Method for simulating sea waves by using barrel-type centrifugal machine and apparatus therefor

A centrifuge and special device technology, applied in the field of simulated ocean waves, can solve the problems of poor test operability and small range of simulated wave parameters, etc., and achieve the effects of easy operation, wide frequency range and good wave elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

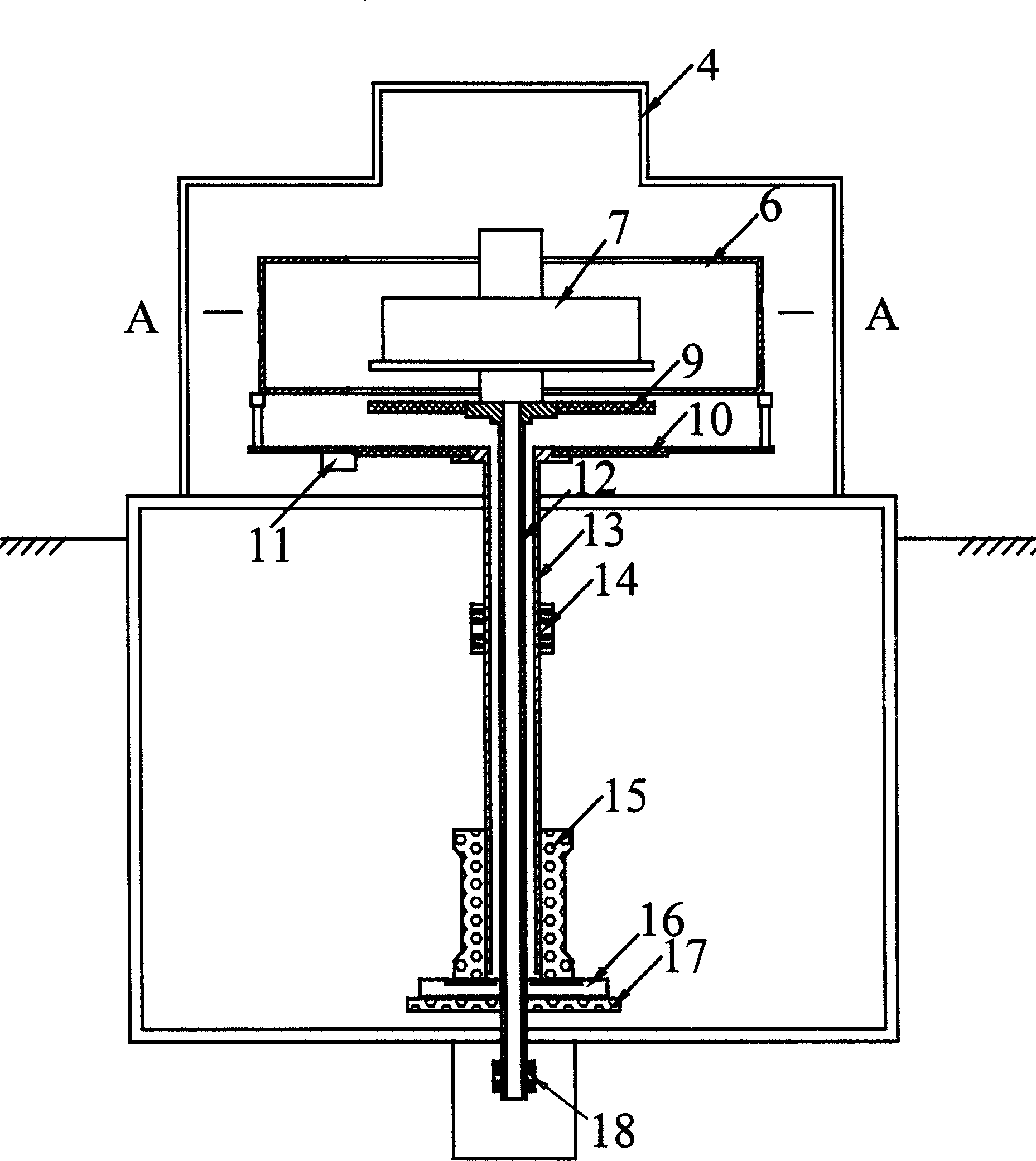

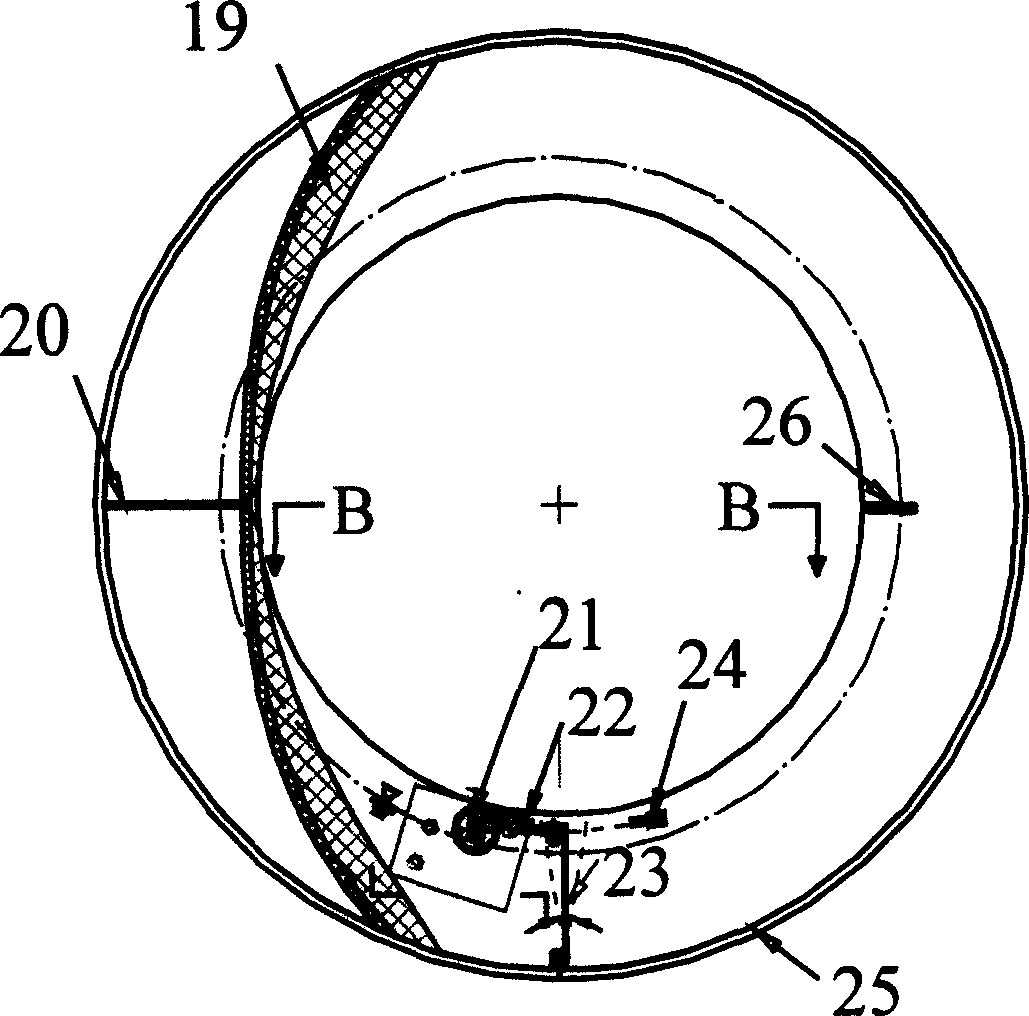

[0044] Make a special device for simulating ocean waves with a drum centrifuge, as attached figure 1 , 3 , 4, and 5. The device is composed of drum centrifuge and wave making device.

[0045] as attached figure 1 and image 3As shown, the drum-type centrifuge includes: a protective cover 4, a drum-shaped groove 6 located in the protective cover 4, a central console 7 located in the drum-shaped groove 6, a lifting device 8 on the central console 7, a central console support Board 9, drum-shaped groove support 10, digital acquisition computer 11 installed at the bottom of drum-shaped groove support 10, inner shaft 12 connected with center console support 9, outer shaft 13 connected with drum-shaped groove support 10 , the first servo motor 15 for driving the outer shaft 13, the second servo motor 17 for driving the inner shaft 12, a clutch transmission 16 is also arranged between the inner shaft 12 and the outer shaft 13, and the A first slip ring 14 and a second slip ring ...

