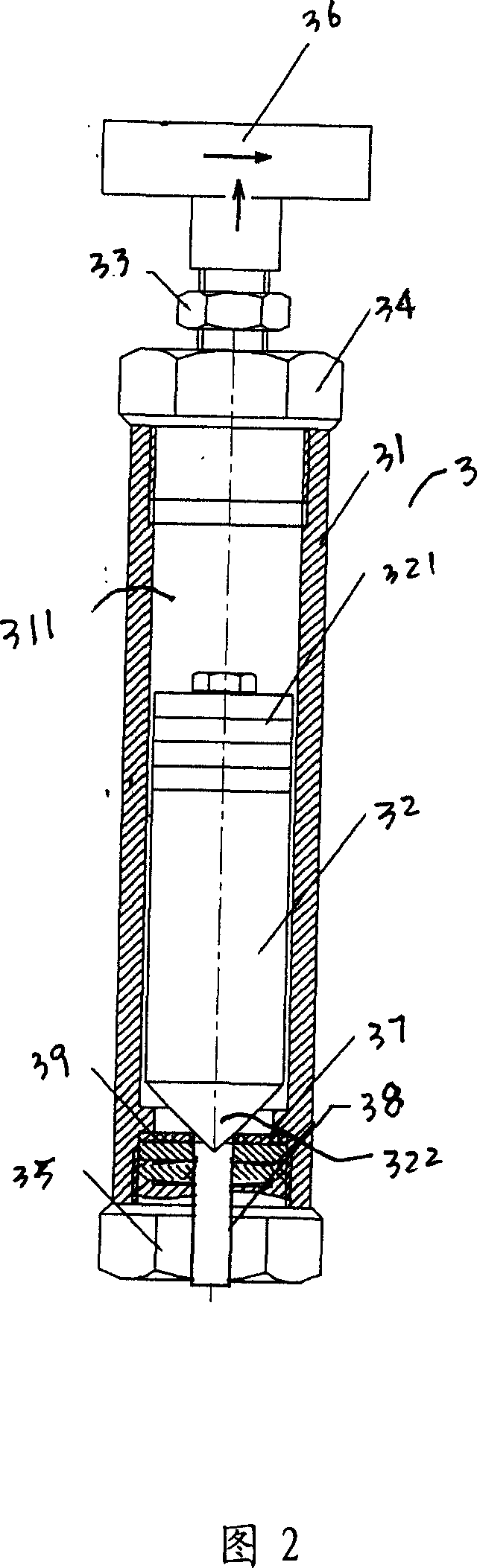

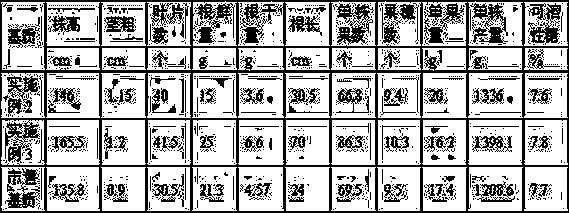

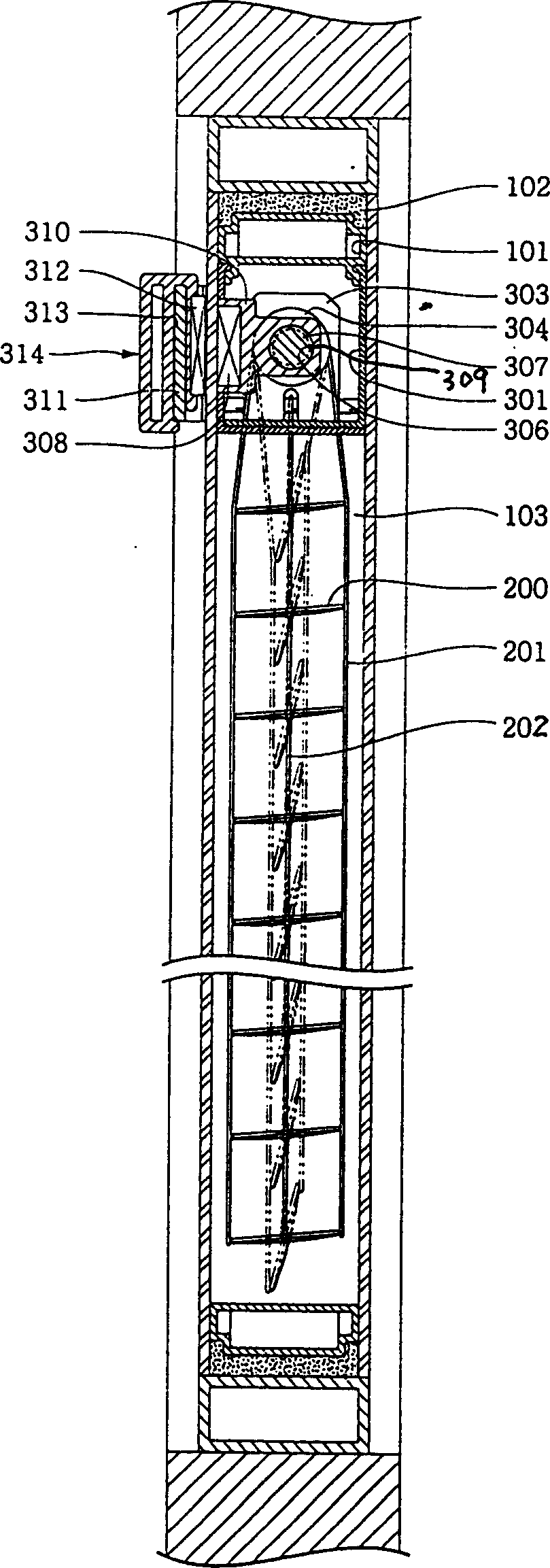

Centrifugal pump

ActiveCN1982719AOptimize structural configurationSolve the problem of not being able to extract liquidPump componentsPriming pumpDrive shaftPump head

A centrifugal pump comprises an impeller installed on the driving shaft. On one side of the impeller disk are disposed main vanes and on the other side of the disk are disposed secondary vanes. There is a preset distance from the starting point of the vane to the hub to form a traffic island area around the hub. A runner formed between vanes is in communication with the traffic island area with the traffic island area with spilling throughholes. The pump body has a chamber for holding vanes and the chamber has a curved channel with a water discharging tube. A liquid intake with an opening and closing mechanism is disposed in the centre of the pump head corresponding to the impeller.

Owner:天津港保税区鑫利达石油技术发展有限公司

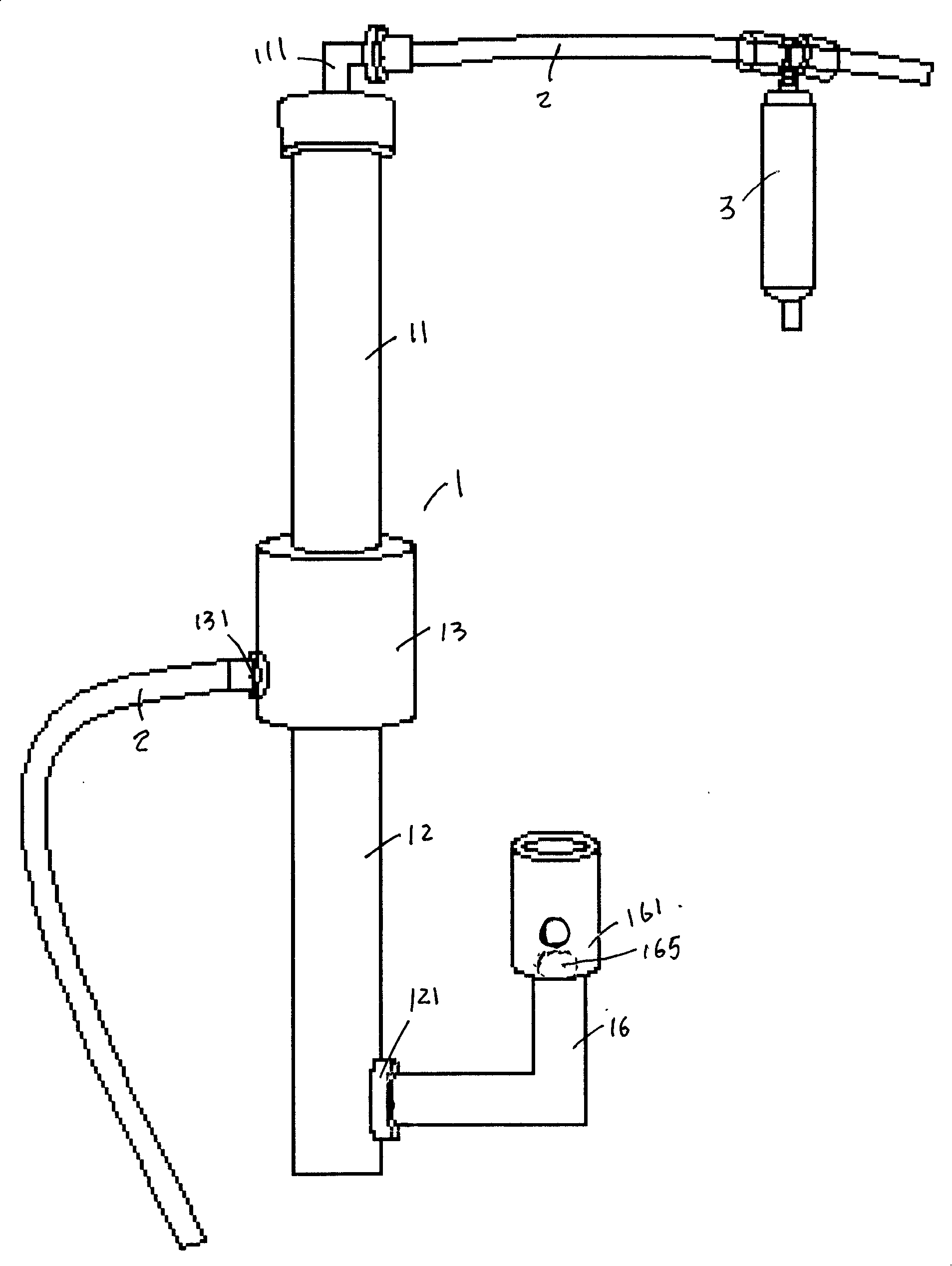

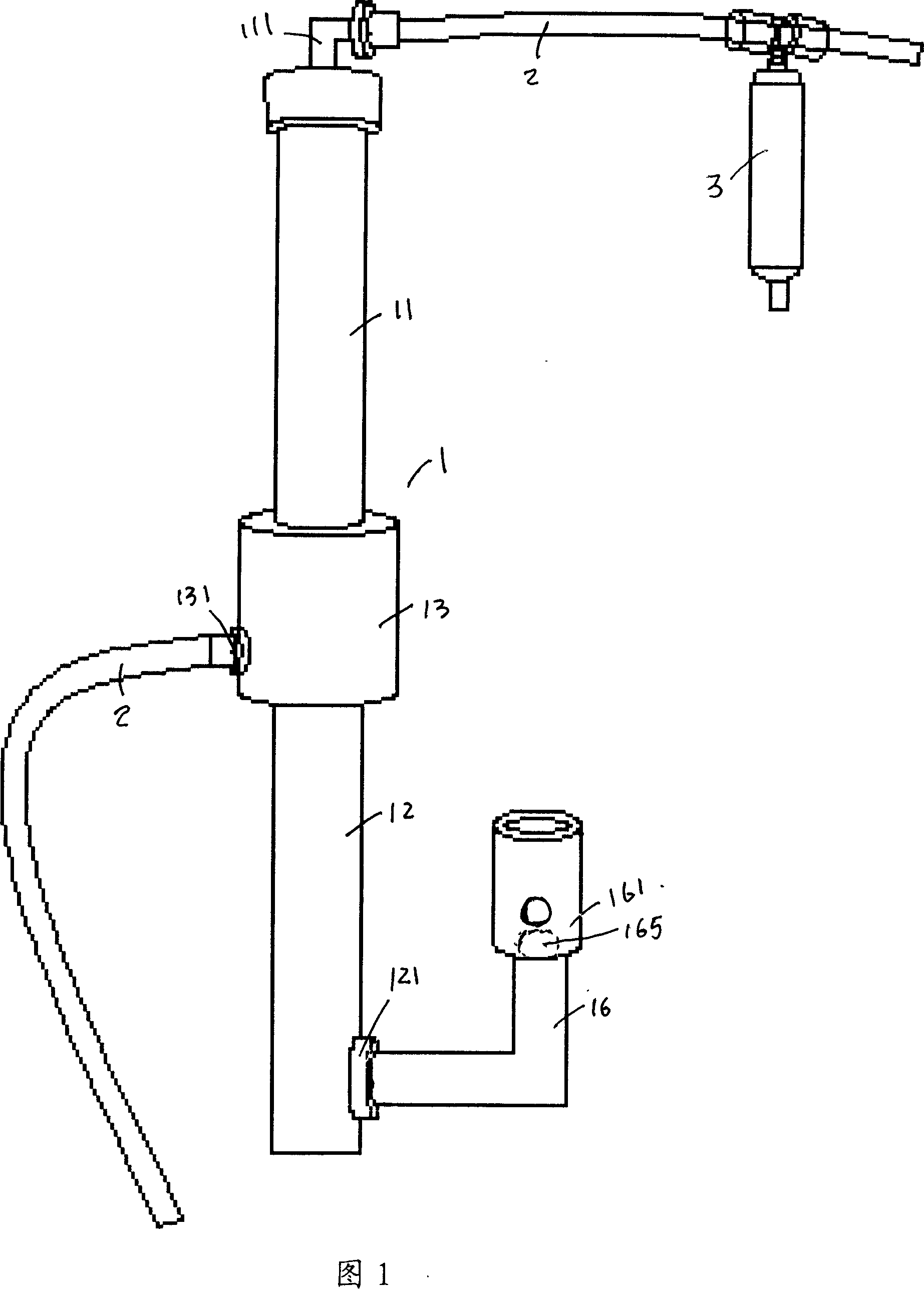

Gas pretreatment device with alarm mechanism

InactiveCN101210491AAvoid the impossibilityReduce dilutionWithdrawing sample devicesPreparing sample for investigationLine tubingDesiccant

Disclosed is a gas pretreatment device with an alarm mechanism, which is a gas treatment mechanism with a liquid collector tube and a dry gas collector tube; wherein the gas pretreatment device is connected with an alarm equipment provided with a negative pressure valve structure via a gas transmission pipeline; an inner chamber of a valve chest of the alarm equipment forms a negative pressure chamber which enables a valve plug to slide up and down; a counterbalance is fixed on the upper end of the valve plug. Reasonable allocation of pipeline structure improves heat preservation performance of pipelines; desiccating agent is arranged in the drying treatment section, so that dried gas flows into the pipelines towards a logging room and various moistures are discharged into the liquid collector tube after dipping down; arrangement of the alarm equipment with the negative pressure valve structure facilitates the timely discovery of problems that liquid is pumped into the gas treatment mechanism or the pipelines are frozen or blocked due to other causes, and prompts operators to troubleshoot problems; and the arrangement of a spilled-liquid tube beneath the liquid collector tube enables the automatic discharge of the liquid even though the liquid is in the gas treatment mechanism and stored in the liquid collector tube. The invention is simple in structure, convenient, practical and easier for industrial extension.

