Sewing machine for up-down differential feeding

A technology of sewing machine and feeding mechanism, which is applied in the direction of sewing machine components, sewing machine control devices, cloth feeding mechanism, etc., can solve the problems of not having both upper differential feeding and lower differential feeding, poor sewing style, etc., and achieve sewing Good effect, combined with reasonable design and simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

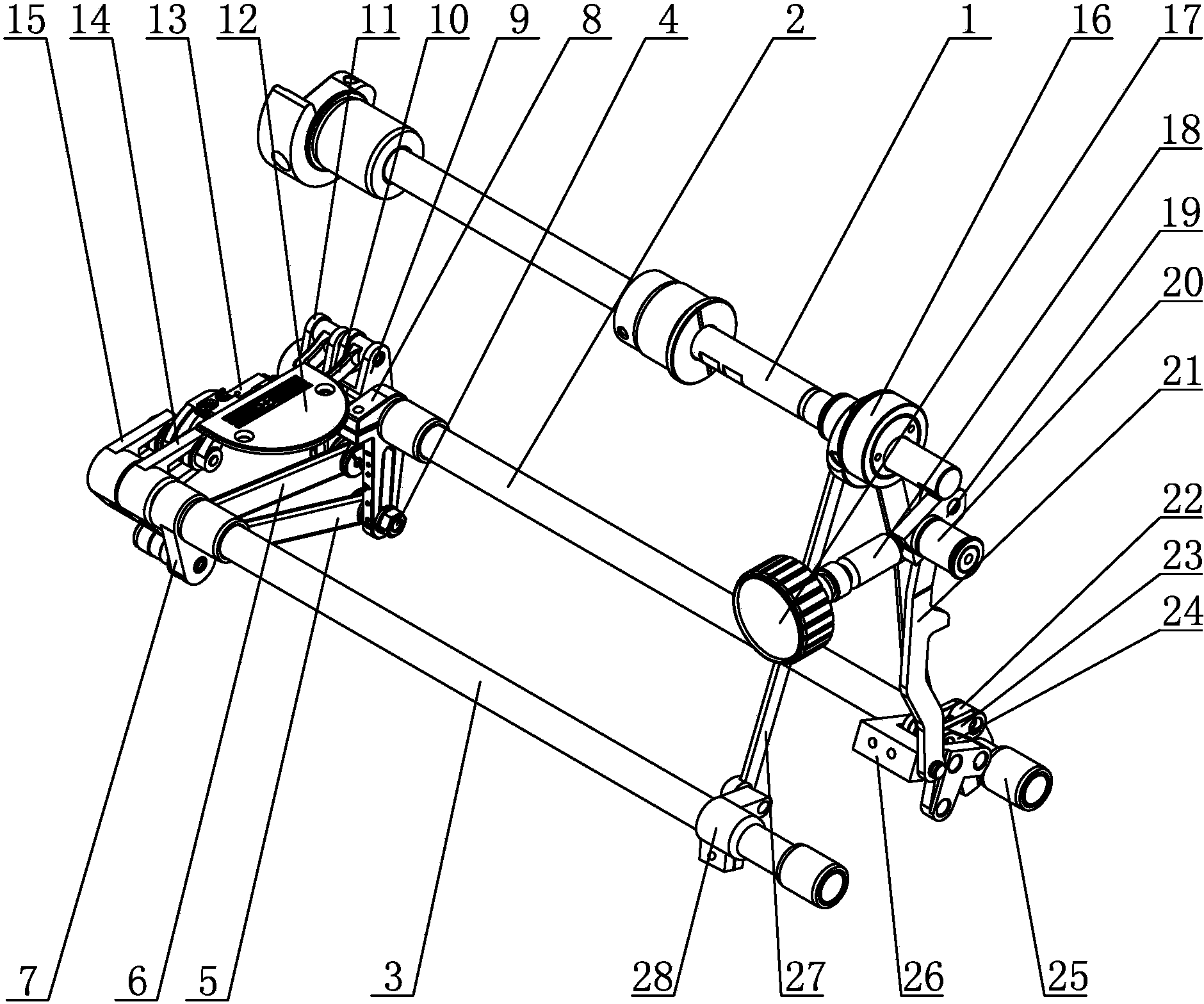

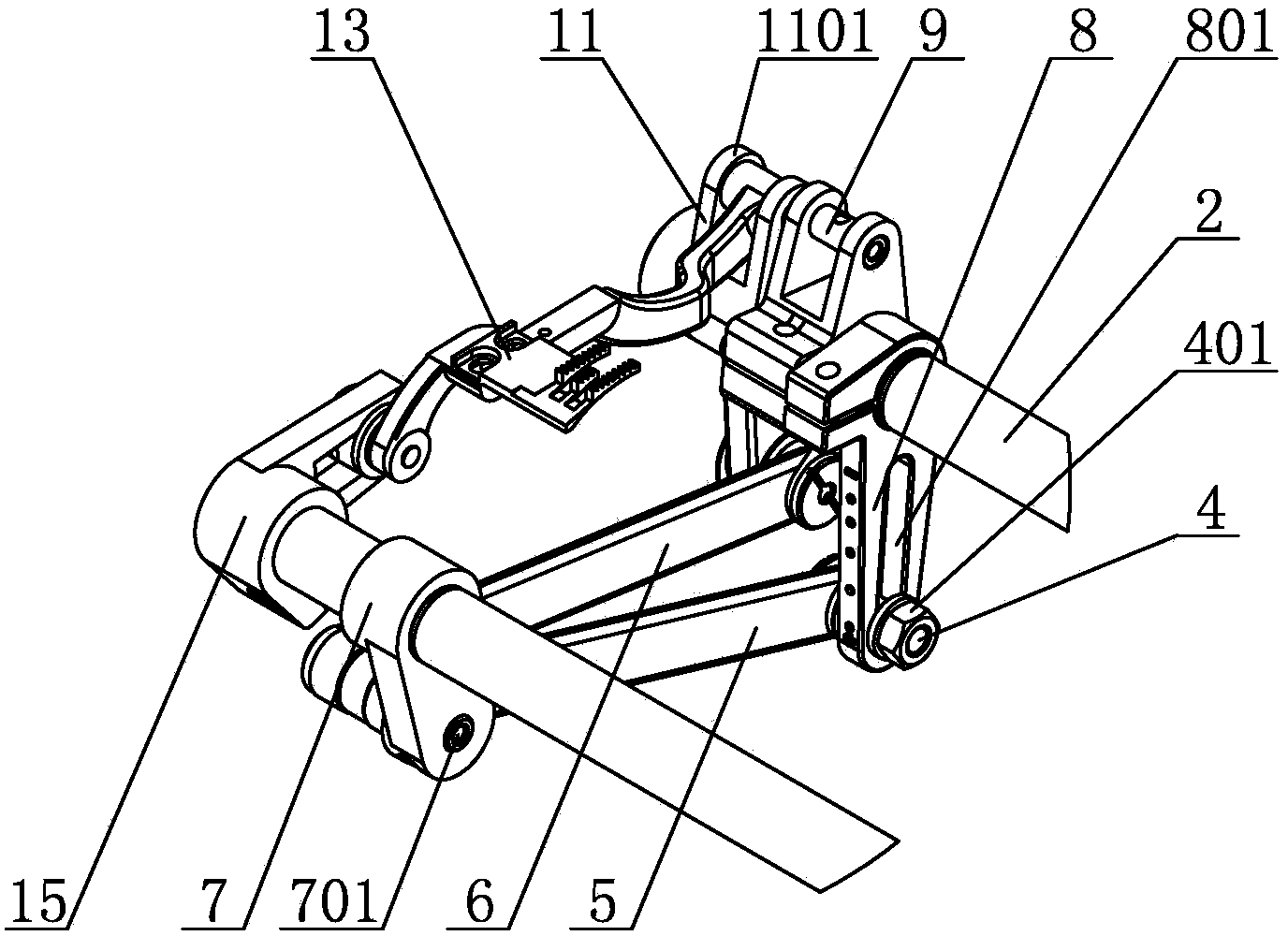

