Organic cultivation medium made of broad bean straw and preparing method thereof

The technology of broad bean straw and cultivation substrate is applied in the field of organic cultivation substrate and its preparation, which can solve the problems of lack of nitrogen elements in fermentation material heap, reduce the decomposition rate of organic matter, incomplete decomposition of nutrients, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A broad bean stalk organic cultivation substrate, the raw material volume ratio is as follows:

[0037] Broad bean straw fermented product: mushroom dregs fermented product: decomposed cow dung: river sand=2.5:2:2.5:3.

[0038] The preparation method of this substrate comprises:

[0039] 1. Preparation of broad bean straw fermented product and mushroom dregs fermented product

[0040] (1) After broad beans are harvested, the stalks are naturally air-dried to semi-dry (moisture content 30%-40%), and crushed to 2.0-5.0cm with a kneading shredder. Pleurotus ostreatus bags are removed from the bag and crushed to a particle size of ≤0.5cm.

[0041] (2) Broad bean stalks and mushroom dregs are piled and fermented according to the standards of bottom width 4.0-5.0m, top width 1.0-2.0m, and height 1.0-1.5m. Add water every 20-25cm thickness, and repeat this 4-5 times, the stacking is successful.

[0042] Among them, broad bean straw is added at 1.8-2.5‰ (mass ratio), mushroo...

Embodiment 2

[0052] A broad bean stalk organic cultivation substrate, the raw material volume ratio is as follows:

[0053] Broad bean straw fermented product: mushroom dregs fermented product: decomposed chicken manure: river sand =3:2:2:3

[0054] For the preparation method of the substrate, compared with Example 1, the difference is that the decomposed cow dung in step 3 is replaced with decomposed chicken manure, and the broad bean straw fermented product, mushroom dregs fermented product, decomposed chicken manure, and river sand are prepared according to 3 : The volume ratio of 2:2:3 is compounded, and the rest of the steps are the same.

Embodiment 3

[0056] A broad bean stalk organic cultivation substrate, the raw material volume ratio is as follows:

[0057] Broad bean straw fermented product: mushroom dregs fermented product: decomposed chicken manure: field soil = 6:2:1:3

[0058] For the preparation method of the matrix, compared with Example 1, the difference is that the sand river in step 2 is replaced by field soil, the decomposed cow dung in the soil in step 3 is replaced by decomposed chicken manure, and the broad bean straw fermented product, mushroom dregs The fermented product, decomposed chicken manure, and river sand are compounded according to the volume ratio of 6:2:1:3, and the rest of the steps are the same.

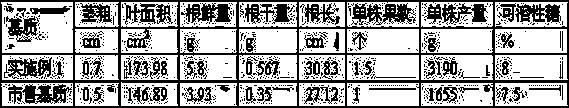

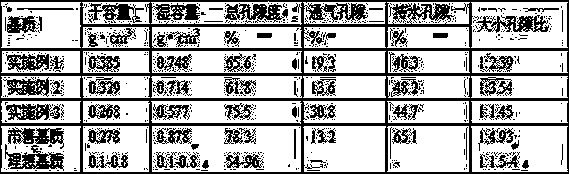

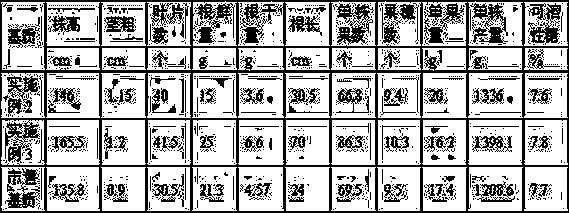

[0059] Comparative test data

[0060] For the broad bean straw organic cultivation substrates obtained in the above-mentioned Examples 1, 2, and 3, the main physical properties were measured respectively and compared with the commercially available straw peat organic cultivation substrates (Ruiyang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com