Owner:天津港保税区鑫利达石油技术发展有限公司

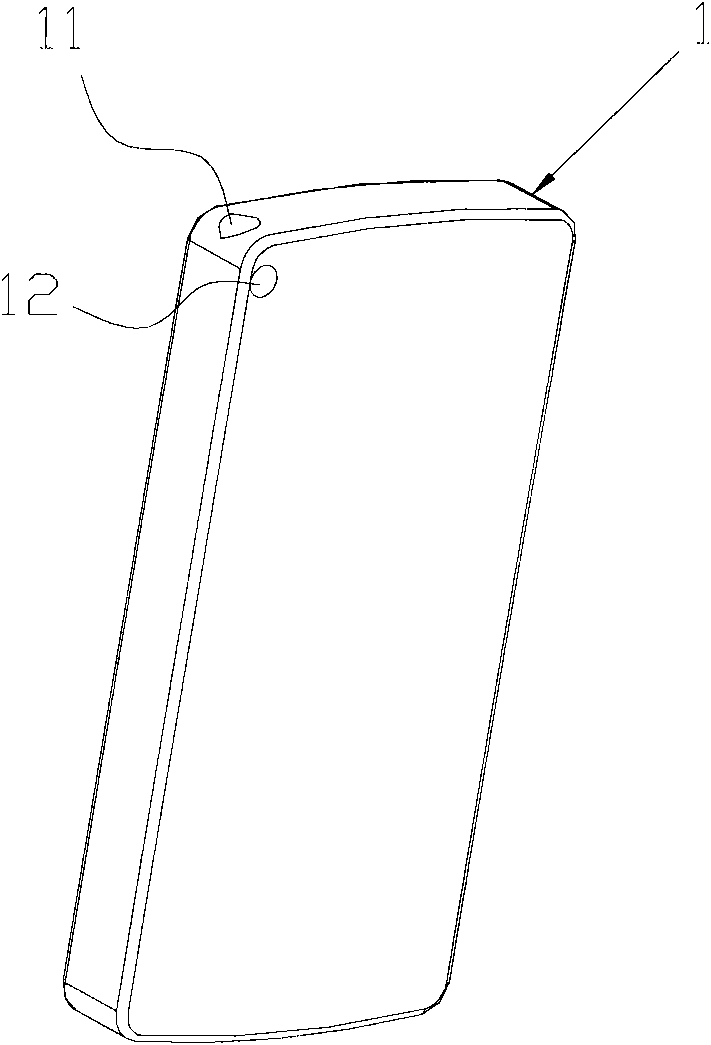

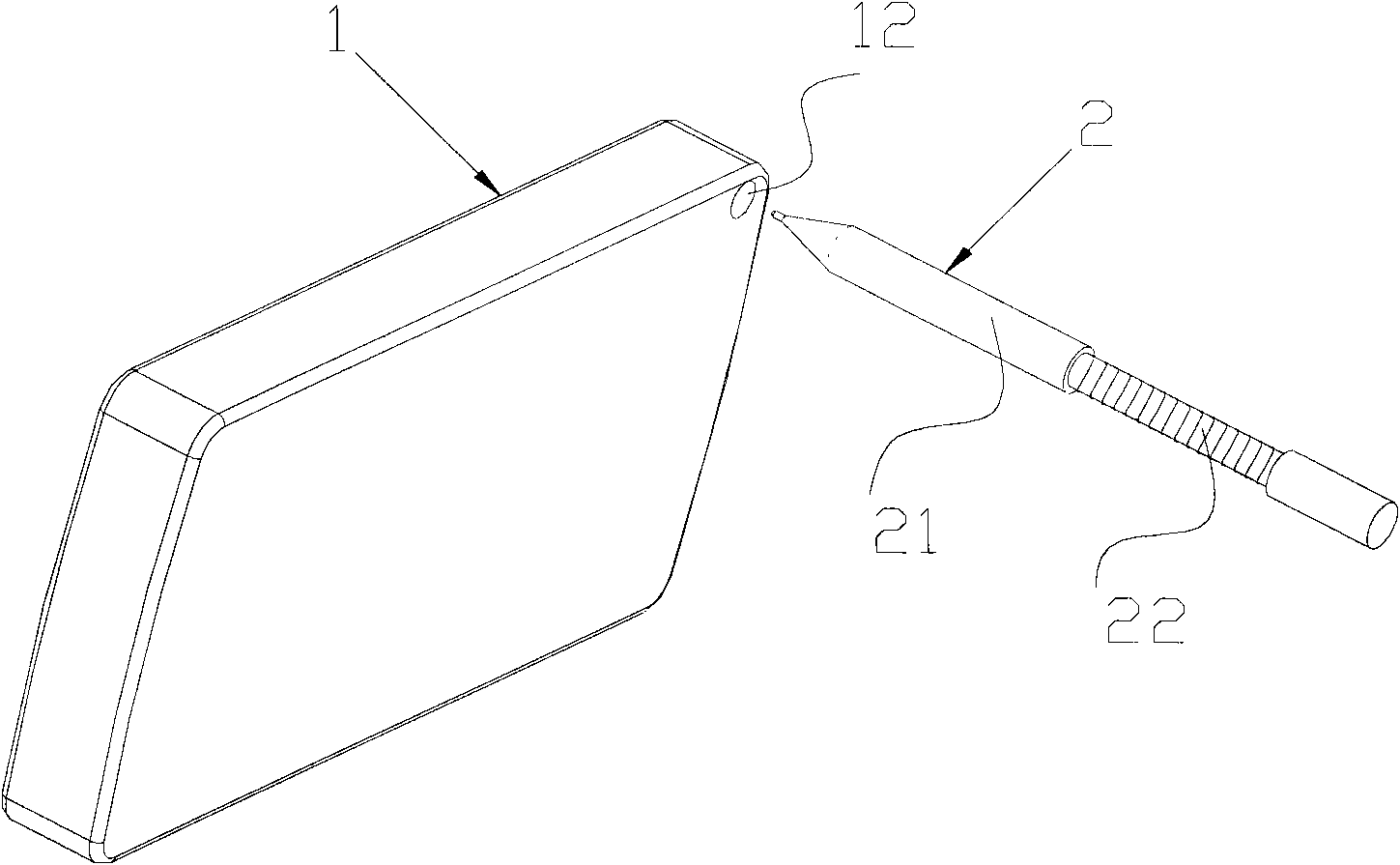

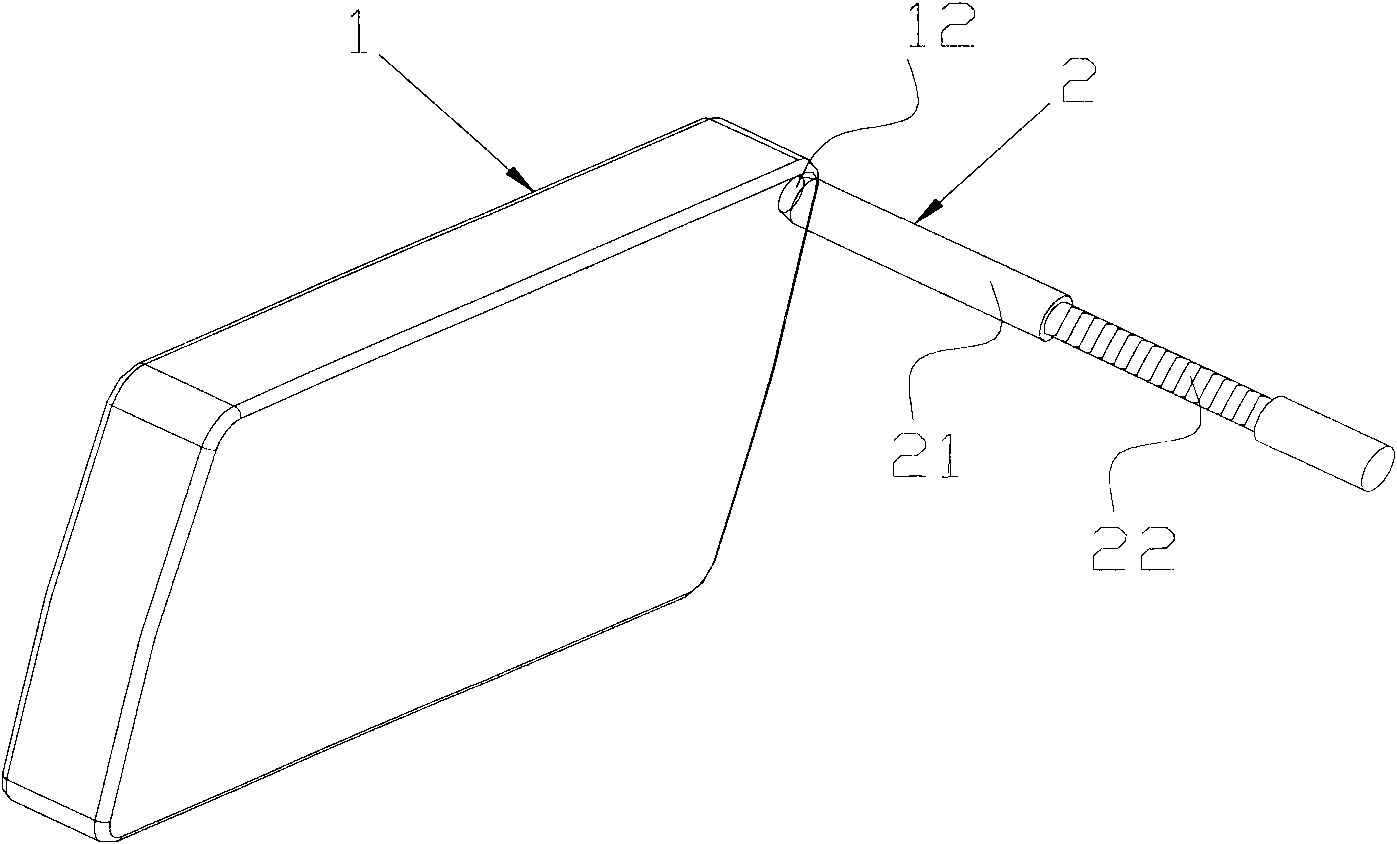

Portable device and handwriting pen thereof

InactiveCN101639736ACost savingEasy to promote in industryDigital data processing detailsRod connectionsHandwritingEngineering

The invention discloses a handwriting pen applied to a portable device, which comprises an outer tube, an inner tube, and a pair of connecting devices, wherein a first end part of the outer tube is used for connecting and supporting the portable device and a second end part thereof is provided with a cavity; a first end part of the inner tube is used to be fixed to a plane and a second end part thereof is pivoted in the cavity of the outer tube; and the pair of connecting devices is arranged in the cavity of the outer tube and on the second end part of the inner tube, and can adjust the lengthof the second end part of the inner tube extending into the cavity of the outer tube, so the portable device has different gradients relative to the plane. The handwriting pen realizes the functionswhich can be realized by complicated parts in the prior art through fewer parts and simple structure, saves cost and facilitates industrial popularization.