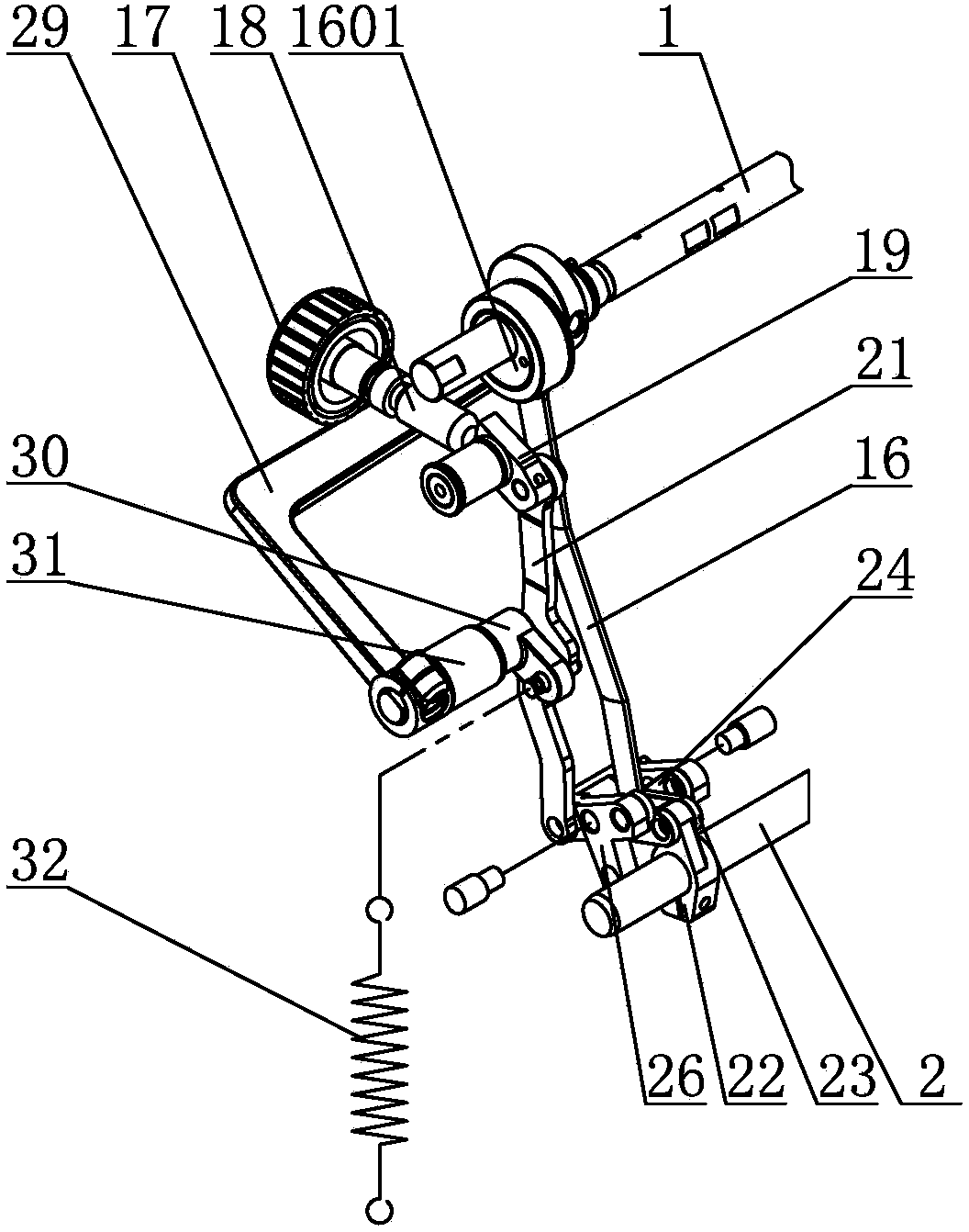

[0028] now attached Figure 1-8 , to further describe the present invention.

[0029] The present invention mainly designs a kind of sewing machine with up and down differential, especially designs the adjustment mechanism in the upper and lower differential feeding mechanism in the sewing machine. The adjustment mechanism includes an upper feeding adjustment mechanism, a main feeding adjustment mechanism, and an auxiliary feeding adjustment mechanism, wherein the auxiliary feeding adjustment mechanism is the key mechanism of the present invention, which can independently realize the adjustment of the sewing machine's lower differential feeding. The auxiliary feeding adjustment mechanism includes a lower differential feeding adjustment crank 8, a lower differential transmission crank 7, a first lower differential feeding connecting rod 5, a second lower differential feeding connecting rod 6, a first bracket seat 9, a feeding tooth 10. The lower differential feeding crank 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com