Water-cooled machine water jacket structure and press mounting technology

A water jacket and pressure technology, which is applied in electromechanical devices, cooling/ventilation devices, and manufacturing motor generators, etc., can solve problems such as poor machining accuracy, low production efficiency, and difficult sand cleaning, and achieve low manufacturing costs and high processing efficiency. High, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

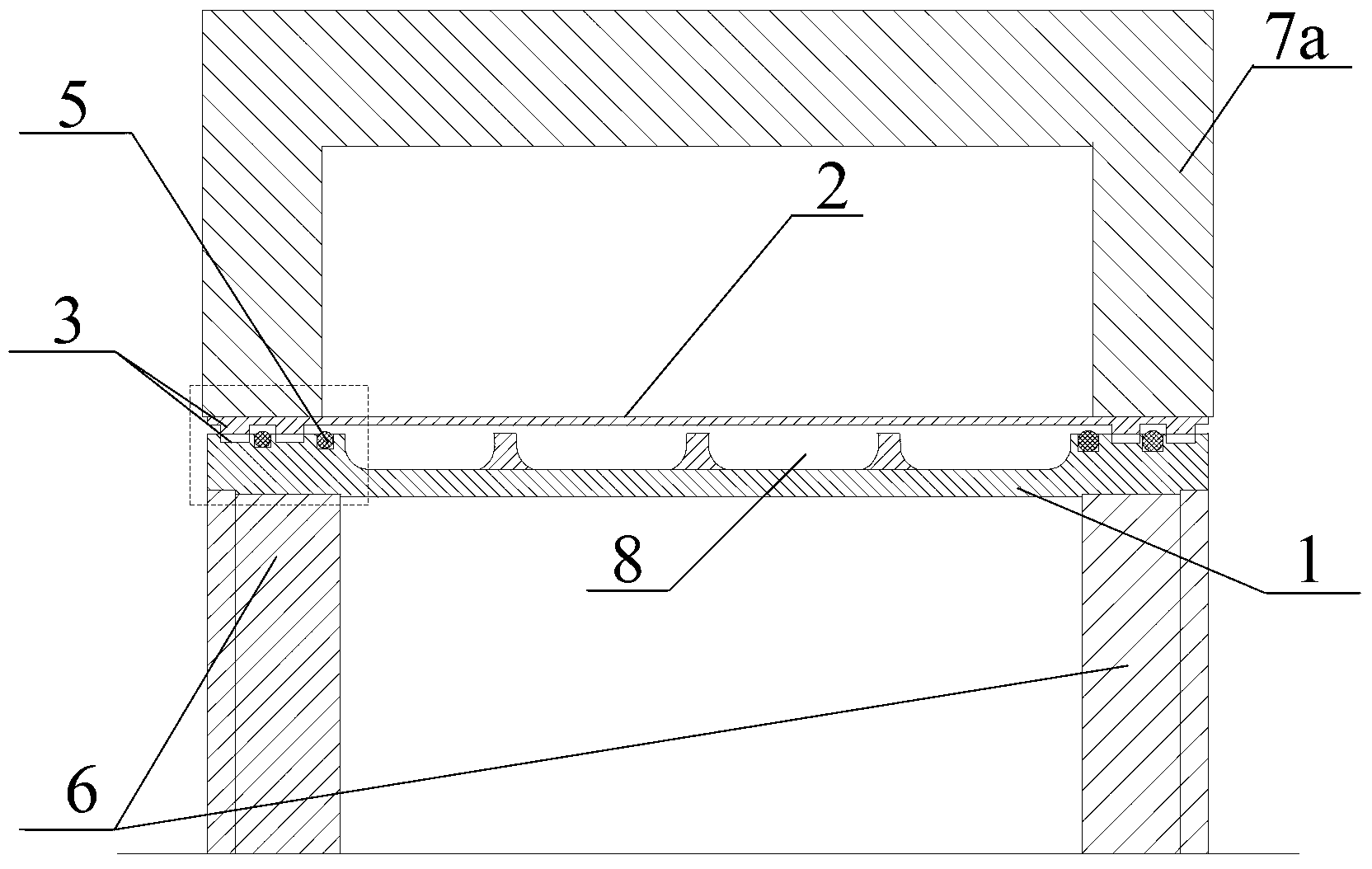