Owner:BYD CO LTD

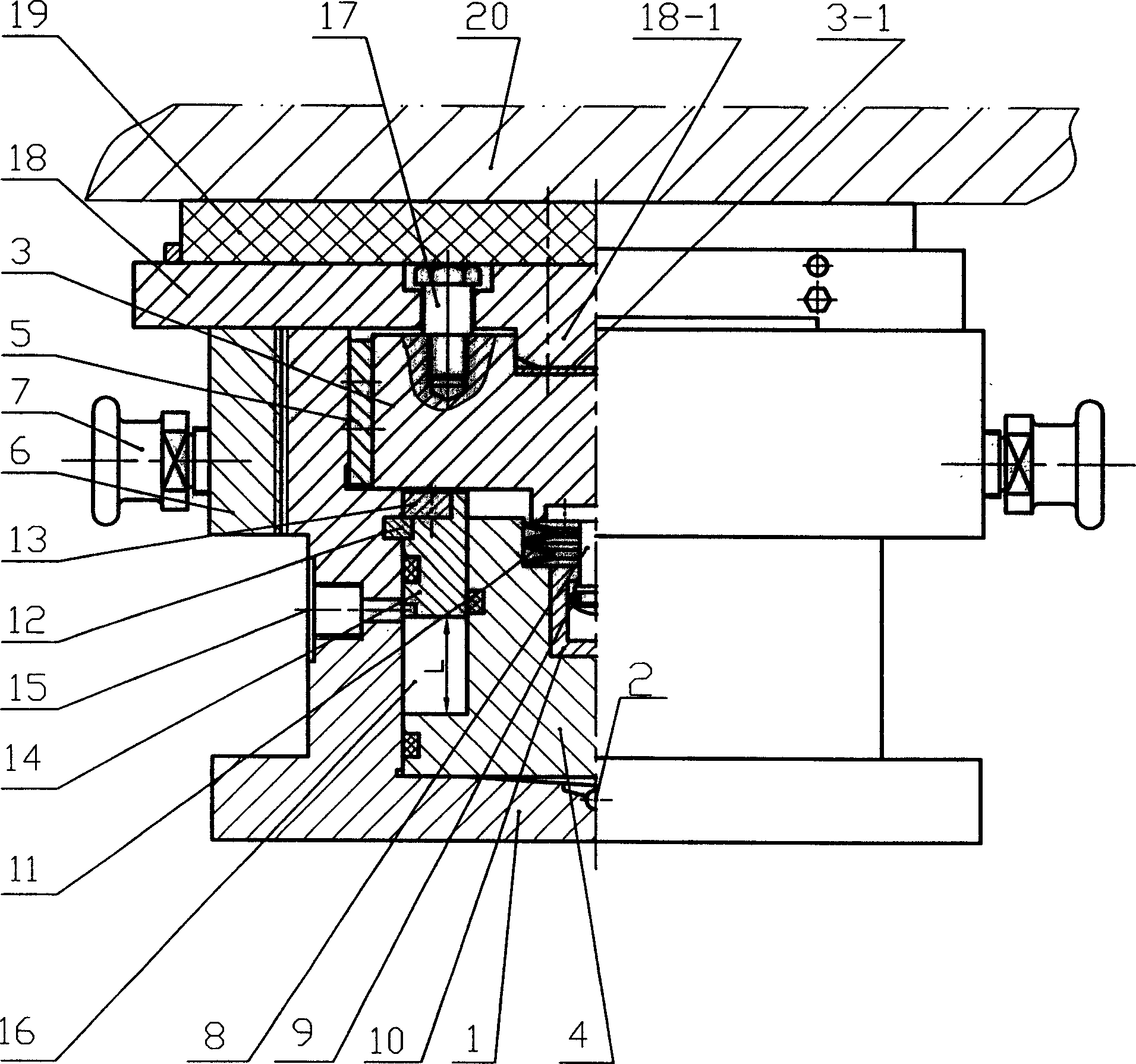

Braking arrangement

InactiveCN1632343ASignificant advantagesSignificant beneficial effectFluid actuated brakesHydro energy generationEngineeringCylinder block

The invention relates to a braking device. There are oil inlet and air holes on the cylinder body, the upper piston and the lower piston are installed in the cylinder body, the limit key is installed between the upper piston and the inner wall of the cylinder body, the nut and handle for adjusting and locking the upper piston are installed outside the cylinder body, the cylinder body and the upper piston The top of the piston fixes the brake pallet and brake shoe eccentrically through the positioning bolt. The lower part of the upper piston is fixedly connected with the piston core. The lower end of the piston core is clamped in the core sleeve of the inner cavity of the lower piston. , the limit sleeve installed between the lower piston and the cylinder body is connected with the inner wall of the cylinder through the ring key and the pressure ring, and the lower piston at the bottom of the limit sleeve and the inner cavity of the cylinder form a gas return working chamber as a mechanically limited space, corresponding to the gas return work The cylinder body of the chamber is provided with a gas return hole communicating with it. The invention has the advantages that: the stroke of the piston is limited by the mechanical limiting device, the piston always moves up and down in a straight line, and the piston is reset by air pressure, which is reliable, safe and flexible.

Owner:郭炜

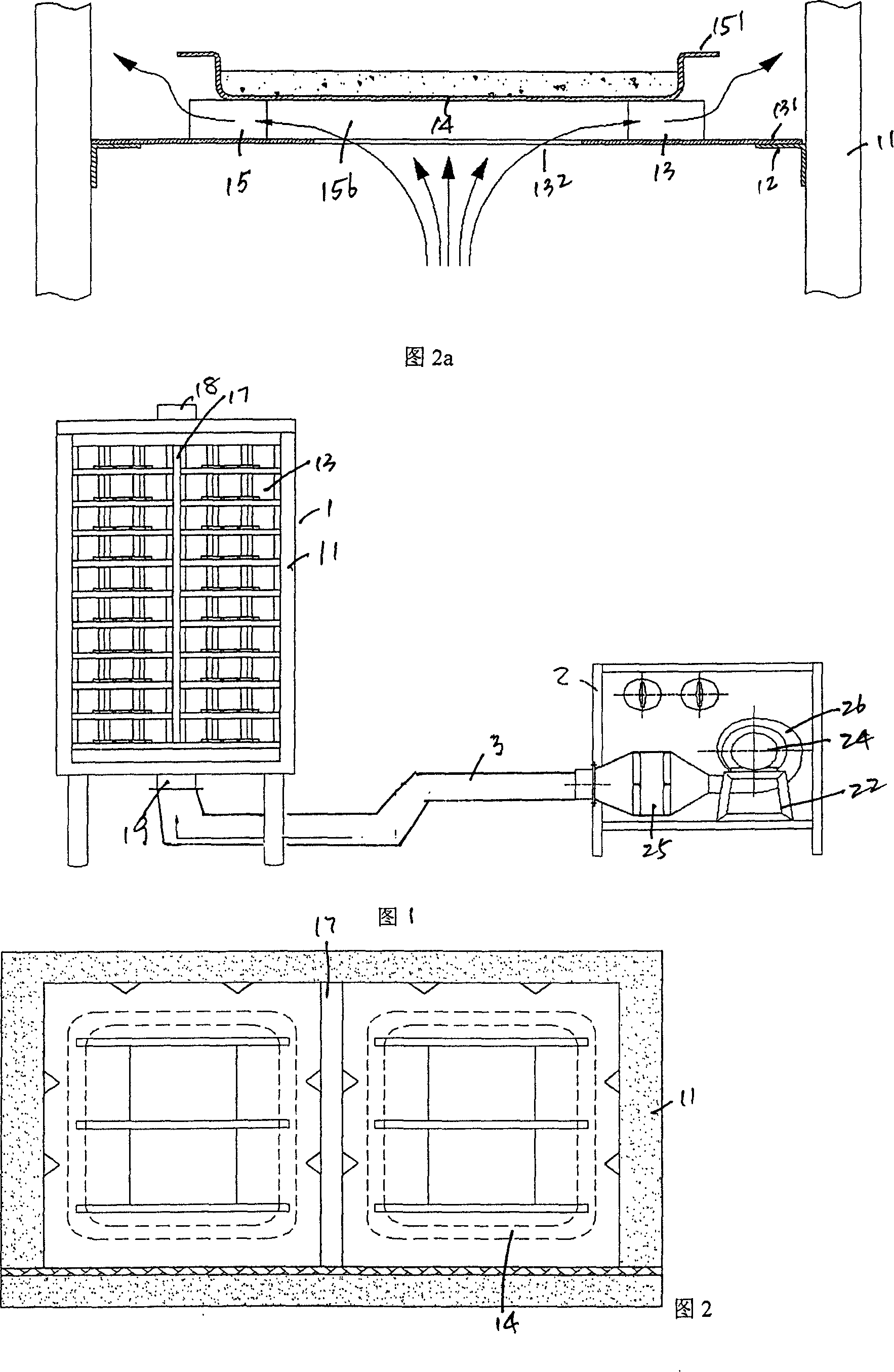

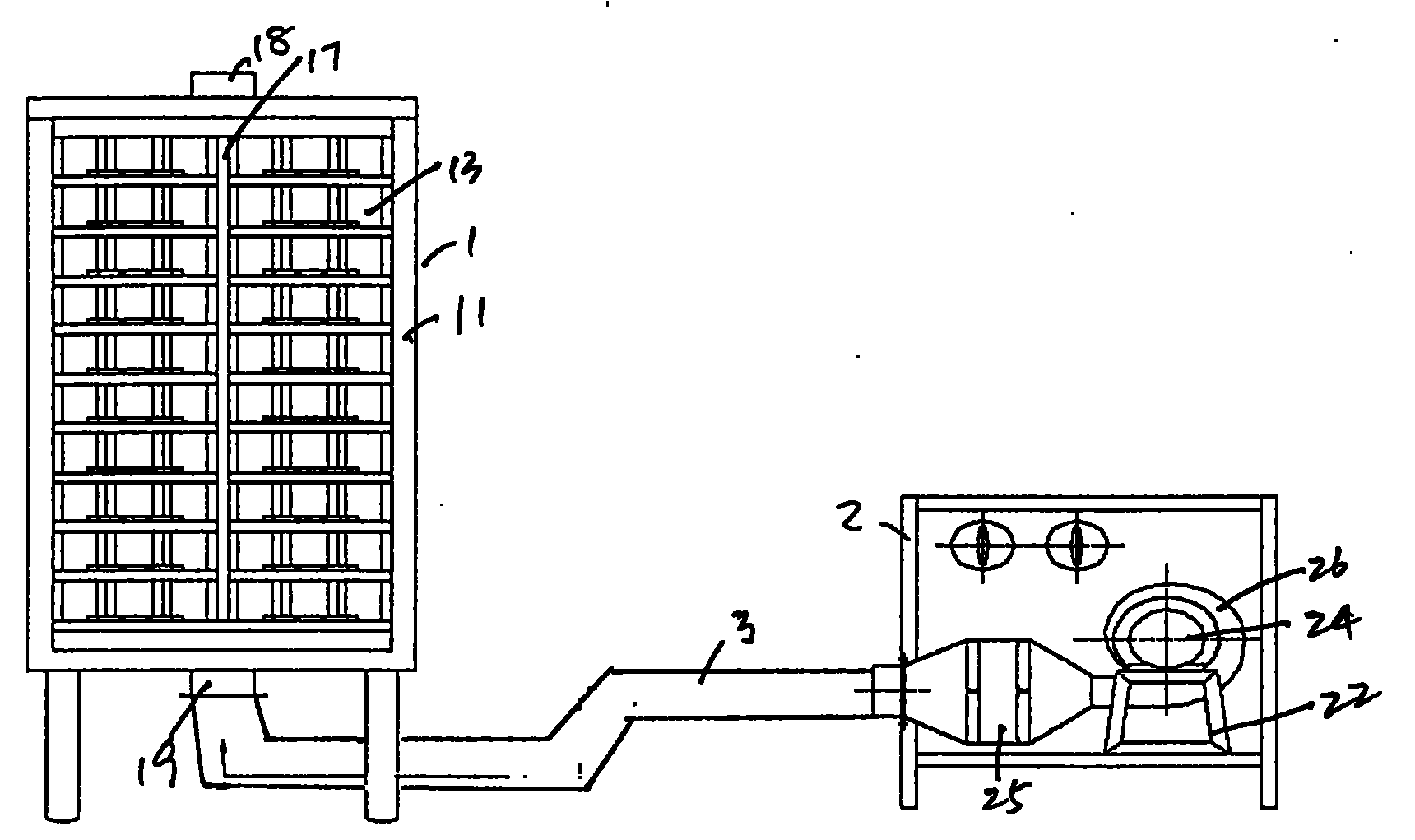

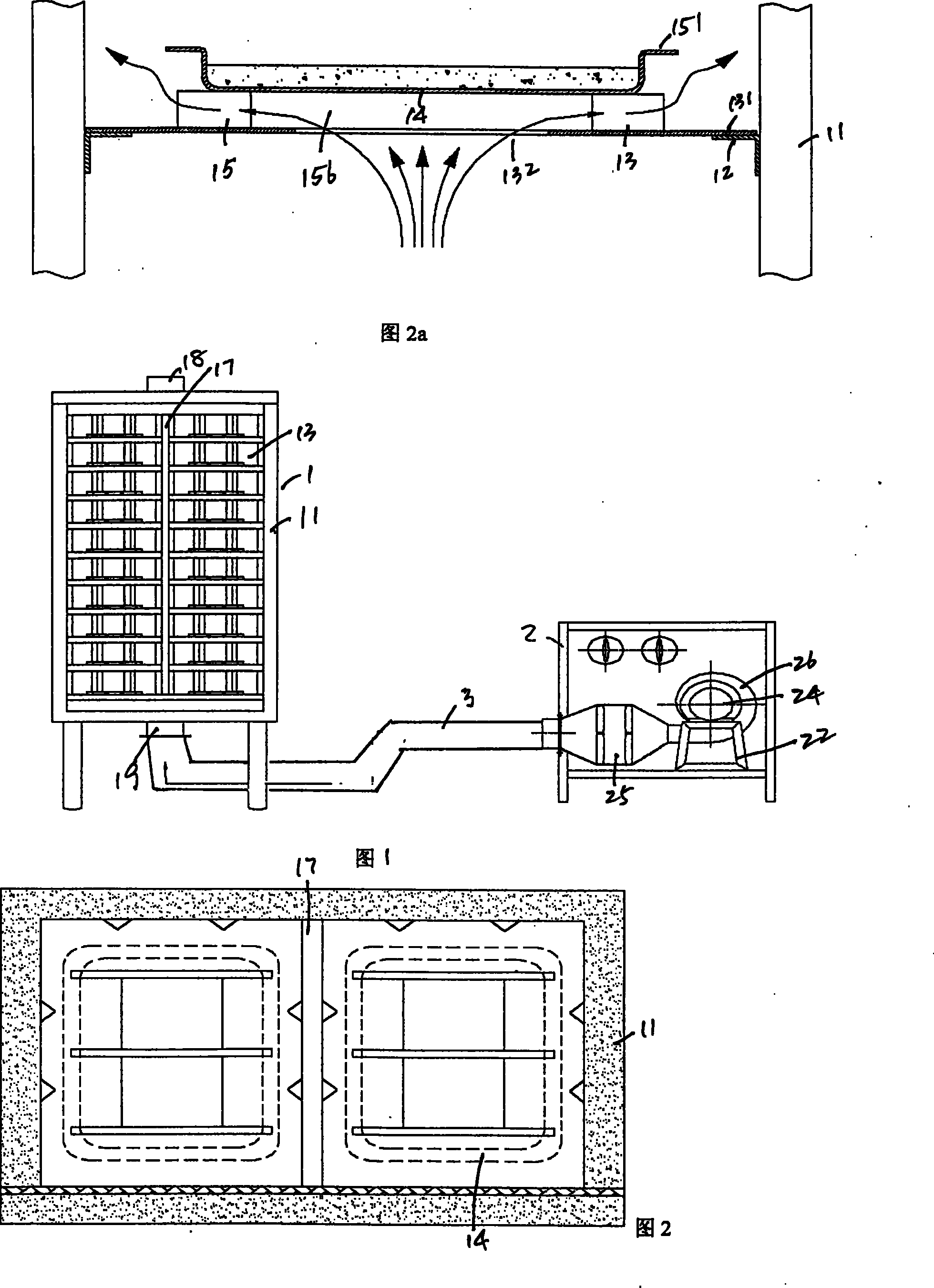

Rock sample drying apparatus and its drying box structure

ActiveCN1936534ASignificant advantagesSignificant beneficial effectPreparing sample for investigationDrying machines with non-progressive movementsEngineeringDry box

