High efficiency liquid permeation and gas resistance fluid composite membrane system

A composite membrane and fluid technology, applied in semi-permeable membrane separation, membrane, membrane technology and other directions, can solve the problems of inability to achieve liquid permeability and gas barrier function, low separation efficiency, low service life, etc., and achieve easy industrialization, promotion and investment. The effect of low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

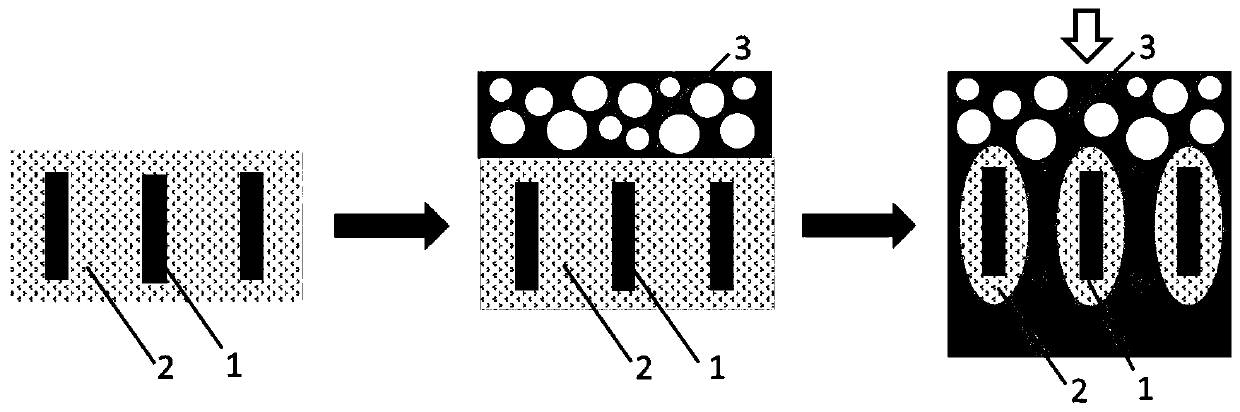

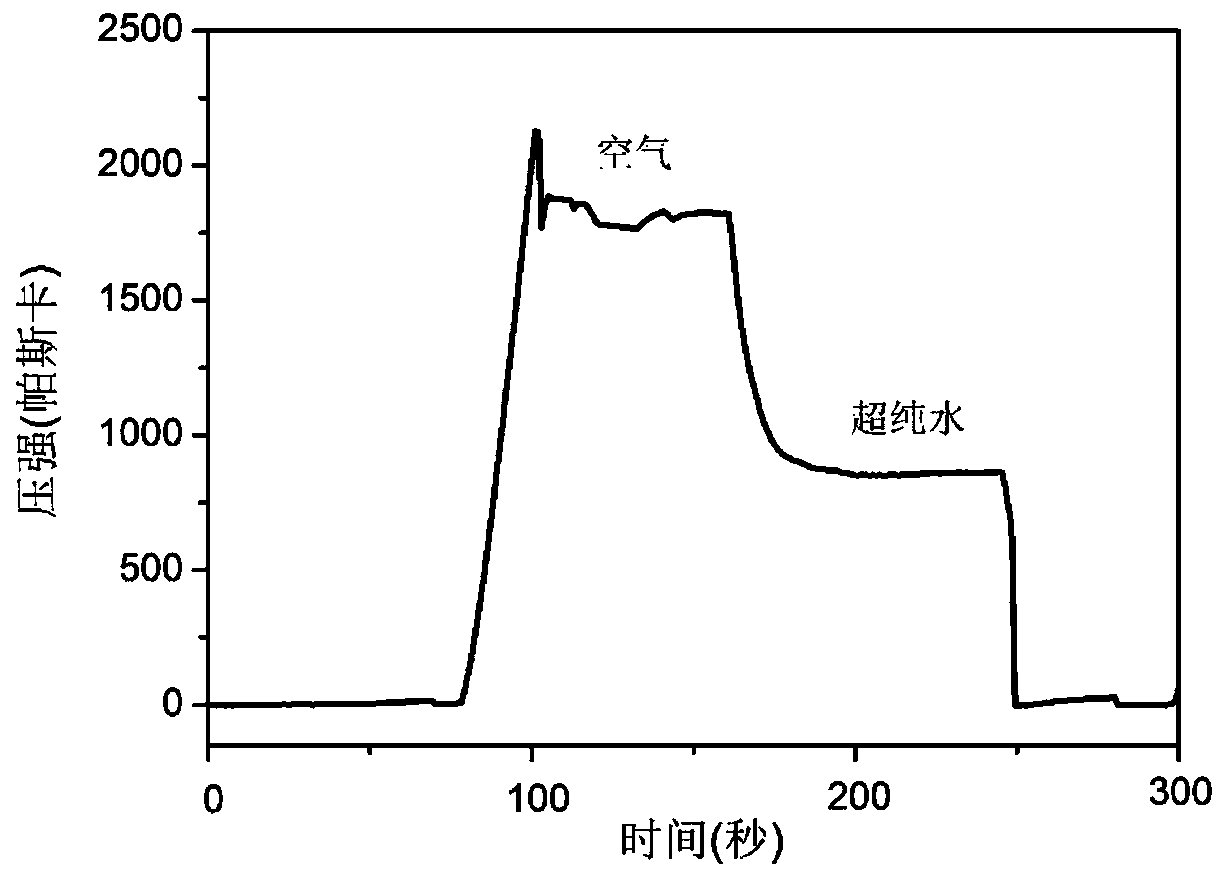

[0026] refer to figure 1 , the high-efficiency liquid-permeable and gas-barrier fluid composite membrane system of the present invention includes a solid porous membrane 1 and a functional fluid 2, and the functional fluid 2 infiltrates the solid porous membrane 1 to form a fluid-gated channel that allows the transport fluid 3 to pass through. It is easier to transport liquid through fluid-gated channels than transport gas at the same flow rate. The wettability of the functional fluid 2 and the solid porous membrane 1 is greater than that of the transport fluid 3 and the solid porous membrane 1, and the functional fluid 2 and the transport fluid are immiscible. When the transport fluid 3 is a gas-liquid mixture, only the liquid can pass through the composite membrane, and the gas cannot pass through.

[0027] The solid porous membrane is made of woven stainless steel mesh with a pore size of 20 μm, a thickness of 180 μm, and a diameter of 25 mm. The functional fluid is made o...

Embodiment 2

[0031] like Image 6 Shown: In order to further illustrate the application of this high-efficiency liquid-permeable and gas-barrier fluid composite membrane system, refer to Image 6 ,Will Figure 4 The gas-liquid separation device shown (in the dotted box 1) is combined with a proton exchange membrane fuel cell (PEMFC) (in the dotted box 2) as a cathode to generate O 2 / H 2 The tail gas of O is separated, so that the water body is condensed at the inlet end of the fluid composite membrane system and then discharged through the fluid composite membrane at the outlet of the rear end, while the oxygen is blocked at the front end of the fluid composite membrane, and is passed into the air inlet of the PEMFC cathode from the pipeline, as The recycling of reaction raw materials is conducive to improving the utilization rate of raw materials and saving the use cost of PEMFC. There is a membrane electrode (Membrane electrode assembly, MEA) between the anode and the cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com