Disc flow allocation radial variable high pressure plunger pump

A technology of high-pressure plunger pump and flow distribution, which is applied in variable capacity pump components, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of limited processing conditions, irreparable, complex structures, etc., and achieve Reduced manufacturing cost, repairability, ease of use, and improved volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

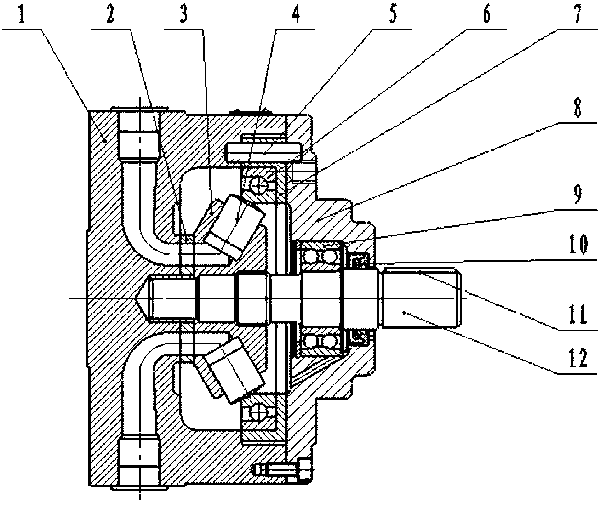

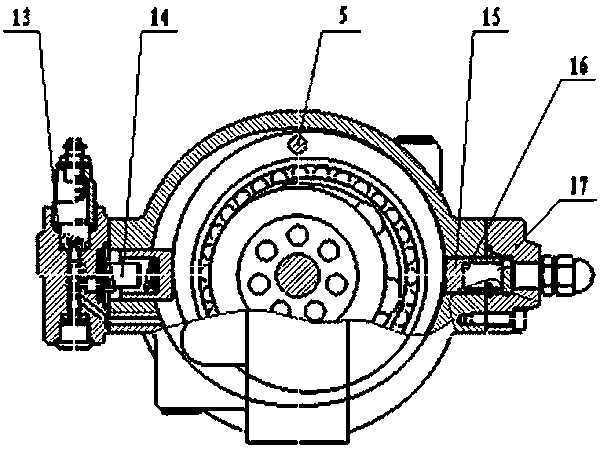

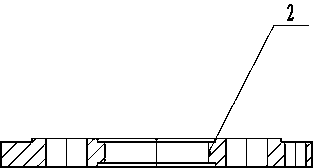

[0018] Such as Figure 1~4 A radial variable high-pressure plunger pump with plate flow distribution shown includes a pump body, a pump cover, a rotor, a stator and a plunger. The oil distribution plate 2 is a circular oil distribution plate. The oil window 18, the static pressure support sealing belt 19 and the silencer groove 20, the oil distribution plate, the pump body 1 and the rotor 3 are combined to form an oil passage. When in use, these three parts are closely connected to generate oil flow and boost pressure. The plunger holes on the rotor are radially arranged, the flow distribution surface of the rotor is closely attached to the flow distribution plate, and the plunger holes are set to form an angle with the axis of the transmission shaft 12, which makes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com