This invention relates to a rock drying device including a drying box and a hot air device feeding hot air to the drying box via a high-temperature insulation feeding pipeline, in which, the drying box is composed of a box with heat-preservation layer and a drawer set of column layers in the box with gaps between the drawer set and the box for gas flow passing through and gaps are remained among layers of the drawers for gas flow passing through, a hot air inlet is set at the middle of the bottom of the drawers, the hot air device is set in a frame formed by a fan driven by a blowout motor connected with a heater meeting the preset heating temperature, said heater is connected with the box by the high temperature pipeline and the box, an intake pipeline is connected with the fan.

Owner:天津开发区利达科技发展有限公司

Glue injection mold and glue injection unit for pultrusion glue injection device of glass reinforced plastic tube

InactiveCN102909868AImprove versatilityMeet the needs of pultrusion profiles with different specificationsTubular articlesYarnEngineering

The invention discloses a glue injection mold and a glue injection unit for a pultrusion glue injection device of a glass reinforced plastic tube, is a divisional application of the original application of 200910069146.0 Glue Injection Unit and Glue Injection Mold for Pultrusion Glue Injection Device of Glass Reinforced Plastic Tube, and relates to a glue solution impregnation device in pultrusion equipment for compounding and hot-setting glass yarns and felts into a continuous section. The glue injection unit comprises the glue injection mold and a mandrel that can guide a glass reinforced plastic molding material to hollowly enter a pultrusion mold, wherein a mandrel through hole allowing the mandrel to pass through is formed in the glue injection mold; injection cavities are arranged along the mandrel through hole; and a negative pressure cavity is arranged between each two adjacent injection cavities. The glue injection mold adopted by the glue injection unit reasonably configures structures of the injection cavities and the negative pressure cavity, so that the glass yarn and felt impregnation work can be accomplished by injecting a glue solution in a closed mold device, the problem that the glue solution is volatilized freely is solved effectively, and the stability of the glue solution viscosity in the whole pultrusion process is ensured effectively. The integral forming mold and mold blocks more facilitate industry popularization.

Owner:天津市金锚科技发展有限公司

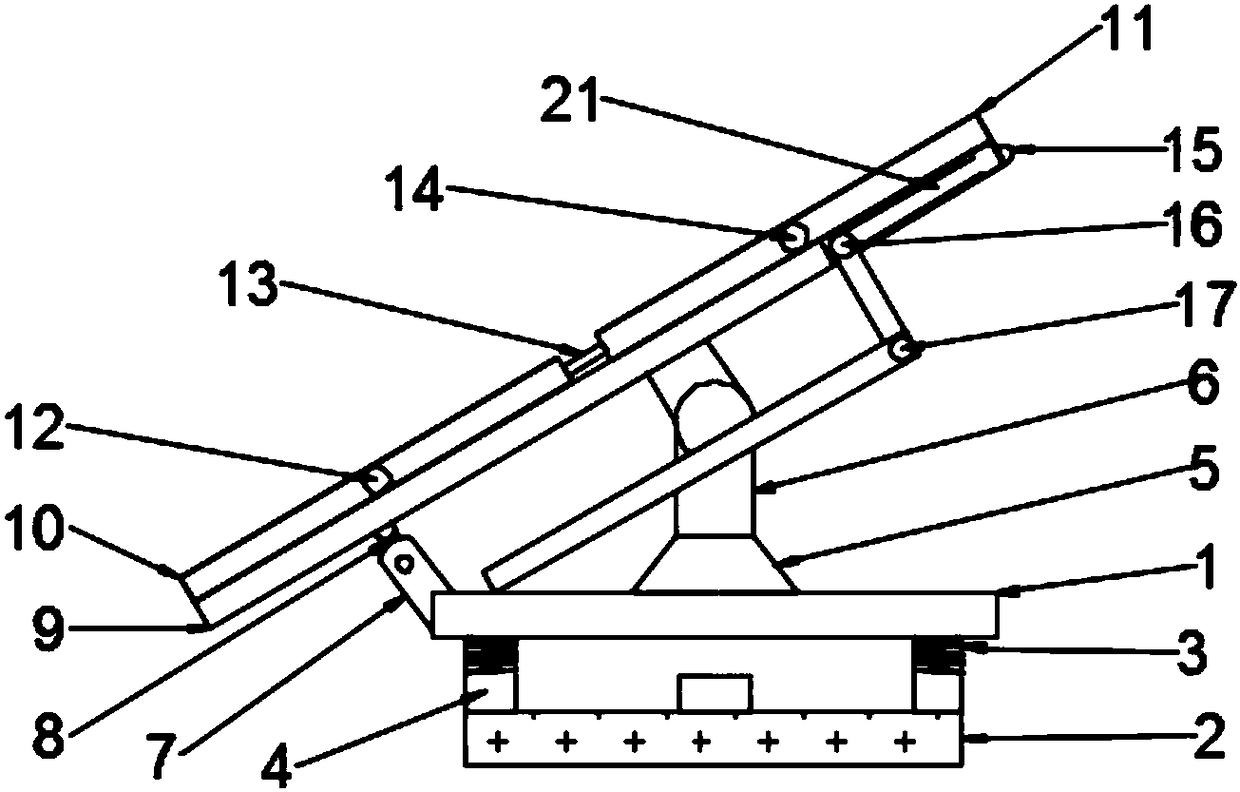

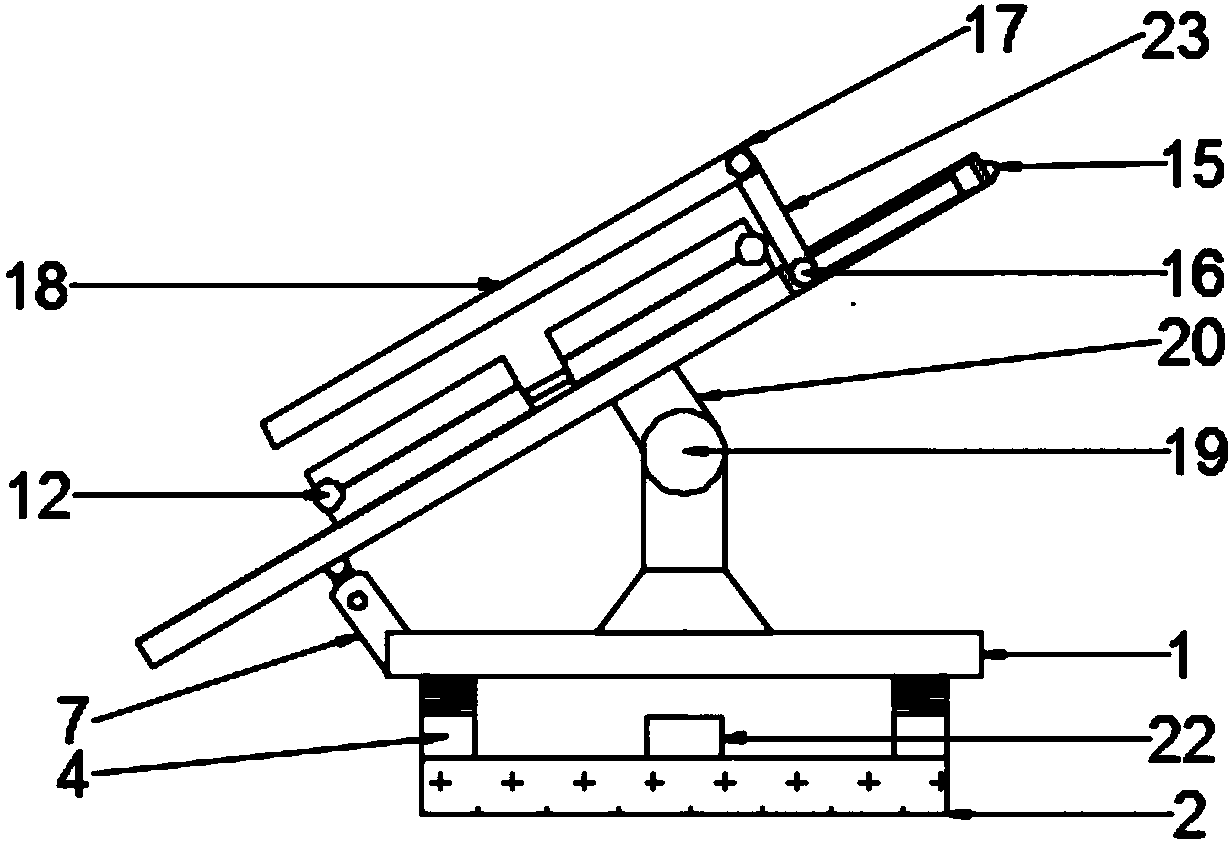

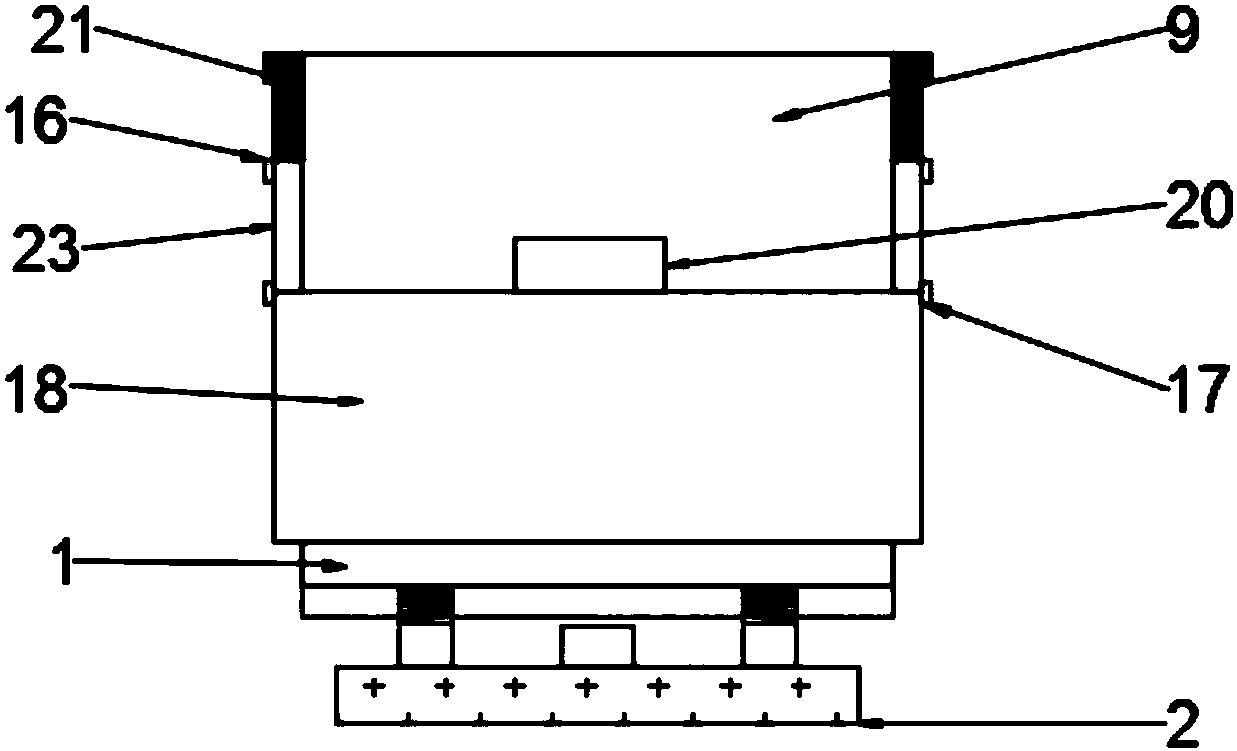

Household photovoltaic power station capable of automatically preventing rain

InactiveCN108173479AReduce shockExtended service lifePhotovoltaic supportsSolar heating energyEngineeringPhotovoltaic power station

