Precious metal jewelry burnishing robot

A robot and precious metal technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of low calendering efficiency, operators are susceptible to strain and pain, and achieve the effect of reducing personnel loss and improving calendering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

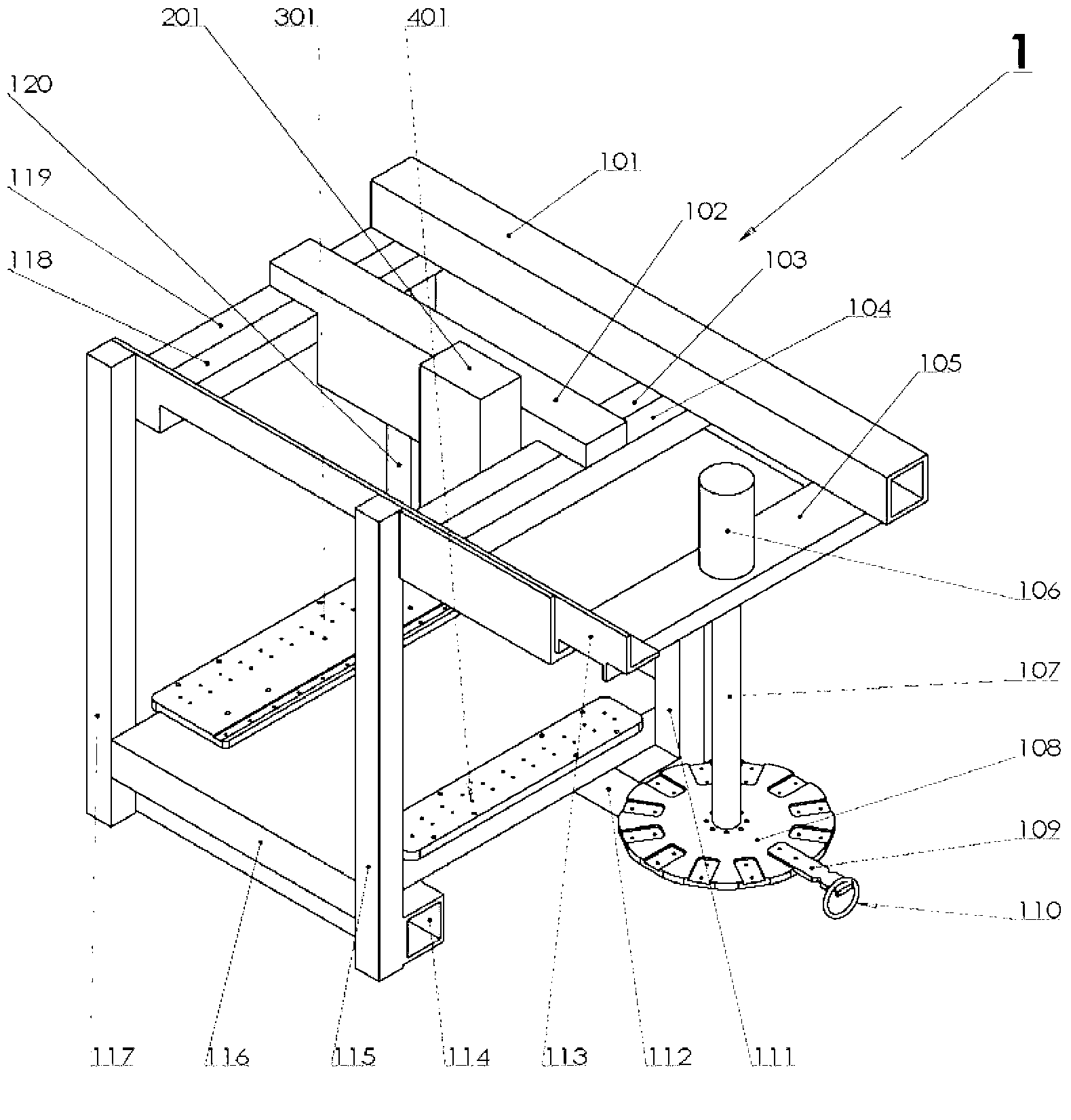

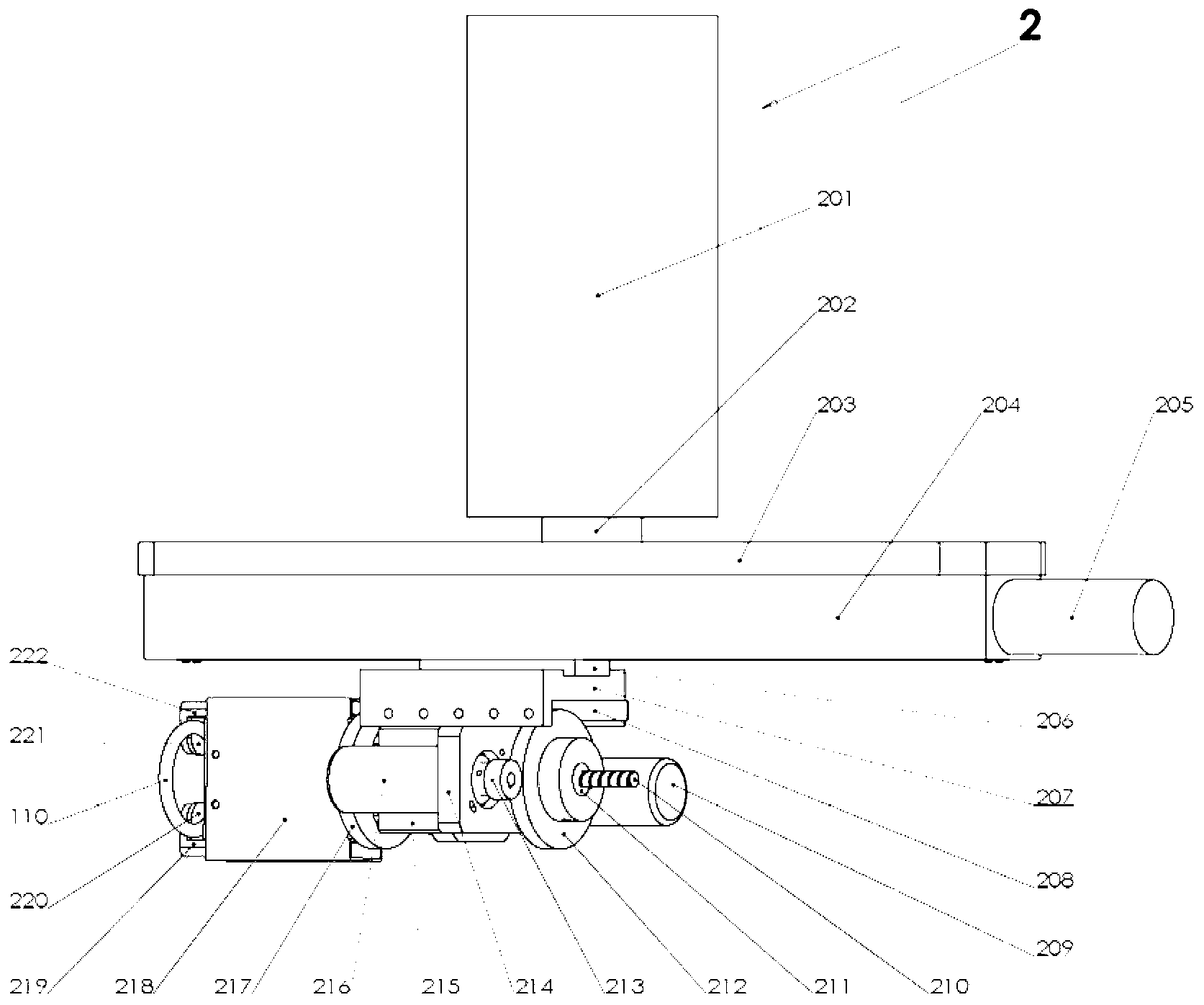

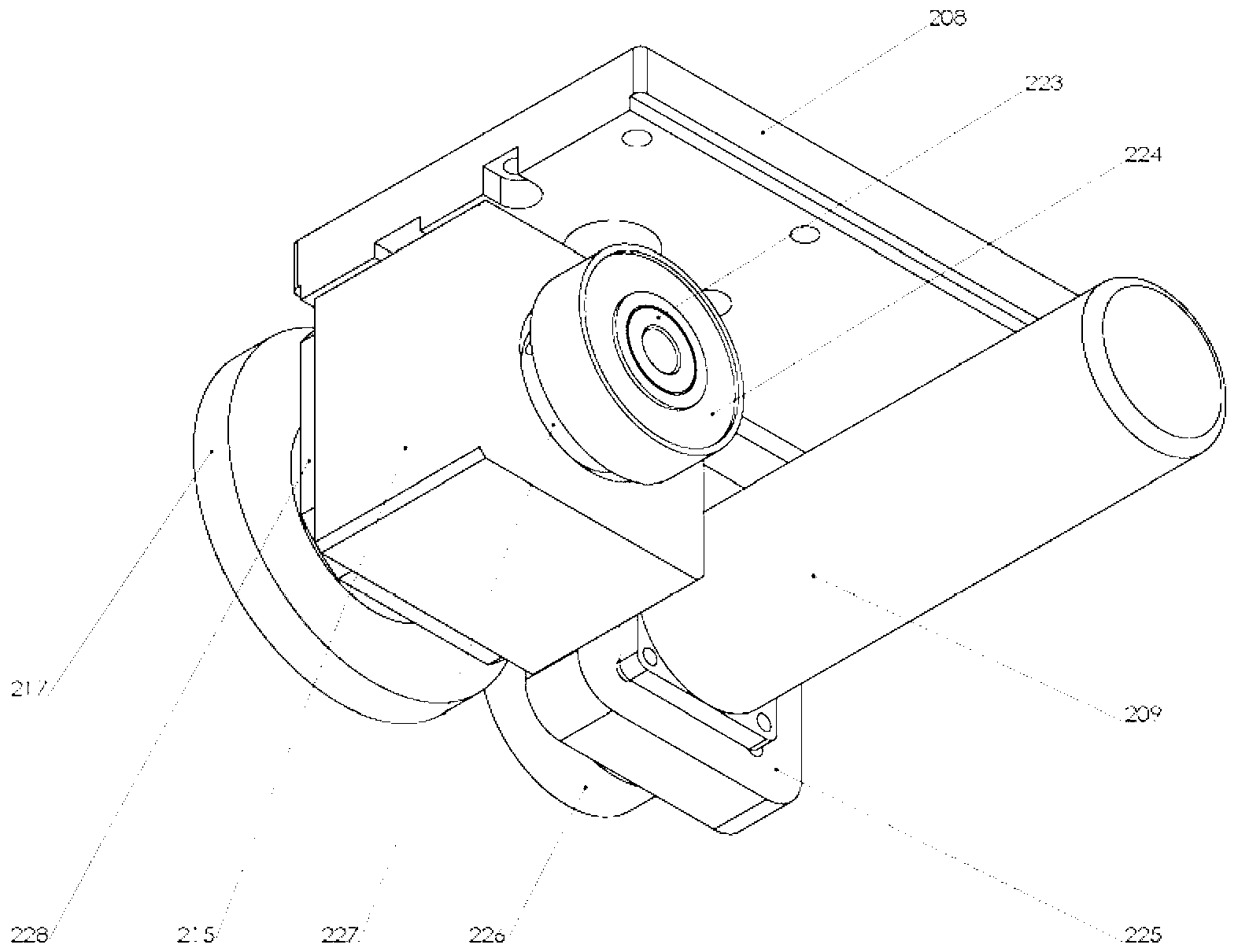

[0058] A precious metal jewelry calendering robot, characterized in that: it is composed of a frame 1 containing a hanging plate, a manipulator 2 arranged in the frame 1 containing the hanging plate, a tool table 3 and an auxiliary table 4, and the manipulator 2 is arranged on the second On one side of the beam 102, the tool table 3 and the auxiliary table 4 are arranged on the base platform 116, such as figure 1 and Figure 9 shown.

[0059] Described framework 1 that contains hanging plate, its structure is as figure 1 Shown, by the 1st column 111, the 2nd column 115, the 3rd column 117, the 4th column 120 and the 1st beam 101, the 2nd beam 102, the 3rd beam 113, the 4th beam 112, the 5th beam 114, the 6 crossbeams 105, the 7th crossbeam 104, the 8th crossbeam 103, the 9th crossbeam 118, the 10th crossbeam 119, straddling the base platform 116 above the 4th crossbeam 112 and the 5th crossbeam 114, being arranged on the 6th crossbeam 105 The first motor 106 containing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com