Embodiment 2

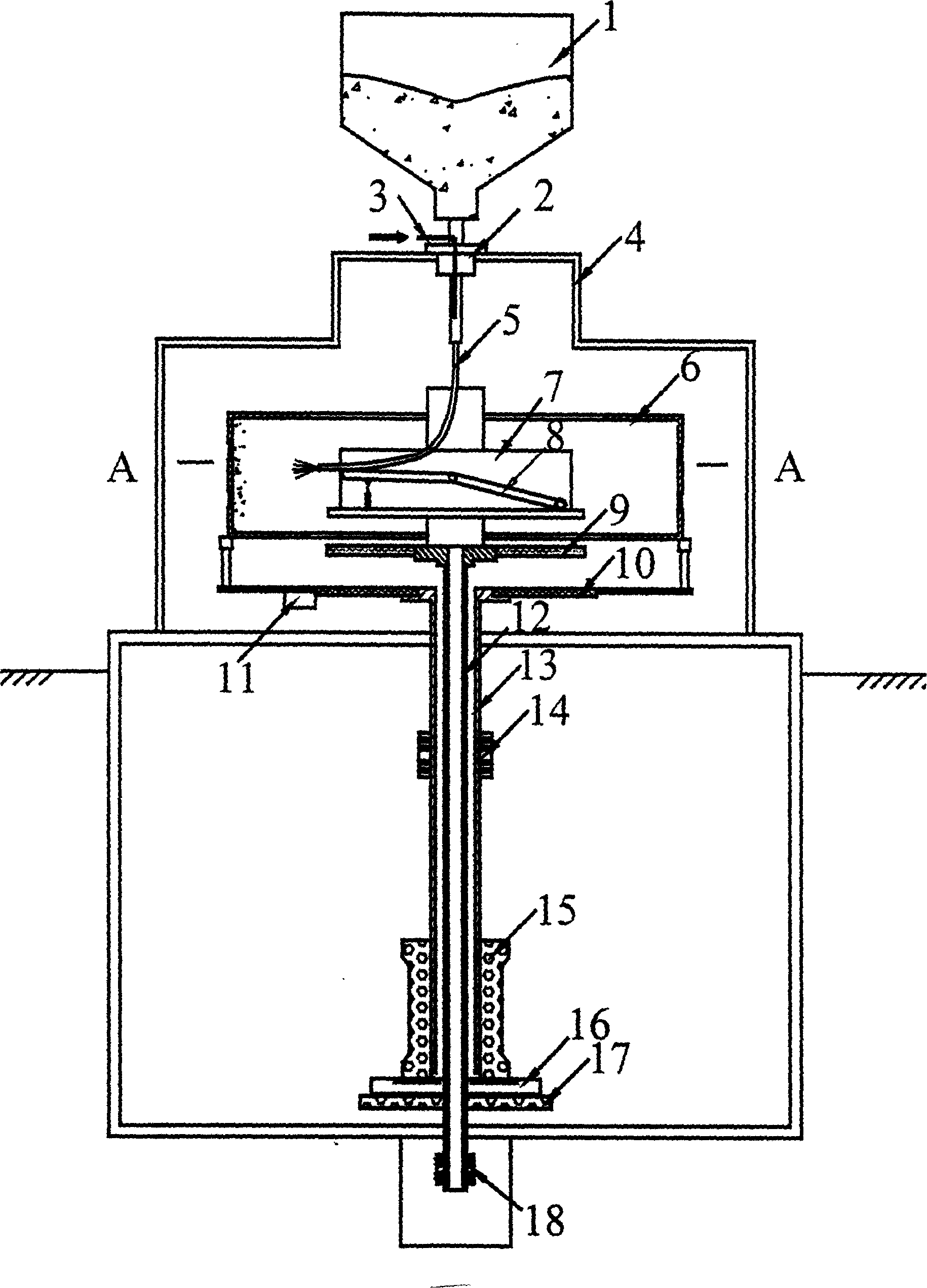

[0055] Make a special device for simulating ocean waves with a drum centrifuge, as attached figure 2 , 3 , 4, and 5. The device is composed of drum centrifuge, wave making device and sand sample preparation device.

[0056] Such as figure 2 As shown, the sand sample funnel 1 is fixed on the protective cover of the drum centrifuge through the steering knuckle 2, and the sand conduit 5 communicates with the sand sample funnel 1 through the compressed air conduit 3. Under the action of compressed air, the sand in the sand conduit 5 Soil is more convenient to flow in the centrifuge drum groove 6, and the lower outlet of sand conduit 5 is installed on the hoisting device 8 that is positioned at the center console 7 of drum type centrifuge, and the lower outlet of sand conduit 5 both can follow central control The table 7 rotates together, and can reciprocate along the axial width direction of the drum-shaped groove 6 together with the lifting device 8 on the central console 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial depth | aaaaa | aaaaa |

| Axial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com