The invention discloses a household photovoltaic power station capable of automatically preventing rain. The household photovoltaic power station comprises a support platform, a base and a solar cellpanel support plate, wherein support legs are arranged on the base, the support platform is arranged on the support legs, a rotation mechanism is arranged on the support platform, a first connection rod is arranged at an upper part of the rotation mechanism, a connection rack is arranged on the first connection rod, the connection rack and the first connection rod are connected via a second hingedevice, the solar cell panel support plate is arranged on the connection rack, and a lower solar cell panel and an upper solar cell panel are arranged on an upper surface of the solar cell panel support plate. The household photovoltaic power station is simple in structure and low in cost and is convenient to install, industrial promotion is easy, the upper solar cell panel and the lower solar cell panel can be timely and effectively protected in rainy days, and the service lifetime of the household photovoltaic power station is prolonged.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

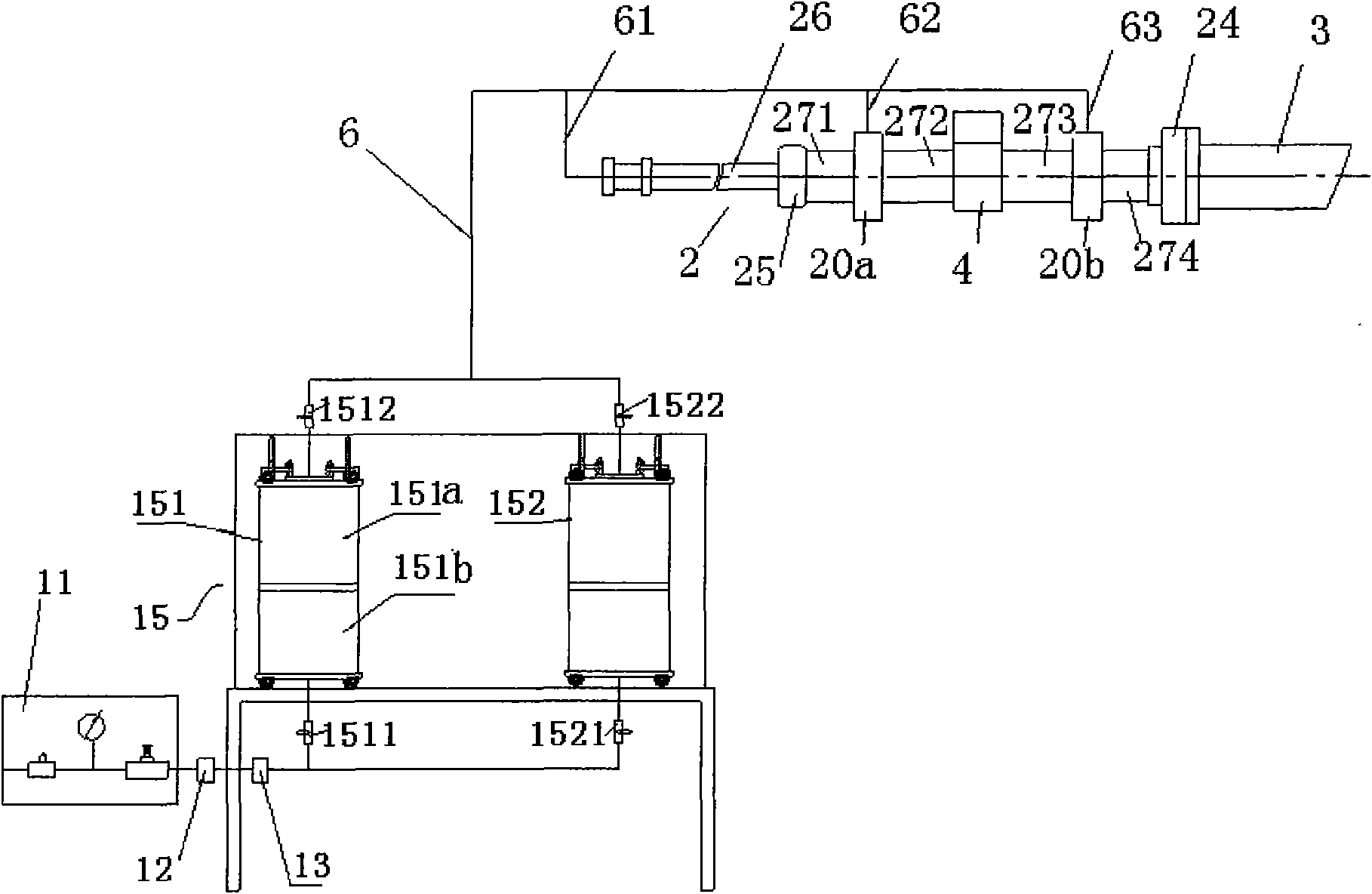

Glue-injection unit of glass fiber reinforced plastic tubular product pultrusion glue-injection device and glue-injection mold

InactiveCN101564899AAvoid the problem of wanton volatilizationGuaranteed stabilityTubular articlesGlass fiberYarn

A glue injection unit of a glass fiber reinforced plastic tubular product pultrusion glue-injection device and a glue-injection mold relate to a device that dips glue solution in pultrusion equipment and leads glass yarn and felt to be compounded and thermoset so as to form continuous sectional materials, wherein the glue-injection unit comprises the glue-injection mold and a mandrel capable of leading glass fiber reinforced plastic sectional material to hollowly enter a pultrusion mold, wherein the glue-injection mold is provided with a mandrel through hole through which the mandrel can pass, injection cavities are arranged along the mandrel through hole and a subpressure cavity is arranged between adjacent injection cavities. The glue injection mold arranged for the glue-injection unit of the proposal helps reasonably configure the structure of the injection cavities and the subpressure cavities, thus being capable of realizing the work of dipping the glass yarn and felt by injecting glue solution in a closed mold device, not only effectively avoiding the problem of free volatilization of the glue solution, but also effectively ensuring the stability of viscosity of the glue solution in the whole pultrusion process. The proposal provides two implementation solutions of an integral forming mold and a mold type block, thus being easier for industrial promotion.

Owner:天津市金锚科技发展有限公司

Gas pretreatment device for logging and its alarming controller

InactiveCN1995699AAvoid the impossibilityReduce dilutionWithdrawing sample devicesPreparing sample for investigationDesiccantPre treatment

The invention relates to a gas pretreatment device for logging and the alarm controller, which is the assistant device of gas measuring equipment in logging work of oil exploration industry, comprising gas treatment mechanism with fluid collection tube and dried air collection tube. Said gas treatment mechanism is connected with the alarming controller with negative pressure valve by gas transmission line. The reasonable allocation of pipeline structure improves the insulation effect of pipeline. Desiccant is set in drying treatment zone so that air after drying flows into pipeline in logging room and various moisture drops down and is discharged form fluid collection pipe. The configuration of alarm controller can realize anti-explosion and alarming. The configuration of overflow pipe at the lower of fluid collection pipe makes the fluid collected in collection pipe drain automatically, when the fluid enters into gas treatment mechanism. The invention is provided with simple structure, convenience and practical and ease popularization.

Owner:天津港保税区鑫利达石油技术发展有限公司

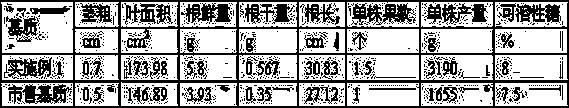

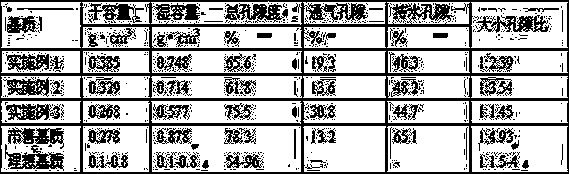

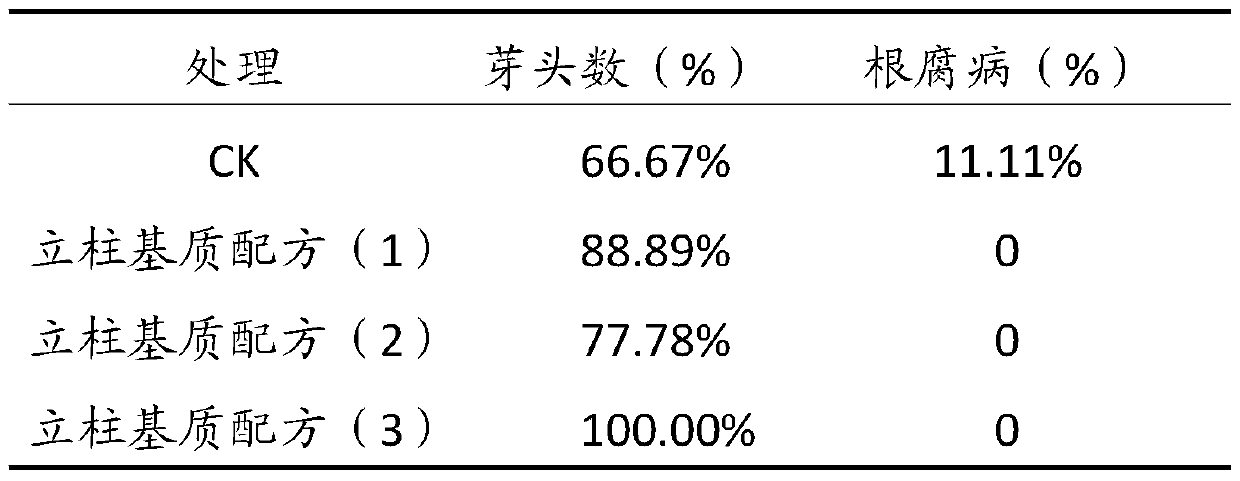

Organic cultivation medium made of broad bean straw and preparing method thereof

InactiveCN109627067AGood physical and chemical propertiesSpeed up decompositionCalcareous fertilisersBio-organic fraction processingBiotechnologyMushroom

The invention relates to an organic cultivation medium made of broad bean straw and a preparing method thereof. The organic cultivation medium is prepared from, by volume, 25%-50% of fermented broad bean straw, 0%-20% of fermented mushroom residues, 8%-25% of an organic fertilizer and the balance base material, wherein the organic fertilizer is one or two of decomposed chicken manure and decomposed cow manure, and the base material is one of river sand and field soil. According to the organic cultivation medium made of broad bean straw and the preparing method thereof, the organic cultivationmedium with the excellent physical and chemical properties is obtained through broad bean straw fermentation production, external source nitrogen does not need to be added for adjustment, the production cost is reduced, the decomposing speed of organic matter is increased, the fermentation process is shortened, and nutrients of fermentation products are more complete and are more sufficient. The preparing method is simple and easy to implement, the preparing efficiency is high, and the organic cultivation medium is easy to industrially popularize.

Owner:临夏回族自治州农业科学院

Centrifugal pump

ActiveCN100402863COptimize structural configurationSolve the problem of not being able to extract liquidPump componentsPriming pumpDrive shaftEngineering

A centrifugal pump comprises an impeller installed on the driving shaft. On one side of the impeller disk are disposed main vanes and on the other side of the disk are disposed secondary vanes. There is a preset distance from the starting point of the vane to the hub to form a traffic island area around the hub. A runner formed between vanes is in communication with the traffic island area with the traffic island area with spilling throughholes. The pump body has a chamber for holding vanes and the chamber has a curved channel with a water discharging tube. A liquid intake with an opening and closing mechanism is disposed in the centre of the pump head corresponding to the impeller.

