Product coating method and its coating structure and glue-extruding gun pushrod

A product and cladding technology, which is applied in the field of layered structure of metal products or alloy products, can solve the problems of complex cladding structure and method, not suitable for production needs, etc., achieve novel products, improve anti-corrosion and wear resistance, and be easy to use The effect of industry promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

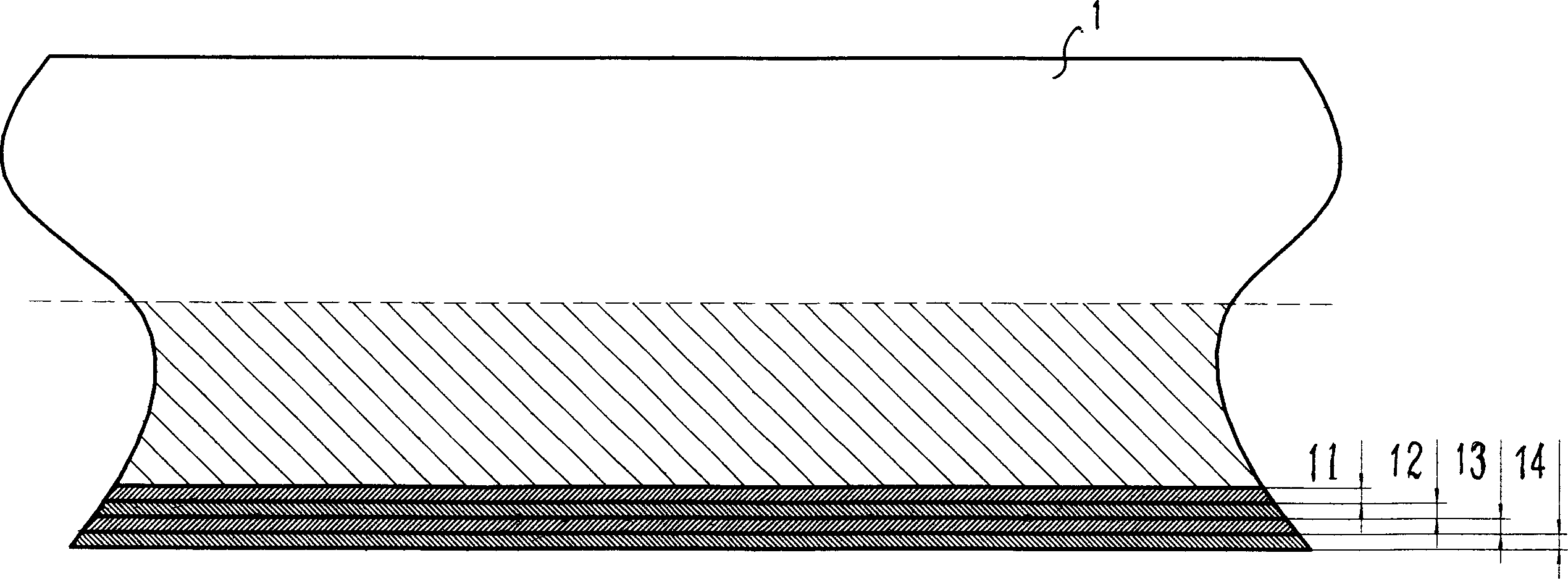

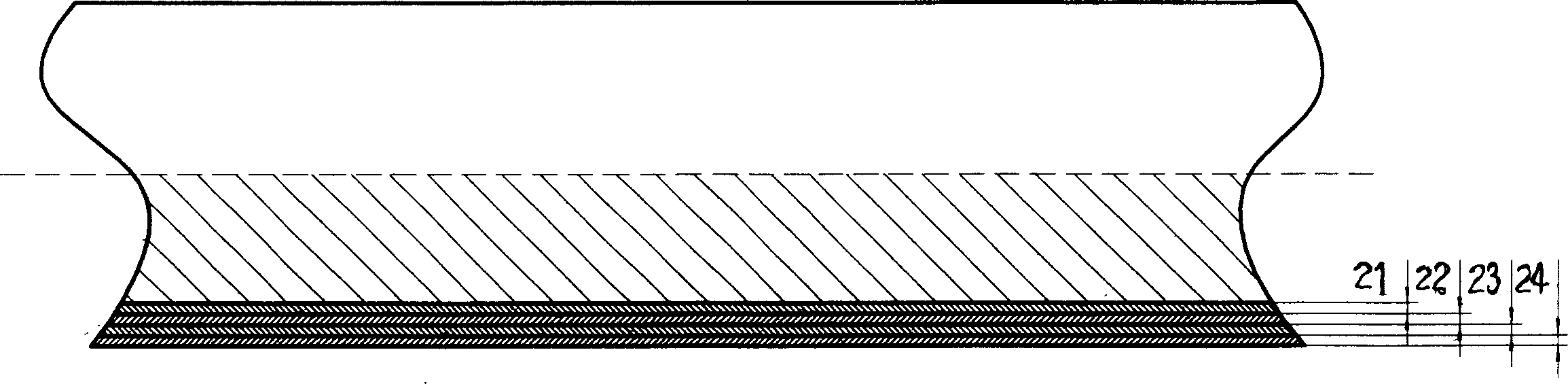

[0026] One of the embodiments, a method for coating a product, is provided with a layer of shot blasting layer (11) on the product substrate (1), and by shot blasting, a layer of shot blasting layer with fine and uniform particles is produced on the surface of the product substrate;

[0027] Coating a coating on the shot blasting layer (11) of the product substrate, that is, coating a metal coating of a certain thickness on the aforementioned shot blasting layer of the product.

[0028] Embodiment 2, a method for coating a product. A layer of shot blasting layer (11) is arranged on the product substrate (1), and a layer of shot blasting layer with fine and uniform particles is produced on the surface of the product substrate by shot blasting. Its layer thickness is 8-12 micron; The thickness of aforementioned coating is the best with 15.3-30.3 micron; This coating is the nickel layer (12) that thickness is 10-20 micron and thickness is 5-10 micron successively. 13) and a chrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com