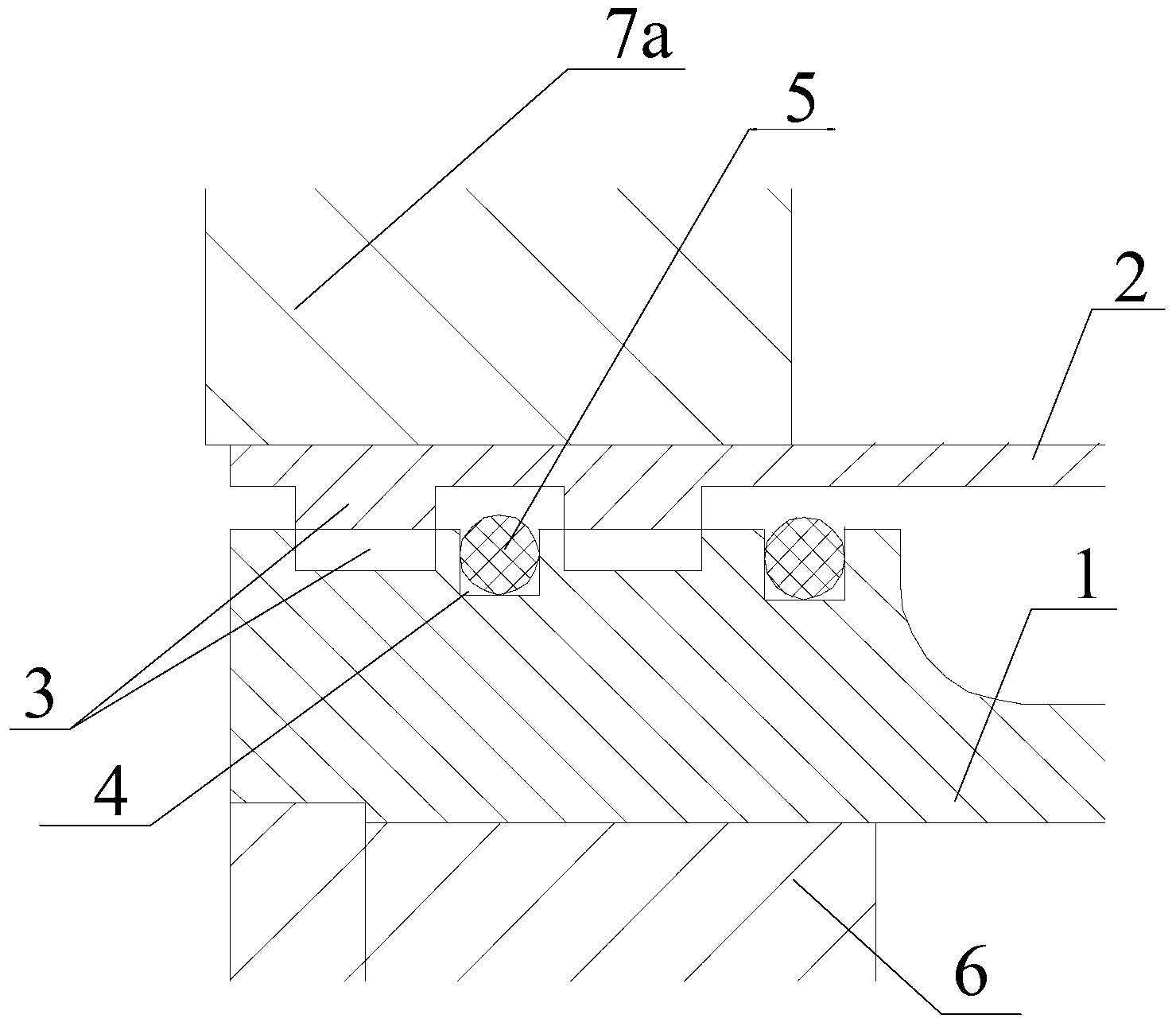

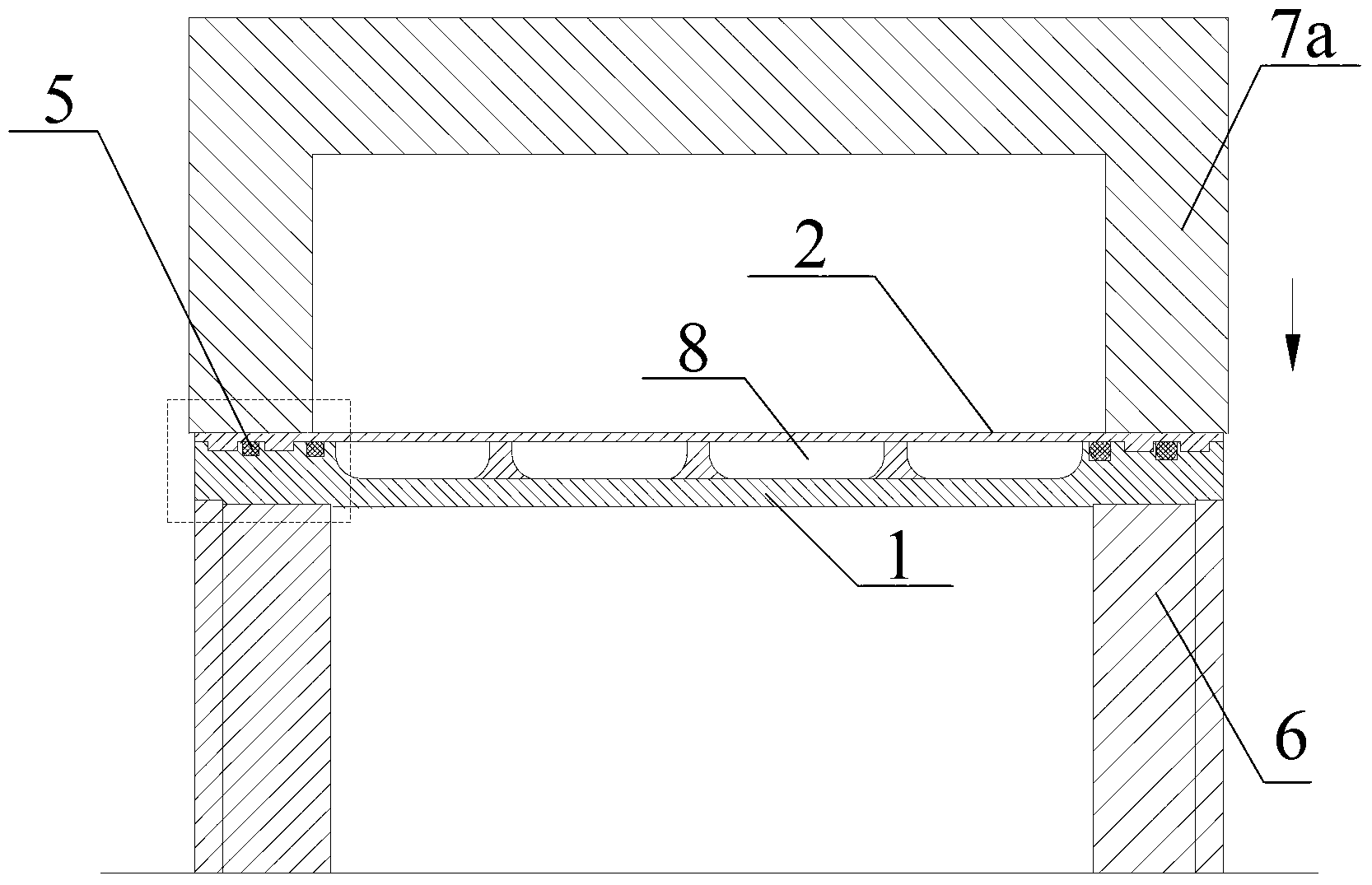

[0024] The specific embodiments of the present invention are described below with reference to the accompanying drawings. The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings. The following description of the embodiments of the present invention is only exemplary and is not intended to limit the subject matter of the present invention. For the described embodiments of the present invention, there are other changes within the protection scope of the claims, which all belong to the subject of the present invention.

[0025] Such as Figure 1 to Figure 5 As shown, 1 is the inner shell, 2 is the outer shell, 3 is the male and female teeth, 4 is the sealing groove, 5 is the sealing ring, 6 is the mold, 7 is the upper and lower press tooling, 7a is the lower press tool, and 7b is the upper press Tooling, 8 is a waterway. For the sake of simplicity, the figure does not mark each male and female tooth, sealing gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com