Owner:天津港保税区鑫利达石油技术发展有限公司

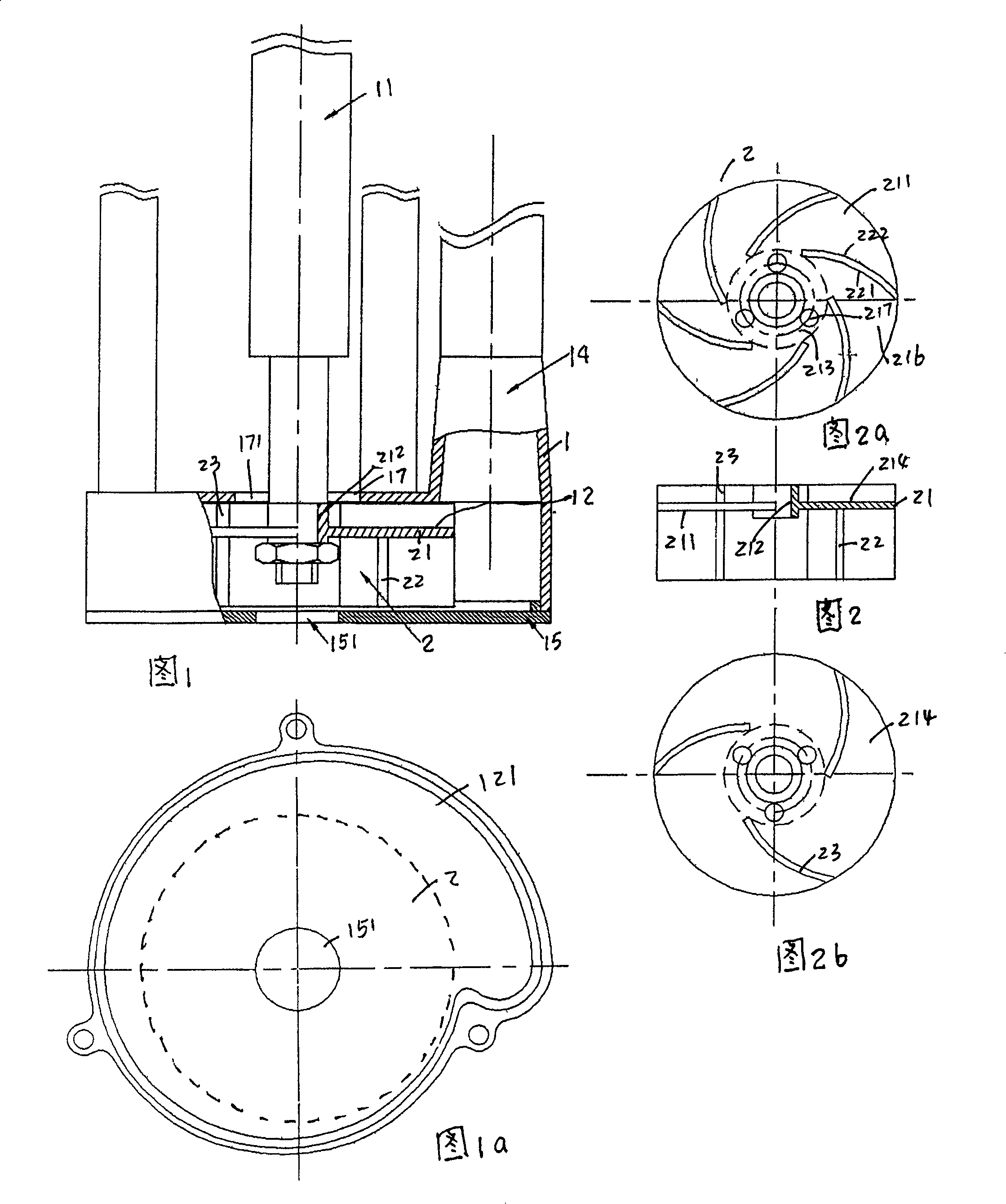

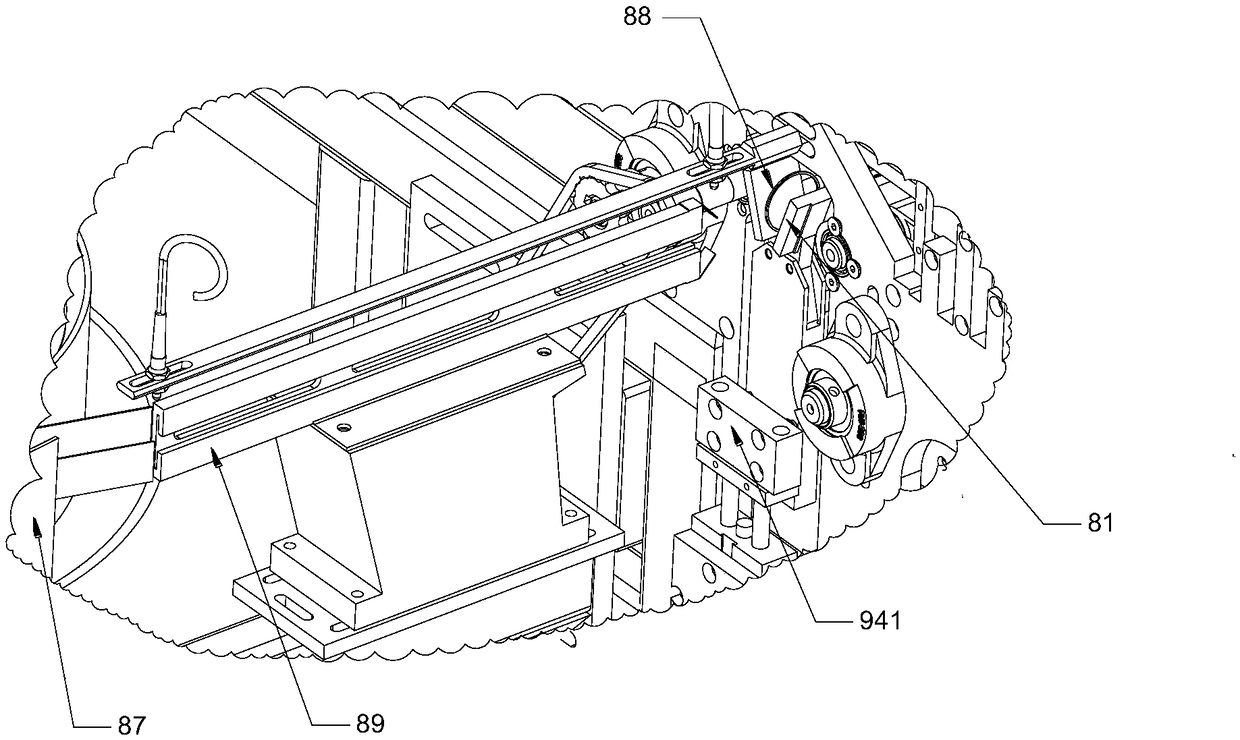

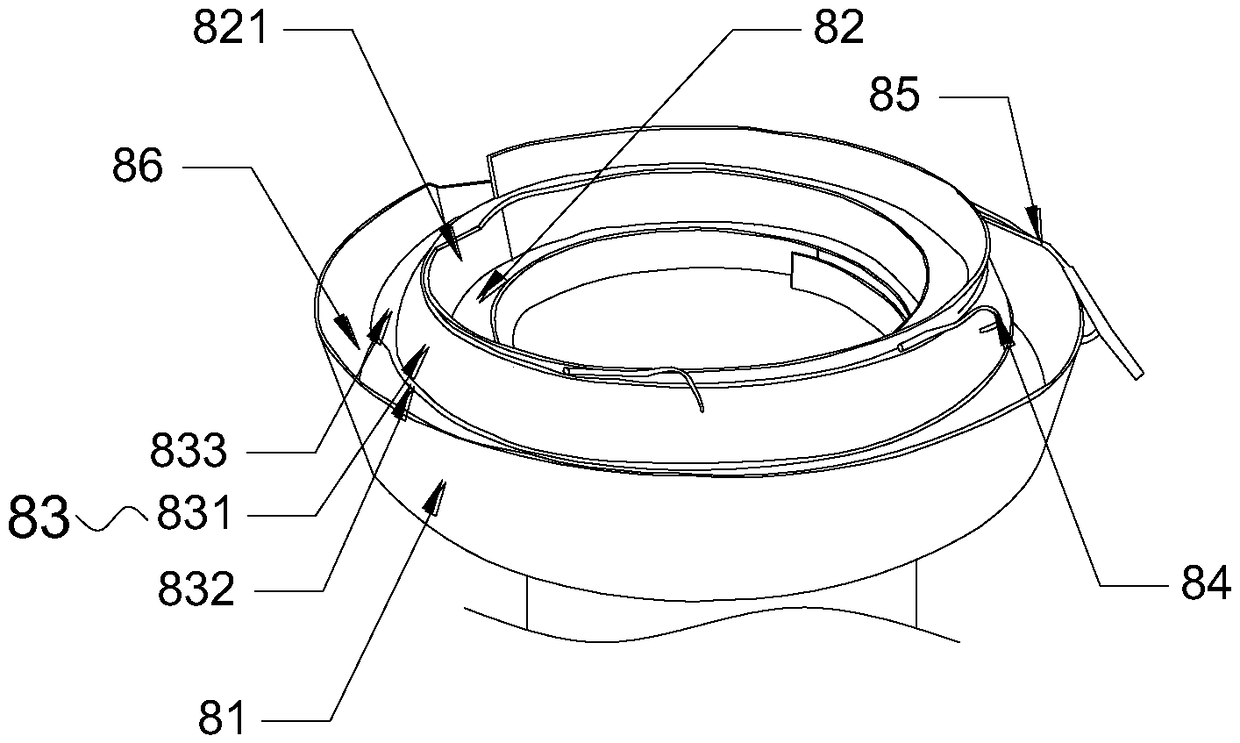

Packing bag binding machine

ActiveCN109466816AEasy accessEasy to transportWrapper twisting/gatheringBinding material applicationEngineeringManipulator

Owner:佛山市团凌塑料机械有限公司

Method, system and device for card application download

ActiveCN103309758BSolve wasteSolve space problemsDigitally marking record carriersFault responseComputer hardwareUtilization rate

The invention discloses a card application downloading method, a card application downloading system and a card application downloading device. The method comprises the following steps of setting an application hidden file and an application example hidden file in a card, wherein the application hidden file is used for storing application data received in a card application downloading process, and the application example hidden file is used for storing downloaded application example data; setting not less than 2 states in the card application downloading process; and judging whether power is cut off or not between the states, and if the power is cut off, clearing the application hidden file or the application example hidden file. According to the technical scheme, influence on the use of the card after the power is cut off in card application downloading and installation processes can be avoided, the utilization rate of a space in the card can be increased, and the card application downloading and installation performance can be improved.

