Centrifugal pump

A centrifugal pump and pump body technology, applied in the direction of pumps, driving pumps, pump components, etc., can solve the problems of inconvenient installation, maintenance, maintenance, complicated configuration, etc., and achieve the effect of simple structure, low manufacturing cost and improving pump efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

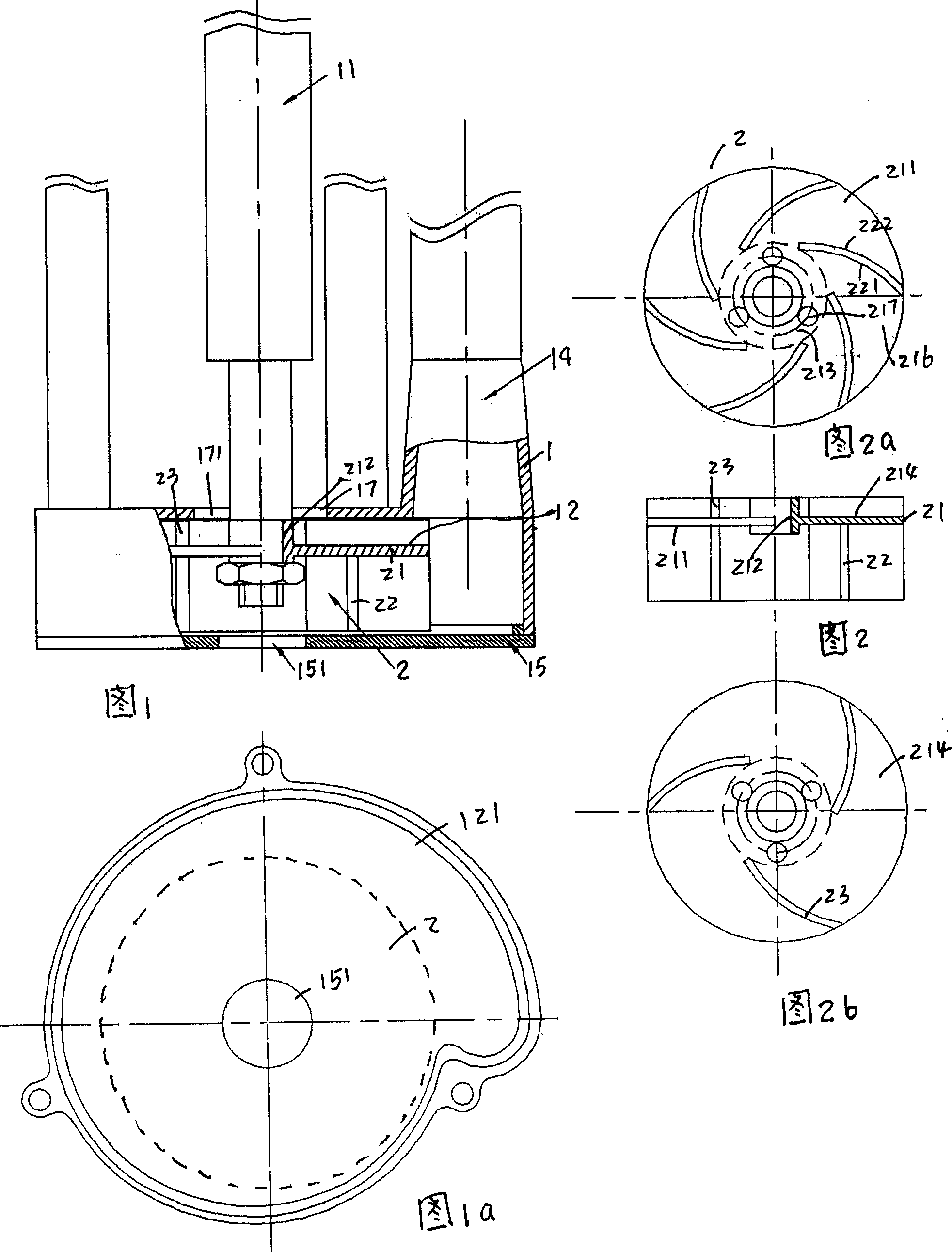

[0030] Referring to Fig. 1-2, a centrifugal pump includes a drive shaft 11 connected to a motor, an impeller 2 is installed on the drive shaft, and the impeller is installed in the pump body 1, wherein the impeller has a disc 21, and the center of the disc is Hub 212, the impeller is mounted on the drive shaft through the hub, and several main blades 22 of equal height and equal thickness are arranged on one side 211 of the disc. On the surface, the radius of curvature at the front of the blade and the radius of curvature at the back of the blade are drawn from the same center point;

[0031] The starting point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com