Owner:CHINA MOBILE COMM GRP CO LTD

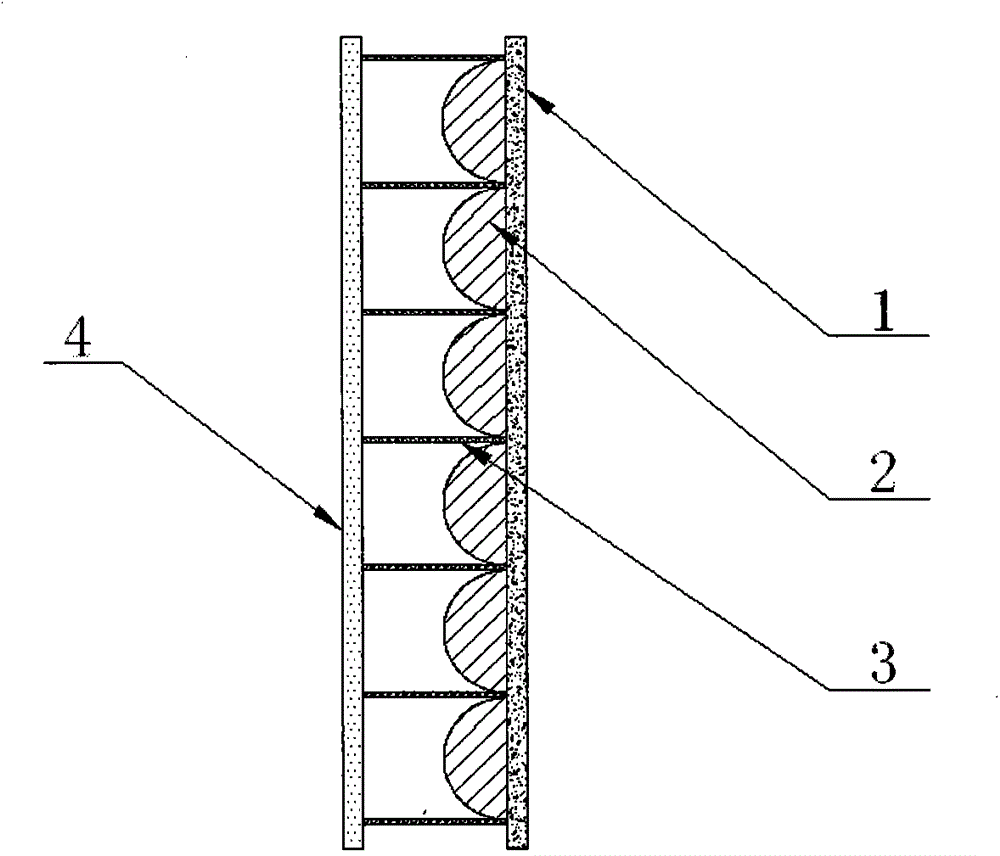

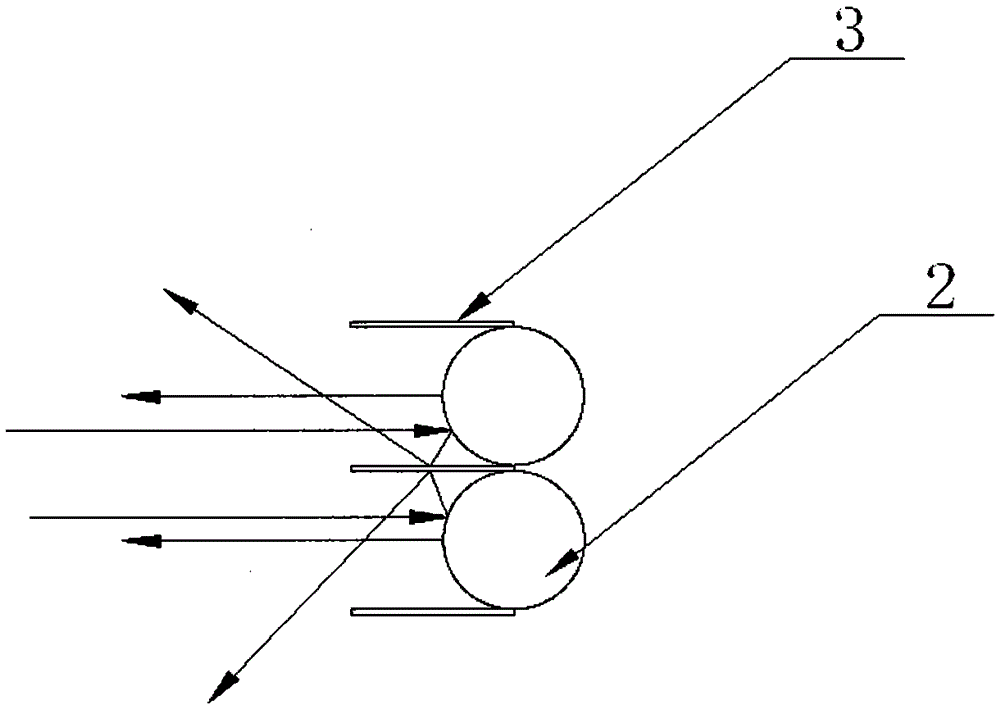

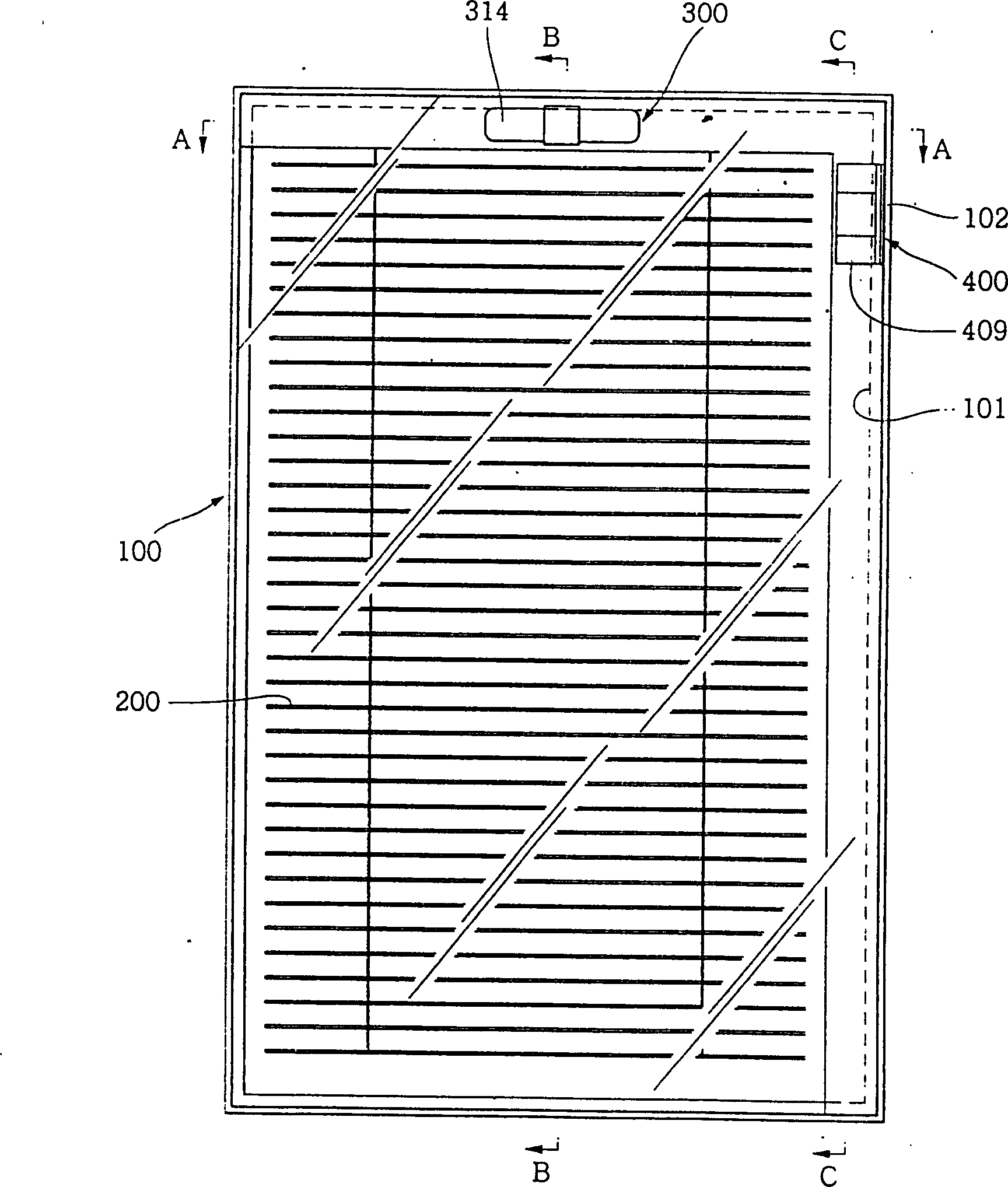

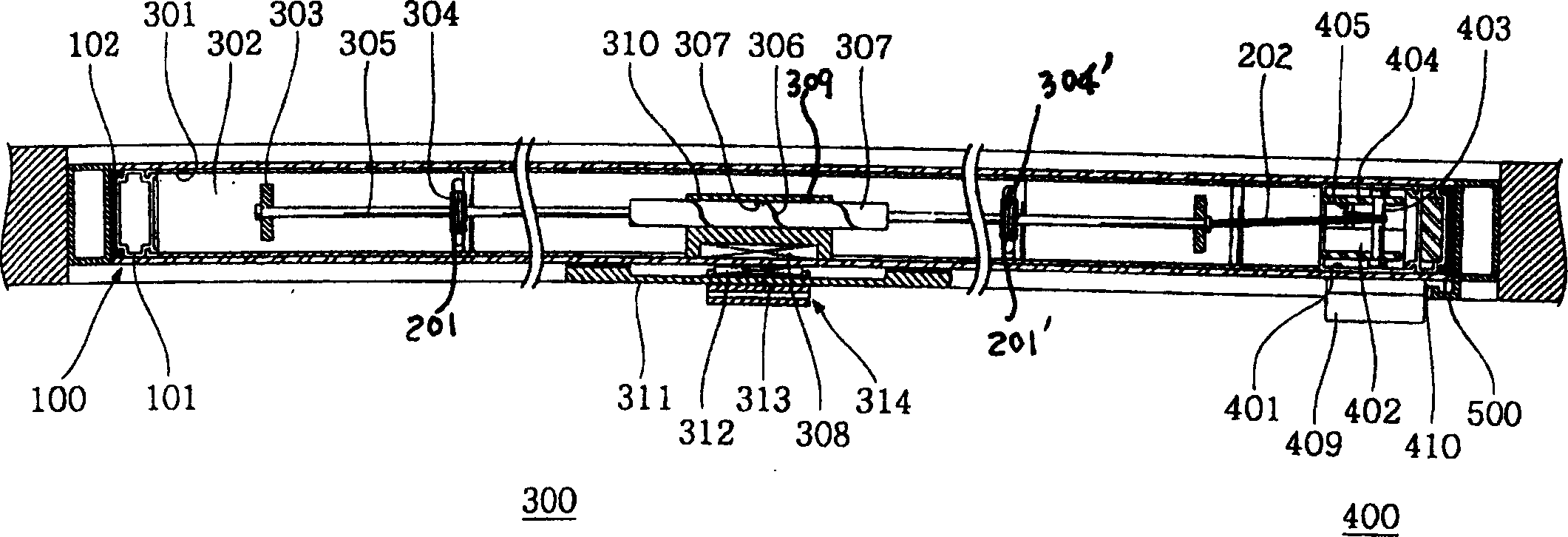

Projection screen, its manufacturing method and method for controlling light with the projection screen

The invention discloses a projection screen, a manufacturing method of the projection screen, and a method for controlling light rays by means of the projection screen. The projection screen comprises a back film arranged on the bottom surface, the upper surface of the back film is covered with a plurality of convex mirrors used for reflecting the light rays, a gap is reserved between side faces of every two adjacent convex mirrors, and light isolation boards used for shielding the light rays are arranged in the gaps and extend outwards in the direction perpendicular to the back film to a light-pervious film. The manufacturing method of the projection screen includes the steps that the back film, the light isolation boards and the convex mirrors are pressed by means of a roller and then are fixedly connected after being pressed. The method for controlling the light rays by means of the projection screen includes the following steps that (a) the light isolation boards are used for isolating ambient light emitted from the periphery of the projection screen, and (b) incoming projection light is reflected to the projection screen by means of the convex mirrors. The projection screen, the manufacturing method of the projection screen and the method for controlling the light rays by means of the projection screen have the advantages that the projection screen which can be used when the intensity of the ambient light is high is not limited by environment conditions; cost is low, resources are saved and industrial popularization is easy to achieve.

Owner:杨作林

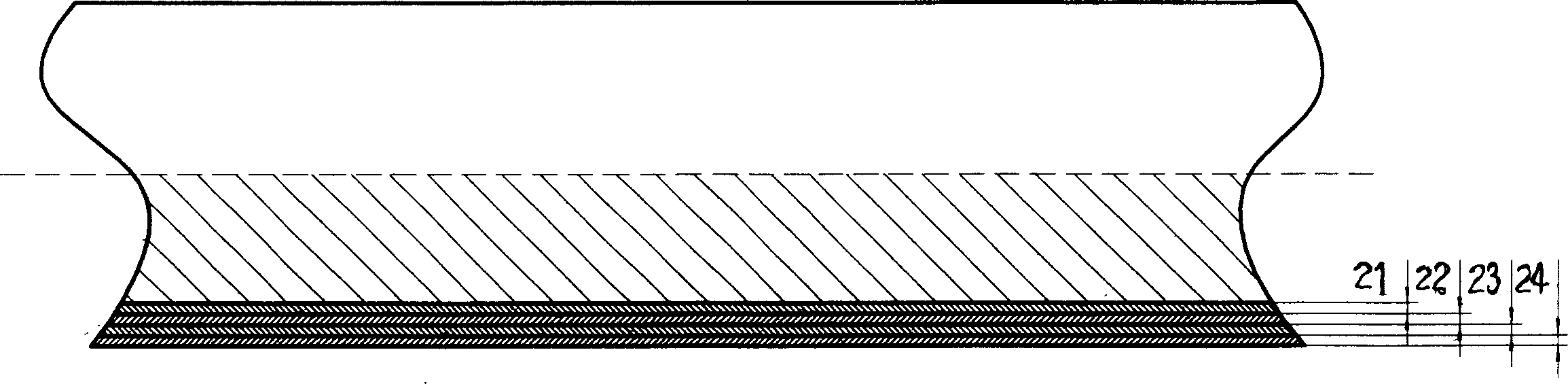

Product coating method and its coating structure and glue-extruding gun pushrod

InactiveCN1528953ASignificant advantagesSignificant beneficial effectOpening closed containersBottle/container closureEngineeringCopper

The invention is a method for product overlaying strata, it set a layer of ball blasting layer on the base body, it produces a layer of ball blasting layer whose particles is tiny on the base surface, there sets a plating layer on the ball blasting layer, and plates metal plating layer on the ball blasting layer. The overlaying strata structure is there has a ball blasting layer on base, and the ball blasting layer is covered by a metal plating layer; the glue squeezing shooter push rod which is made up by the method, the plating layer are copper layer, nickel layer and chromium layer. The invention applies to surface overlaying strata of product. It can enhance the corrosion resisting and grinding resisting property of product, the process is simple.

Owner:李杰

Improved dual-layer glass window with louver

InactiveCN1162606CSimple structureIngenious ideaLight protection screensUnits with parallel planesFixed frameWindow shutter

An improved dual-glass window with louver window between two glasses features that the fixing frame of the said dual-glass window has a transverse frame unit in it, the said transverse frame has two axles able to be turned and a magnetic angled regulator for regulating its angle, and a vertical frame of the said louver window has a magnetic open-close regulator for regulating the open (or close) state of louvers. Its advantages are simple structure, and high safety and reliability.

Owner:天津青亚玻璃制品有限公司

Glass fiber reinforced plastic tubular product pultrusion glue-injection device and glue-injection unit

A glass fiber reinforced plastic tubular product pultrusion glue-injection device and a glue-injection unit relate to a device that dips glue solution in pultrusion equipment and leads glass yarn and felt to be compounded and thermoset so as to form continuous sectional materials, wherein a glue solution supply unit and the glue-injection unit are connected through a glue solution conveying pipe in a manner of being capable of injecting the glue solution to the glue-injection unit which is configured in a manner of being capable of connecting with a pultrusion mold. The proposal can realize the work of dipping the glass yarn and felt by injecting the glue solution in a closed mold device and effectively avoid the free volatilization of the glue solution and ensure the stability of viscosity of the glue solution in the whole pultrusion process. The proposal can control the glue solution supply, and the glue-injection mold has strong adaptability and is easier for industrial promotion.

Owner:天津市金锚科技发展有限公司

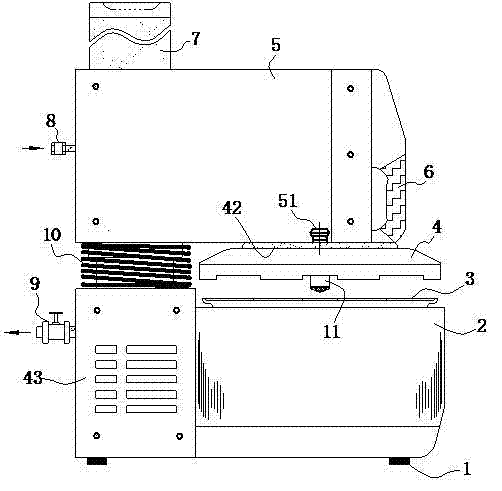

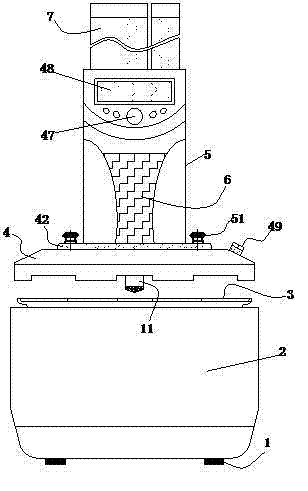

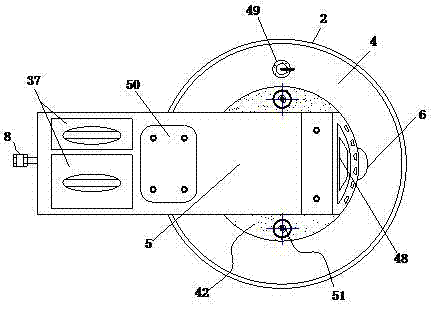

Full-automatic cooker

InactiveCN102151068BSimplify complex mechanical structuresSimple structureCooking vesselsMicrocontrollerAutomatic control

The invention discloses a full-automatic cooker, which mainly comprises a rice supply structure, a cleaning structure and a heating structure, and is characterized in that: the rice supply structure is arranged in the body of the device; the body is connected with the heating structure and a cover; the cover has a direct covering type structure or a cover-turning type structure; and the cleaning structure is arranged at the upper end of the cover or in a shell of a pot, and is provided with a lifting shaft cleaning structure or optionally provided with a spiral lifting cleaning structure or atelescopic cleaning structure. The full-automatic cooker also comprises heat preservation design, power-off design, time setting, rice quantity setting and water quantity setting, a local control panel singlechip is combined with an embedded system, a data instruction is connected to a display screen, the automatic control is carried out by a programmable logic controller (PLC), or the PLC forms a network communication interface, performs data transmission and the like, and a series of automatic cooking programs or remote control commands are executed. Through optimized combination, the structure is simplified, the manufacturing cost is low and the full-automatic cooker is suitable for industrial promotion.

Owner:戴文育

Cultivation substrate and method for reducing dragon fruit root rot diseases and promoting growth

The invention relates to the field of dragon fruit cultivation, in particular to a cultivation substrate and method for reducing dragon fruit root rot diseases and promoting growth. The cultivation substrate comprises straw biochar and microbial residues in a conventional substrate. The to-be-achieved effect of the invention is to provide a cultivation substrate and method for reducing dragon fruit root rot diseases and promoting growth. The cultivation substrate is green and free of pollution, the cultivation method is simple. The cultivation substrate has a relatively smaller bulk density and loose texture, and facilitates the root growth. The porous structure of the straw biochar can delay the release of nutrients, increases the utilization rate of fertilizers, and also plays a better role in reducing the dragon fruit root rot diseases. The cultivation method is simple and easy to perform, does not require specific fertilization management, and facilitates industrial popularization.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Gas pretreatment device for logging and its alarming controller

InactiveCN1995699BAvoid the impossibilityReduce dilutionWithdrawing sample devicesPreparing sample for investigationDesiccantPre treatment

The invention relates to a gas pretreatment device for logging and the alarm controller, which is the assistant device of gas measuring equipment in logging work of oil exploration industry, comprising gas treatment mechanism with fluid collection tube and dried air collection tube. Said gas treatment mechanism is connected with the alarming controller with negative pressure valve by gas transmission line. The reasonable allocation of pipeline structure improves the insulation effect of pipeline. Desiccant is set in drying treatment zone so that air after drying flows into pipeline in loggingroom and various moisture drops down and is discharged form fluid collection pipe. The configuration of alarm controller can realize anti-explosion and alarming. The configuration of overflow pipe atthe lower of fluid collection pipe makes the fluid collected in collection pipe drain automatically, when the fluid enters into gas treatment mechanism. The invention is provided with simple structure, convenience and practical and ease popularization.

Owner:天津港保税区鑫利达石油技术发展有限公司

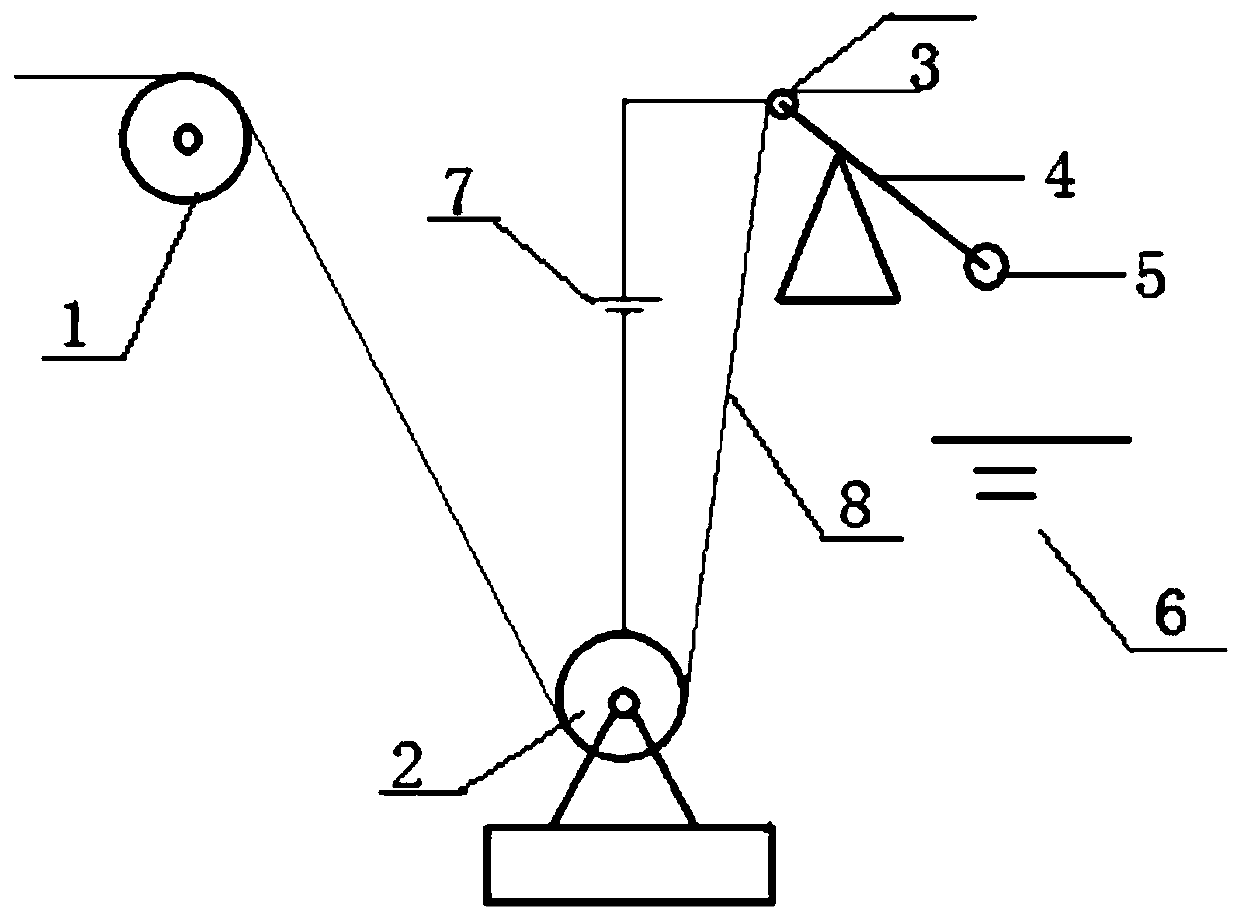

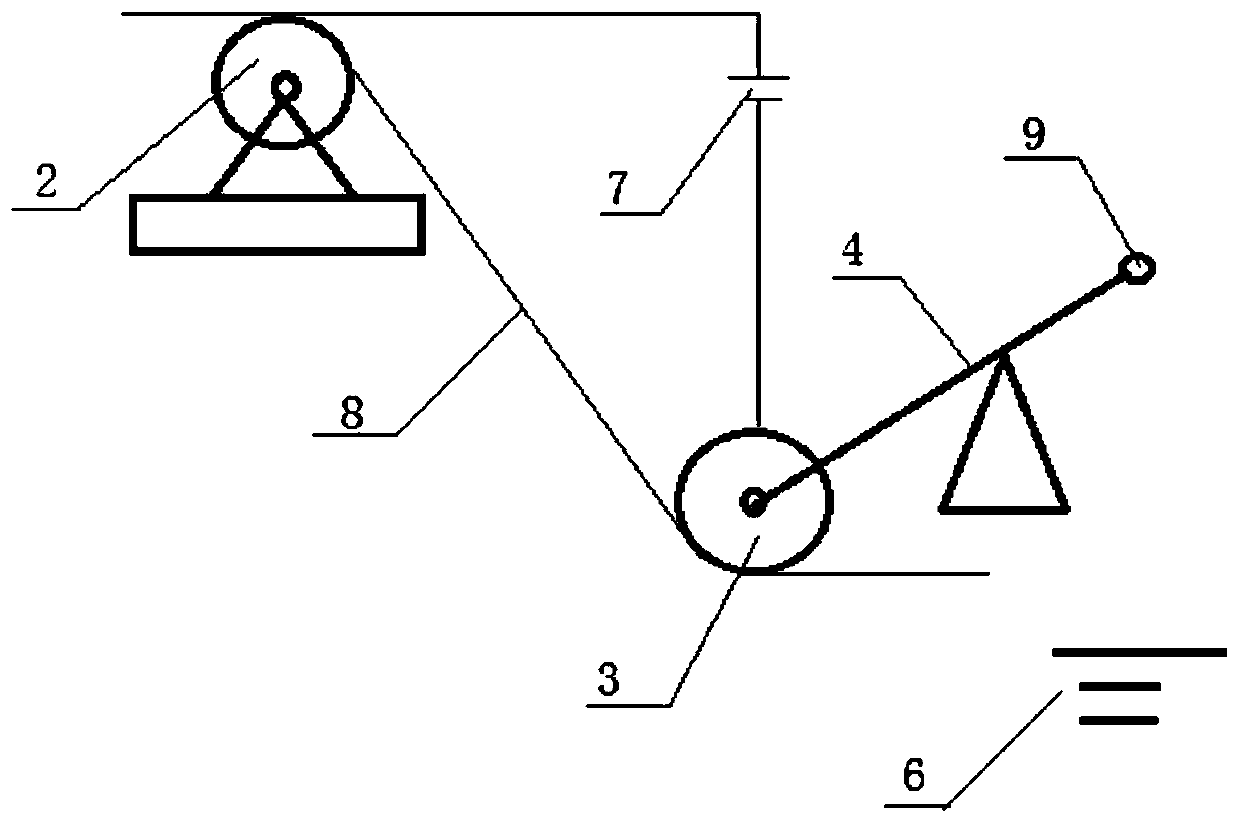

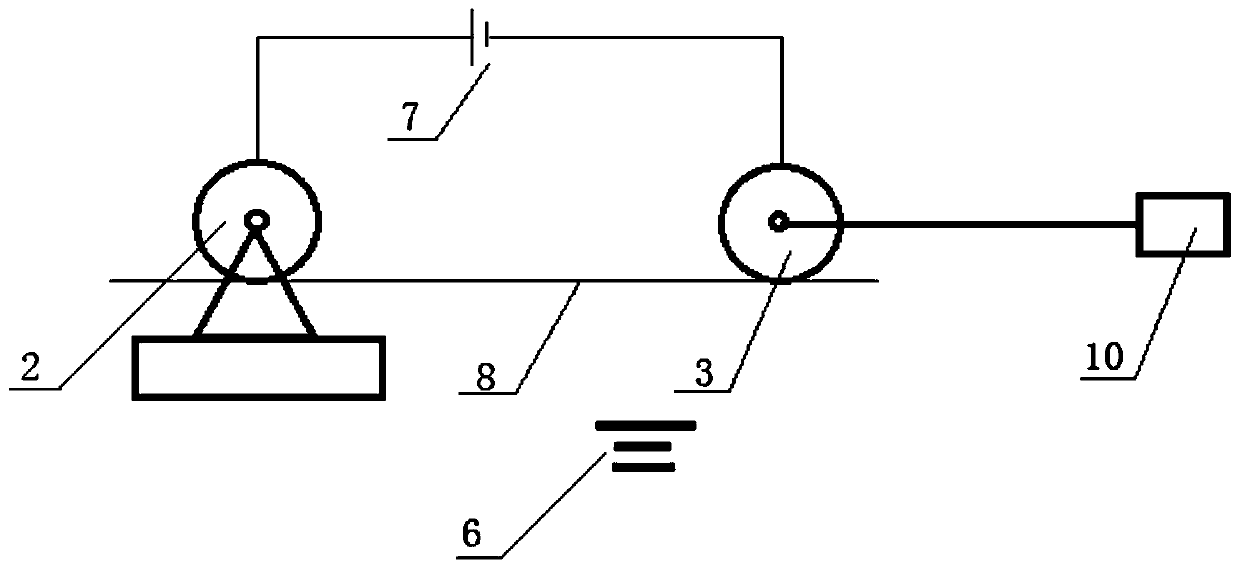

Continuous training method and continuous training device for shape memory alloy wire

InactiveCN111500950AEasy to promote in industryAvoid training with too much or too little stressContinuous trainingBlock and tackle

The invention discloses a continuous training method and a continuous training device for a shape memory alloy wire. The continuous training device is composed of a fixed pulley and a wire dischargingpulley. The shape memory alloy wire can be sequentially fixed between the fixed pulley and the wire discharging pulley for training. Fixed stress is applied to the part, fixed between the fixed pulley and the wire discharging pulley, of the shape memory alloy wire, the shape memory alloy wire is located in the load of the specific range, pulse current is conducted for training the wire, and evolution of the strain of the shape memory alloy wire in the training process is monitored till strain is stable, and then training is finished. According to the continuous training method and the continuous training device, through control over the fixed stress and monitoring of strain, the purpose of monitoring the training process is achieved macroscopically; and a mark joint for training ending isclearly provided for the first time. The continuous training device for the shape memory alloy wire is simple in structure, high in operability and easy to be industrially popularized.

Owner:常州艾易泰合金科技有限公司 +1

Rock sample drying apparatus and its drying box structure

ActiveCN1936534BOptimize structural configurationIssues Affecting SafetyPreparing sample for investigationDrying machines with non-progressive movementsDry boxRock sample

This invention relates to a rock drying device including a drying box and a hot air device feeding hot air to the drying box via a high-temperature insulation feeding pipeline, in which, the drying box is composed of a box with heat-preservation layer and a drawer set of column layers in the box with gaps between the drawer set and the box for gas flow passing through and gaps are remained among layers of the drawers for gas flow passing through, a hot air inlet is set at the middle of the bottom of the drawers, the hot air device is set in a frame formed by a fan driven by a blowout motor connected with a heater meeting the preset heating temperature, said heater is connected with the box by the high temperature pipeline and the box, an intake pipeline is connected with the fan.

Owner:天津开发区利达科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com